The design committee alerted me this morning to the fact that perhaps the size of the bore through the eccentric strap needed some consideration as there was a chance that my final bore for the shaft might break through into the track the strap runs in. So, some concentrated thought and measuring. They were right, it's all very well making stuff out of your head but you have to keep checking!

So, the three jaw and the set up came off the lathe and the 2 jaw SC went back on and I bored the strap out to what I worked out was the right size.

.

Lots of careful measuring and checking with every measuring device I have. The digi calliper is handy but I don't regard it as consistently accurate.

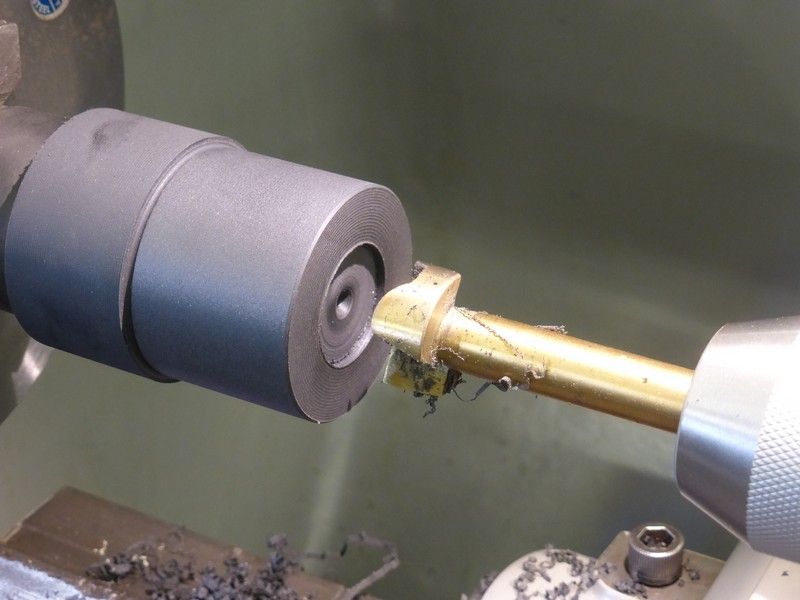

Once I had the new bore size for the strap I got on with the difficult job of carving the track out in the eccentric for the strap. Lots of chatter and trying different tools. I got there in the end and finished to size with emery strip to get a finish.

Here's my finished result.

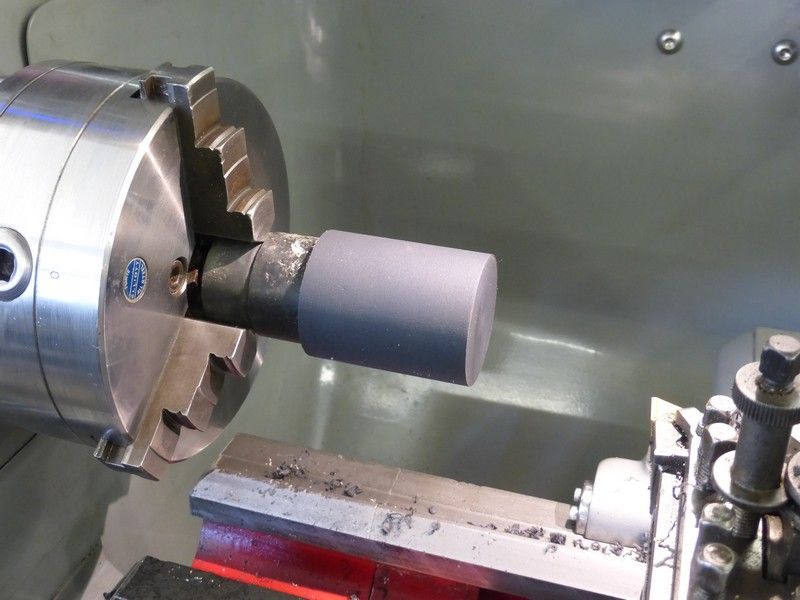

The next job was to check the diameter of the shaft and bore the eccentric. I started with a series of drills taking me up to .5" in stages.

Then a very careful bore to a size that slips on the shaft comfortably, no need for a tight fit as the eccentric will be held by two 1/4" socket head grub screws when we get round to it. Next job was to clean up all the edges on the strap, polish the two end faces on the eccentric and after mounting the strap on the eccentric, try it on the engine.

Lovely! A nice snug but sliding fit on the shaft. The strap is perhaps a touch on the tight side on the eccentric but that's good as it will soon wear in when the engine has been run a bit. This is good fitting and generous bearing surfaces. It will never wear out....

A good morning... I have tidied up most of the tools and first thing tomorrow I'll have a good clean up before measuring for the valve rod.

And yes, you're right. That package is my new M&W dial calliper. Do not drop!