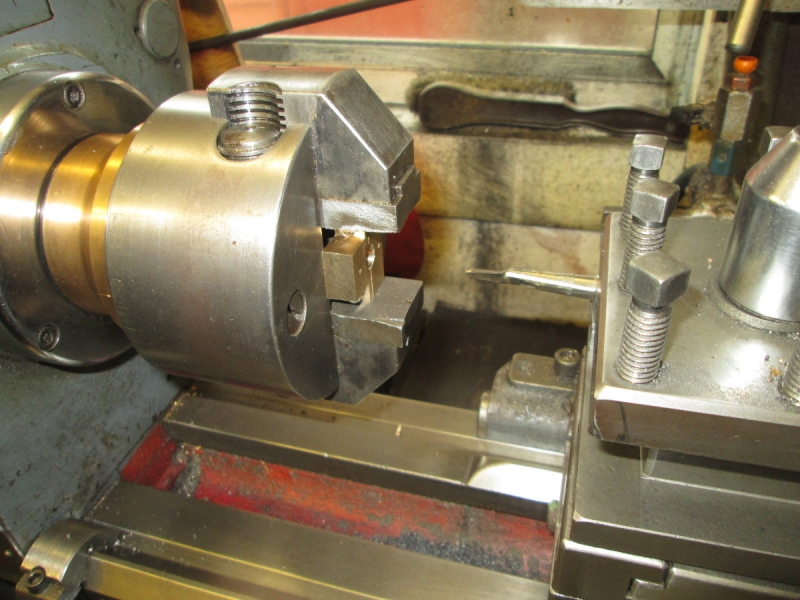

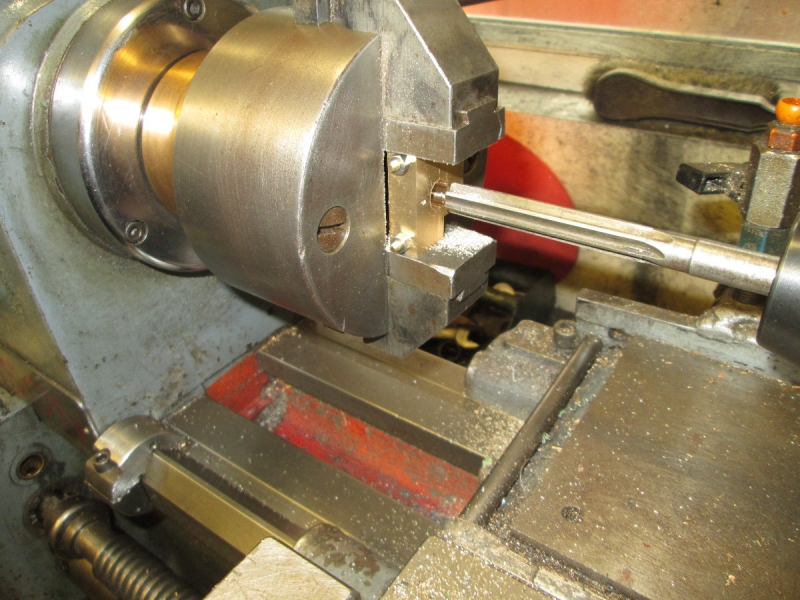

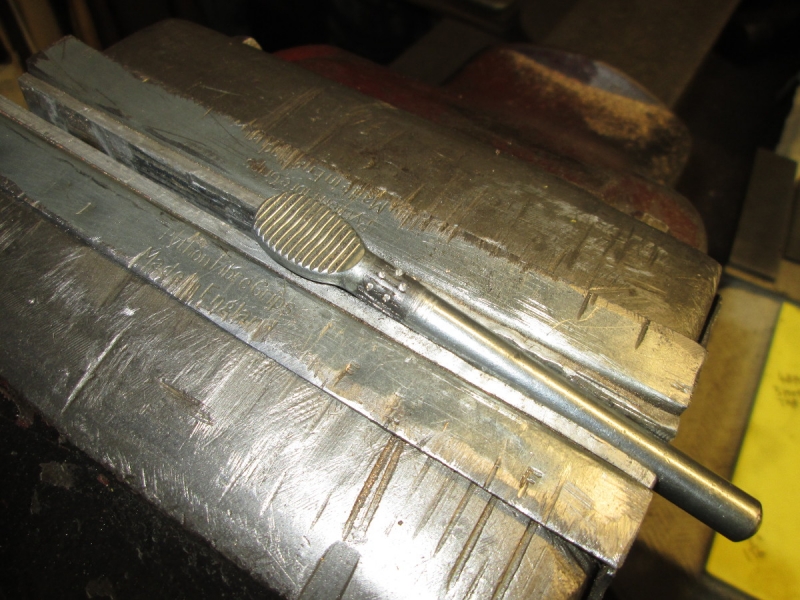

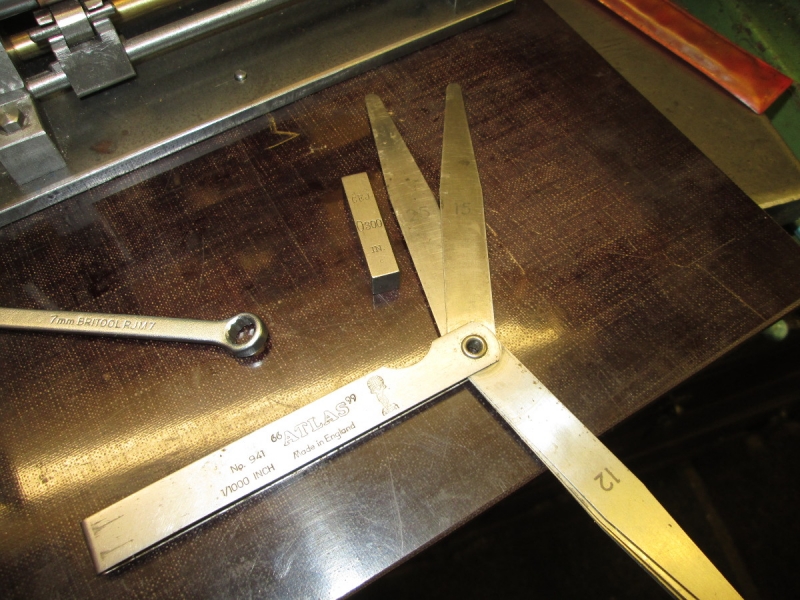

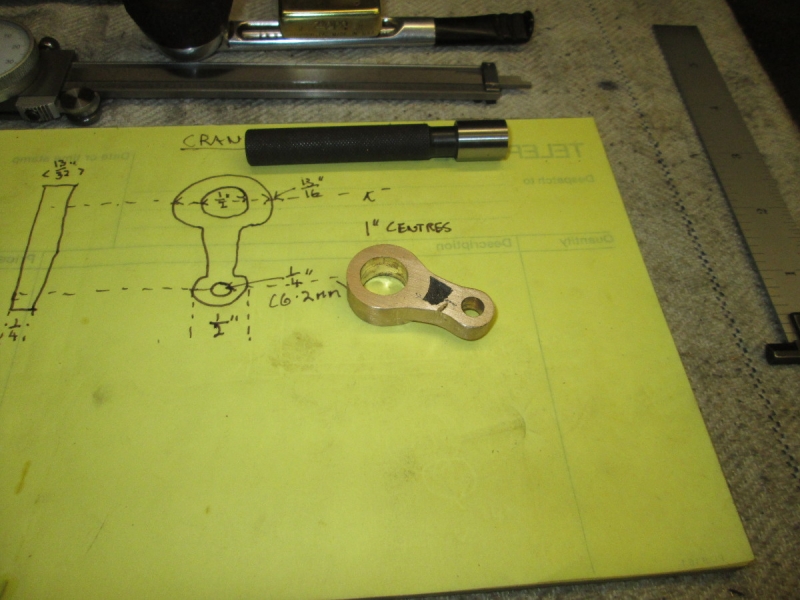

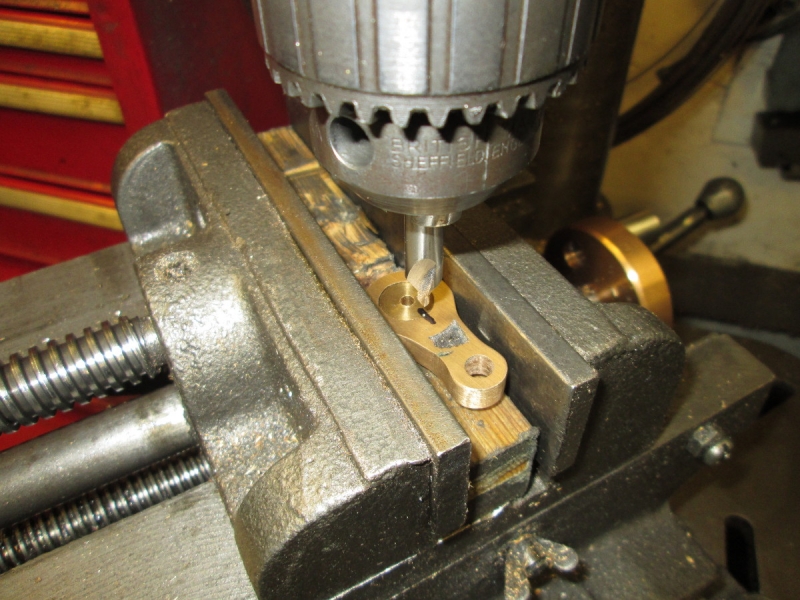

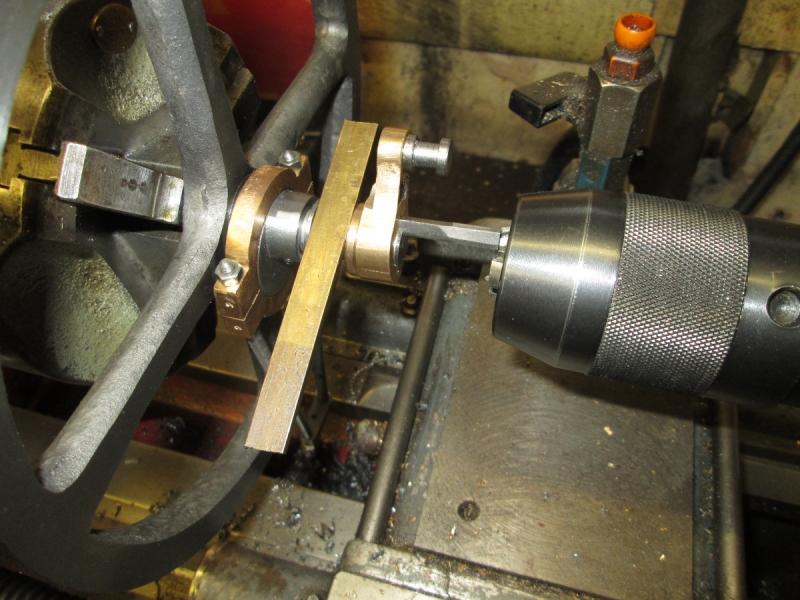

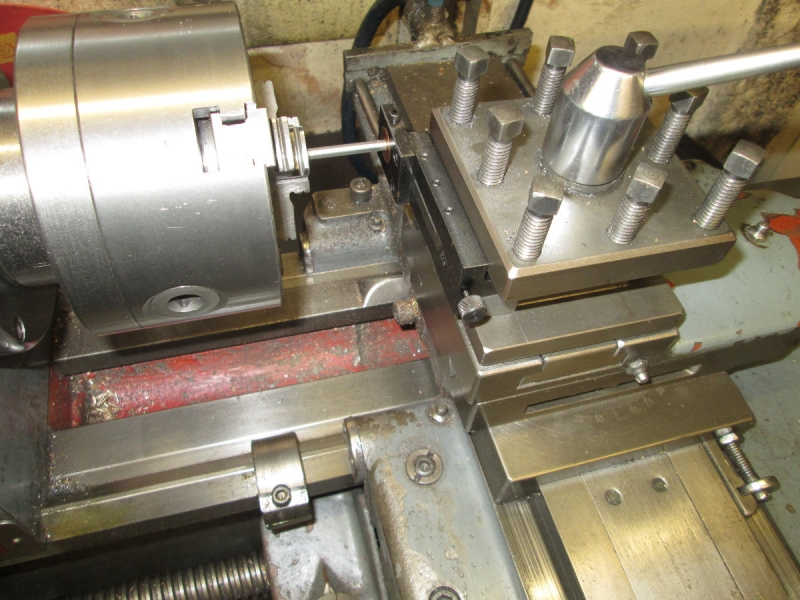

Remember me making the two lathe bed stops? One for Mick and one for me. It came out to play this morning and I soon knocked off two eccentric rods after polishing the stock.

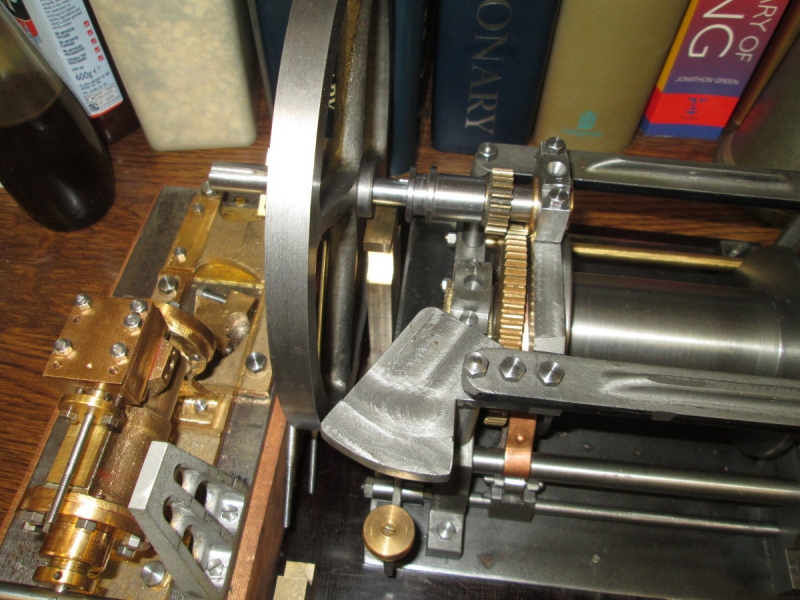

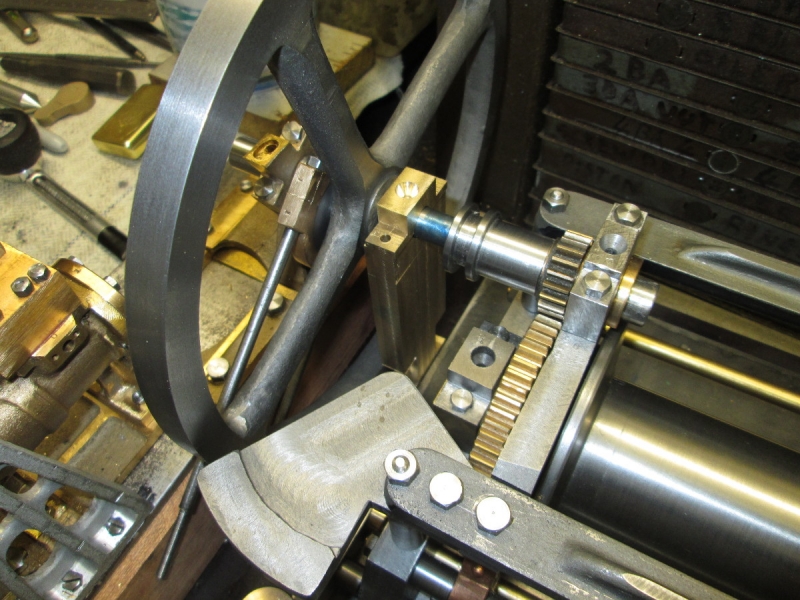

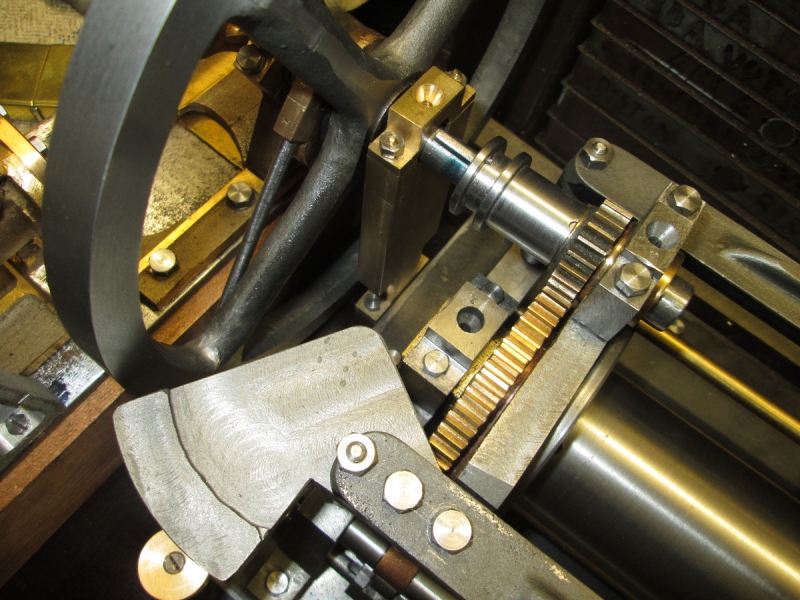

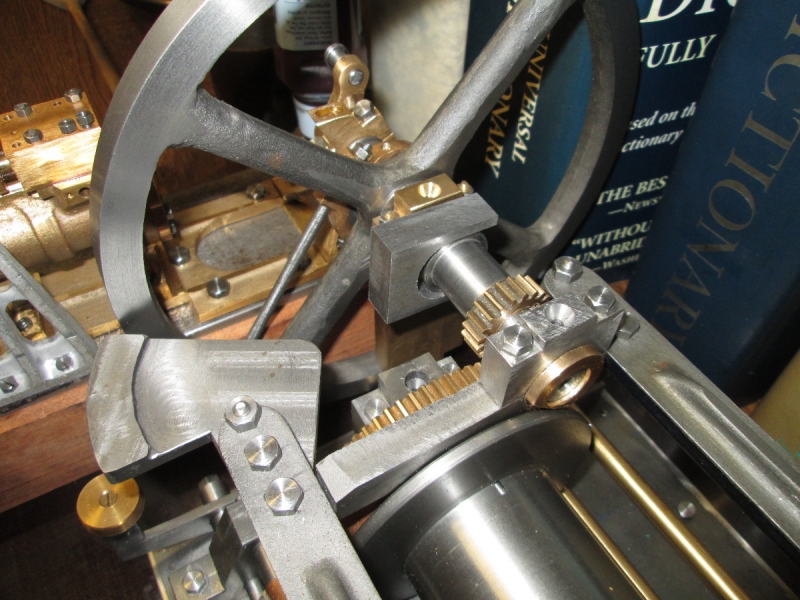

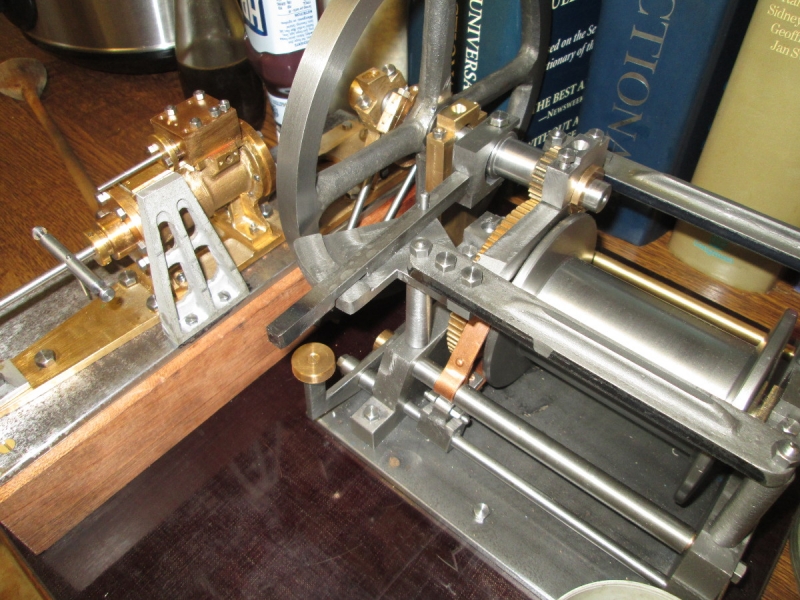

Now you can see why the clamp bolts were temporary. The rods will eventually need to have a bend in each end but I'll leave that until I have made the cross-member they fit in. I have no doubt that P will note I have cut the setscrews back until they are just below the surface of the eccentric boss.

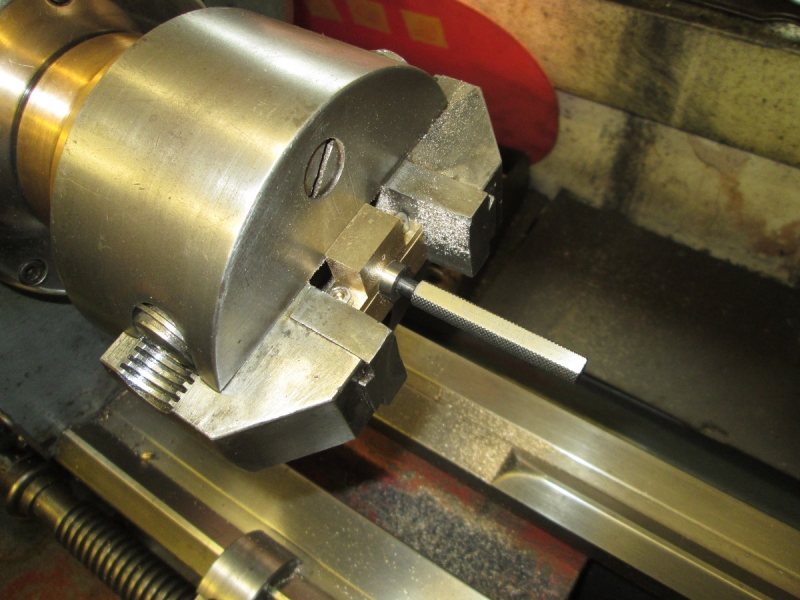

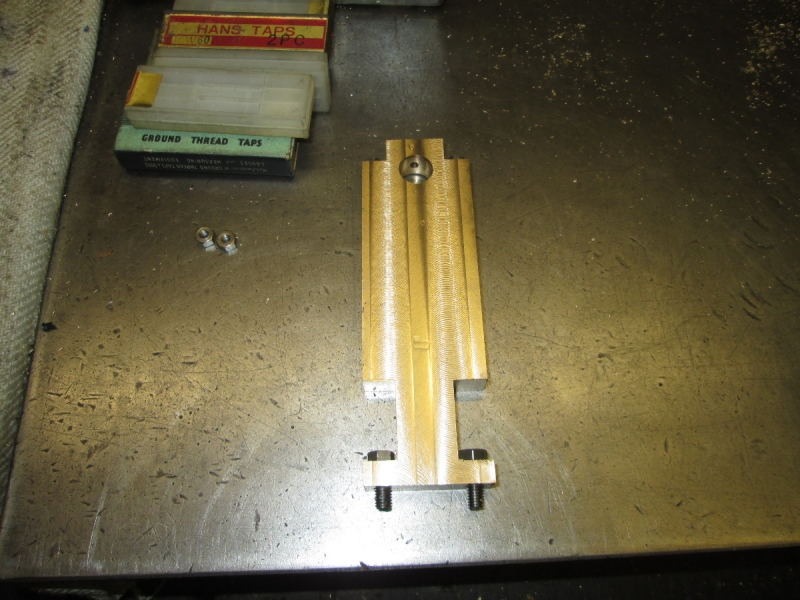

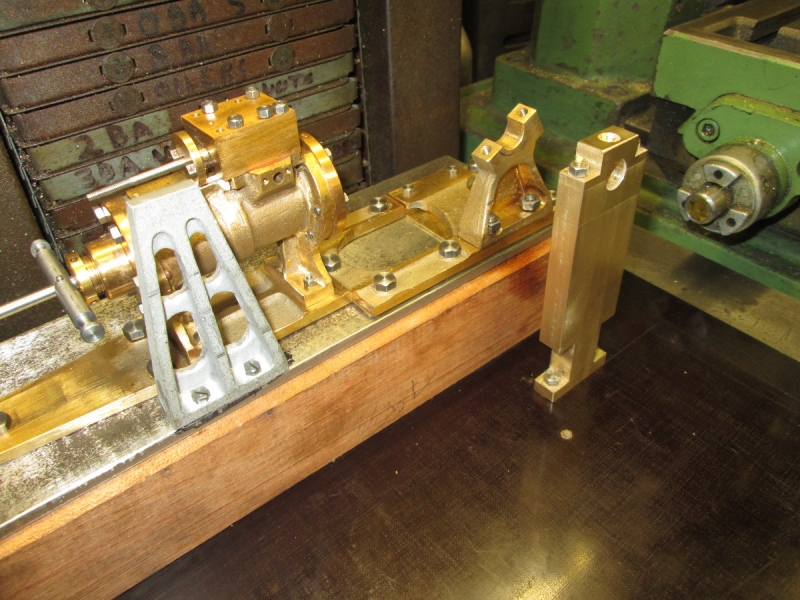

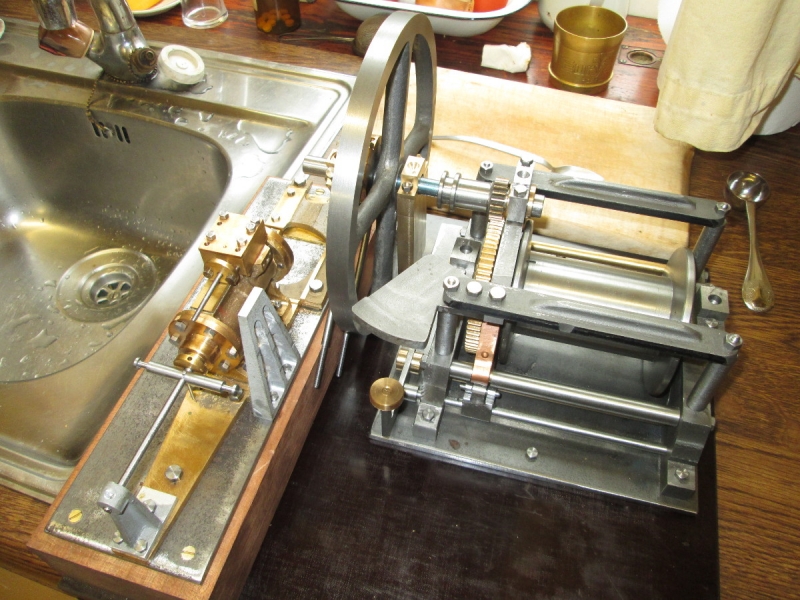

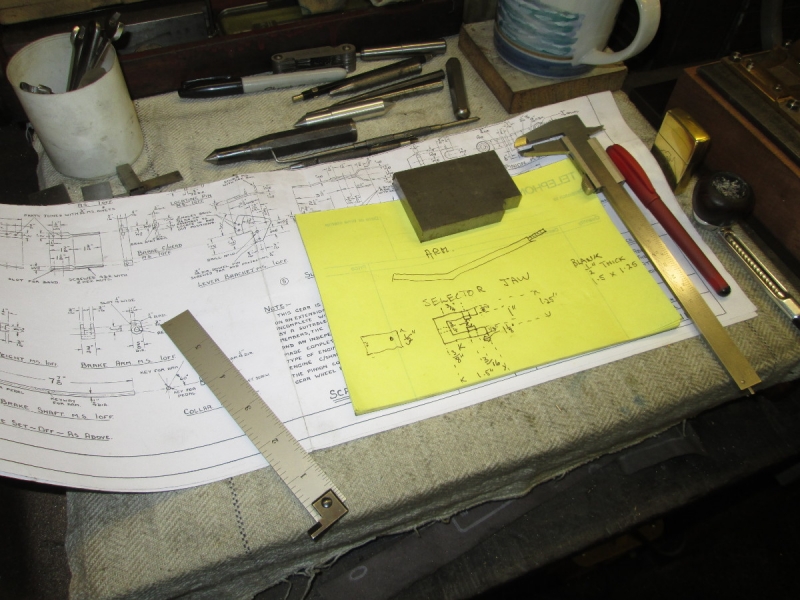

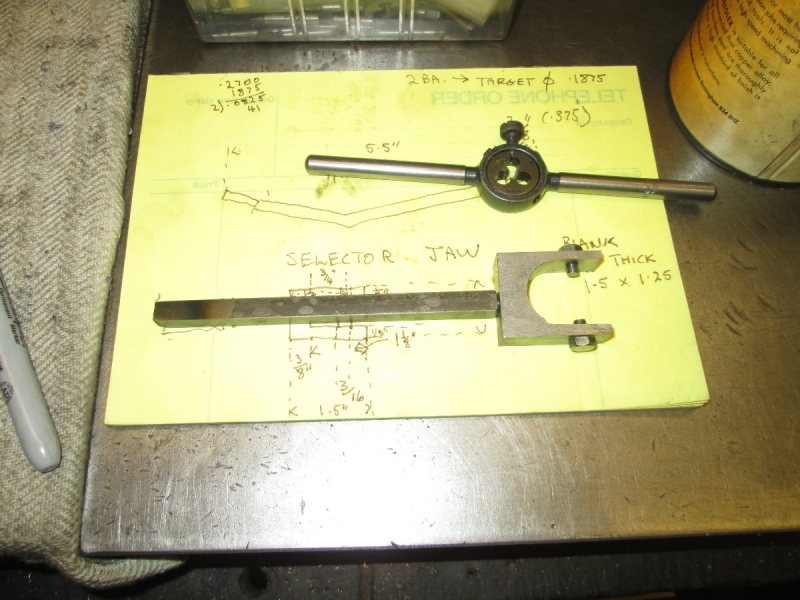

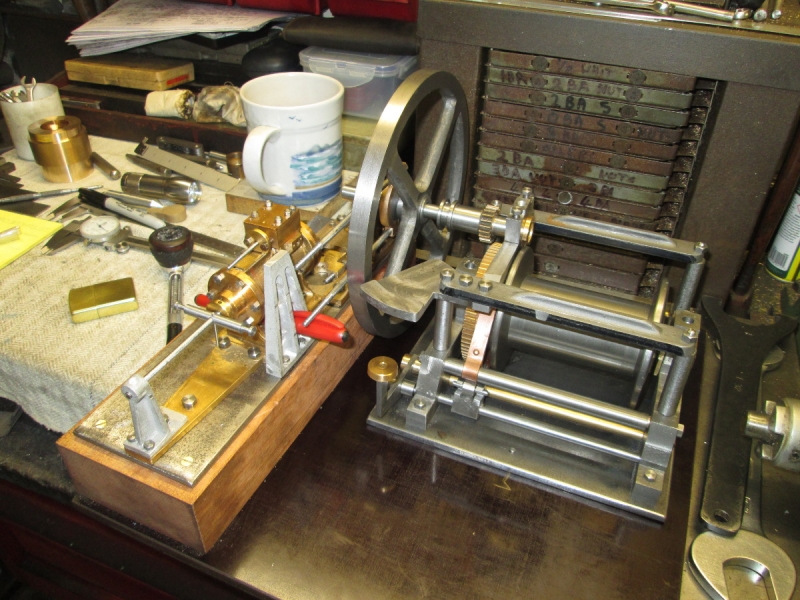

I've decided that the next job is to make a decision about the outrigger bearing. I work best when I can see the problem clearly so I mounted the winch in its place (Those dowels are a blessing!) and did some very careful measuring and a fag packet drawing. Then up to the treasure chest upstairs to find a piece of bronze stock. Just think what those treasure chests have saved me over the years, never walk past anything that looks useful!

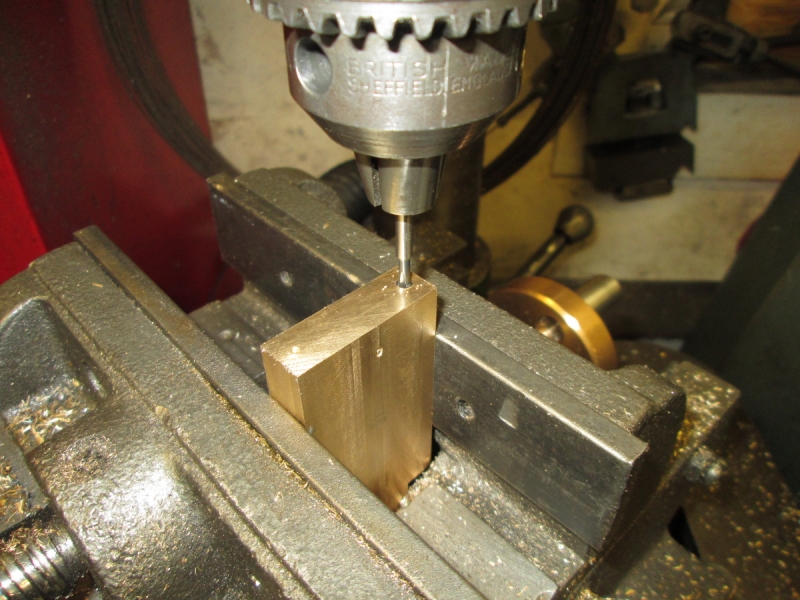

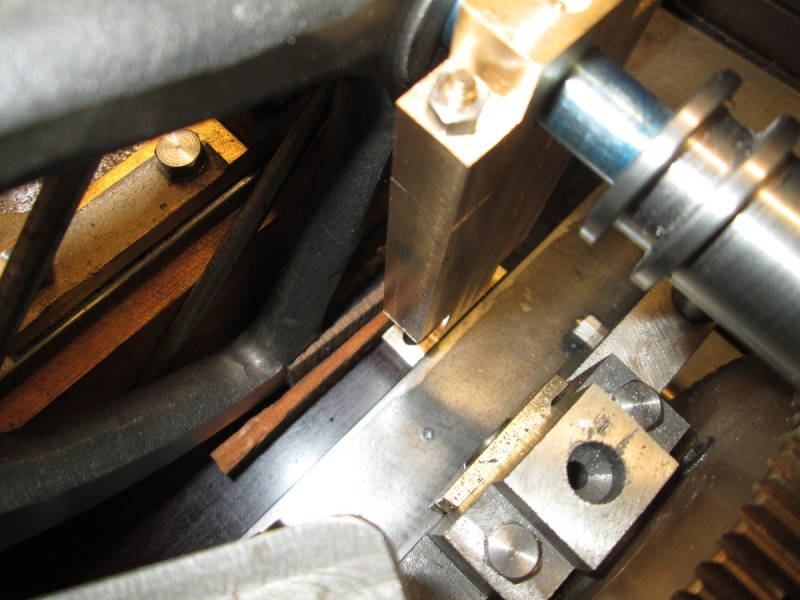

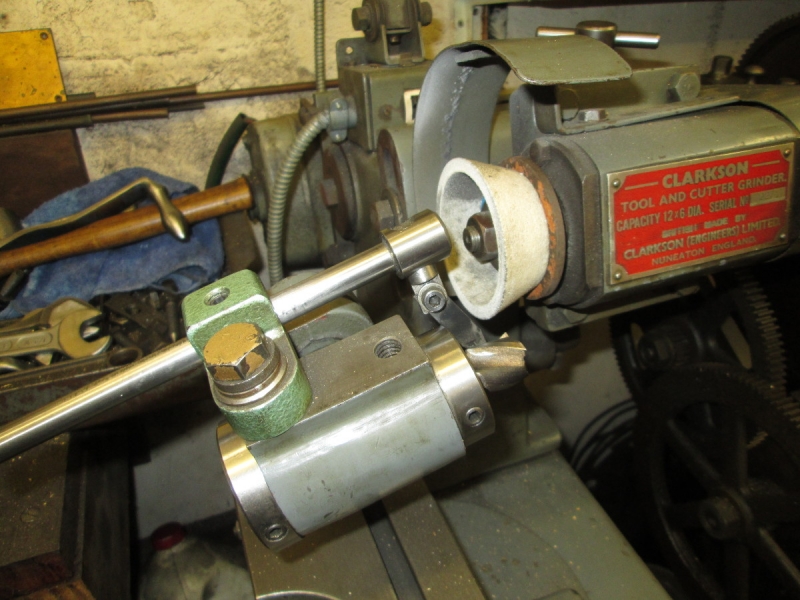

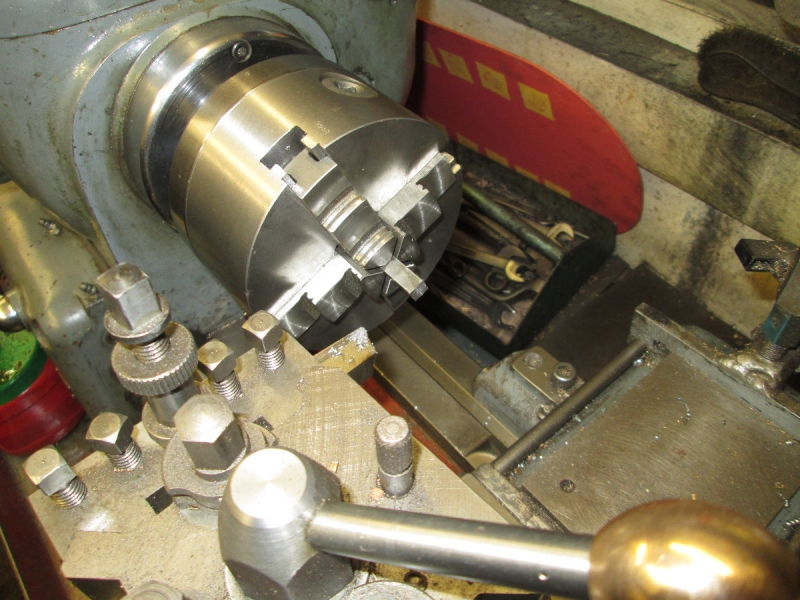

This is some 1 1/2" X 1/2" bronze bar that Eddie Spencer left behind when he lived in this house. Years later I told him how careless he had been and he told me to keep both bars. This is the fag end of the first one getting the treatment in the HM.

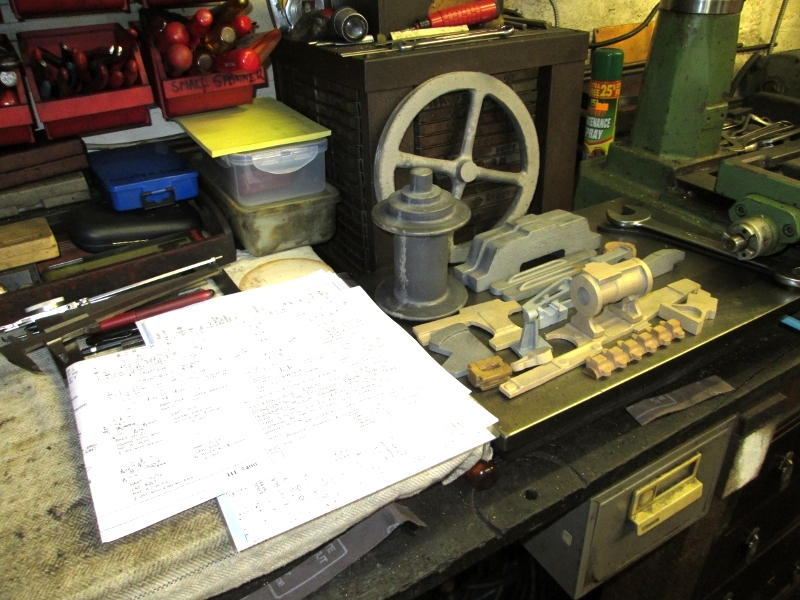

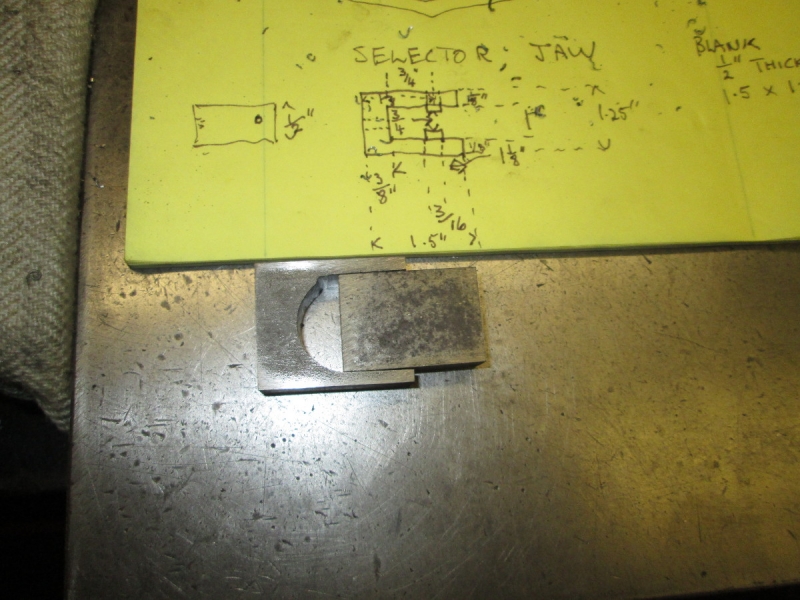

Here we are at knocking off time. I have the design clear in my head and the big piece is for the base. The smaller one will be made into the actual split bearing. I think I'm happy with it..... It's getting a bit populated isn't it! Don't worry about the size, these pieces are going to shrink as usual! All I seem to do is make lumps of metal smaller and a different shape. Engine building in a nutshell!