SHED MATTERS 2

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

Good! Nice to know Kev. I have had to resort to cunning wheezes for the next bit.......

I solved a separate problem more easily yesterday. I have never been satisfied with the wooden bases on the big compound and Margaret's engine. I measured up what I need and sent a begging email to Mick the Shed! He's so good at polished wood and usually has some nice mahogany about his person....... His terms are very good!

I solved a separate problem more easily yesterday. I have never been satisfied with the wooden bases on the big compound and Margaret's engine. I measured up what I need and sent a begging email to Mick the Shed! He's so good at polished wood and usually has some nice mahogany about his person....... His terms are very good!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

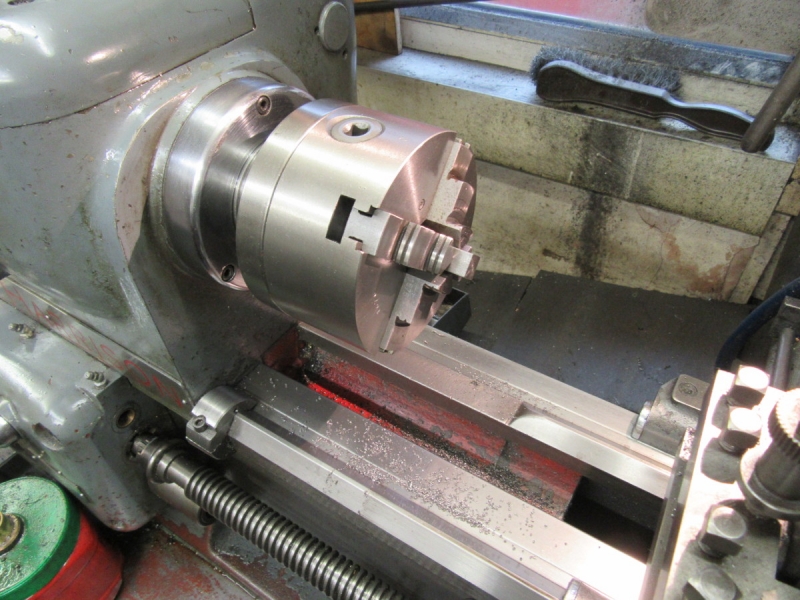

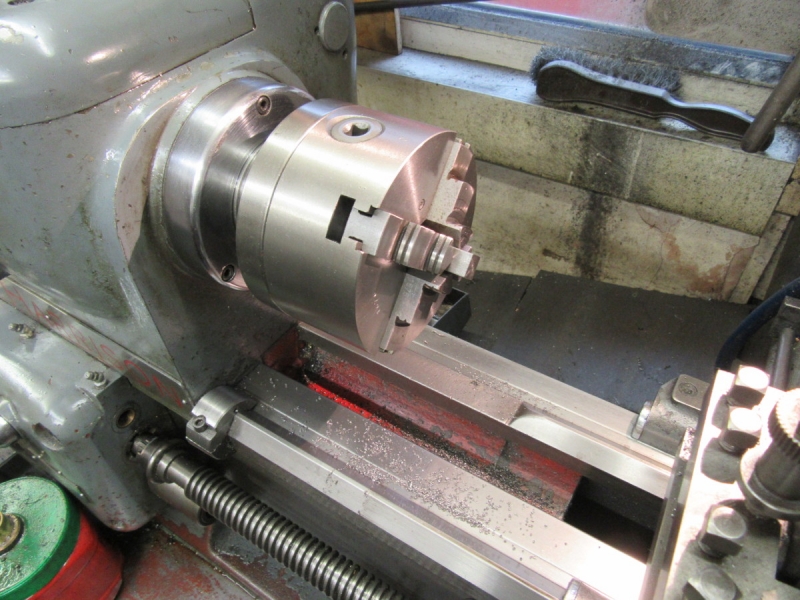

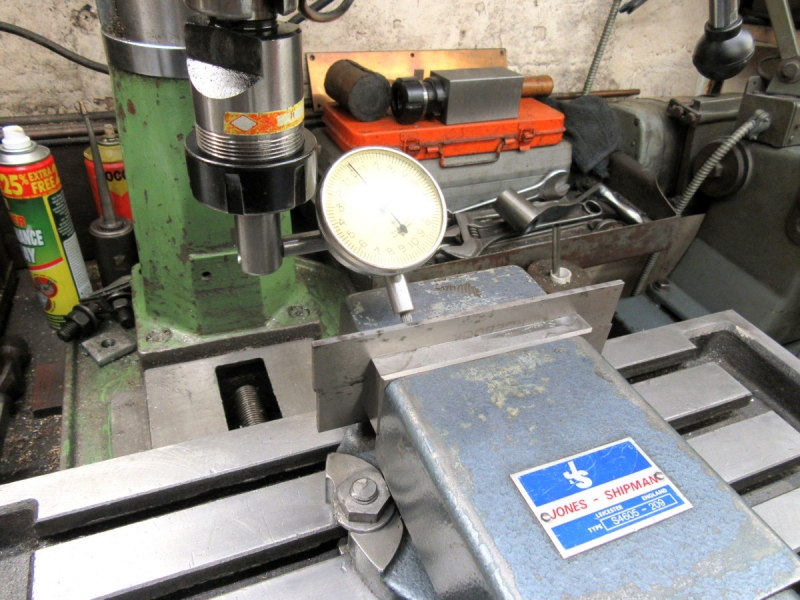

Always a nice start to the day when you have a clean lathe. I put the top slide to 27.5 degrees, the Whitworth threading angle, which clears the top slide from the tail stock nicely.....

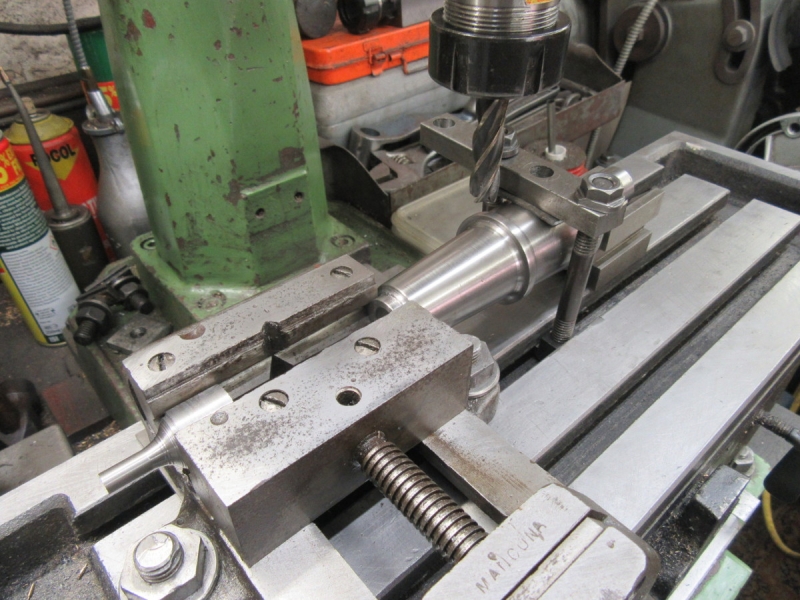

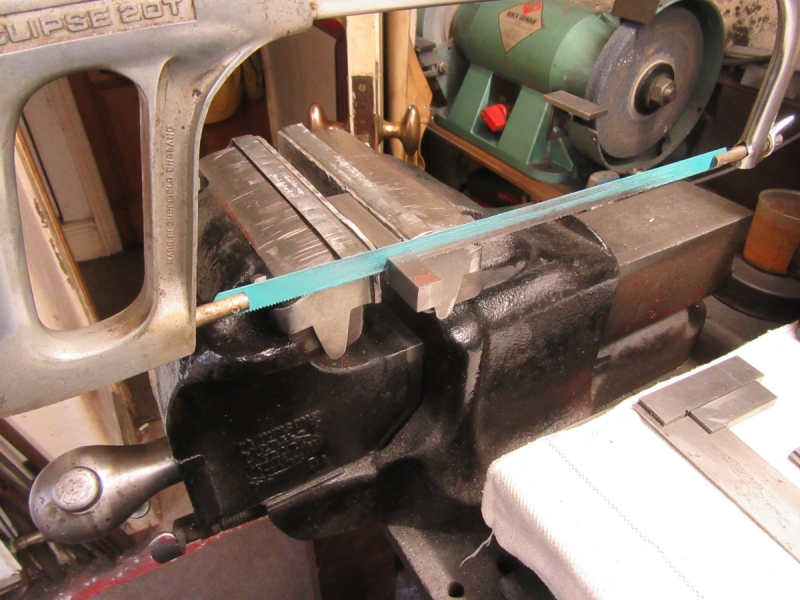

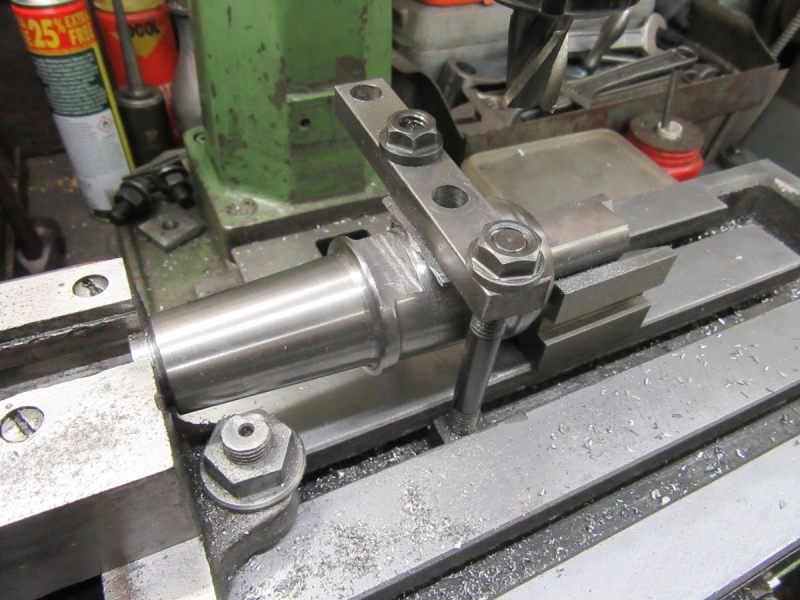

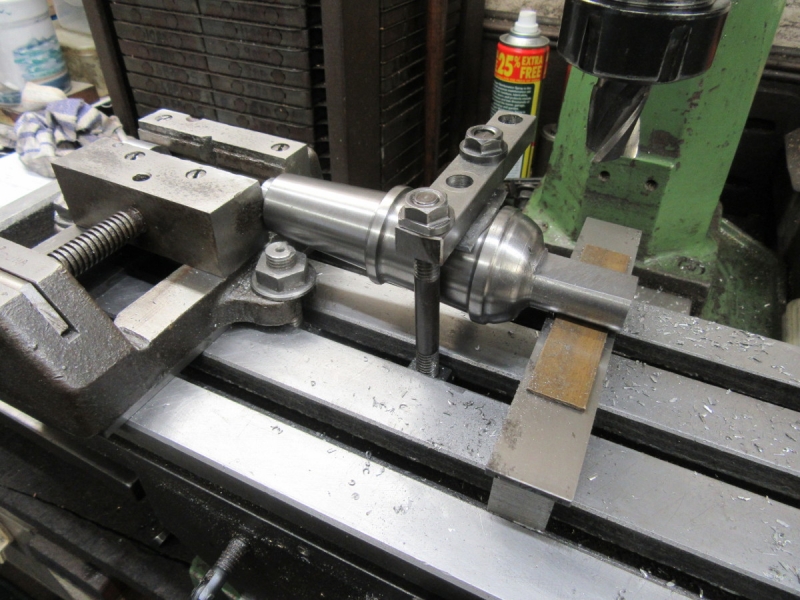

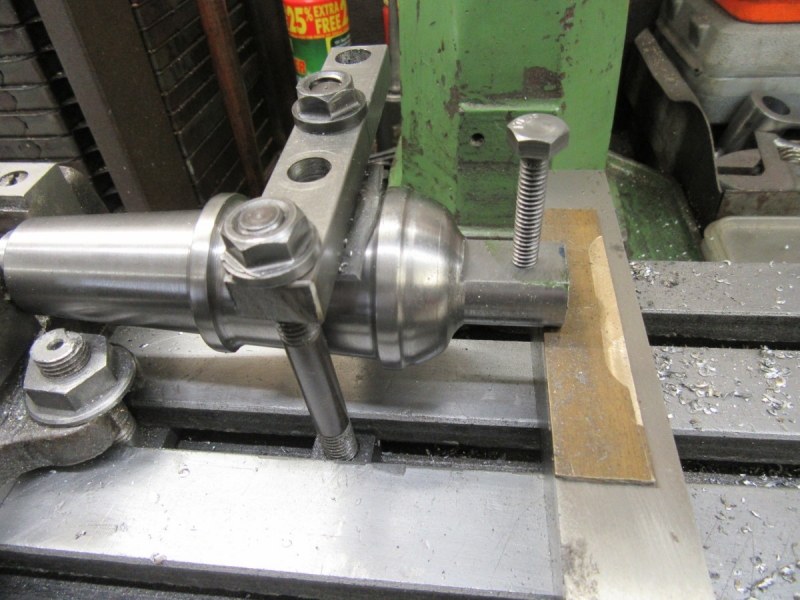

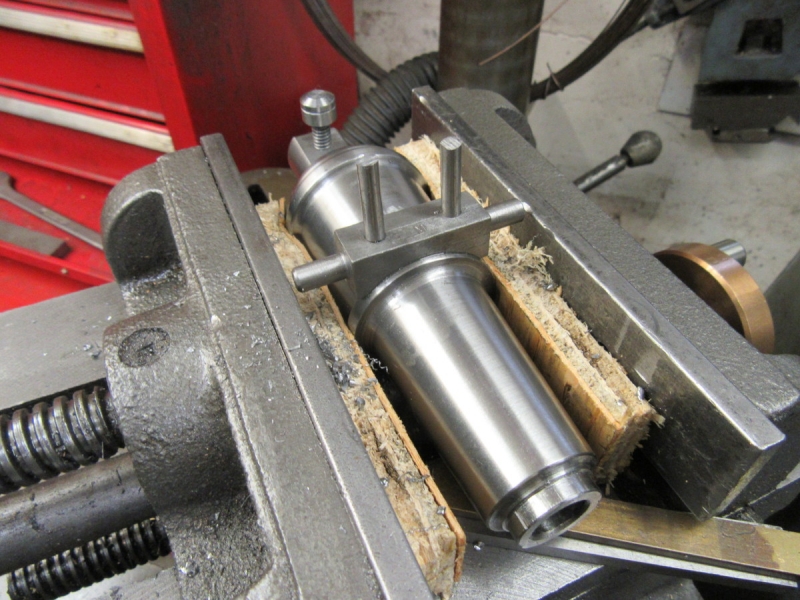

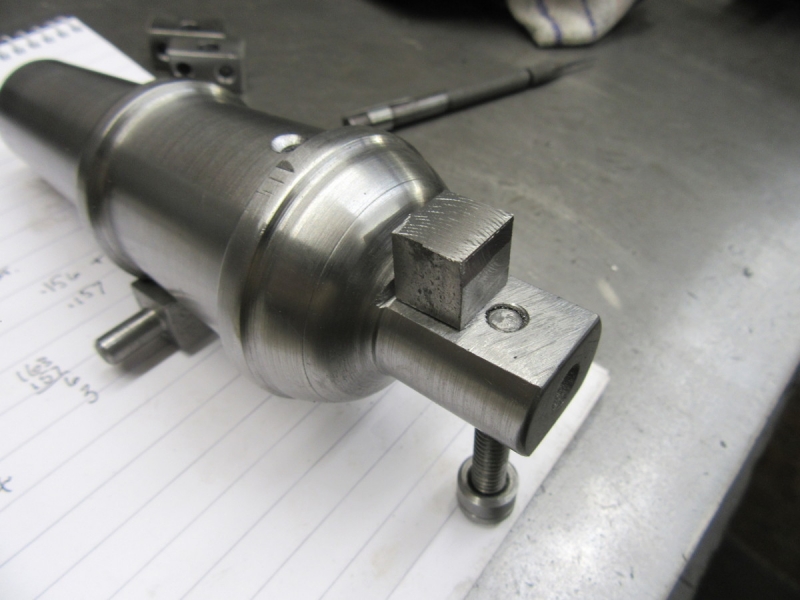

Today's task is to do some milling on the carronade. I need to make a flat for the block which will carry the trunnions and put a flat on each side of the spigot ready for working on it. As you can see, It's not what you might call a handy shape so I had to find a way of holding it. I worked out the basics on the surface plate. I can't remember when I used this little vise last but it's handy because it has a 'V' in each jaw which will do nicely for holding the piece. I noticed the maker's name on it, 'Mancunia', one of the myriad small firms that made tackle for model makers 100 years ago.... It's been abused during its life (not by me!) but I have refurbed it and it's a good little vise.

A short while later.... I'm ready to make my first cut but quite a lot had to be done to get here! I turned a scrap end down to the same size as the muzzle so that I could help the vise to shut parallel when the pressure comes on. The vise is packed up with parallels to match the height of the 'V' block so I can get the centre line somewhere near parallel with the cut. I want to leave the spigot clear so I can get the cutter to it so I have pulled it down on to the the bed as above. I had to drill a hole in the clamping bar and put a piece of lead under the it. It feels quite secure.......

I found a 1/2" cutter and used it to cut a flat that looks about right. The slot won't be exactly 1/2" but I shall make the trunnion mount to fit. I've decided that I am going to fit it using two dowels and Loctite so I must remember to drill the holes before I turn the job over.

My last blow was to fit the bigger cutter ready for putting the flat on the spigot. Must remember to sharpen the 1/2" cutter..... it was a bit dull. One thing I haven't mentioned is that this piece of black bar isn't mild steel. I have an idea it was left over from making some big studs for the Whitelees and I suspect it's the old EN8, some tough stuff. It surprised me when I was getting the shape into it, it cut OK but very hot.

Slow work I know but it's going all right..... A good morning.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: SHED MATTERS 2

Do you have, in your box of treasures, an m6 (or equivalent) nut and bolt about two and a quarter inches long?

Kev

Stylish Fashion Icon.

Stylish Fashion Icon.

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

I'm sure I will have something that will do Kev, it's just under 1/4" but how big is the hole? Pop round any time..... If Ian reads this I'll bet he has m6........

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

Pop in Kev, we can sort something out......

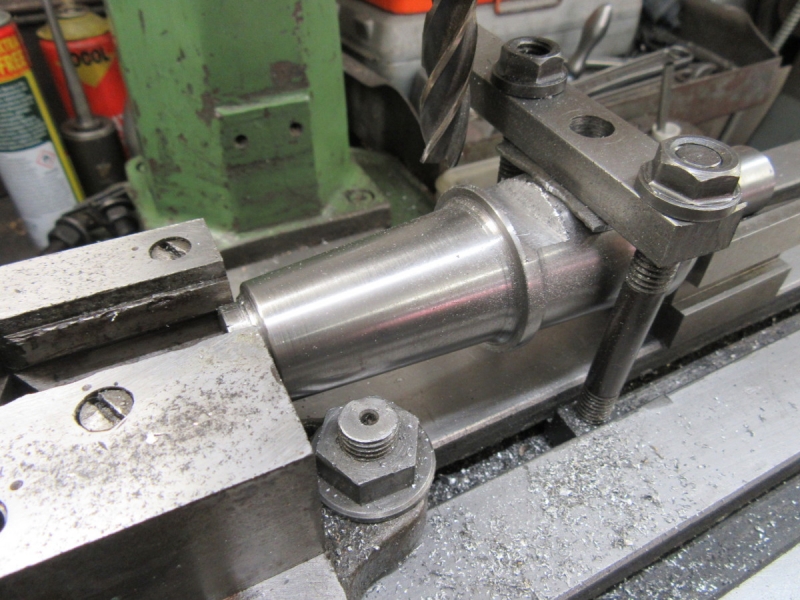

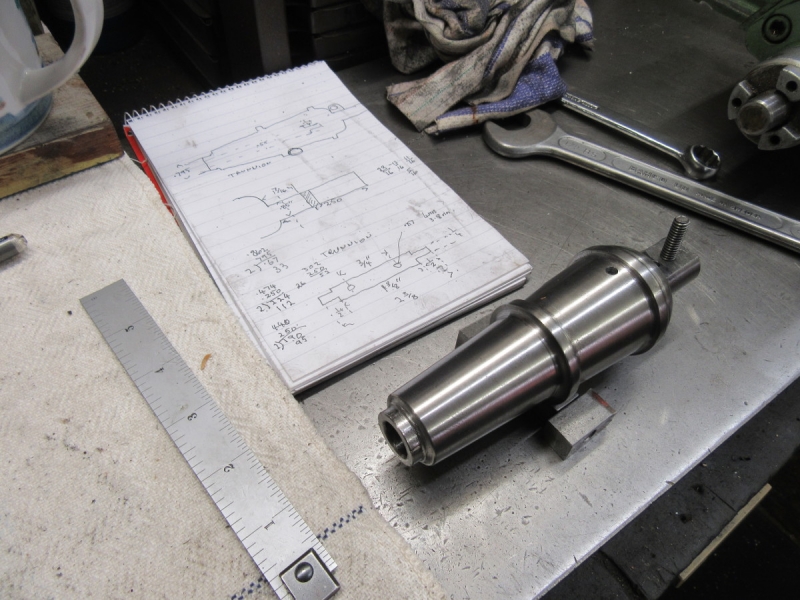

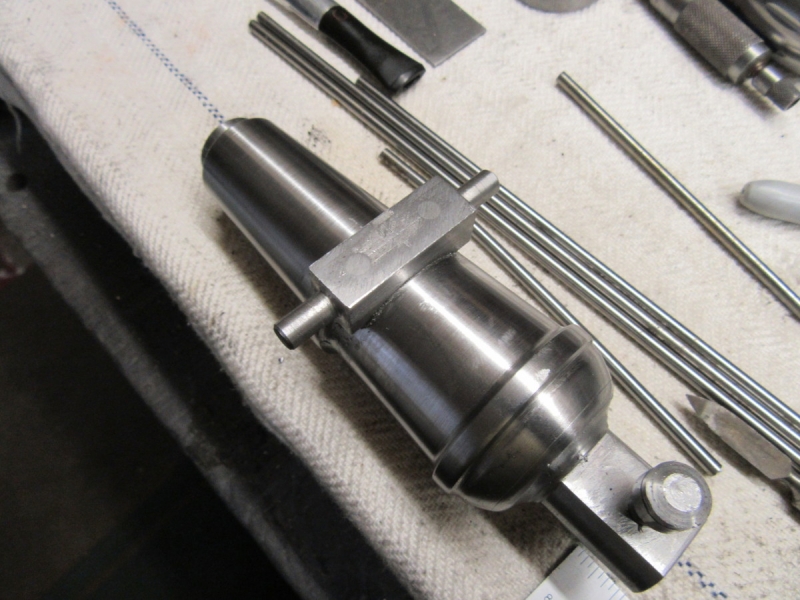

First blow this morning was to put the flat on the spigot at the breech. Before I turn it over I want to address the matter of the trunnions and carriers.

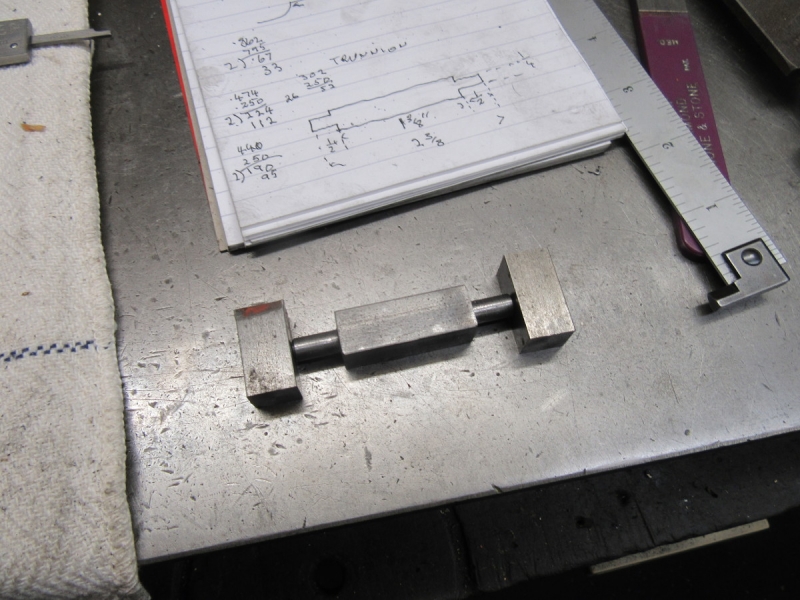

I got the key steel box out and found some 1/2" square key steel.

Into the lathe and square the end before measuring the length I need, 2 3/8" overall.

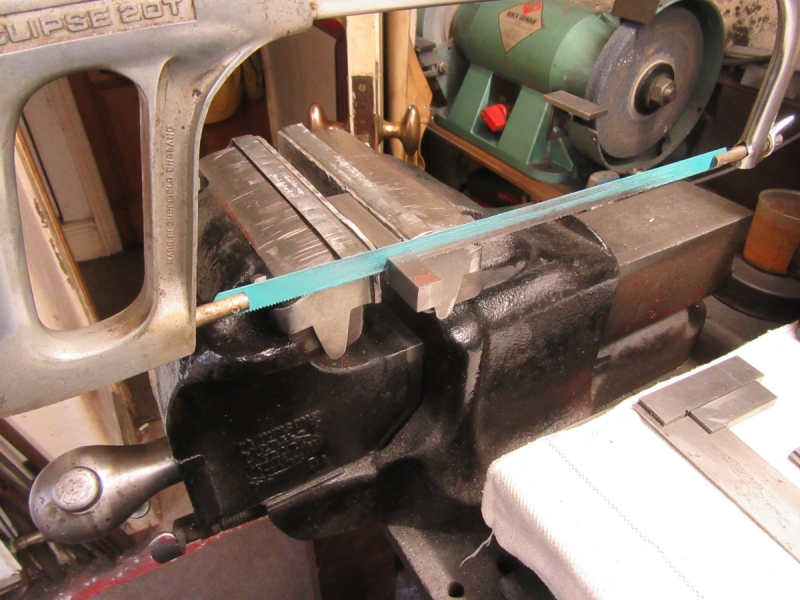

This is against my deepest beliefs as you know but I couldn't really justify putting it into Mrs McMaster....

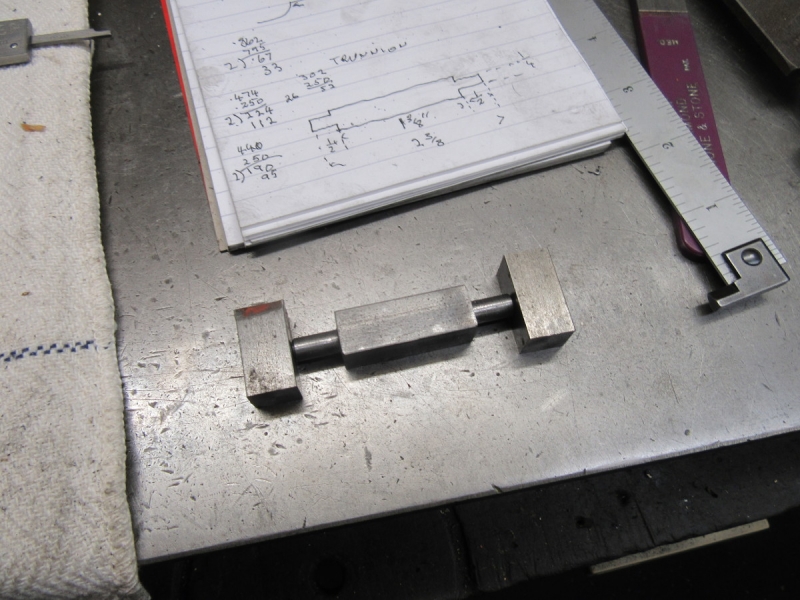

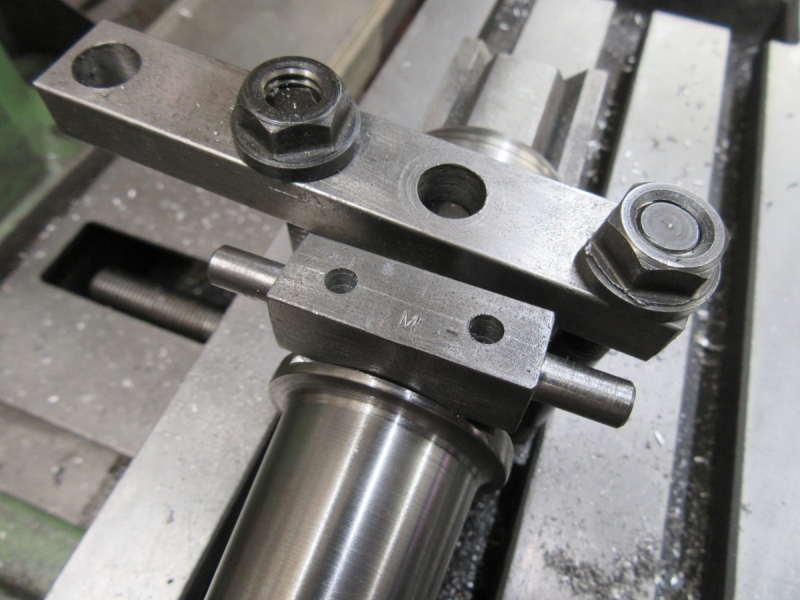

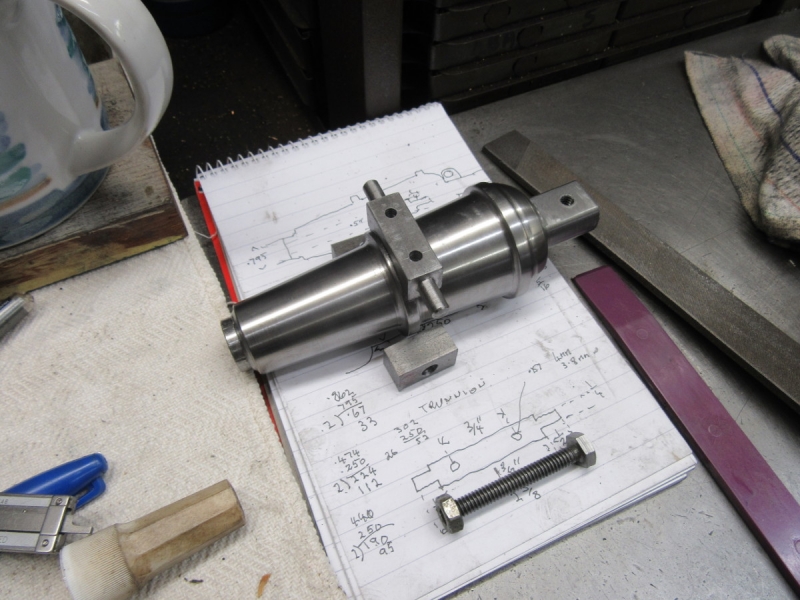

I haven't bored you with putting the 1/4" trunnions on the end. If you remember I cut the slot this is to sit in and settled for fitting the block to the cut. You're never absolutely sure what width old cutters are actually going to cut. As it turned out the key steel is a perfect interference fit. Nice!

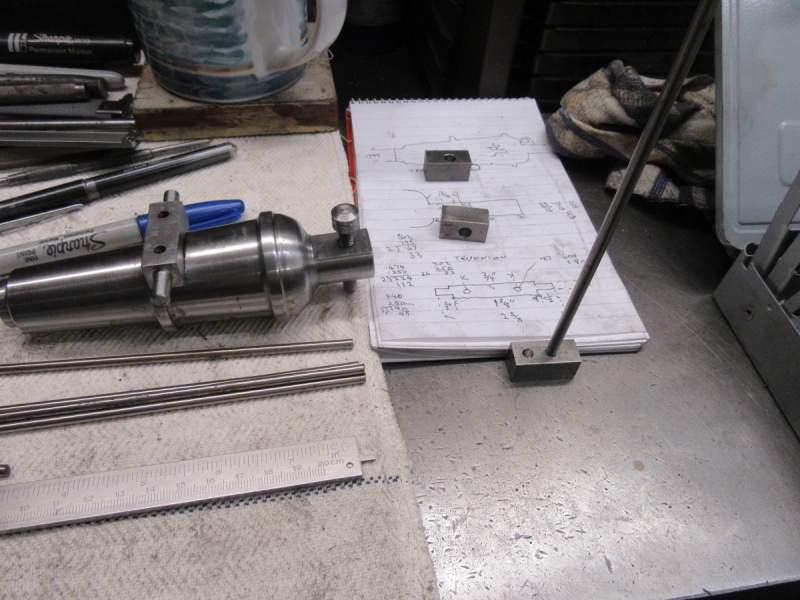

I cut two more slugs of key steel for the carriers and bored them 1/4". I'll address putting some shape in them and drilling for the holding down bolts later. It seemed the right time to do this while I had the key steel out.

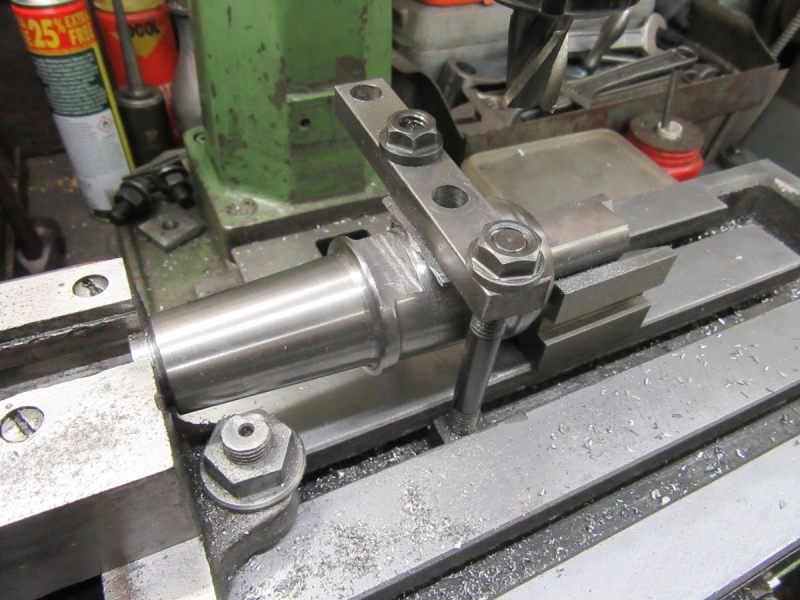

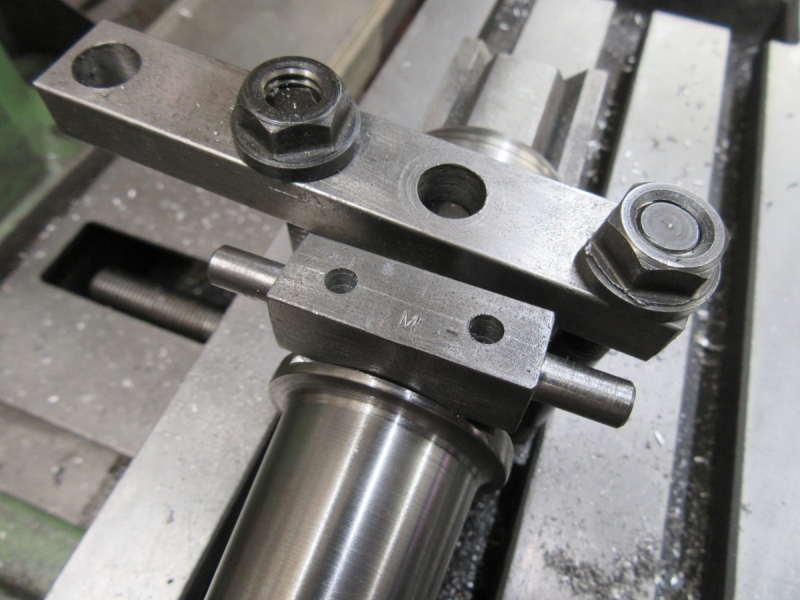

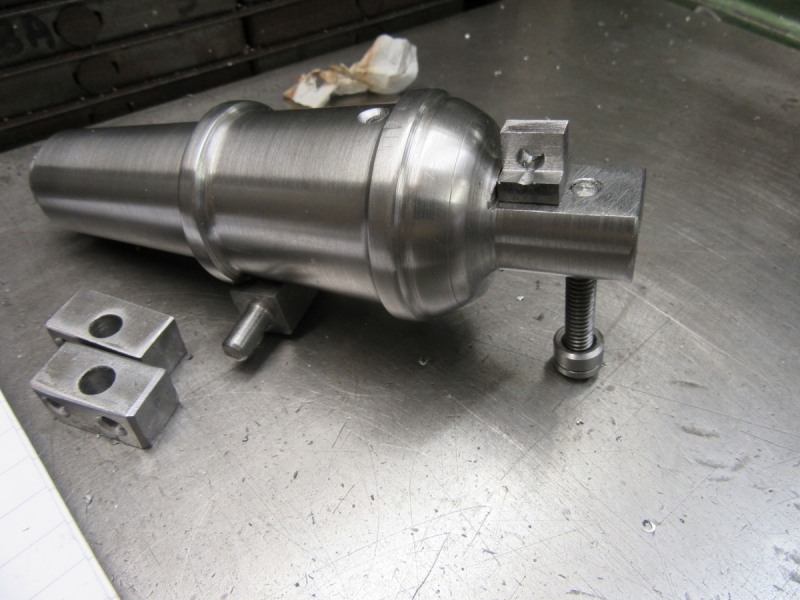

Here's the trunnion block sat on the slot, not driven in. I have drilled for the dowels that I shall use to make sure I have a firm fit when I press it home with Loctite. I considered silver solder but this will be OK. Now we need a new setup to mill the flat on the other side of the spigot. Notice that I have put a witness mark on to show which shows which size is towards the muzzle. That makes sure that my dowels will line up.

Here we are at knocking off time. I have made the second flat but now I want to have a think about what comes next. I have two holes to drill, one for the eyebolt for the recoil rope and the other for the elevating screw. This setup is ideal and it looks as though it makes sense to do it now. There's also the small matter of the end of the spigot with the centre in, it needs cutting off and milling looks like a good route. This isn't going to be the handiest item to hold when it comes off the bed!

First blow this morning was to put the flat on the spigot at the breech. Before I turn it over I want to address the matter of the trunnions and carriers.

I got the key steel box out and found some 1/2" square key steel.

Into the lathe and square the end before measuring the length I need, 2 3/8" overall.

This is against my deepest beliefs as you know but I couldn't really justify putting it into Mrs McMaster....

I haven't bored you with putting the 1/4" trunnions on the end. If you remember I cut the slot this is to sit in and settled for fitting the block to the cut. You're never absolutely sure what width old cutters are actually going to cut. As it turned out the key steel is a perfect interference fit. Nice!

I cut two more slugs of key steel for the carriers and bored them 1/4". I'll address putting some shape in them and drilling for the holding down bolts later. It seemed the right time to do this while I had the key steel out.

Here's the trunnion block sat on the slot, not driven in. I have drilled for the dowels that I shall use to make sure I have a firm fit when I press it home with Loctite. I considered silver solder but this will be OK. Now we need a new setup to mill the flat on the other side of the spigot. Notice that I have put a witness mark on to show which shows which size is towards the muzzle. That makes sure that my dowels will line up.

Here we are at knocking off time. I have made the second flat but now I want to have a think about what comes next. I have two holes to drill, one for the eyebolt for the recoil rope and the other for the elevating screw. This setup is ideal and it looks as though it makes sense to do it now. There's also the small matter of the end of the spigot with the centre in, it needs cutting off and milling looks like a good route. This isn't going to be the handiest item to hold when it comes off the bed!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: SHED MATTERS 2

There's a bit more room than 6mm, I'll bring the bits around with me

I trust the pictures make sense, it's the teatowel rail that a small boy thought would make a good swing...

I trust the pictures make sense, it's the teatowel rail that a small boy thought would make a good swing...

Kev

Stylish Fashion Icon.

Stylish Fashion Icon.

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

Good idea Kev, We can make fitted bolts if we haven't got tailor mades.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

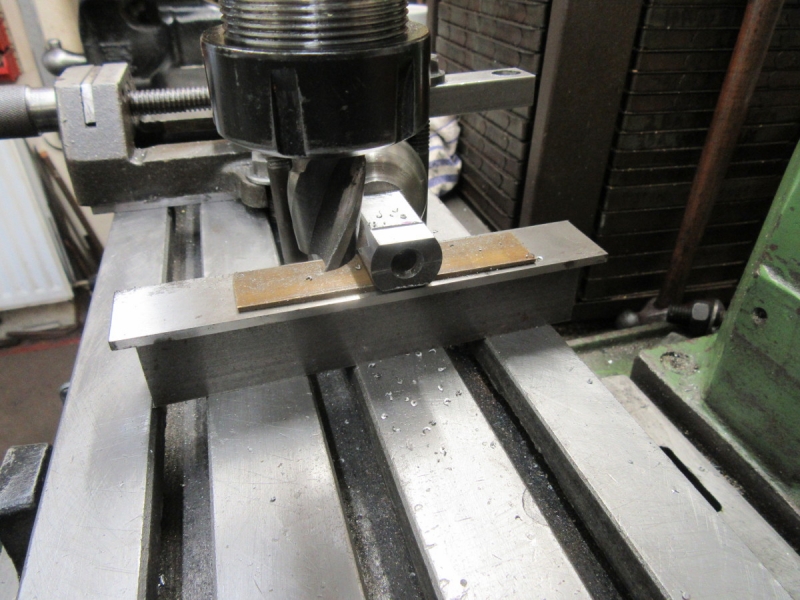

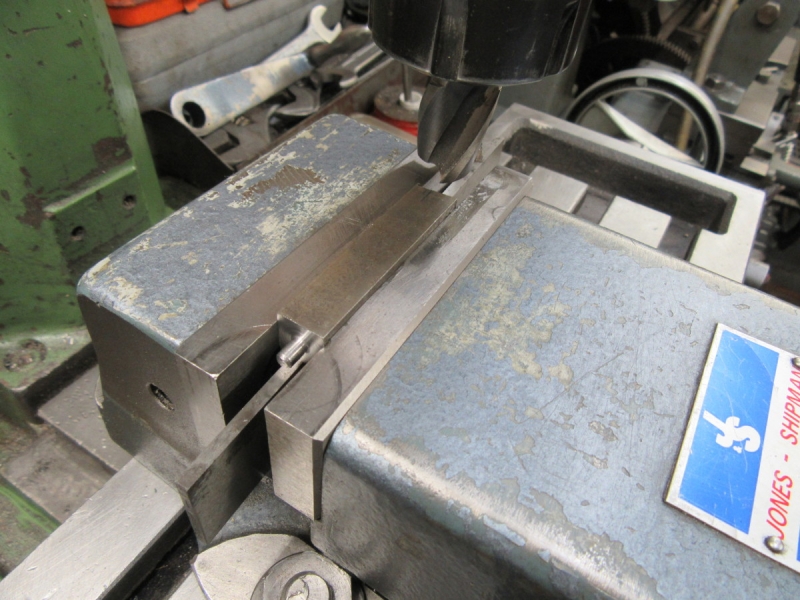

First job this morning is to cut the excess off the spigot, I need to get rid of the centre I used for turning it. The best way is to mill it off with small careful cuts. First because I want to make sure I don't disturb the setup. Second because my El Cheapo mill makes better cuts if you don't get greedy!

Now I need to drill some holes, I could do it using the collet chuck but it's a good thing to take it off every now and then, they can freeze in the taper if you don't. I'm going to put the keyless chuck on. Bleeding obvious tip, use two opposing taper drifts to get the chuck off the taper that will always get them!

I drilled and tapped the spigot for 1/4" Whitworth, it will look OK as the original elevating screw was a coarse thread. Besides it's easier as I have plenty of Whitworth set screws.

I popped the screw in so I could measure for the position of the dowel that will locate the recoil rope eye. I'll make that later to fit the gap.

One more hole to drill, a 1/8" drilling into the powder chamber for the touch hole.

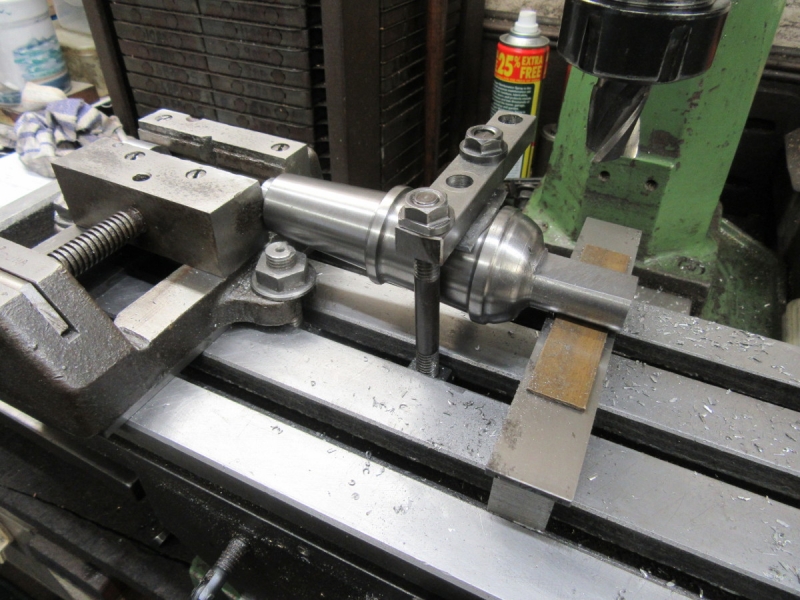

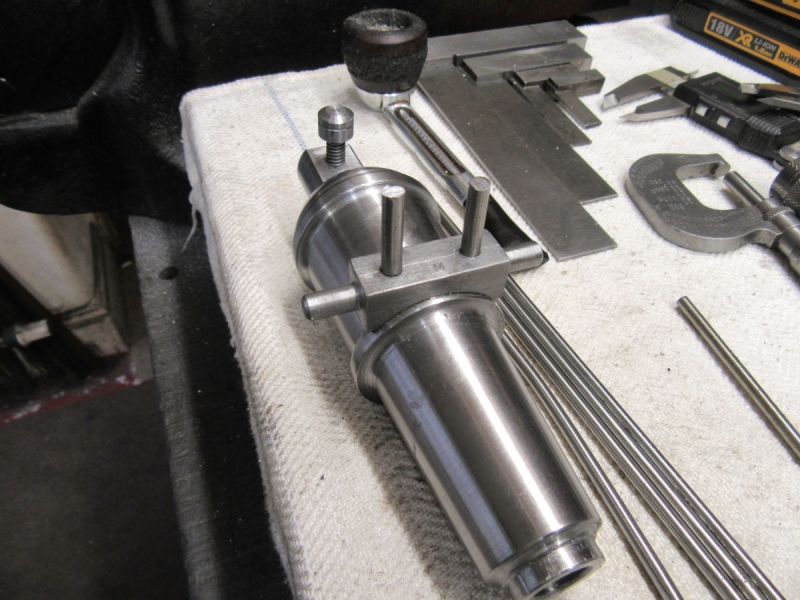

Here's where we are at. It's tilted a bit because I haven't driven the trunnion block home, I want to fit the locating dowels first. I almost did it while I was under the setup but decided to do it a bit differently. I broke my setup down, put the collet chuck back on and put some tools away. Then I knocked off early because I have to go to the surgery for a blood test.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: SHED MATTERS 2

Fettled with a fitted bolt, top job Stanley. Thank you. I've used a short piece of plastic tubing until I can find an 8mm nut to 'lock' it off.

Kev

Stylish Fashion Icon.

Stylish Fashion Icon.

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

A bit of housekeeping for a kick off. I put the vise back on the VM and trammed it in.

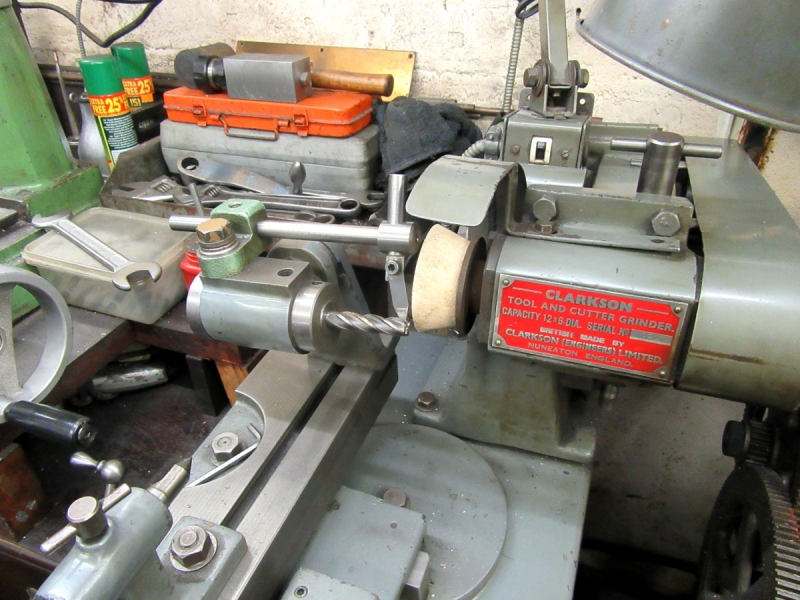

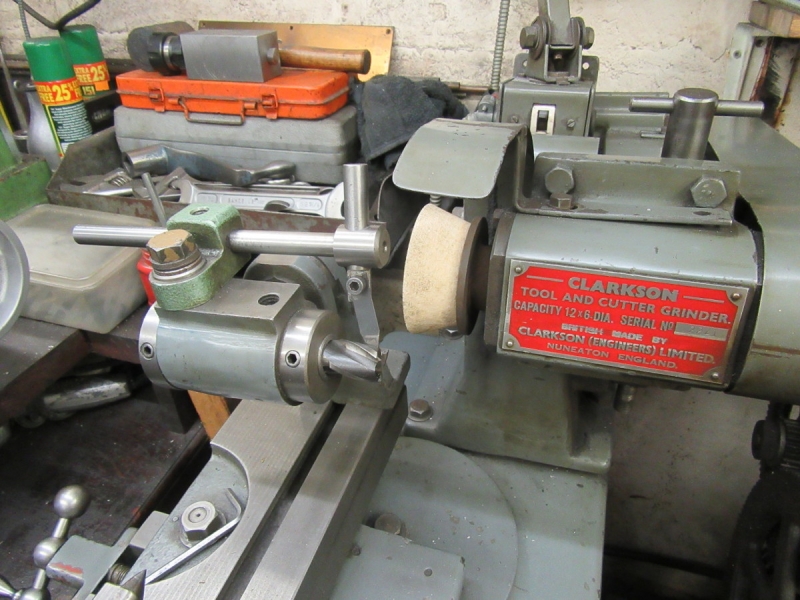

Remember me saying the 1/2" cutter was a bit dull? I gave it a quick sharpen in the T&G grinder.

Then I spent quite a lot of time tidying up the spigot. I could quite easily do more to it later!

Part of the tidying up was the recess for the trunnion block. Once I was satisfied I pressed the block in bedded on Loctite 638 and put it on one side to cure. I shall drill for the dowels tomorrow.

Then I fitted another nut on the head of the elevating screw to give me enough meat to install a handle. I got my silver steel out to find some more 4mm rod. Best investment ever when I bought this bundle for a tenner in a sale at K Steels many years ago. Never walk past a bargain!

Here's where I was when Susan came to visit......

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

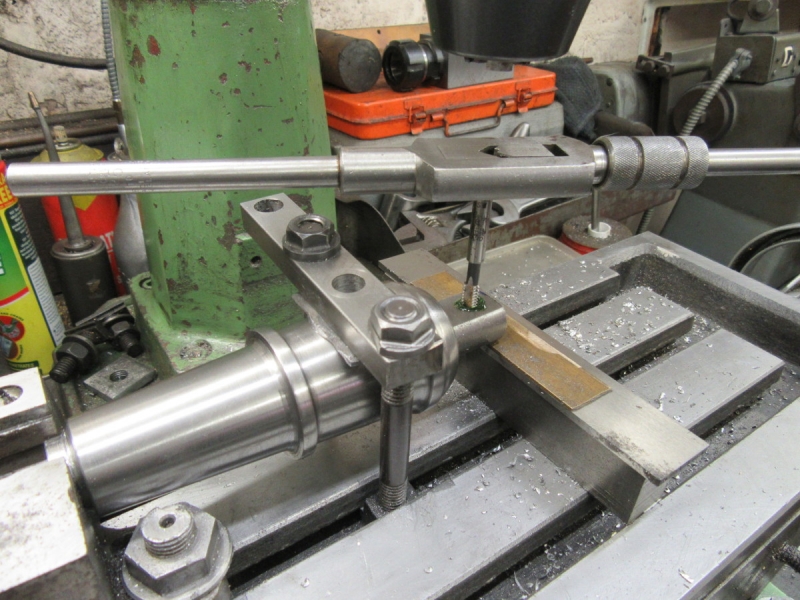

The 4mm silver steel you can see on the left is a loose fit in the holes in the trunnion block so I found a piece of 3/16" SS. I drilled some trial holes in a bit of scrap to find exactly the right drill to give me an interference fit.

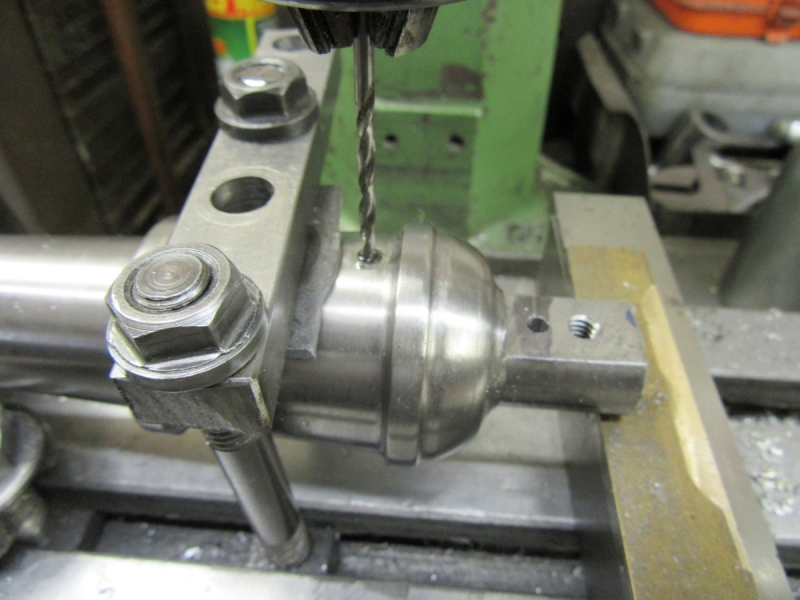

This set up had to be imaginative! I needed to hold the piece securely without damaging it and it's very awkward, not a square surface on it. So I did some fiddling and then took my heart in my hands and poked two holes in the block to give me 1/4" entry into the material of the carronade.

I got the dowels entered and went to the bench.....

I soon realised that I had a bit more interference than I expected so I went back to the compound vise on the pillar drill and set it up solid in there. Good job I did because I didn't half have to leather them to get them fully home. This trunnion block will never move! By the way, I didn't put any Loctite on the dowels, if I had they could have built up enough pressure in the hole to blow the block off!

I filed the heads of the dowels off while it was in the vise and here's the result. Quite pleased with it, it looks tidy and it's certainly firmly fixed!

By the way, I countersunk the touch hole. Then I decided on 2BA fixings for the trunnion housings marked the blocks and drilled the holes. Than a bit of titivating to make them look pretty.

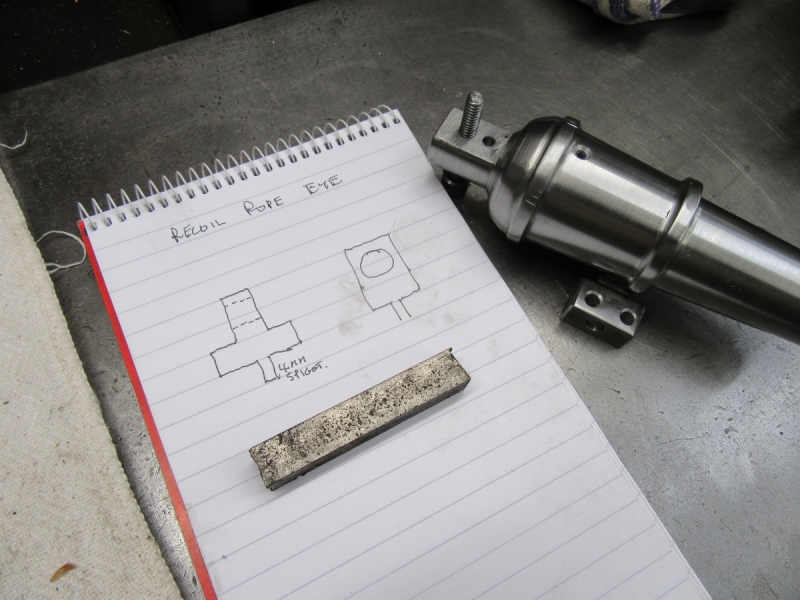

It was getting close to closing time but I went into the drawing office and designed the ring for the recoil rope. I had a furtle through the key steel and found a piece that will do. That's the job tomorrow morning, make the fixture and fit it on the spigot.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

Thanks Kev, it pleases me too. The nice thing is that it isn't the exact shape I drew out, it modified itself while I was turning it freehand and it worked. CNC machines can't do that.... I always say it's sculpture!

I was thinking about those dowels and how hard I had to leather them to send them home. They'll have just as good a hold as a bolted connection would, perhaps even better.

I was thinking about those dowels and how hard I had to leather them to send them home. They'll have just as good a hold as a bolted connection would, perhaps even better.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

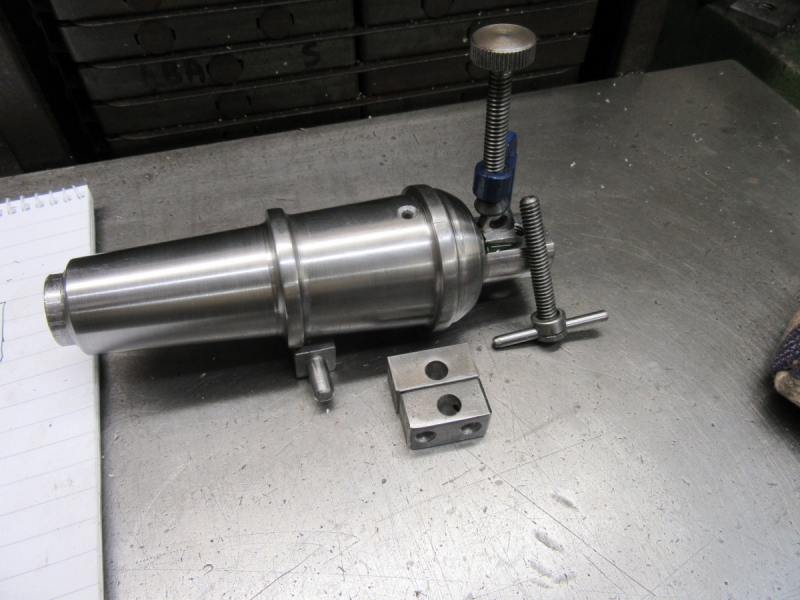

You know what we are doing..... I measured the socket for the recoil rope ring and turned a spigot on the end to fit the hole. Then into the VM to reduce one side slightly for clearance of the elevating screw.

So far so good, now to find the ring inside the block.

Now I need to reduce the stock to get a web in the centre. I have very little hold on it so light careful cuts!

I had to strike a balance between the depth I want to cut to and having enough hold on the stock to make the cut possible. This meant my last cut had to be as close to the hardened jaws as possible. So out with the old fitter's trick, wet a cigarette paper and lower the cutter until it picks it up. That was OK but I realised that the near jaw was a thou higher and the cutter is rubbing on it.

I could have crashed on, the cutter wasn't damaged but it was better to do the job properly and put an edge back on it.

Back into the VM with the cutter and do the other side. This isn't quite as deep of course but I can adjust that. Here we are at closing time, lots to do yet to it but I think you can see where we are going. Amazing how long little things like this take but no matter, we aren't on piece work! Onward and upward!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

This morning we are refining the recoil rope eye. I started by doing a bit more light milling to make sure it was symmetrical. Then I decided to mill the corners off to make rounding the top easier. This was going well until the piece slipped before I finished the first one1 A quick stop and a rethink.

I decided that filing was a better option. Luckily no real damage had been done. I used the vise on the VM because it has very accurate jaws and set to.

How long is a piece of string. I kept going until I was fed up and here's where we ended up.

The first thing I had to do was grind a bit out of the jaws of this small 'C' cramp so it would fit on the assembly. I was considering sweating the ring on but the spigot is a good fit and I decided Loctite 638 was going to be plenty good enough. I'll leave it to cure overnight before I clean the excess off.

I turned to the elevating screw and fitted the handle to it. It's an interference fit and didn't need any Loctite, it's tight enough.

Then I had a think and what I need to do now is design the carriage. This is a move into woodwork and the drawing office so I decided to knock off early and come to that fresh tomorrow morning.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: SHED MATTERS 2

Looks a bit better now. The other two hoop back chairs to do and it'll be a nice looking trio, I'll then need to find somewhere to put them as there's no room hereBig Kev wrote: ↑06 Apr 2018, 10:36

Just thought I'd show my latest project. The Windsor chair had been painted with a satin finish acrylic paint, along with the two spindle backed chairs. There's no age to them, I uncovered a manufacturer's stamp on the bottom which shows '88', but they are in good condition and too good to go into the recycling. The person throwing them out was replacing them with a new set.

A lot of paint stripper, a heat gun and a few hours graft and the Windsor is back to bare wood. A few more hours of sanding and a few coats of wax will make a world of difference.

Kev

Stylish Fashion Icon.

Stylish Fashion Icon.

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

Fancy ditching good chairs like those..... You've made a good job of it Kev. Now for the same standard on the other two!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

It's been a busy morning! All my jobs done but no real shed. My only blow this morning has been to go and inspect my neighbours woodpile (with his permission of course) and look for a piece of wood I can get the carriage and its associated parts out of. He only had softwood but this is a nice well seasoned piece and will do nicely once I have made up my mind what I am going to do. The design committee is working on that one!

Notice that I have a piece of oak in reserve, it's not big enough for the carriage but there will be other bits.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: SHED MATTERS 2

I have a few pieces of 'butcher's block' worktop if that is any good to you.

Kev

Stylish Fashion Icon.

Stylish Fashion Icon.

- Stanley

- Global Moderator

- Posts: 90300

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

I need 4 pieces of hardwood 1/2" thick and 4" X 8" if you have anything anywhere near that. What I have will be a bit soft but I can manage. Can't afford to spend anything at the moment......

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!