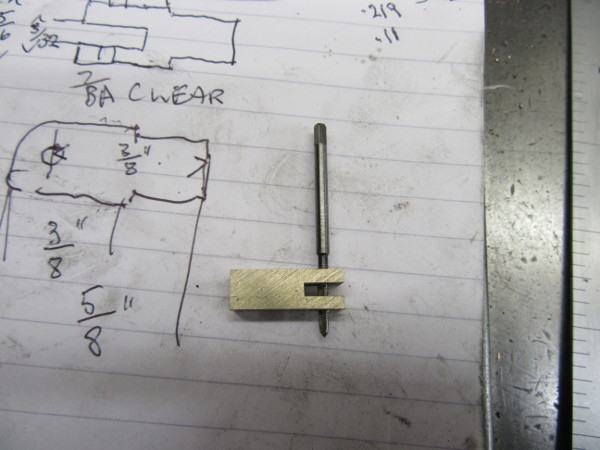

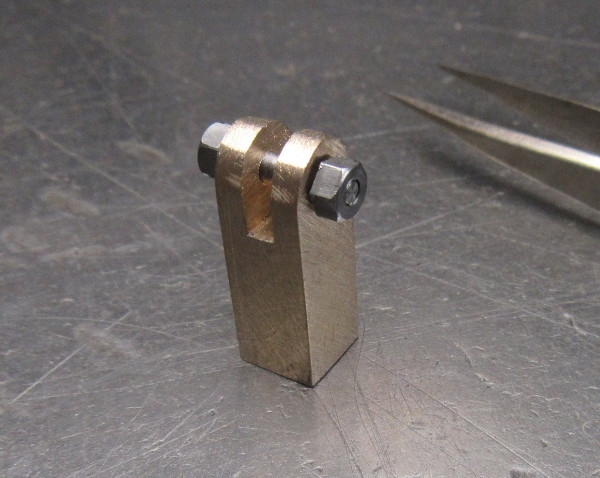

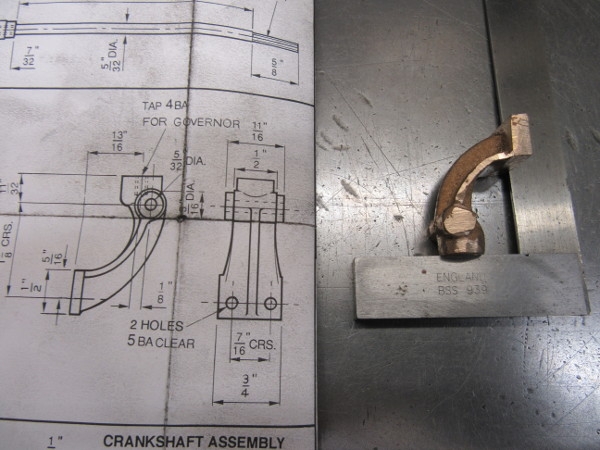

Not the usual start to the day. But at the moment my two pairs of brogues need the cobbler and I can't get there until next week so I am wearing what my dad always called 'laughing side boots', here they are usually called dealers boots. The tabs with which you pull them on are difficult to sort out and this hook will make it dead easy.

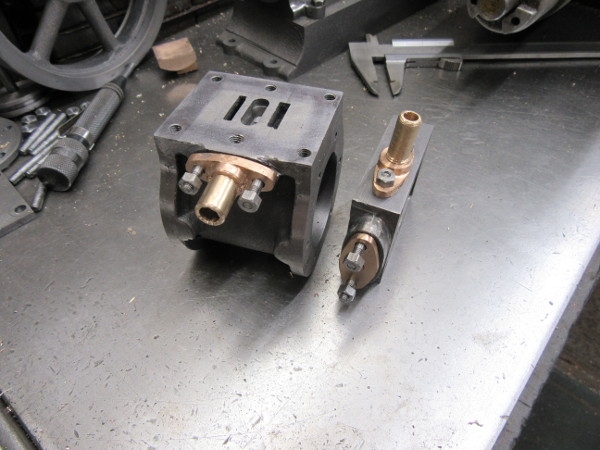

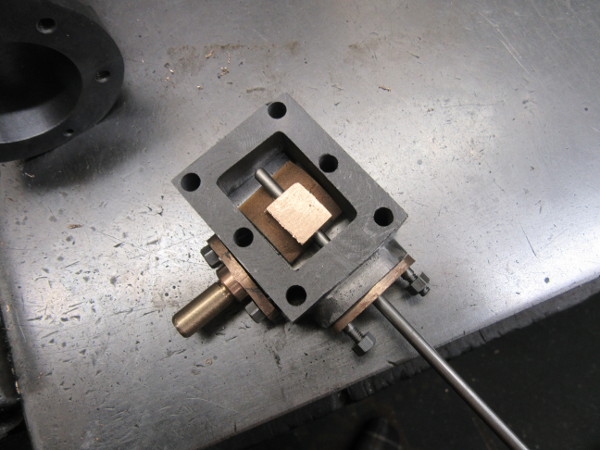

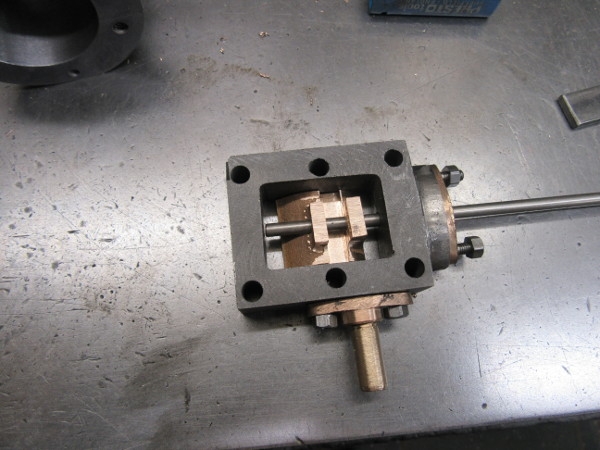

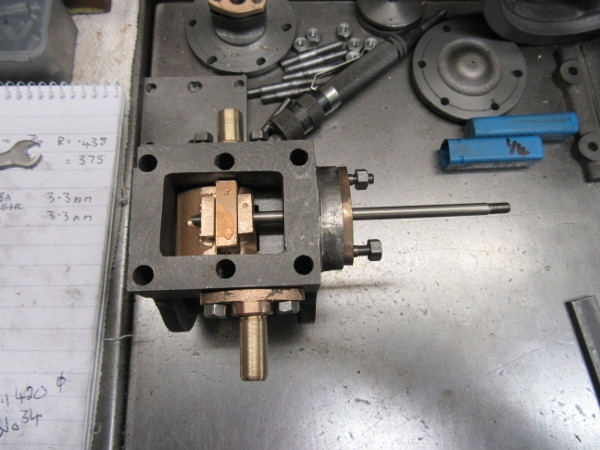

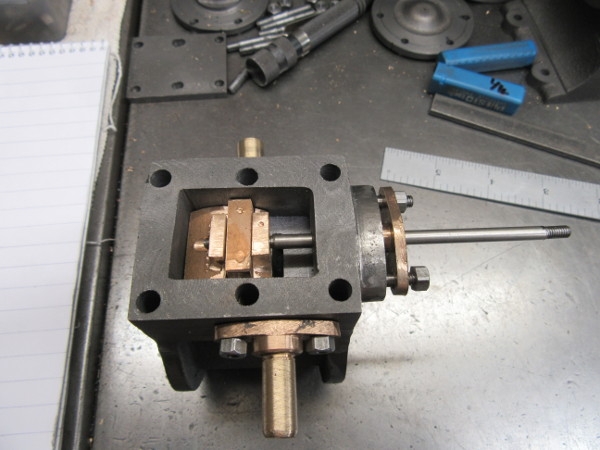

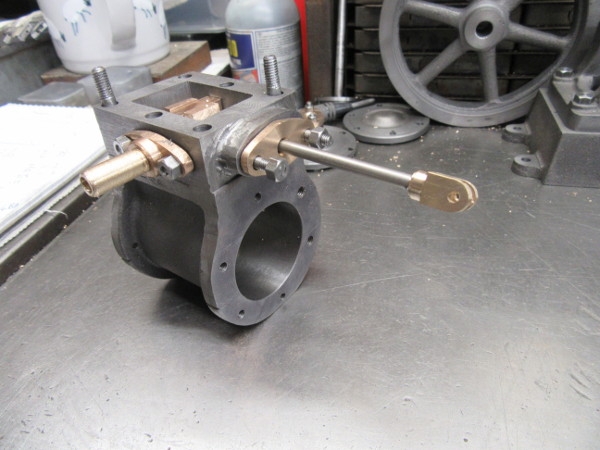

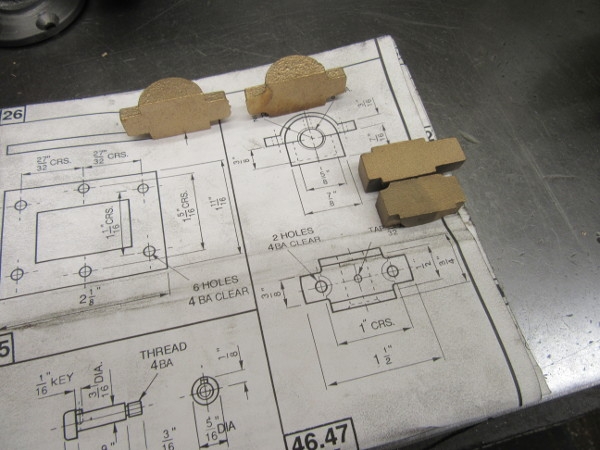

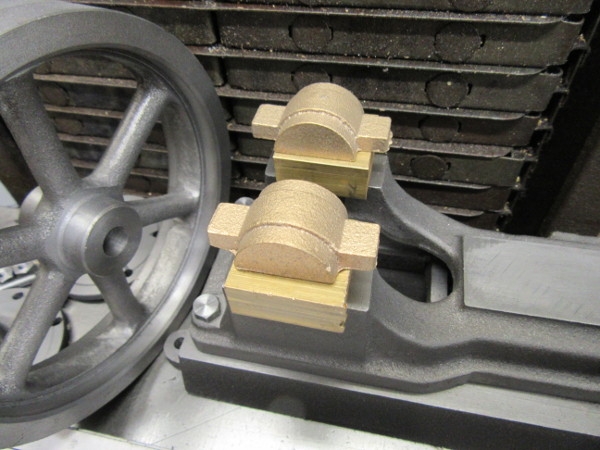

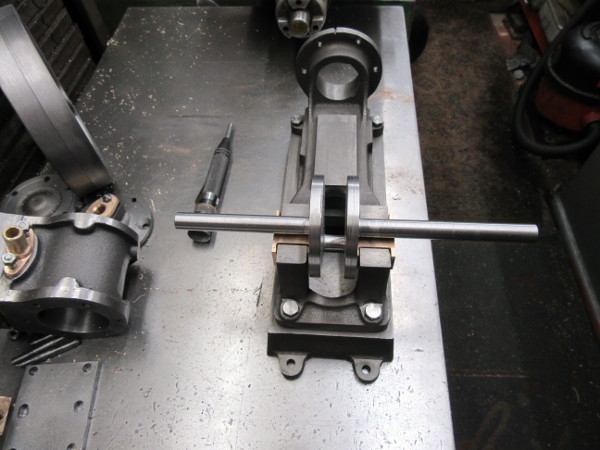

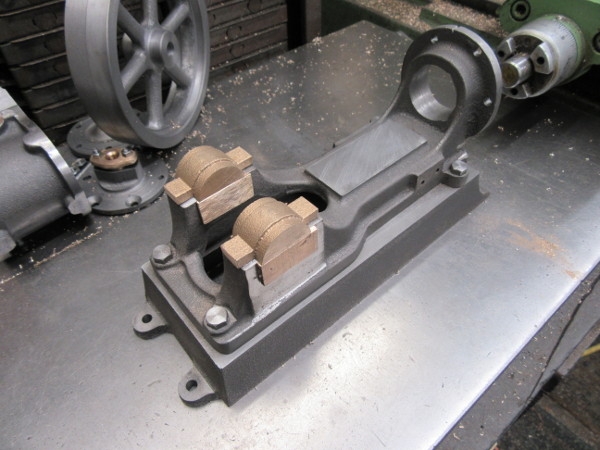

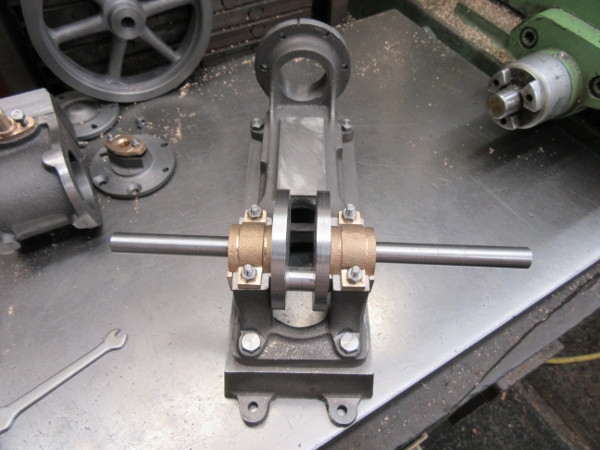

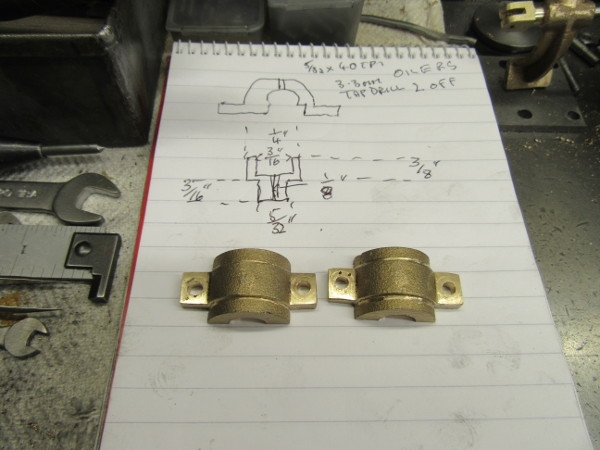

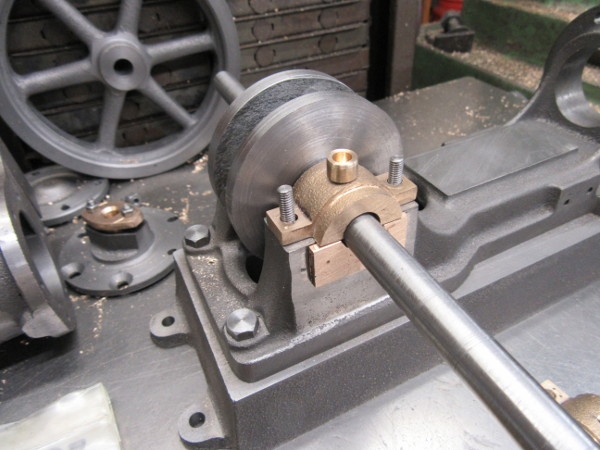

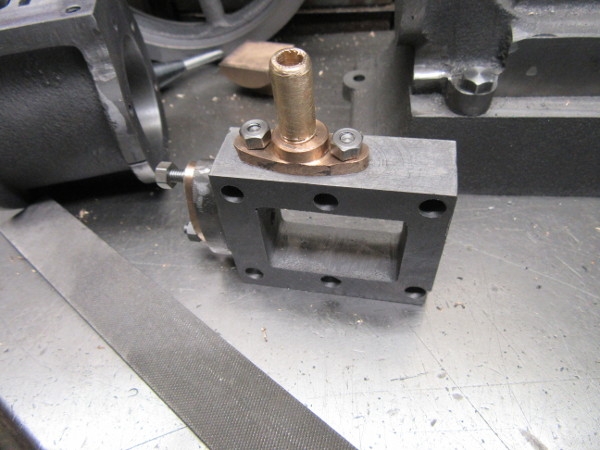

I then went on to making the steam and exhaust pipes and the first job was a shufti in the brass ends boxes To find material for the 5/16" steam pipe and the 3/8" exhaust.

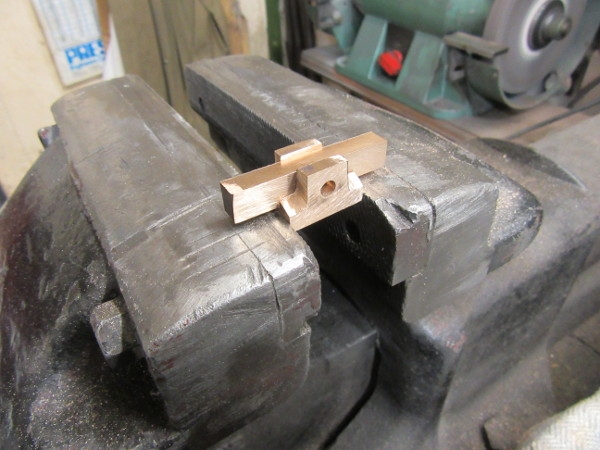

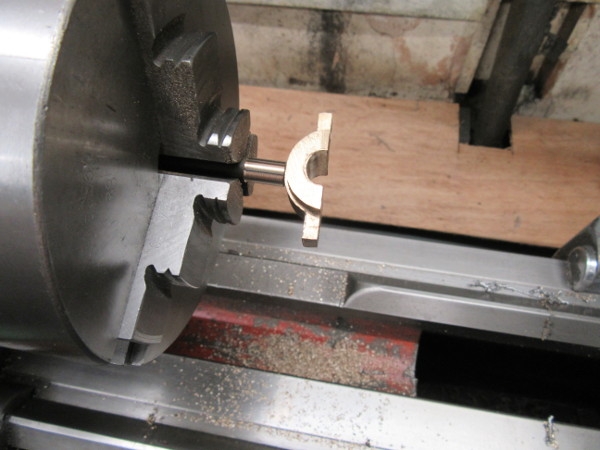

It didn't take long to make the steam pipe and thread it 5/16" X 26tpi.

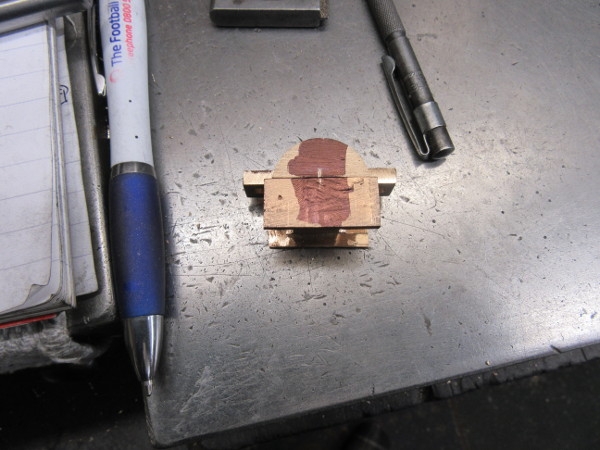

Then I found a piece of scrap brass to make the exhaust out of. Then it was time for early doors shop at the Co-op.

A productive morning but not all engine related! (That's why we have sheds....)