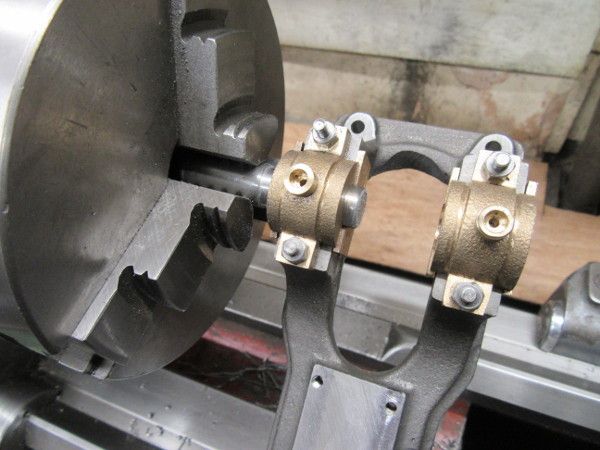

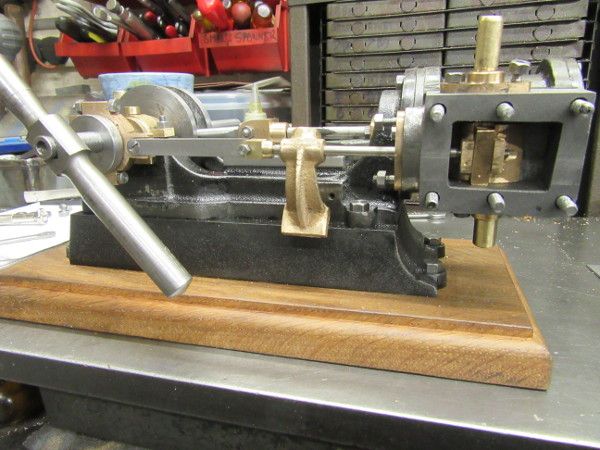

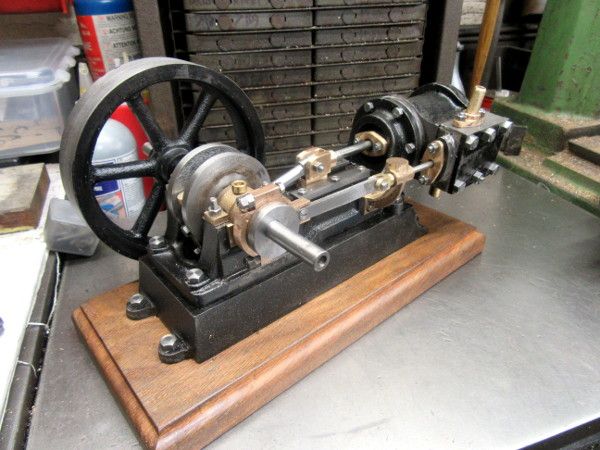

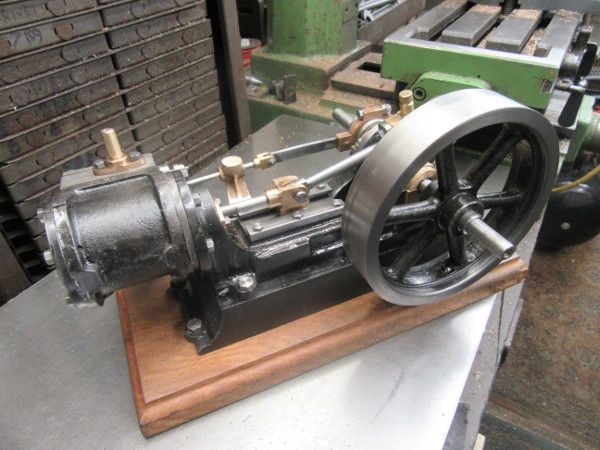

I went in the shed much easier in my mind because I am going to address a matter I have been Ignoring, the fact that I totally cocked up when I re-bored the pedestal bearings after cocking up the first time. This morning as you can see I went to some considerable trouble to get set up to bore for the third time. I have stripped the engine down and in the course of doing that I have made sure that all the studs, nuts and bolts are in good order and fit properly. Then I took a long time setting the bed up under the pillar drill and boring the bearings until I had a clean parallel bore. I then measured to make sure I had got it right. Then a careful measure and a decision on the bore and si9ze of the two sleeves I shall make for the crankshaft so that it is a good fit in the bearings. Last I found a piece of 1/2" steel to make the sleeves and that will be the job tomorrow, some accurate turning and I always enjoy that!