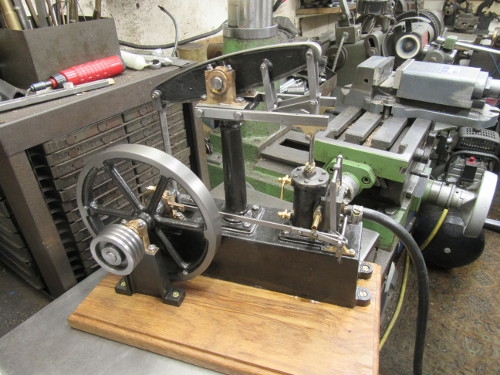

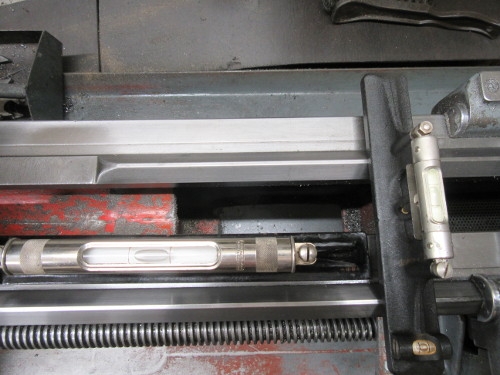

This first pic tells the story about the lathe in that as far as level is concerned, the lathe is fine and needs no correction. I did another check as well on the compressor. I was pleased to see that while the pressure has dropped a bit, there is plenty of pressure left. This should be the situation for about three days, we'll see. So I put the machinist's levels away and got on with it.

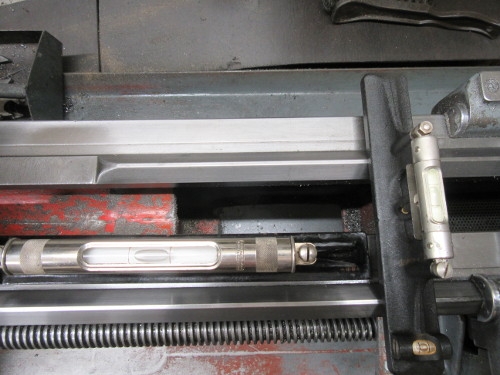

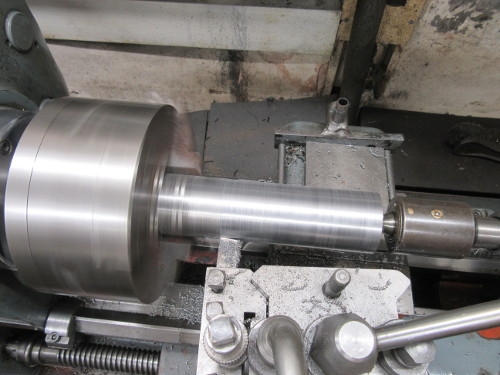

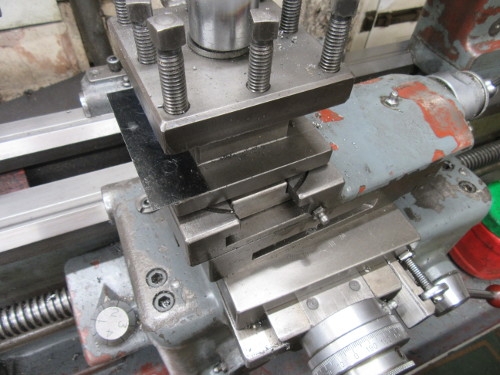

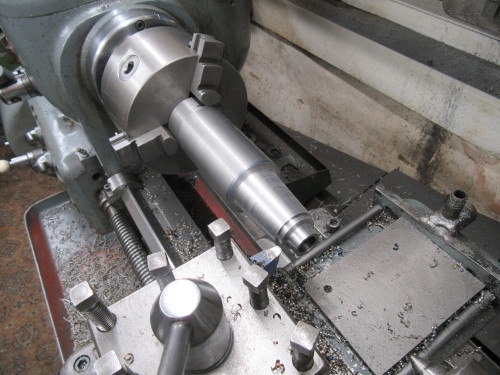

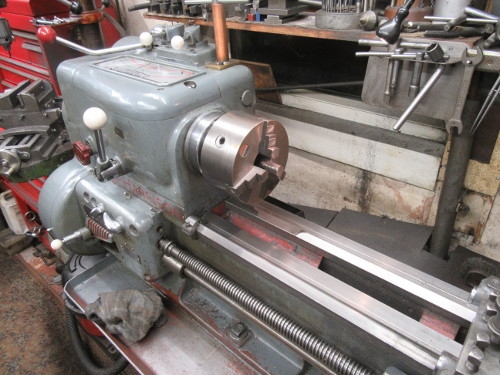

I forgot to mention, I had cleaned Mrs Harrison. Next job was to put a bigger chuck on as I am dealing with heavier stock. This is the original Pratt 3 jaw SC chuck that came with the lathe. A good chuck!

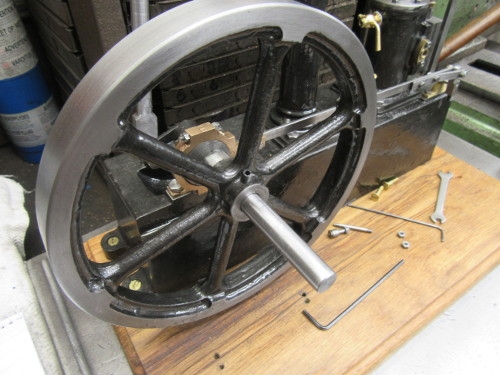

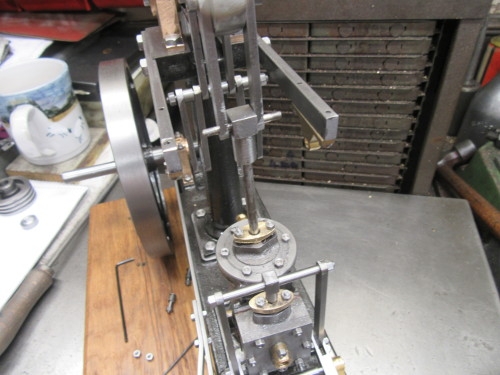

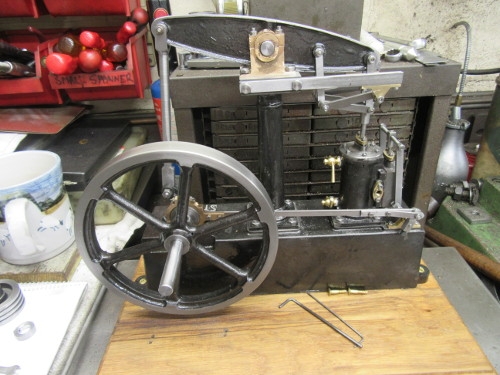

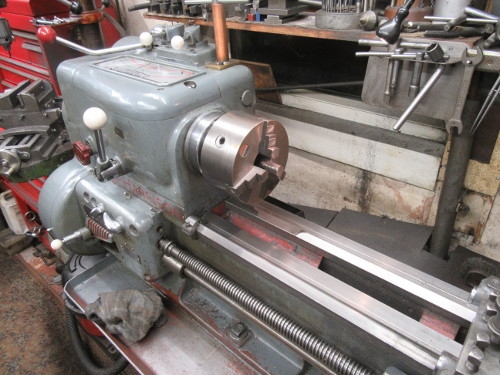

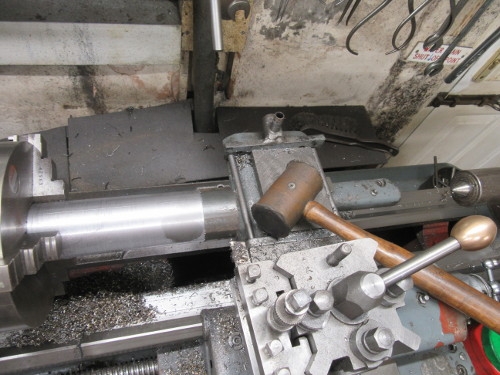

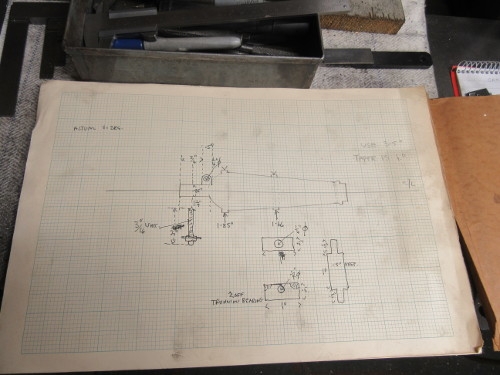

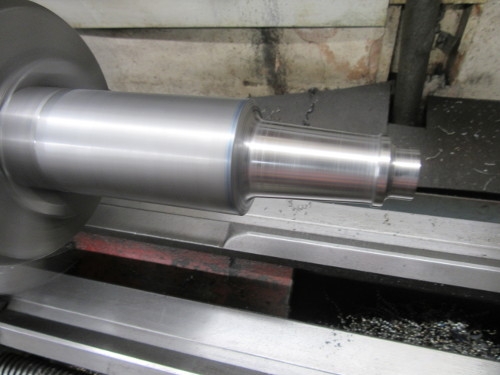

Here's a clue about my next job, I want to make at least one of these. I measured it and the piece of stock I dug out for the test will do for making these.

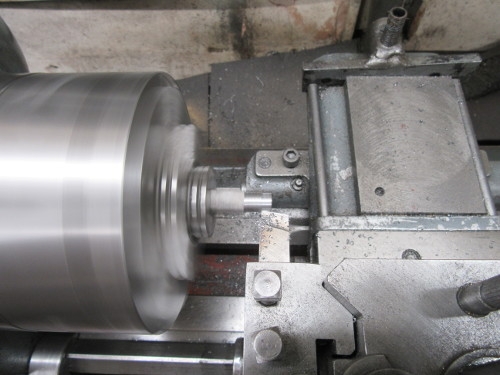

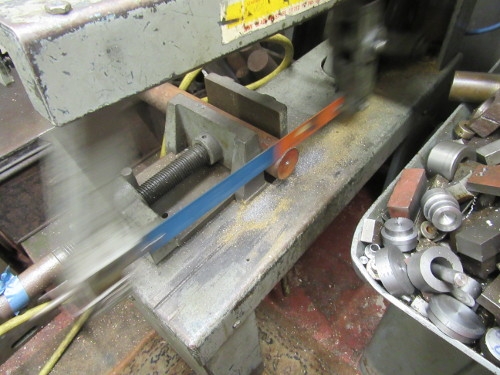

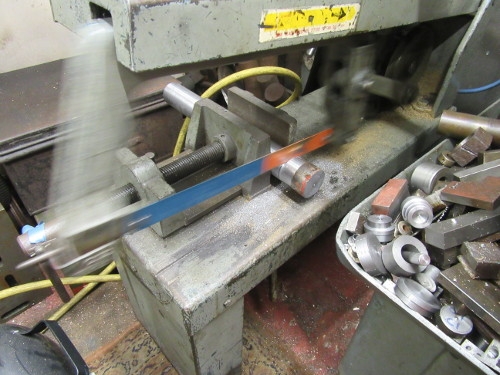

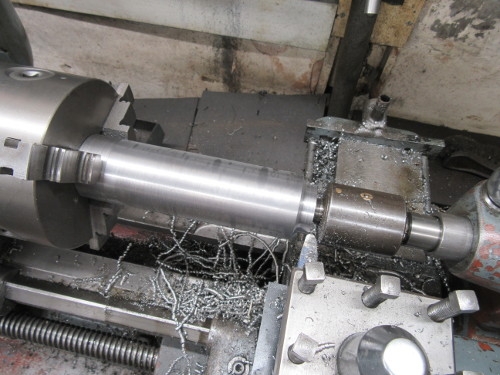

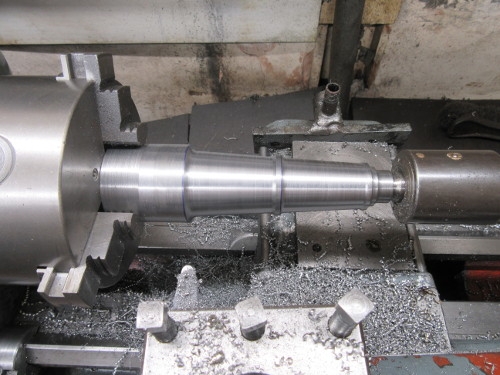

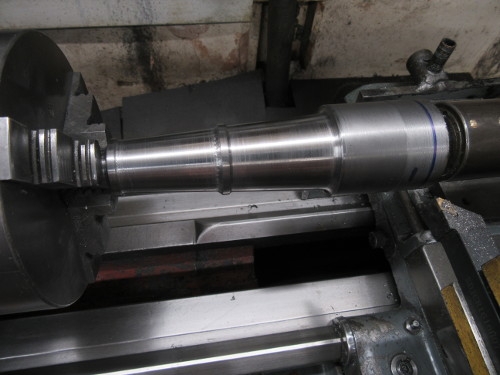

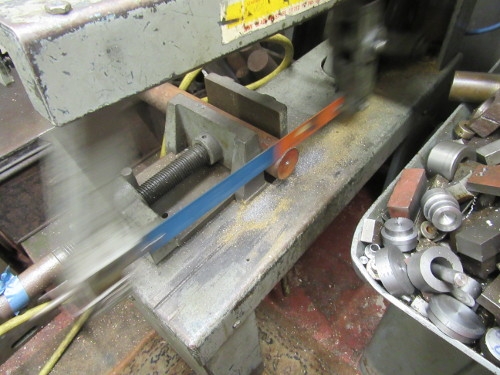

The stock I got out is very rusty, from the look of the read paint on the end I think it will be what used to be called EN8, I'm sure there will be another designation now. I wanted a clean end and so into Mrs McMaster. What a lovely noise she makes....

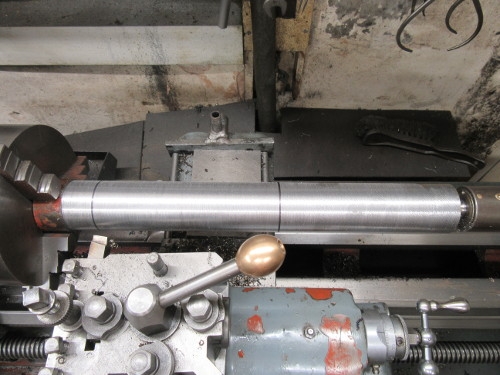

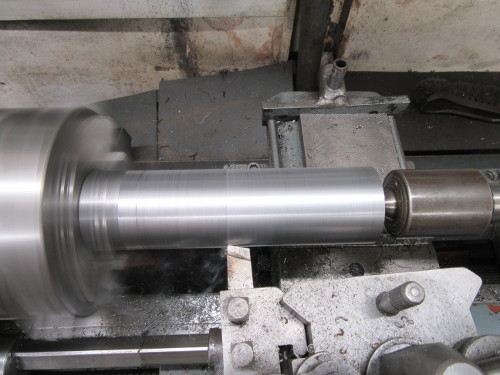

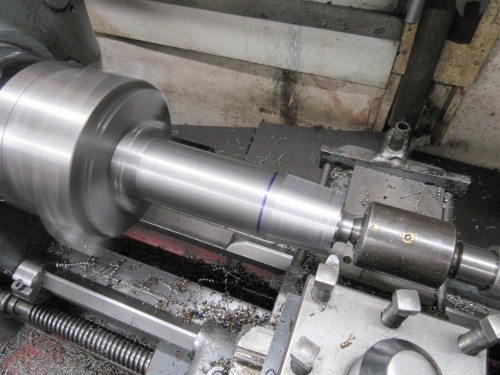

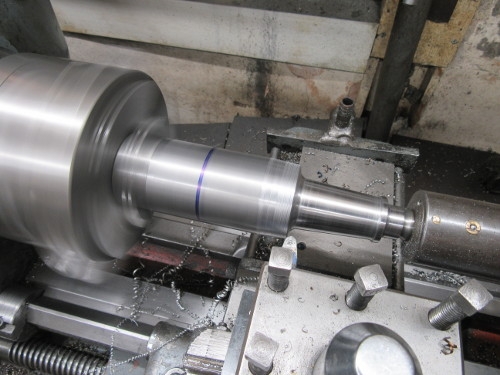

Here we are set up and cutting. A lot more of this and at knocking off time I had a quick measure. The piece I have turned is 14" long and the difference between the ends is just half a thou. I think we can say that the smash I had hasn't done any damage. This is well within expected limits. Try it with your lathe and see what results you get. That was it for this morning, tomorrow I'll cut my stock for the project. Very pleased with my checks....