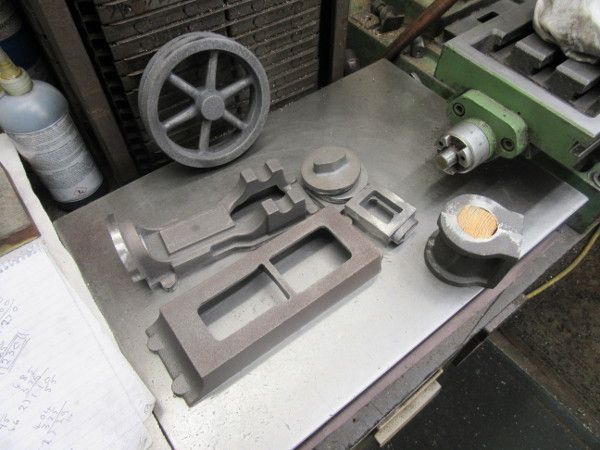

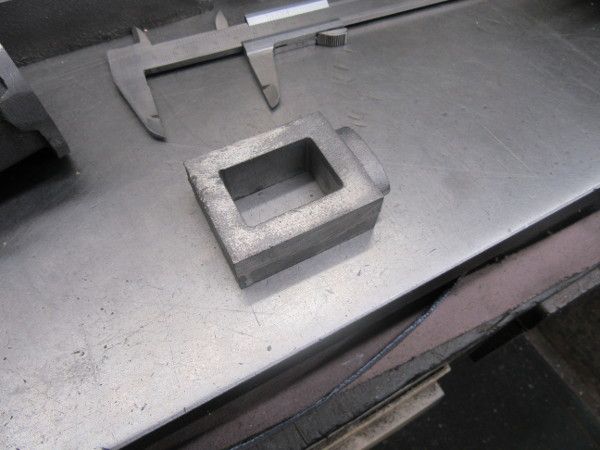

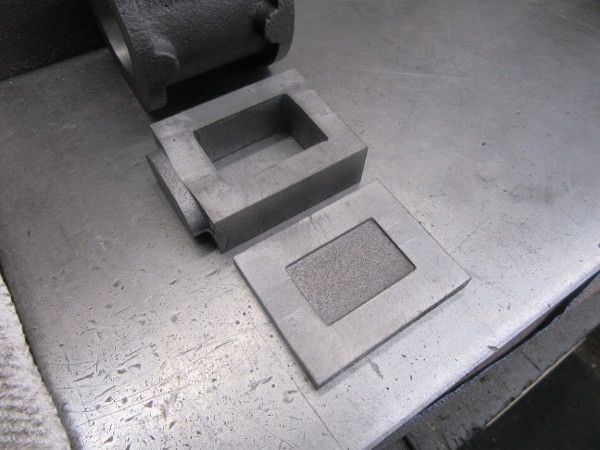

We need glands and here's what the rough castings look like. I have made fag packet drawings to embed the sizes in my head....

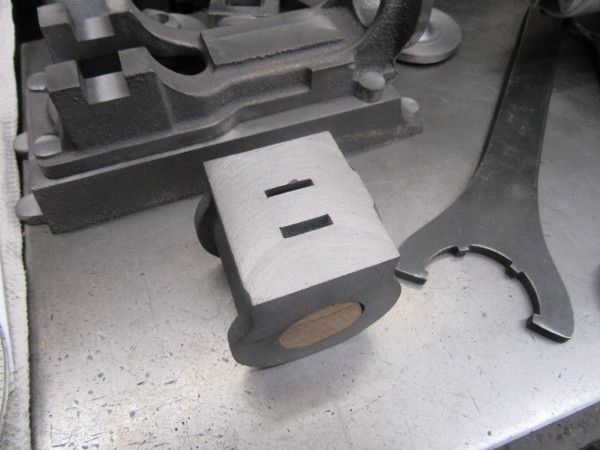

There's nothing subtle about fettling castings. Get on to the grinding wheel and do the best you can to get rid of the flash and casting debris.

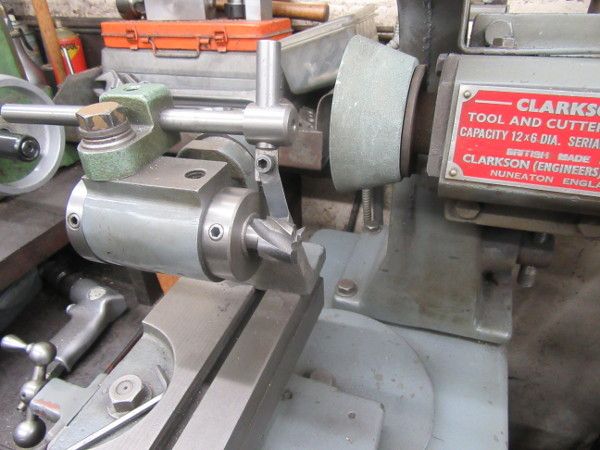

Every now and again I like to start with a fresh HSS cutter that hasn't had its angles gradually degraded by repeated sharpening. Here's the new one getting honed on the diamond hone....

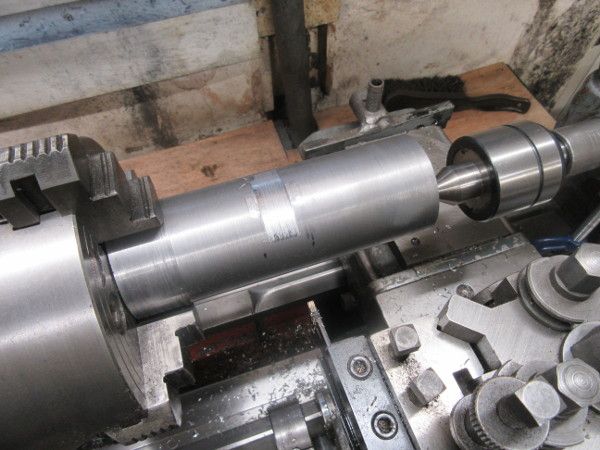

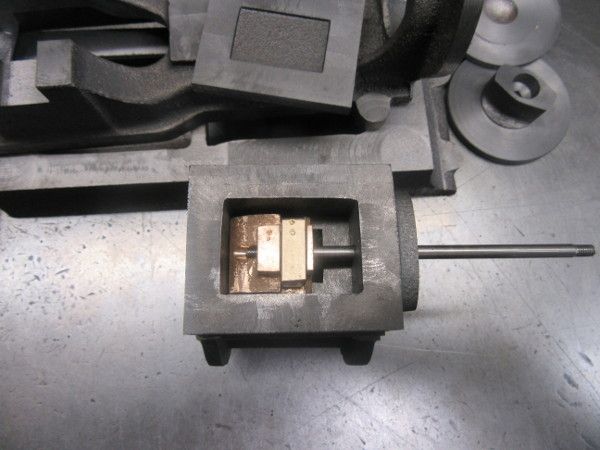

Cutting the face was easy because we had the spigot to grab but this side needs a different approach which is by way of being today's bleeding obvious tip. If you have a central hole, use the centre to press the gland against the chuck. This is good enough for light cuts....

A short while later.... we have a piston rod gland ready for fitting. It still needs some hand work to refine the finish but the basic machining is done. Tomorrow I shall do the same with the valve rod gland. Quiet productive morning....