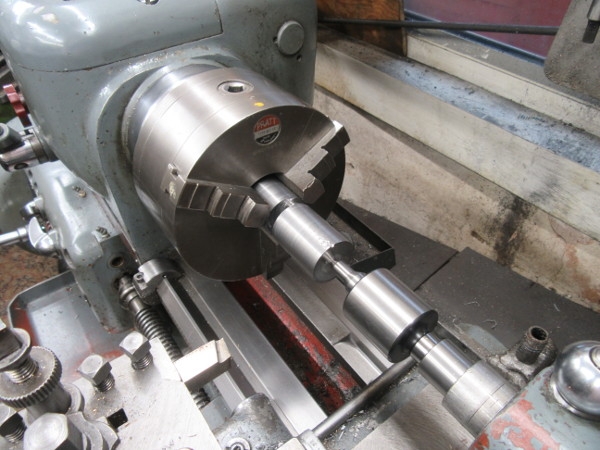

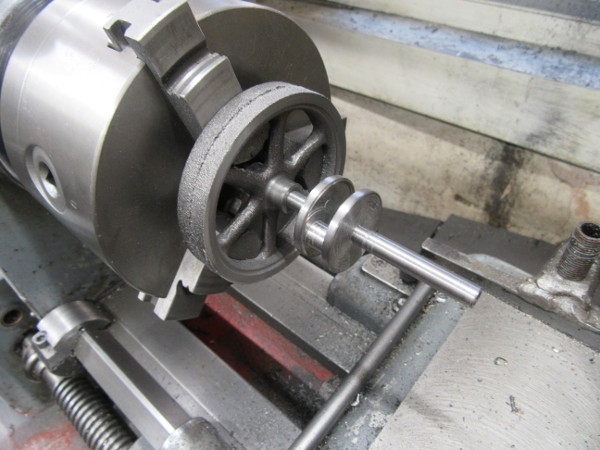

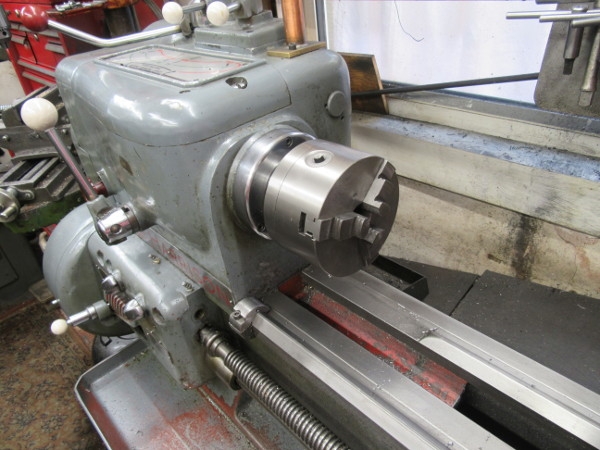

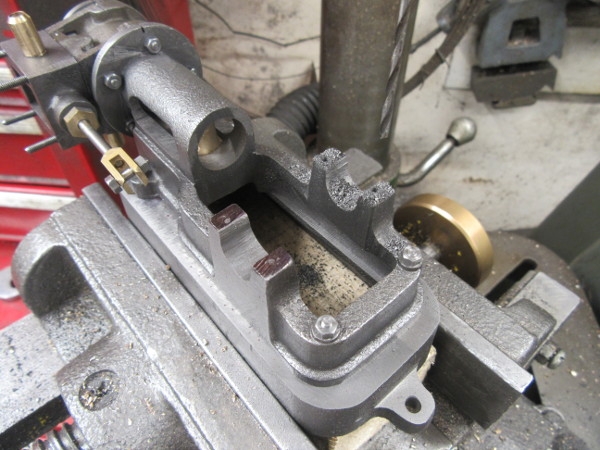

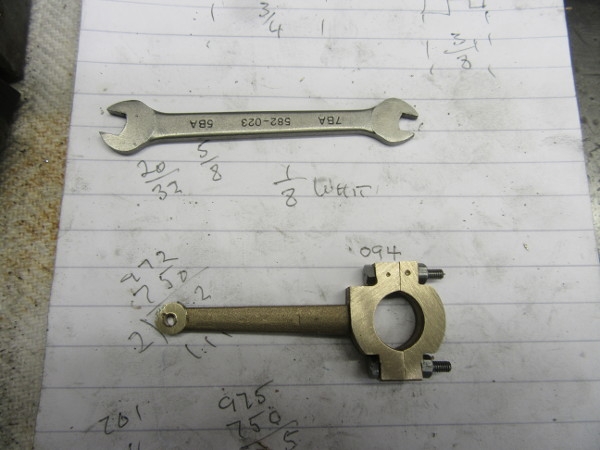

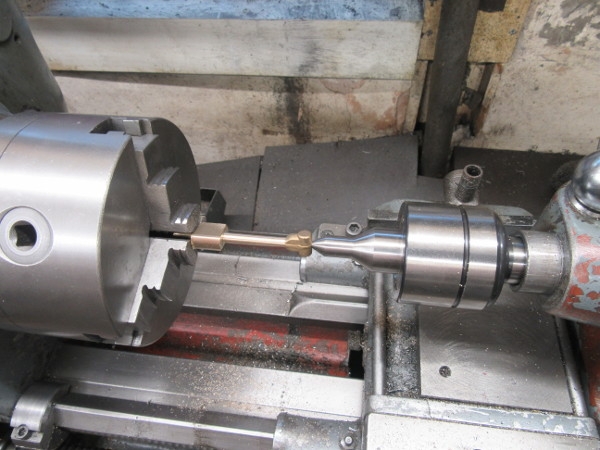

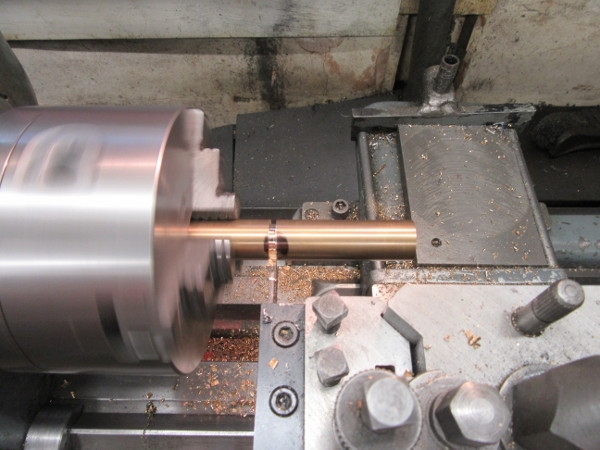

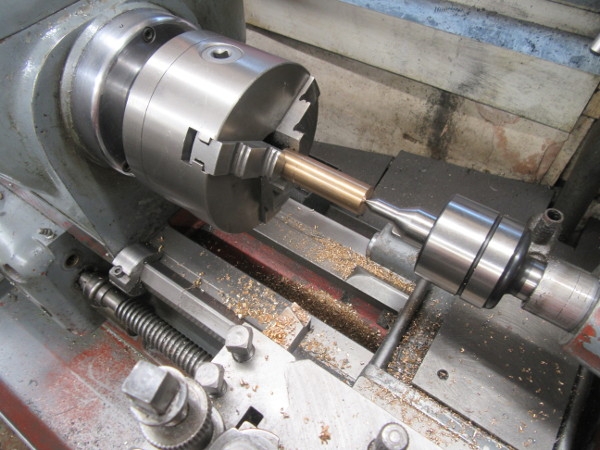

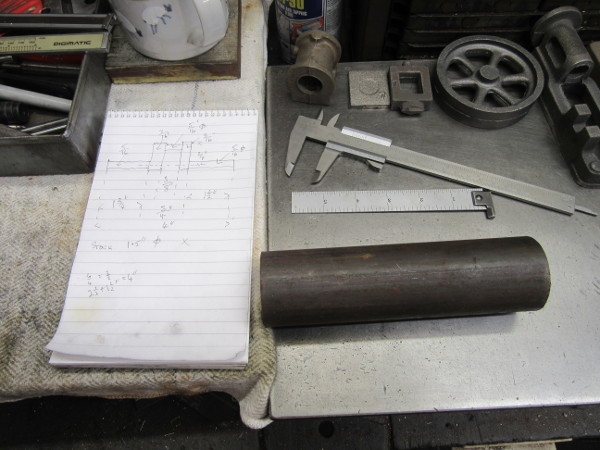

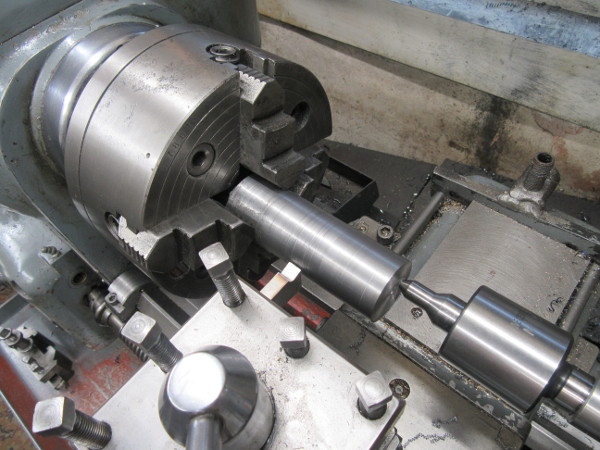

I decided to cut the 5/16"wide crank pin with a 5/16" cutter, it seemed like a good idea at a time. So I got everything set up ready for a perfect bit of turning.

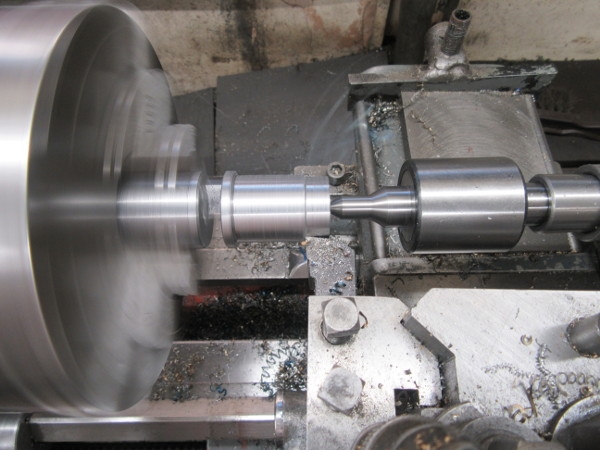

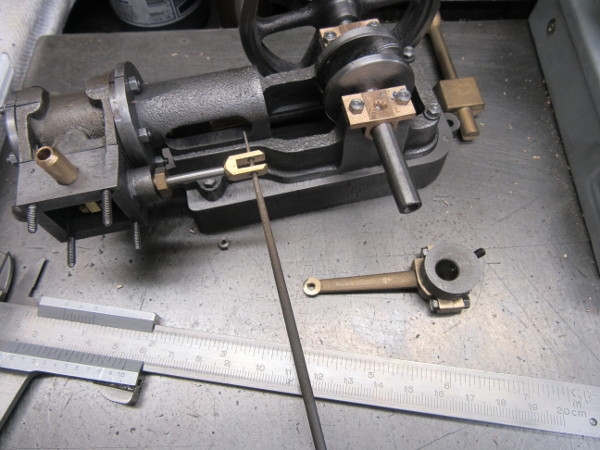

I realised straight away that the new live centre had too much overhang and so I went back to my old heavier centre that is 3MT and hasn't as much overhang. Away we go, cutting well.

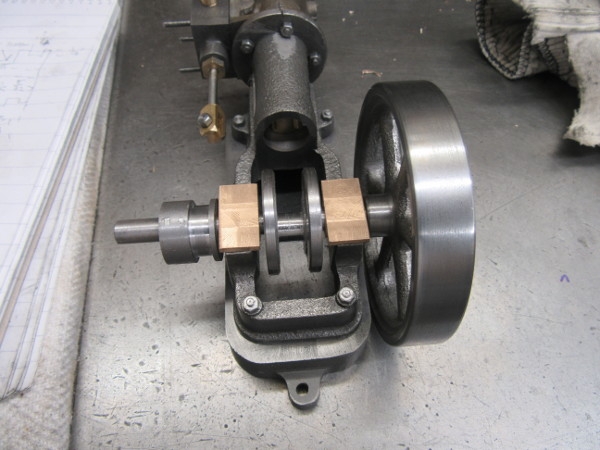

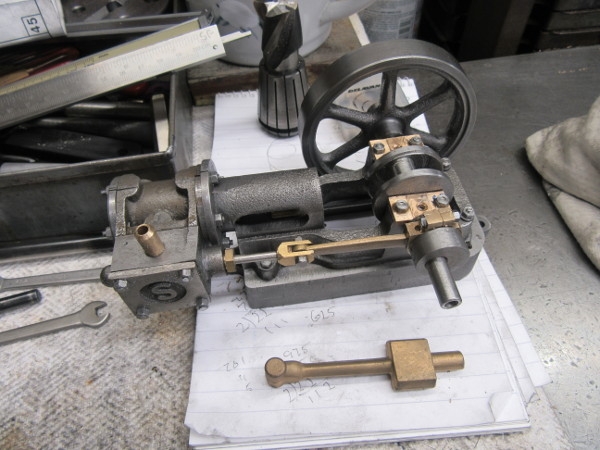

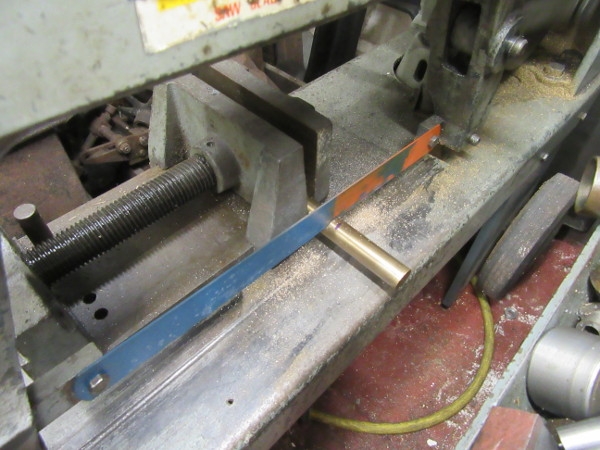

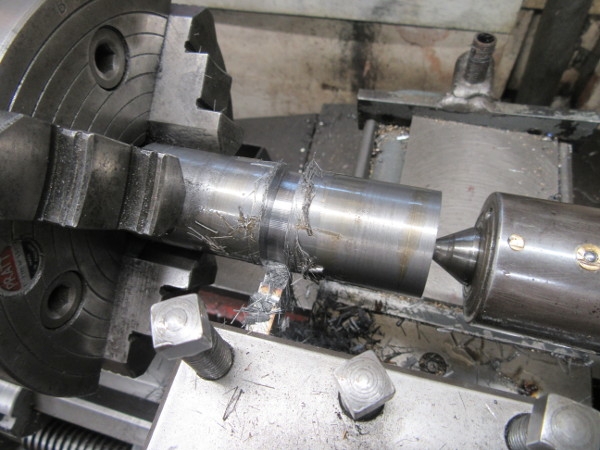

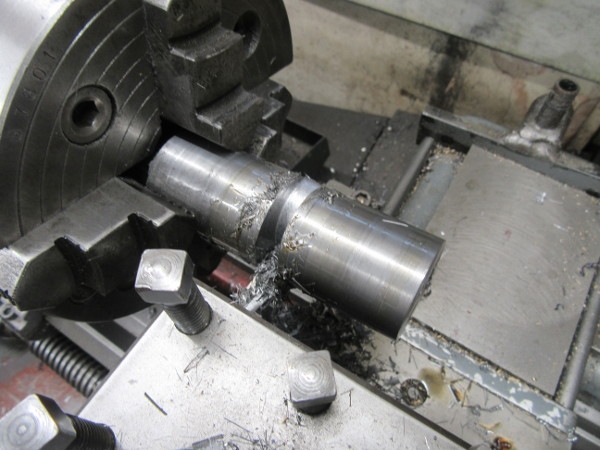

Here's what happened, and it was a direct result of having the cutter as wide as the cut, it dug in and brought me to a dead stop. Luckily it was before I got in too far and there was still enough strength in the workpiece to stand the jam.

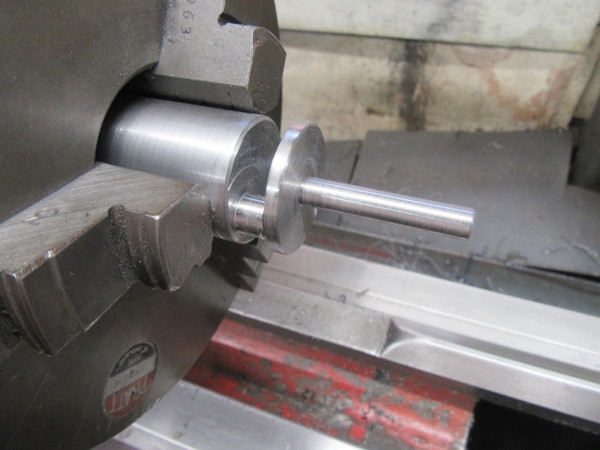

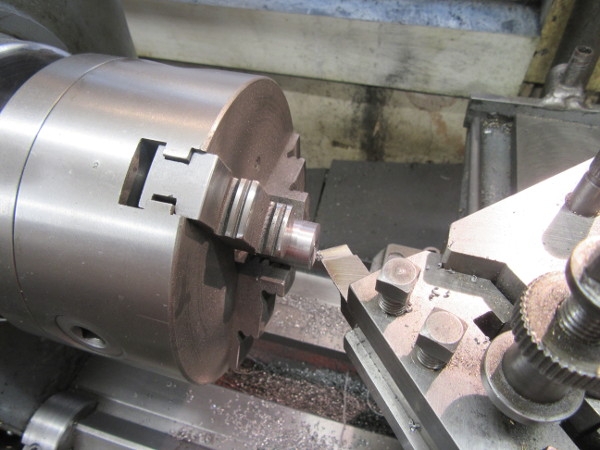

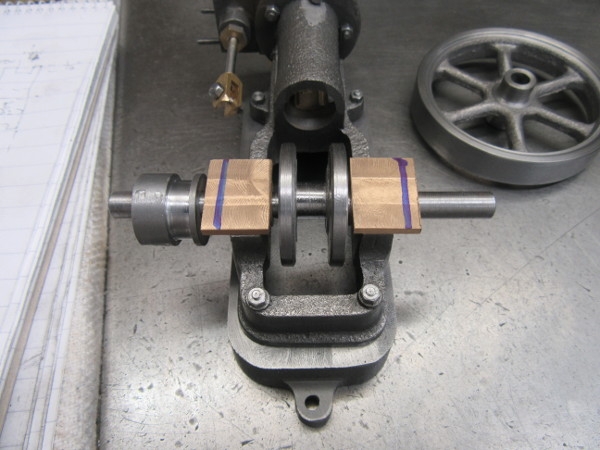

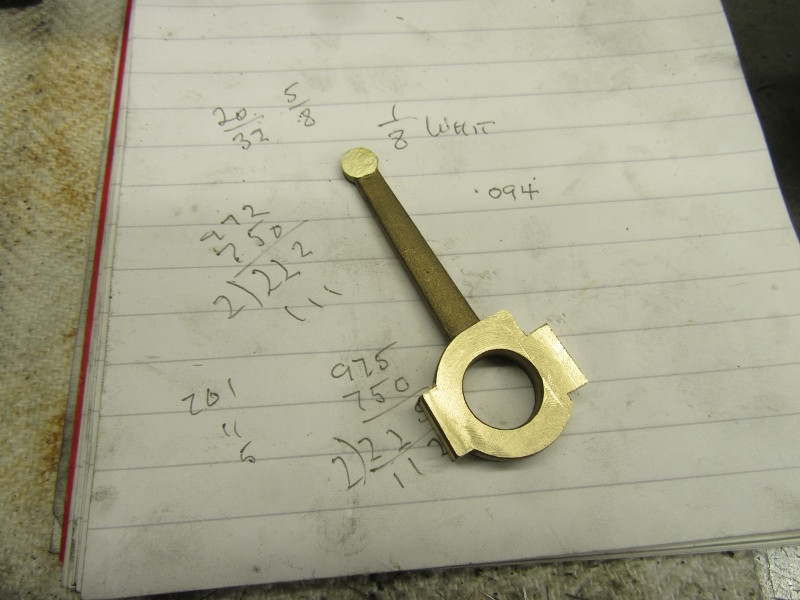

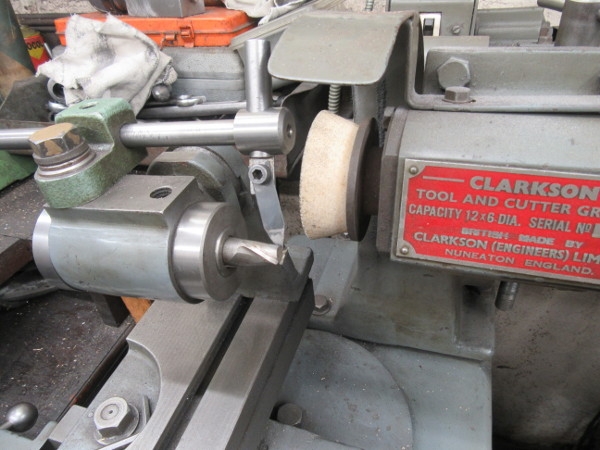

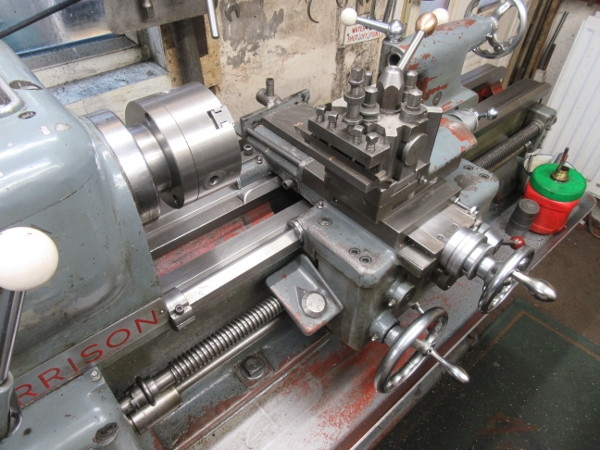

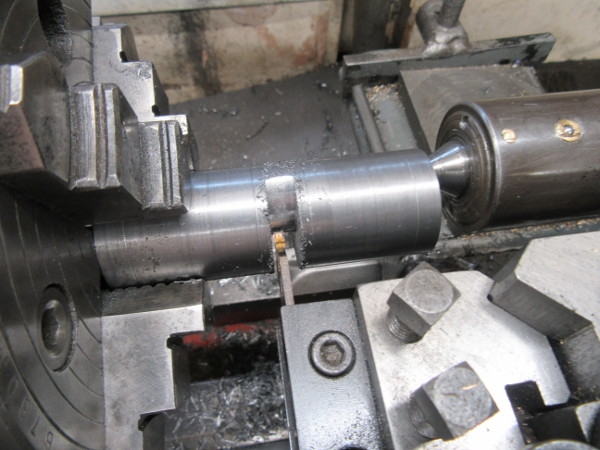

I set up again, this time with an indexed parting tool. This solved the problem and then it was just a matter of quietly cutting away at the stock until I had a 9/32" crank pin.

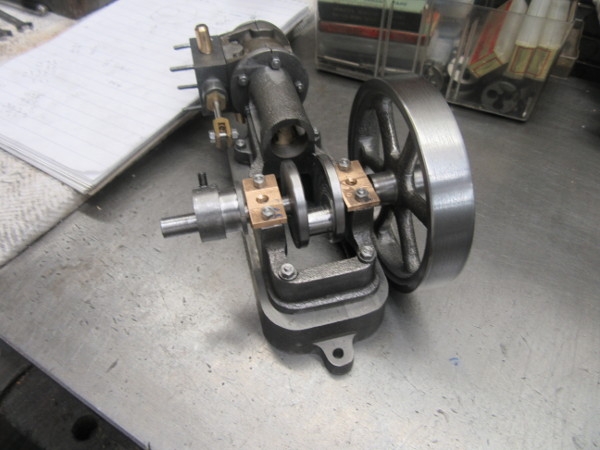

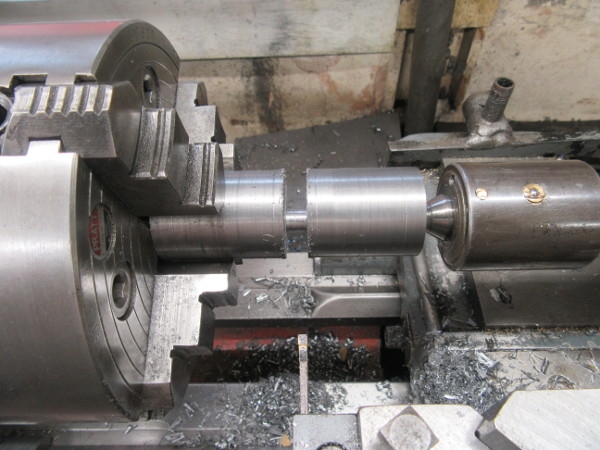

Once I had the pin finished I gave it a polish with fine emery paper.

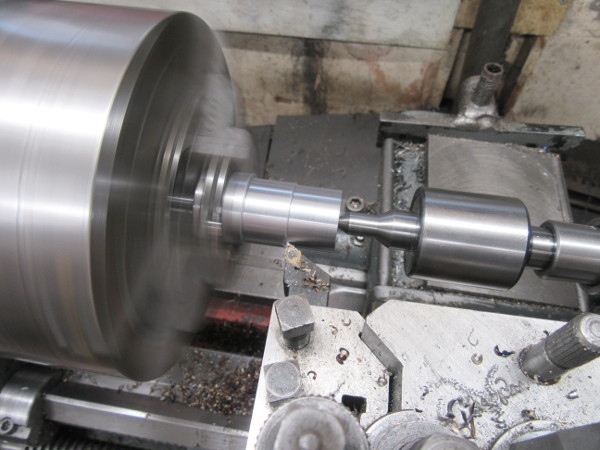

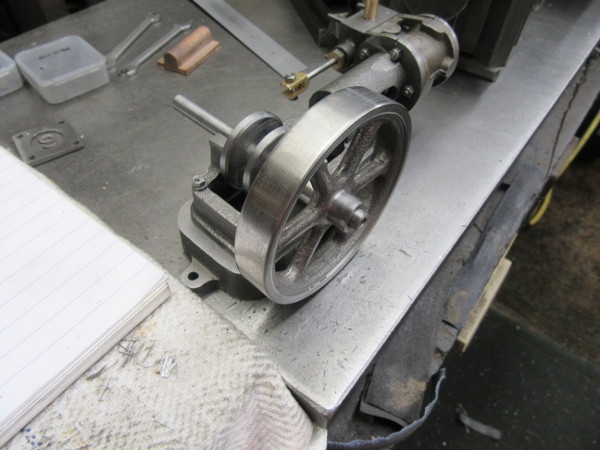

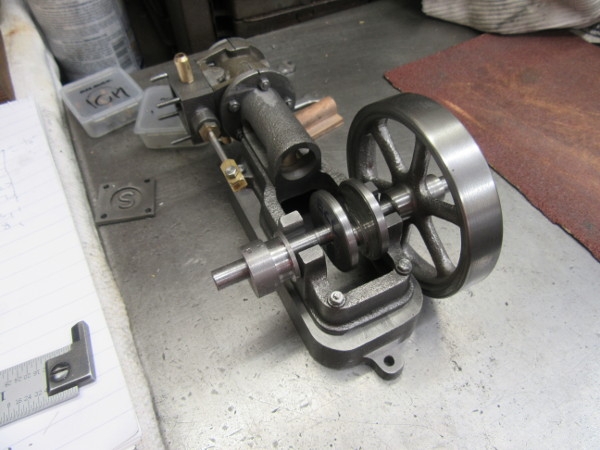

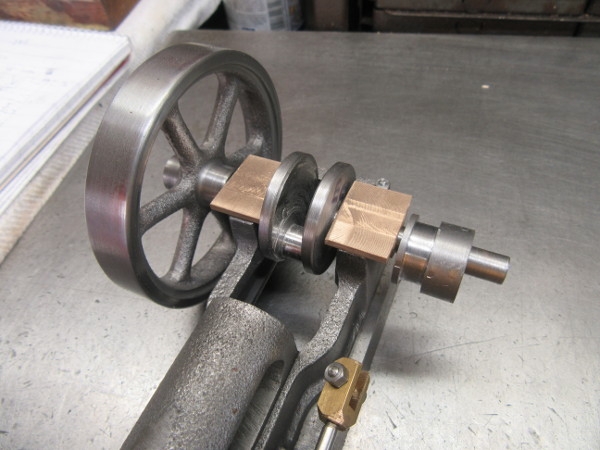

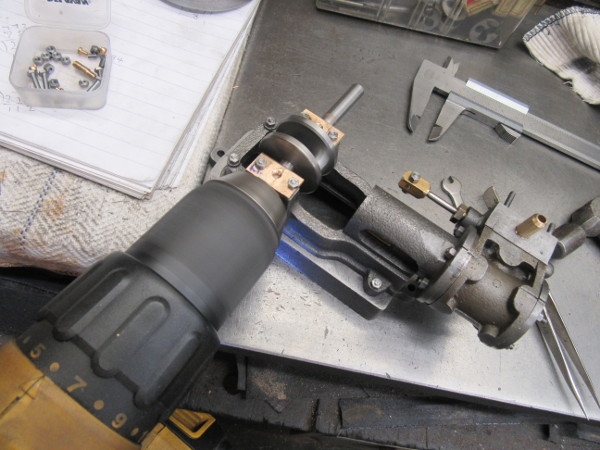

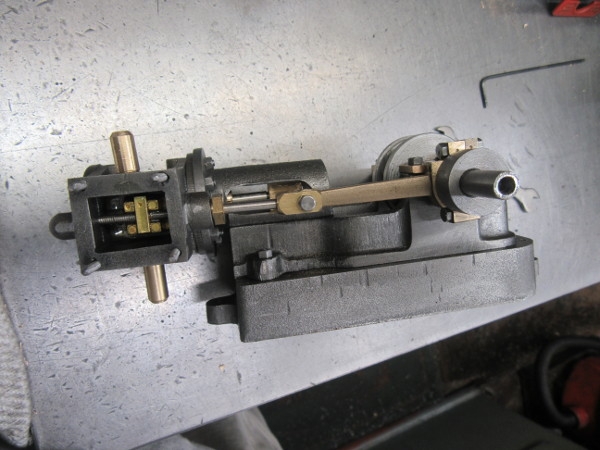

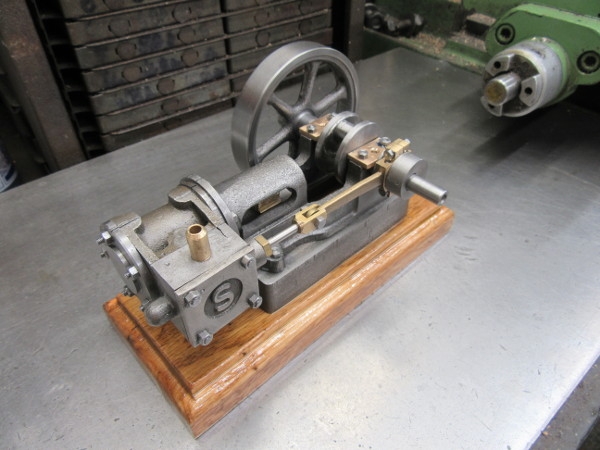

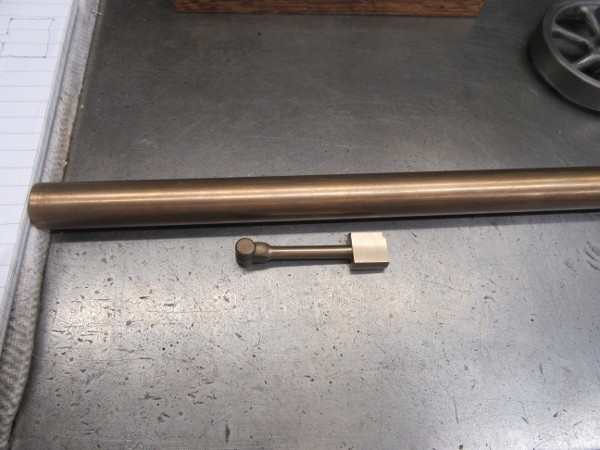

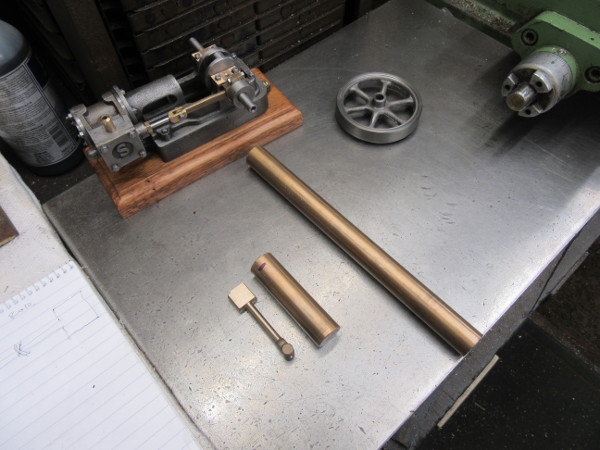

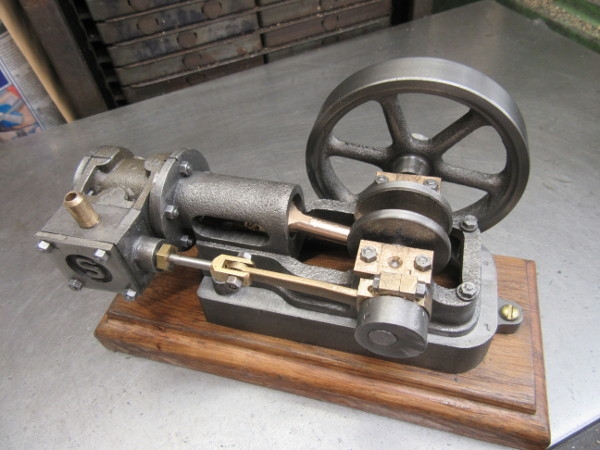

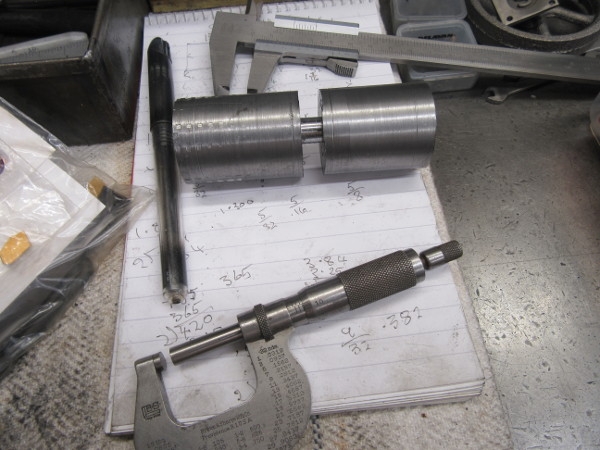

Here we are at knocking off time, we have a crank pin, now to get rid of the excess stock in each end.

All right that was a mistake but it's all a learning curve and I should have stuck to the cutter always use but you have to experiment sometimes.