Shed Matters 3

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Easiest way to make it run would be to By-pass the regulator box because that's where the problems start from but I'm content to let it lie and get on with another project like beating cancer!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Sorry lads, activity in the shed is temporarily suspended. I am having another operation tomorrow so I am gatting all my ducks in a row!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

All went well Lads. Bit of recuperation now but I shall be back!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Making good progress lads. It won't be long..... But at the moment I am being careful!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

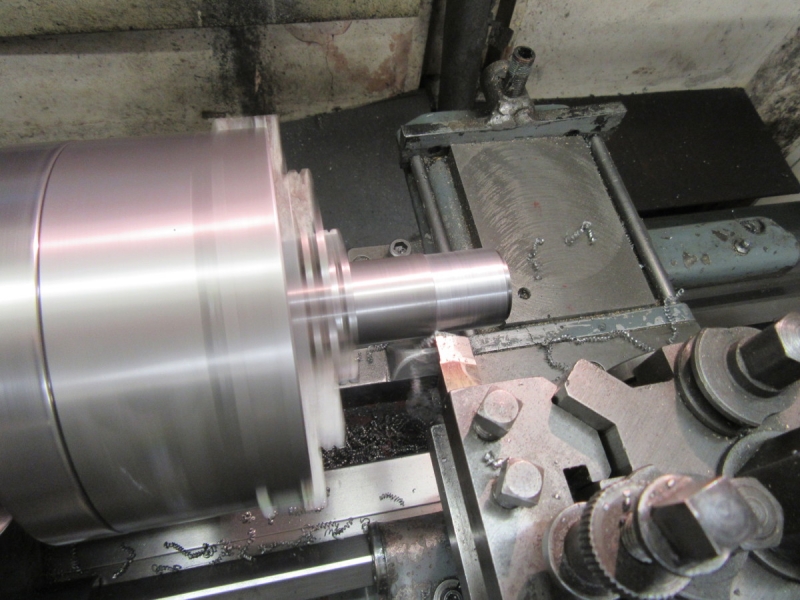

I put a toe back in the water this morning and went in the shed. No set purpose, I just needed a potter to get me back into the groove. My first job was to re-sharpen my favourite cutter. This piece of Cobalt HSS is sharpened with a left hand cutter on one end and a right hand one on the other. Having sharpened it I wanted to make sure that each end was cutting on centre without any adjustment needed, all I have to do is swivel the tool post round. The best way to test this is to cut a face on a piece of steel. So I did this and just had to raise the cutter a touch to get both ends singing to the same hymn sheet. Then I cleaned up my swarf. One good job done!

You won't be surprised to see that my next blow was to touch my milling cutter up after making sure it was backed off and had a good gullet. Then back into the mill.

Not what you'd call tearing trees up but useful checks and it makes sure that whatever I do I know that the lathe and the VM are ready. Sorry it was nothing more exciting, but it's a start after a traumatic interruption!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

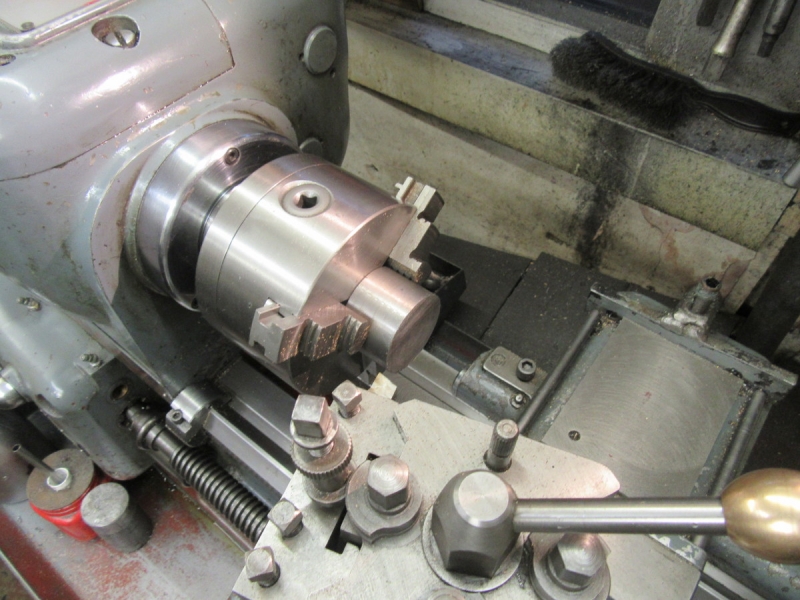

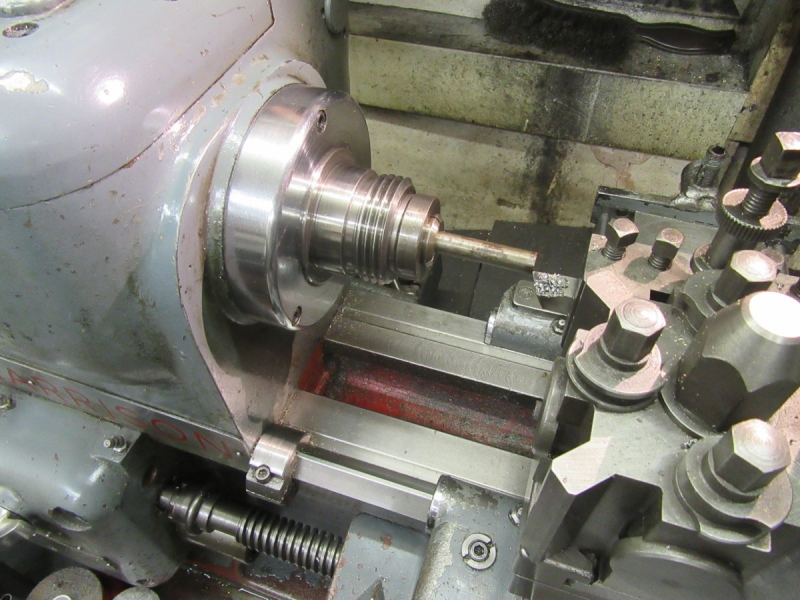

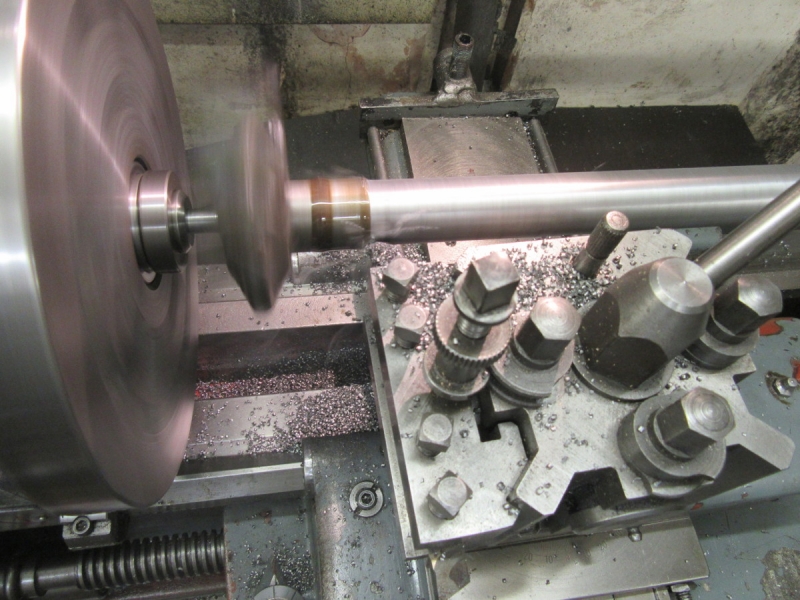

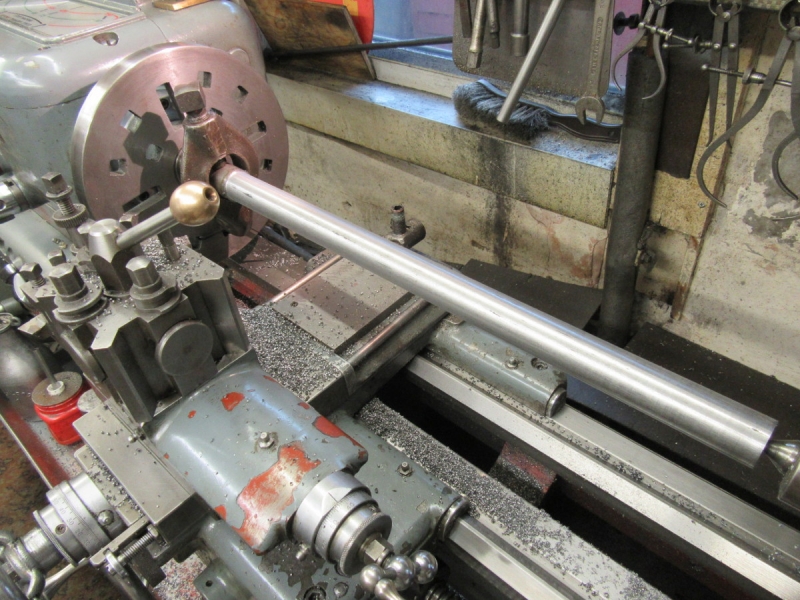

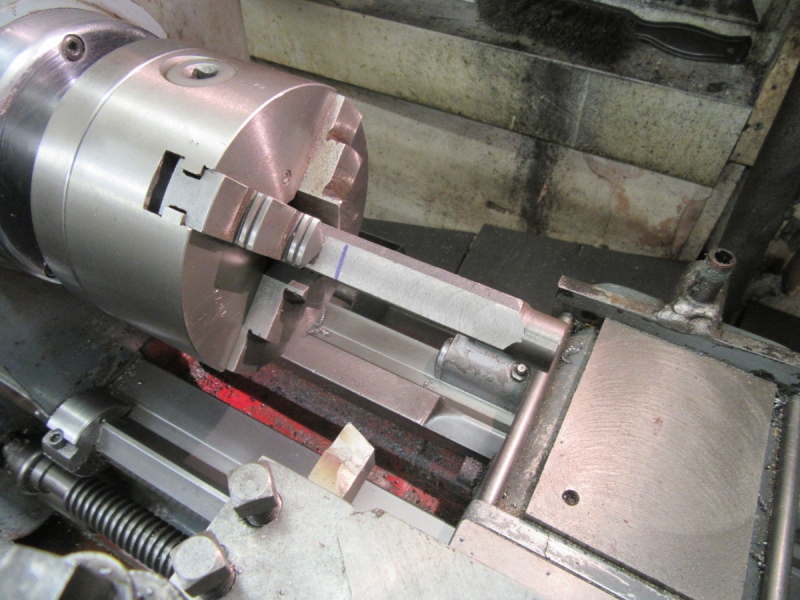

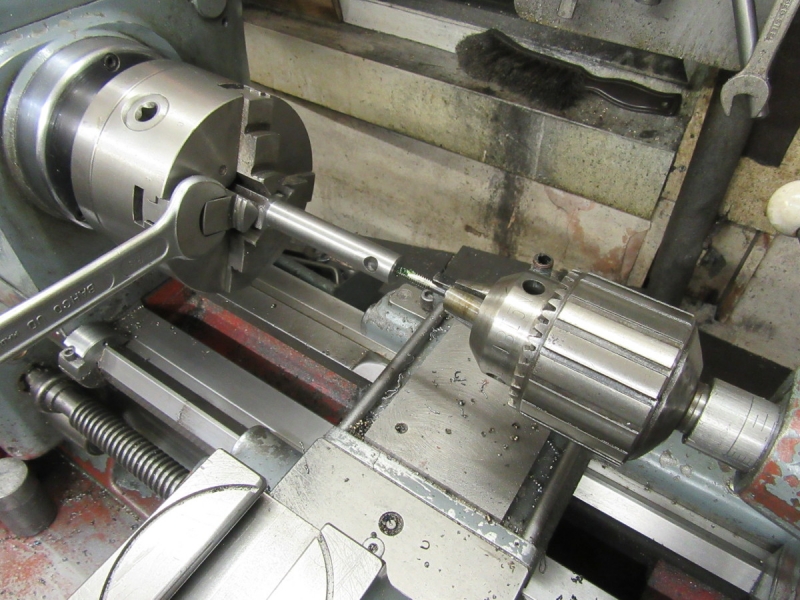

Three hours in the shed today! There's an old Scottish saying, "When a man isn't fishing he should be mending his nets." My version of net mending this morning is to check whether Mrs Harrison is turning true or adding a taper. I was going to test the levels first but decided to cut straight to the chase and turn a test bar. I found a piece of bar 20" long and that's what I wanted, then I noticed it was my old friend, the piece of wrought iron shafting! But that just made it more interesting so I faced it at each end and put a good big centre in. The way to get the most length and a true fix in the lathe is to turn between centres so I needed a dead centre at the chuck end. I got the collet chuck out after I had faced the bar and got set up to have the maximum length. Then I looked for a piece of steel, turned it to a uniform diameter and faced it at each end.

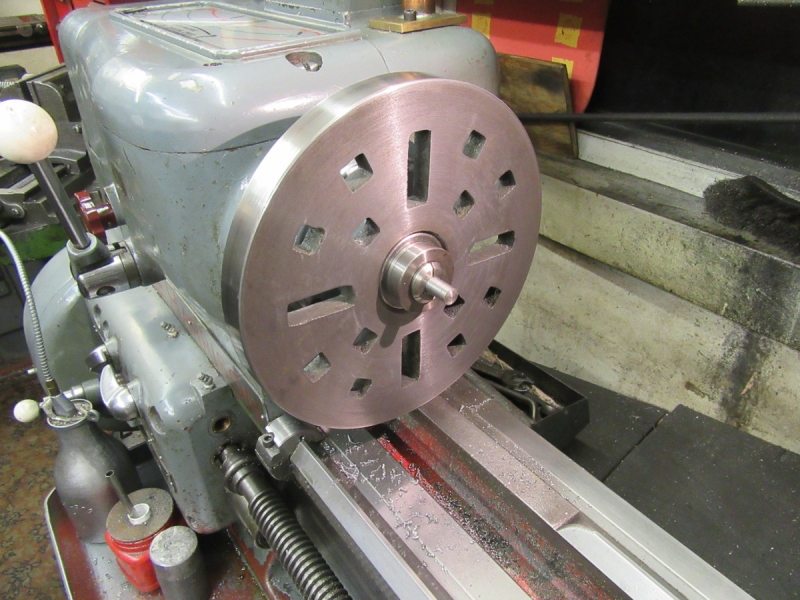

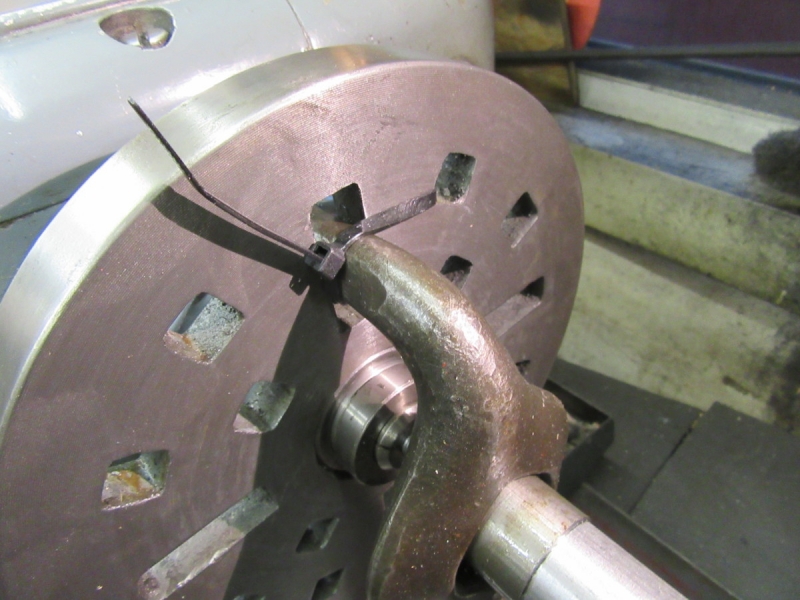

Next job was to set up the catch plate and I got a bit of a shock. I had two catch plates and had used one to make a chuck back a while ago. I got the other one out and found it didn't fit! I don't know how I missed that. No matter, I put the face plate on, first time I have ever used it! Now we need a centre.

I set the cross slide to 30 degrees and put a point on the centre. By the way, no need to make it needle sharp, you only catch your hand on it later!

Here we are set up. The dog fits nicely into a slot in the face plate. I have of course got a nice sharp cutter ready. I set up for a 20thou cut and started only to run into horrendous chatter.

I tried a slower speed and a finer feed and eventually got a reasonable 10thou cut, I wasn't bothered about a fine finish, I could take a light finishing cut to get that.

It was a long cut but eventually I had it done.

I wondered how a ceramic cutter would perform, this one is a very heavy shank and I thought it might be more rigid. It started well but then deteriorated rapidly so I abandoned it.

I used a cable tie to stop the leg of the dog chattering in the slot, it made a big difference.

This is an old cast steel tool that came out of Newton's shed. Entirely different grind and I Have a fancy to try it when I've got a result. But first I honed a bit more radius on my HSS cutter, set a light cut on a slow feed and a slower drive, 117rpm.

Much later after a long cut and some overtime we have a reasonable finish. I miked it and there is just a shade over a thou of taper in 18", that'll do me!

While the cut was going on I got the stone out and made a good job of sharpening the old CS cutter. Tomorrow I'll set it up and see how it performs.

If anyone is wondering why I didn't chase that thou out, I don't want to do it by adjusting the tail stock until I have checked the levels. As it stands it's probably more accurate than most lathes and I am not thinking of doing anything so high precision. Not a bad result and very interesting. I think this old piece of shafting is a very bad piece of wrought iron, it has a lot of slag inclusions. I'll bet I could get a better result on a piece of better steel.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

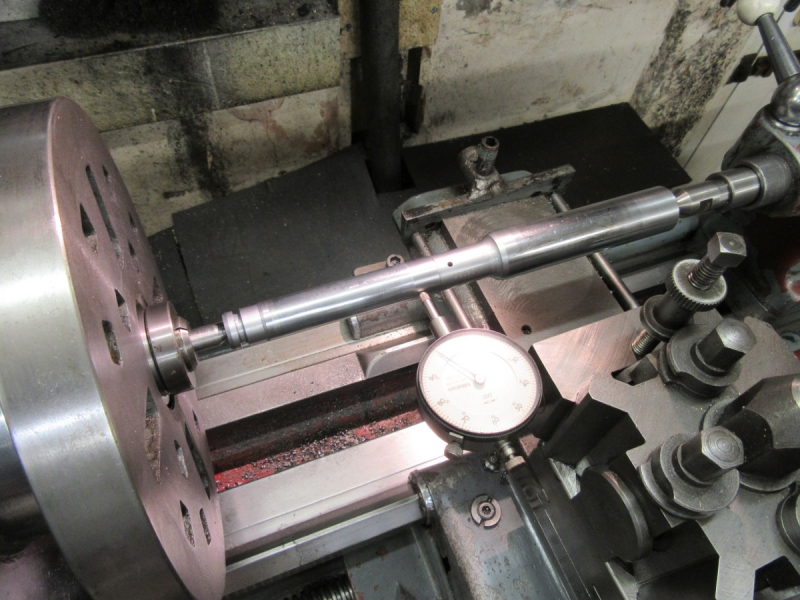

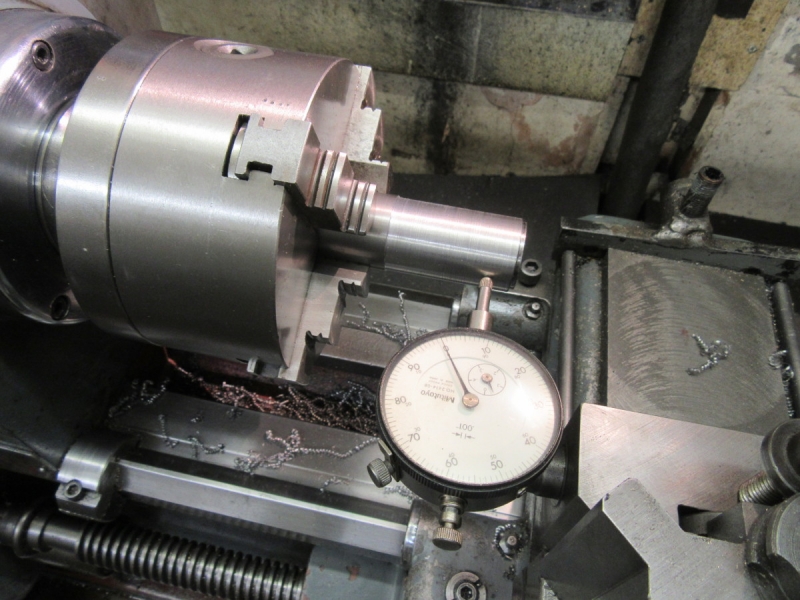

I'm playing out this morning, I want to find out how good the old cast steel tool is at handling the wrought iron and seeing if I can learn anything from it. So, the tool is sharp, I honed it yesterday. All I had to do was make sure it was set dead on centre. (You can see the slag inclusions clearly!)

I put myself in the mind set of a bloke with a treadle lathe who knew there were limits to how fast he could treadle! So, 48rpm and a 5 thou cut. That was OK so here I went for 20 thou and when I had done a suitable amount I moved down to the other end and did the same there then miked both ends. Same result as yesterday, one thou over the full 18" and the same rough finish! (That finish could be where the thou is, it certainly isn't helping!)

Next I popped my test bar in and all I could find over almost 4" was less than a tenth of a thou. That'll do me!

I stripped my collets and the faceplate off and put them away and popped the 4 jaw SC on. I put a slug of scrap in and took a 25 thou cut over it.

I ran the DTI over it and couldn't find anything that can't be put down to the finish. I think my conclusions are that that bar is a lousy piece of wrought iron! The cast steel tool is as good as the HSS within its limits of speed and temperature and Mrs Harrison is quite accurate enough for anything I shall do on it.

I've enjoyed that!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I had occasion to talk about anvils the other day and it reminded me that I have a nice 28lbs anvil that has been neglected for 74 years. Not with me, but that's the date it was made. The aim is not to polish it, just to get the rust off it and oil it up. I used the wire brush on the angle grinder and yes, I had the sense to wear my face shield, those brushes are notorious for shedding bits of high tensile steel wire like needles, not what you want embedded in your eye!

Once it was cleaned off you could read the marks; RH, 28lbs, and the War Office broad arrow and the date 1944, You can also see the difference between the body and the face. This is the best sort of English anvil, it has a steel face. I searched for the maker but wasn't successful. I was reminded that the round hole used either for punching or, like the Hardy hole, used for mounting another tool is the 'pritchel hole'. I also found that the small anvil on top is actually a jeweller's anvil and nothing to do with this anvil! It has a mark as well, a dolphin.

That looks a bit better! I shall stop keeping it under the bench where it gathers dust and rust!

Not a lot done but it's a start. I feel better for that.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: Shed Matters 3

It looks great, you should definitely have it on display.

Kev

Stylish Fashion Icon.

Stylish Fashion Icon.

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I'm tending that way Kev. Thanks for nudging me! I shall cover the base with rubber first!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

With Kev's voice ringing in my head I set about covering the base of the anvil with rubber to make it kind to the surface it goes on.

Not a biggie, here it is sitting on the surface plate while the glue sets and I decide where, in the house, it's going......

Then I cleaned the shields on the fluorescent lights in the kitchen, but that's for another topic.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: Shed Matters 3

Next to the stove in the fireplace, that's where I'd put it anyway

Kev

Stylish Fashion Icon.

Stylish Fashion Icon.

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Good thought, the hardy hole would do nicely for holding the poker!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

The anvil went into the front room this morning Kev....

Then I went for a potter. The first thing I looked at was this.... For many years I used neat cutting oil for continuous lubrication of cuts but I haven't used it for years, I get by with the brush and I am considering getting Noga mist lubrication. The plastic tank has about 20 litres of neat cutting oil in it. It has got to go, the valuable space will soon get used. If any of you have access to a clean plastic 25litre container I'd be pleased to hear from you. I can't shift it until I have something to put the oil in.

In the process of clearing up round the tank this caught my attention. It's what's left of a longer boring bar that I shortened to make it more useful. It's cast steel and it struck me that it would be a handy short and very stiff boring bar that will be useful so I chucked it up.

After a lot of fine cuts and very blue chips I re-honed the cutter and got this finish on the last pass. Tomorrow I'll fit a HSS cutter in it. The cast steel parting tool behind is a candidate for another larger boring bar! I'll give it a bit of thought.

If you're wondering what this is all about, join the club. I am a sucker for abandoned bits of technology and found this at the side of the road earlier this morning. When I had a proper look at it I realised that it wasn't a hexagon socket at all, it is a funny shape inside. It has the number F 501 on it and I am wondering if it is a special socket for taking the anti-theft nut off a car wheel. If it is and it is any good to anyone just shout!

That's it, only an hour in there but I enjoyed it and did a lot of thinking.

Then I went for a potter. The first thing I looked at was this.... For many years I used neat cutting oil for continuous lubrication of cuts but I haven't used it for years, I get by with the brush and I am considering getting Noga mist lubrication. The plastic tank has about 20 litres of neat cutting oil in it. It has got to go, the valuable space will soon get used. If any of you have access to a clean plastic 25litre container I'd be pleased to hear from you. I can't shift it until I have something to put the oil in.

In the process of clearing up round the tank this caught my attention. It's what's left of a longer boring bar that I shortened to make it more useful. It's cast steel and it struck me that it would be a handy short and very stiff boring bar that will be useful so I chucked it up.

After a lot of fine cuts and very blue chips I re-honed the cutter and got this finish on the last pass. Tomorrow I'll fit a HSS cutter in it. The cast steel parting tool behind is a candidate for another larger boring bar! I'll give it a bit of thought.

If you're wondering what this is all about, join the club. I am a sucker for abandoned bits of technology and found this at the side of the road earlier this morning. When I had a proper look at it I realised that it wasn't a hexagon socket at all, it is a funny shape inside. It has the number F 501 on it and I am wondering if it is a special socket for taking the anti-theft nut off a car wheel. If it is and it is any good to anyone just shout!

That's it, only an hour in there but I enjoyed it and did a lot of thinking.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

You have a choice if you're making a boring bar, you can put the cutter in at right angles which is the easiest and means you can have a good bite for your set screw or you can set the cutter at an angle which means you can cut right to the bottom of blind holes. I chose the latter and accepted the fact that my set screw will only have a few threads engaged. So the first job was to decide on the angle and mill a flat from which you can bore the hole.

Then under the drill and cut the hole on low speed and with plenty of oil, this is tough material!

I had to file the hole a touch for the 5/16" cutter which is a very good fit.

Then I got my act together, a 1/4" socket head screw and all the tackle I need to install it.

I threaded it in the lathe and if you are wondering why I used my big Jacobs ball bearing super-chuck, it has the best grip and is dead on centre. I knew that I had to have everything right as this was not going to be easy cutting in the cast steel. Lots of oil and plenty of backing off and I cut it successfully with no problems.

Here's the result, a useful boring bar. I haven't sharpened the cutter yet, I'll do that when I use it. At the same time I'll grind a flat on the cutter so that my set screw has a better hold although it's OK as it is. Socket screws are good material and so is the thread.

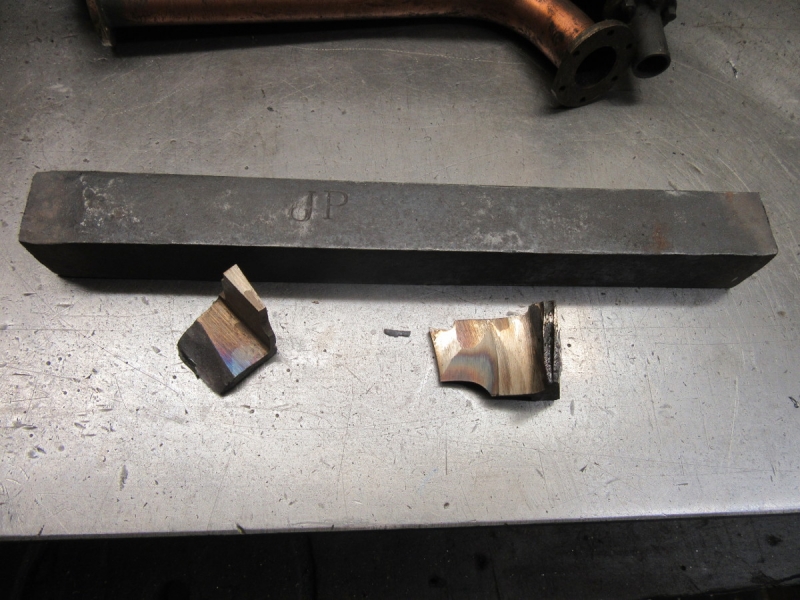

Then I turned my mind to Johnny's old parting tool (Hence the initials on the bar) and thank god for abrasive slitting discs! I tried it in the lathe but it's far too hard to do anything with as it is, it's hardened and tempered. The only cure for this is to wait for a cold day, light the front room stove, get a good clean hot fire going and chuck it in there for the evening leaving it to cool slowly in the ashes. That will normalise it and give me a chance!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I decided there was no point in hanging about, I took the tank down and put it on the bench outside. First I was surprised because there was less oil in it than I thought, 10ltr at the most. I put a cover on the top in case it rains. I shall have to attack the problem of a container later. I want to get on!

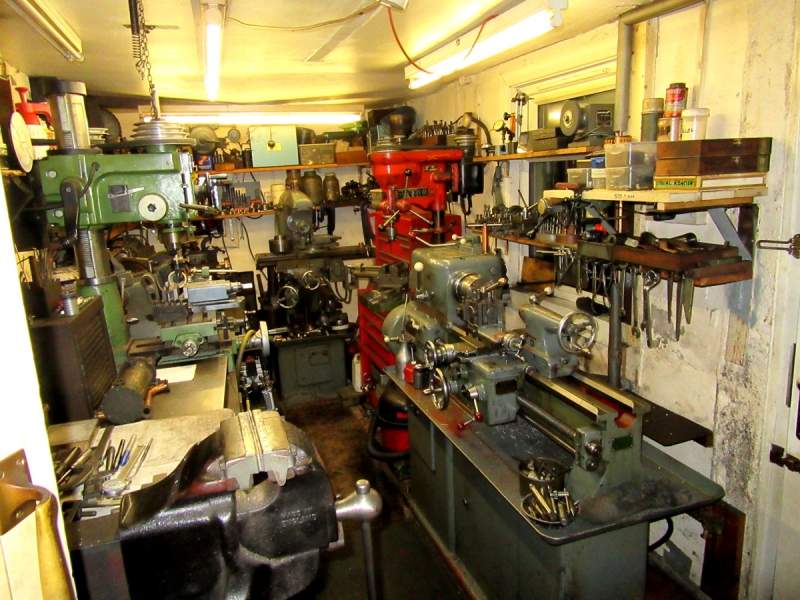

The first thing is that getting the big black tank out made the shed feel twice the size! I screwed two battens on to raise the shelf level a bit higher so I can get at the power point underneath easier. Now I need a shelf 12" X 24". My mate Ian has a lot of wood in his yard and I can have whatever I need so I went for a furtle and found some 4" wide rough board that was exactly the right length to make 3 x 4" pieces that will make my shelf up.

A bit later I had them cut to length and had planed the front one so it looked half way tidy. The shed looks so big! Now I have to decide what will be best on there. At the moment I am thinking anything lathe related..... One thing is certain, it's a big improvement.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

It took a while for the cutting oil to run out, it was down at freezing point but I let it dribble while I did other things inside. The bleach container took nearly all the oil so that worked out well. Meanwhile.....

This was the scene at knocking off time. I have put all the items which are in constant use on the lathe on the shelf and as this meant that I was getting rid of a lot of clutter in other parts of the shelves, especially in front of the window, it means that I have more light, better organisation and also a big bonus, I could get at the window to clean off the oil thrown on it by the chuck. I also vacuumed up all the chips and bits of swarf that have gathered amongst the clutter over the years. I'm really pleased with the change and as I said yesterday, it makes the shed feel twice as big.

On another front, I'm looking at what I want to make next! It is almost certainly another engine.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

The shed is in good order after my reorganisation, it looks and feels bigger now. Question is where do I go next? I am convinced that having a good project on the go is good for me and after my recent brush with cancer and what looks like a good chance of living a bit longer I need to start one.

I'm looking at engine castings and in particular at Camden's offerings. There are some interesting engines on there. I have asked the kids to let me spend some of the Burial Fund. There are no pockets in a shroud......

I'll let you all know when I have made a decision.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

The kids were unanimous in there approval of getting the castings so today will be more research. I think I know what I fancy but want to strike the mean between too small to be enjoyable and not so heavy I can't lift it! I'm favouring Camden I think......

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

No, too many fiddly bits, remember I am partially blind!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Well, I finally got enough articles written to get the paper off my back (5 over the last two days) and I have had a good look at castings. I think I have almost made a decision and it's an engine! However, the price of the castings is shocking so I have decided to hang fire for a while and do some saving up. But, I wanted to get back in the shed....

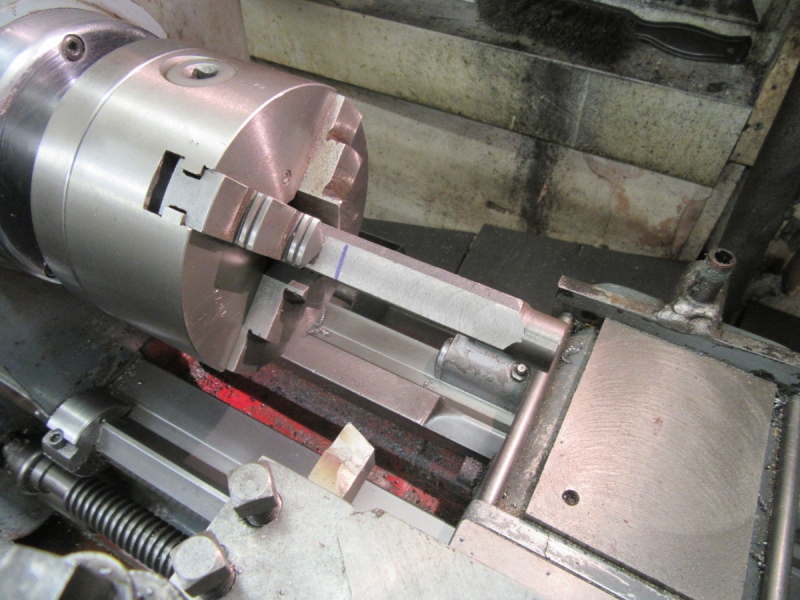

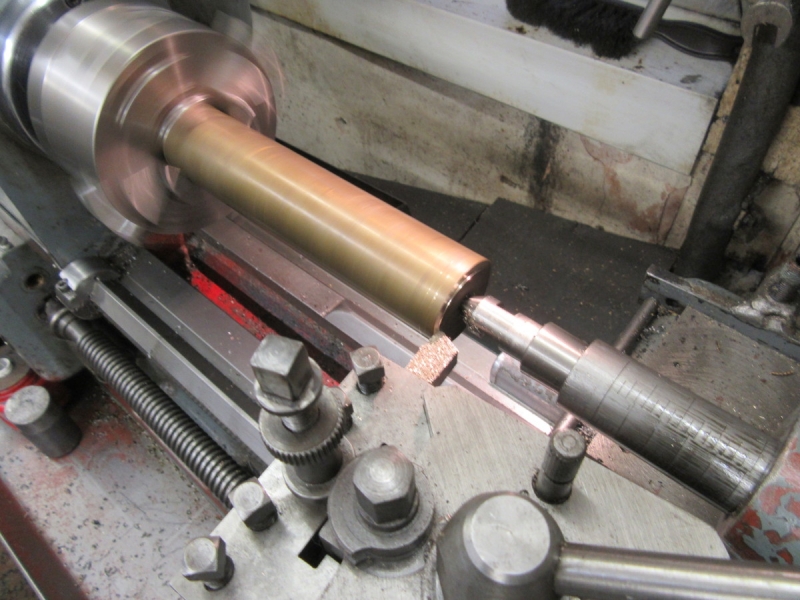

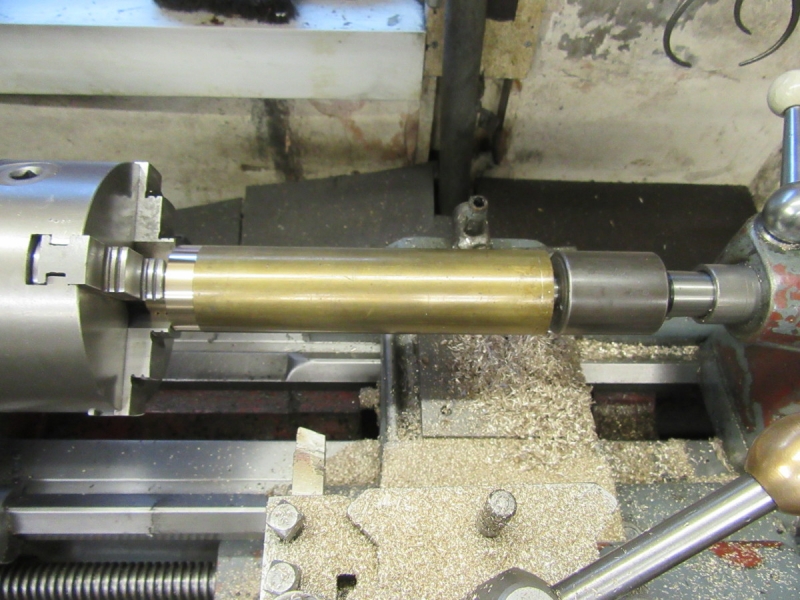

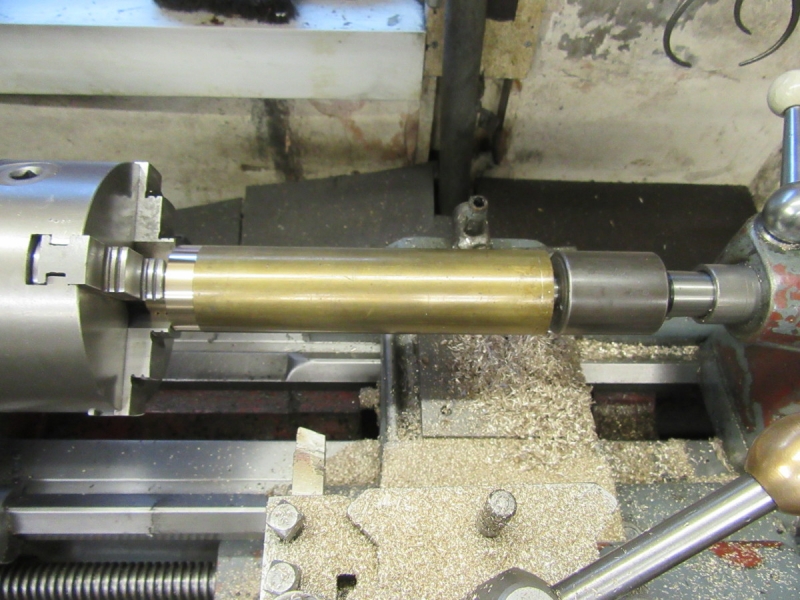

I really enjoyed making the Carronade so I decided to make a bow chaser cannon. These were a lot longer and were mounted in the bow of a boat so that during a long chase they had enough range to reach the enemy and hopefully disable them by damaging the masts and rigging, often using chain shot which was two balls held by a short length of chain so that it acted like a flail. It will be cheap because I have all the materials I need in stock. I could have made it out of steel but I happened to have a 40cm bar of 40mm brass. (I looked it up and this would cost the thick end of £200, I am a man of wealth!)

So I made a few decisions and set some measurements.

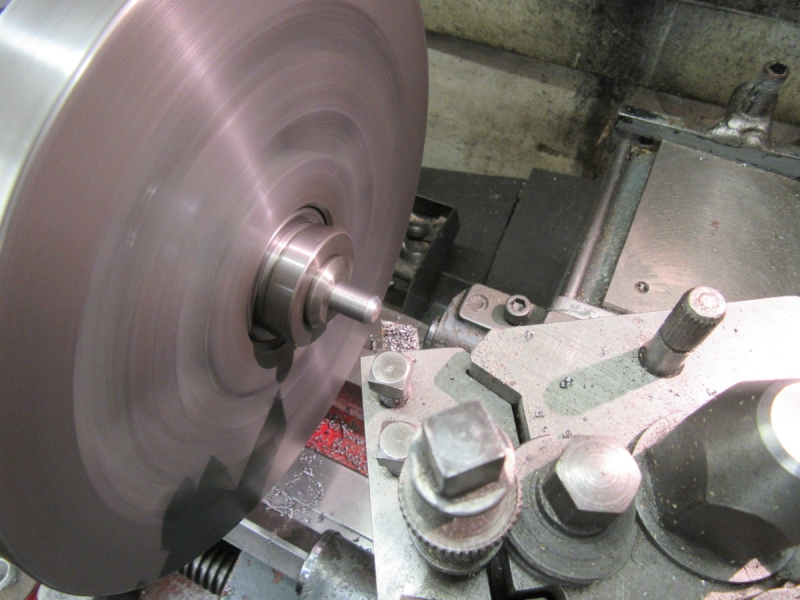

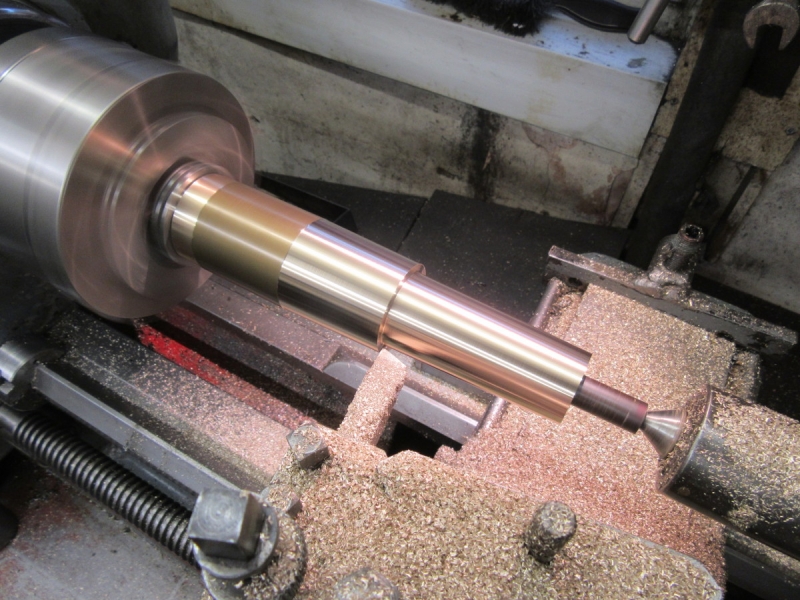

I think you might have guessed where I went next! Thanks Lads..... Mrs Harrison whistled through the bar in no time.

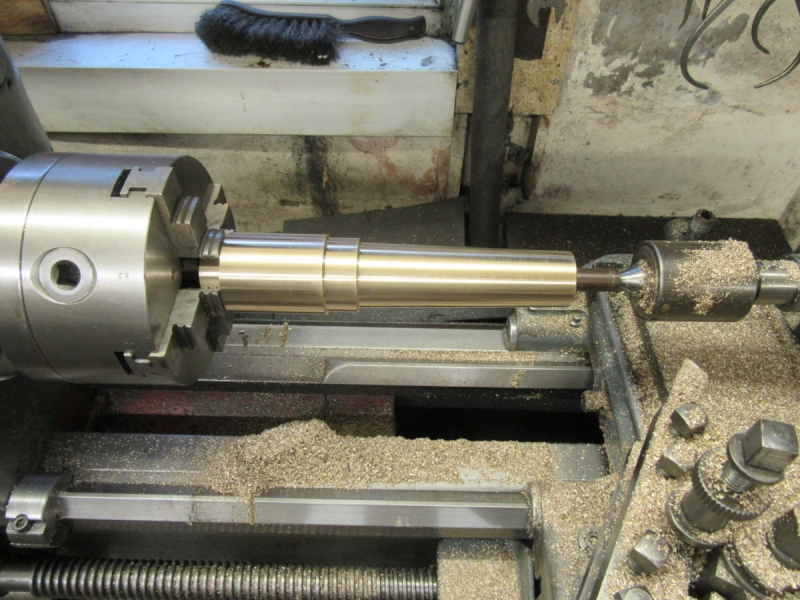

First job was to centre the bar and face the end.

I faced and centred the other end and addressed doing the bore because this is the best time to do it. I decided on 1/2" bore and of course needed a long series drill. A bit of a dig in the treasures and a sharpen and I was ready. Amazing how long a drill you need.....

I started the bore with a small drill and then a normal 1/2" jobber then set up the long drill. Good job I have a bed long enough!

Not long afterwards I had my bore.

I used a countersink to convert the end of the bore to a large centre.

Here we are at closing time, ready to start shaping the exterior......

I really enjoyed making the Carronade so I decided to make a bow chaser cannon. These were a lot longer and were mounted in the bow of a boat so that during a long chase they had enough range to reach the enemy and hopefully disable them by damaging the masts and rigging, often using chain shot which was two balls held by a short length of chain so that it acted like a flail. It will be cheap because I have all the materials I need in stock. I could have made it out of steel but I happened to have a 40cm bar of 40mm brass. (I looked it up and this would cost the thick end of £200, I am a man of wealth!)

So I made a few decisions and set some measurements.

I think you might have guessed where I went next! Thanks Lads..... Mrs Harrison whistled through the bar in no time.

First job was to centre the bar and face the end.

I faced and centred the other end and addressed doing the bore because this is the best time to do it. I decided on 1/2" bore and of course needed a long series drill. A bit of a dig in the treasures and a sharpen and I was ready. Amazing how long a drill you need.....

I started the bore with a small drill and then a normal 1/2" jobber then set up the long drill. Good job I have a bed long enough!

Not long afterwards I had my bore.

I used a countersink to convert the end of the bore to a large centre.

Here we are at closing time, ready to start shaping the exterior......

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

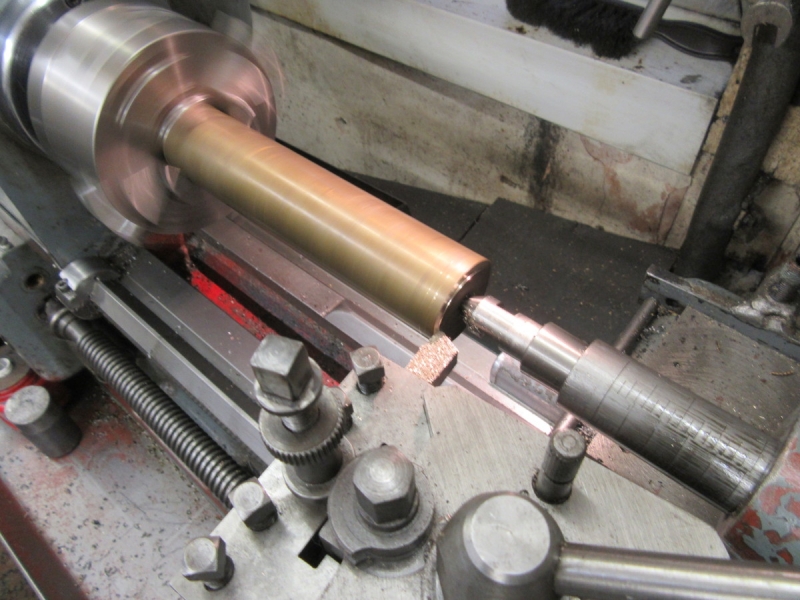

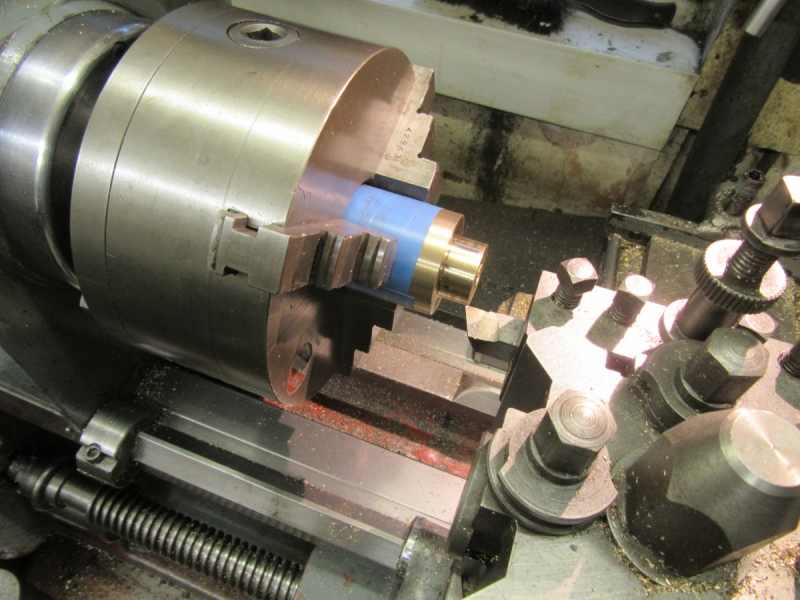

I had decided that I needed to extend the centre so as to make the turning easier. I found this piece of 1/2" steel which was a perfect fit, so perfect it was hard to push it into the bore because of air pressure! Now I want a centre in it.

I forgot to take a pic here.... I have always said you can't have too many chucks and this was a good example. No self centring chuck is repeatable, if you take the work out it is on a slightly different centre. I needed to saw the end of the bar, face it and put an accurate centre in it. So I screwed the chuck off complete with the stock and popped a three jaw on. Easy to face it and pop a centre in.

Here we are. The stock back on the lathe with the centre in. It doesn't need to be fixed of course because it only has to act as a centre, not holding anything.

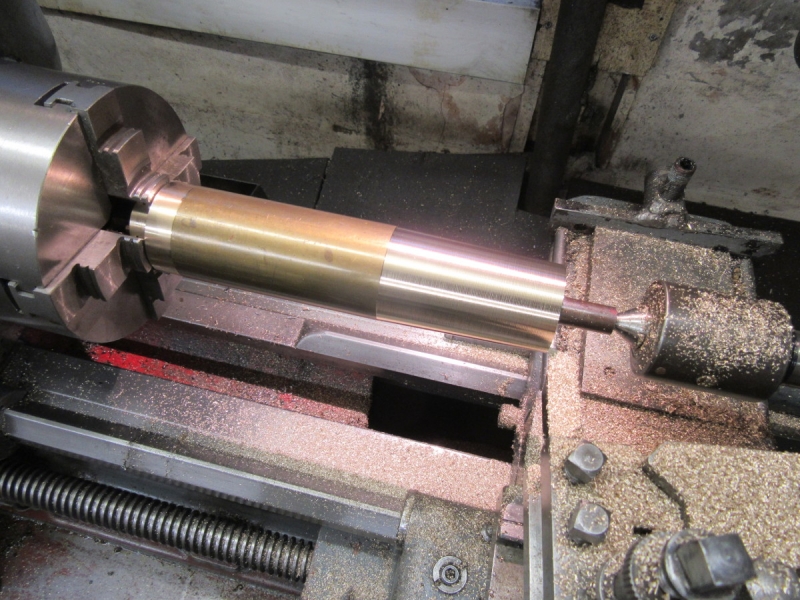

I took a guess and offset the top slide one and a half degrees and it turned out to be about right. You can get Machinery's Handbook out and work out the value mathematically if you are a perfectionist. This will do for me..... Here we are after a couple of light cuts, looks OK.

I didn't have enough travel to do the full taper I wanted so I moved the carriage forward to have another bite at it. The tapers will match of course because the angle hasn't changed. Then I decided where I wanted to install the trunnions and marked where the taper had to go to.

Here we are at closing time. I have broken the edges of the transitions with a chamfer and I will take a decision tomorrow about modifying the muzzle to make it a bit more interesting. At the moment it looks quite plain and modern. I shall think about it......

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Only got an hour in the shed, I had a young woman to distract me..... First a bit of detail on the muzzle.

Then a change of chuck, I needed a bigger bore. A bit of work on the other end....

And here we are at knocking off time.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!