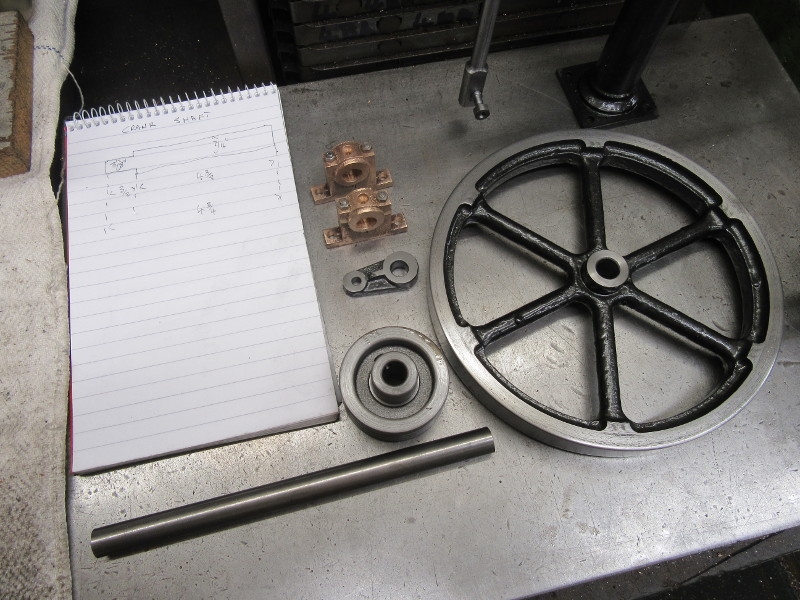

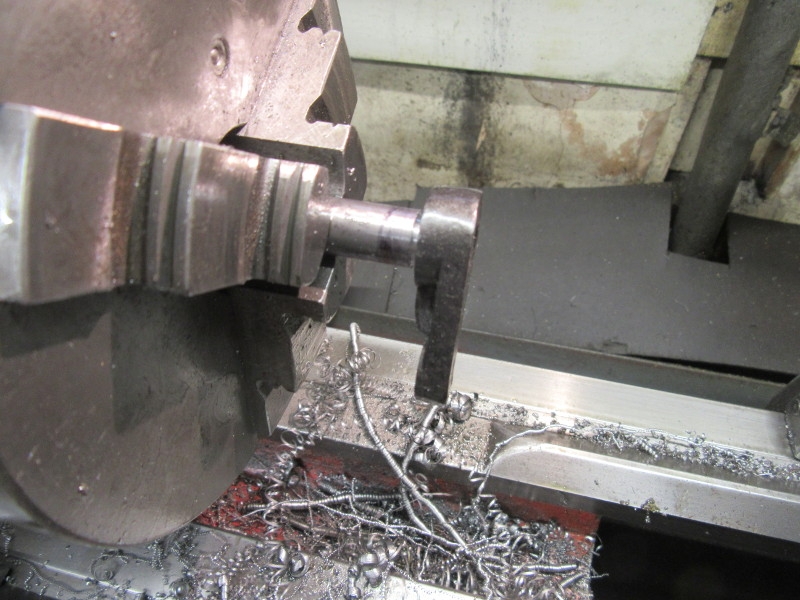

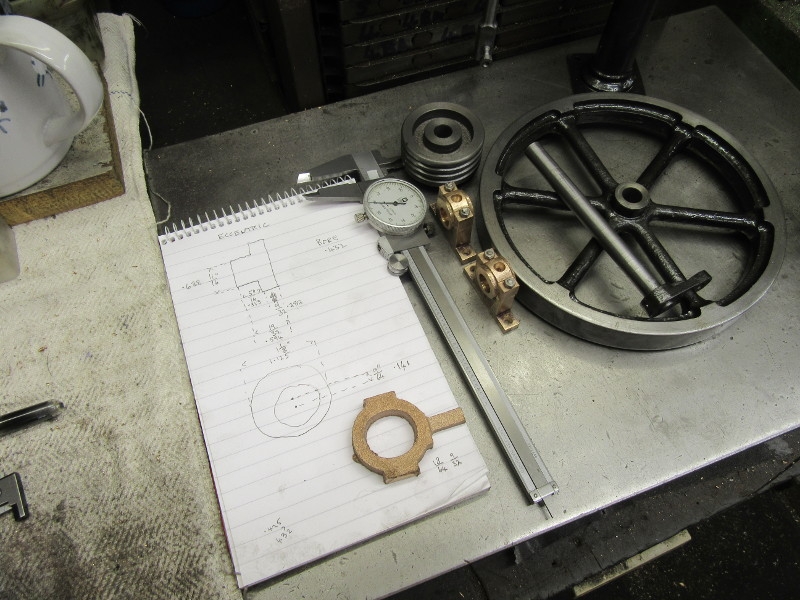

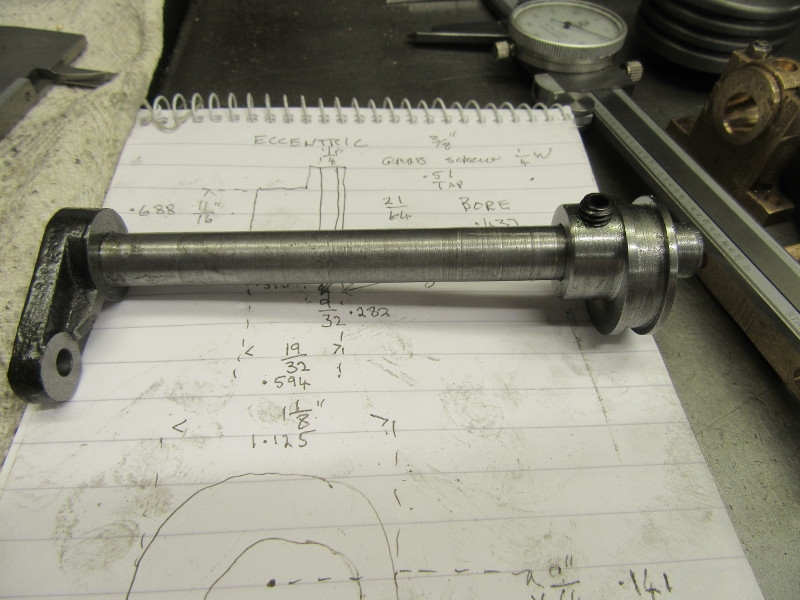

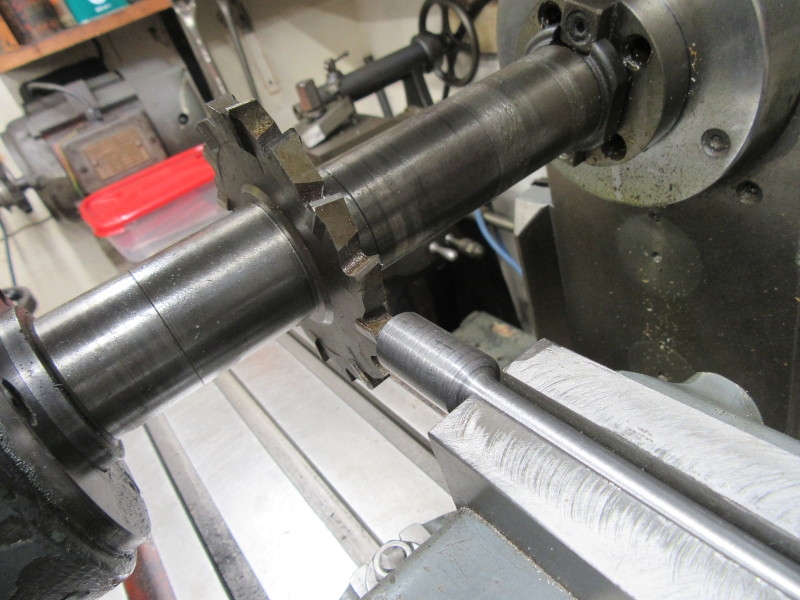

I took the con rod out of the lathe, cleaned it up and cleaned the lathe as well. Today's task is to cut the slot in the larger end that fits over the end of the beam. Nowt to it.....

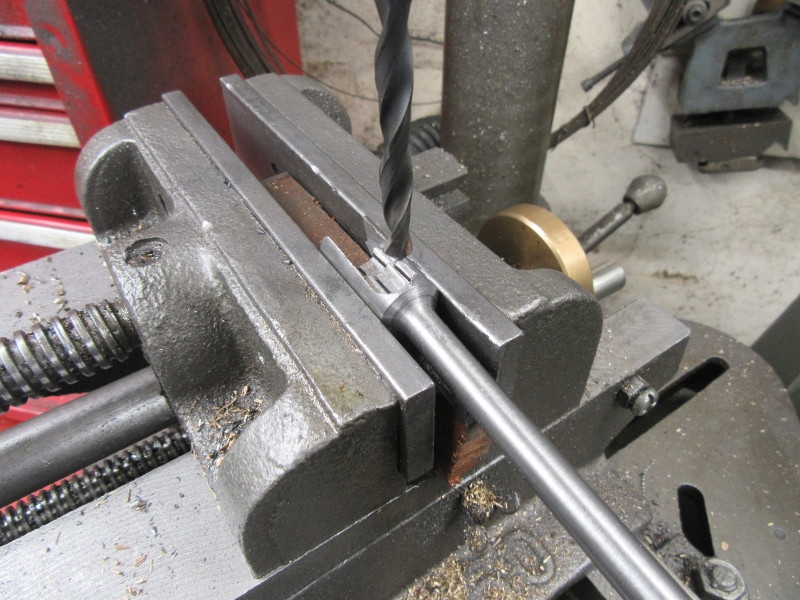

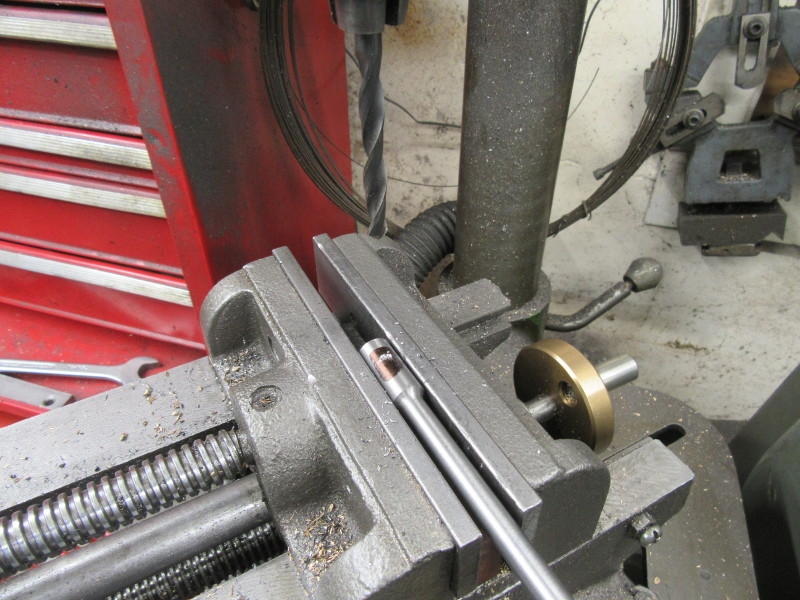

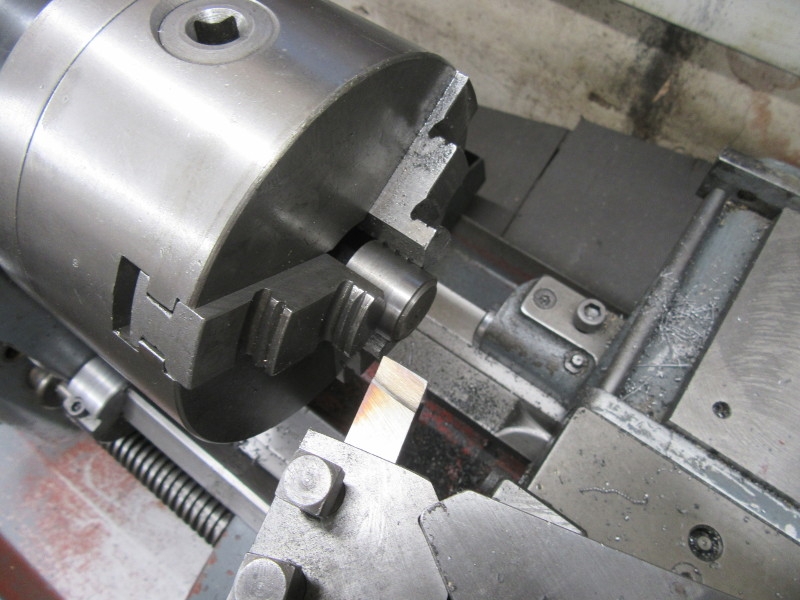

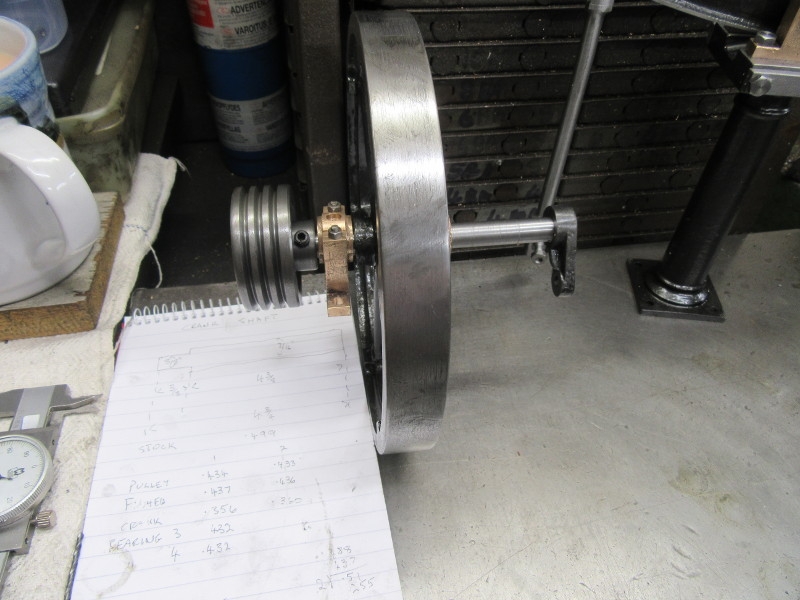

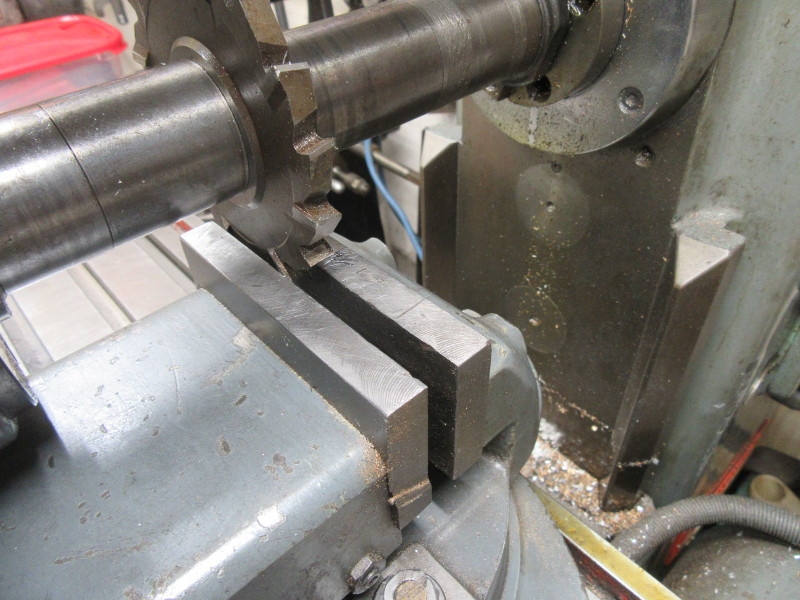

I decided to cut it with a 3/8" cutter on the horizontal mill. So first job was to get the vice mounted on the mill and make sure it was dead in line with the cutter. Lots of ways to do this but the simplest is to tighten the jaws on the cutter before you tighten down the nuts that hold it on the bed.

All set up and ready to go!

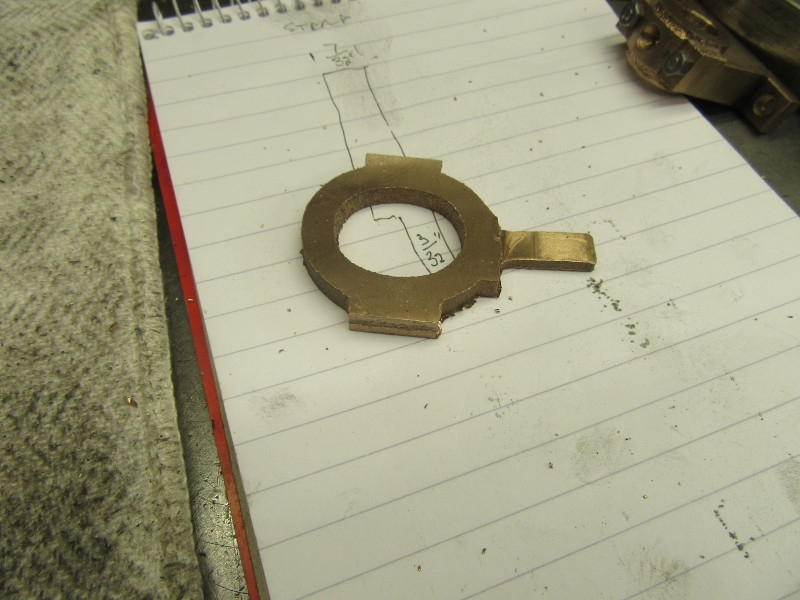

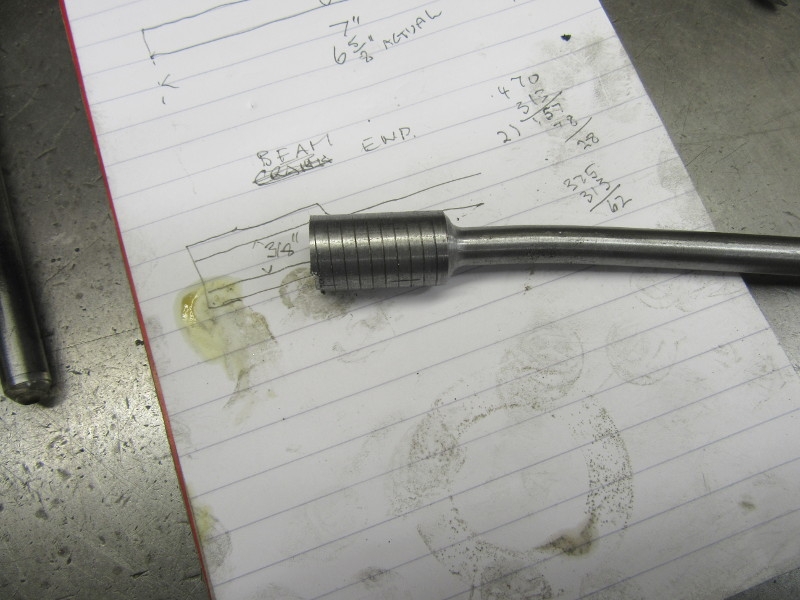

This was the result, I bent the rod. Nice. Deep Joy.

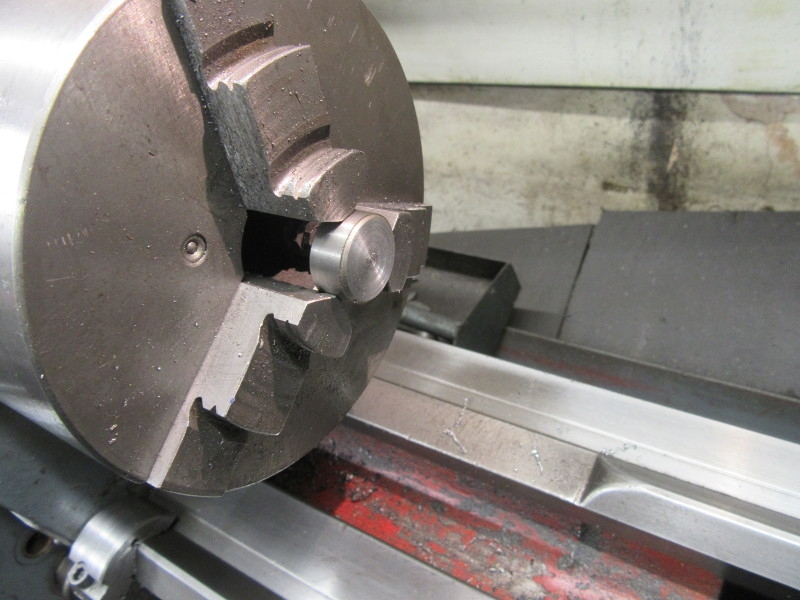

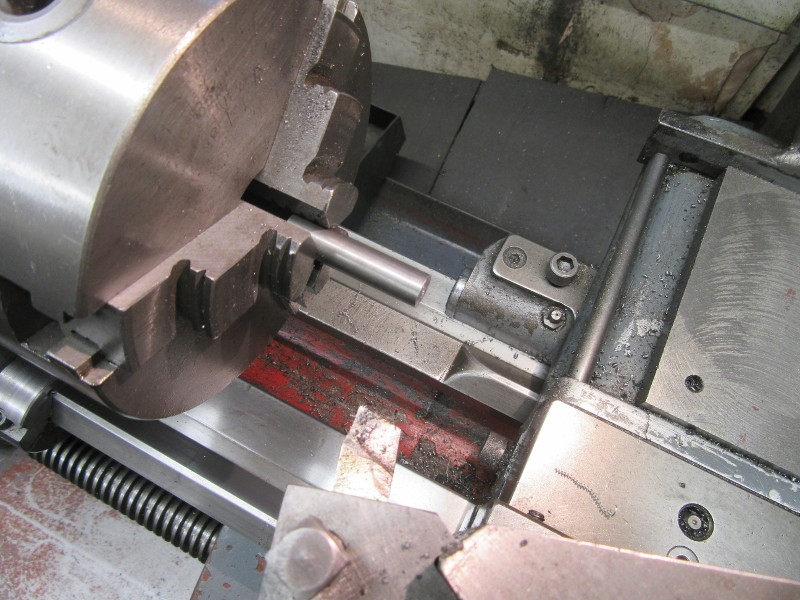

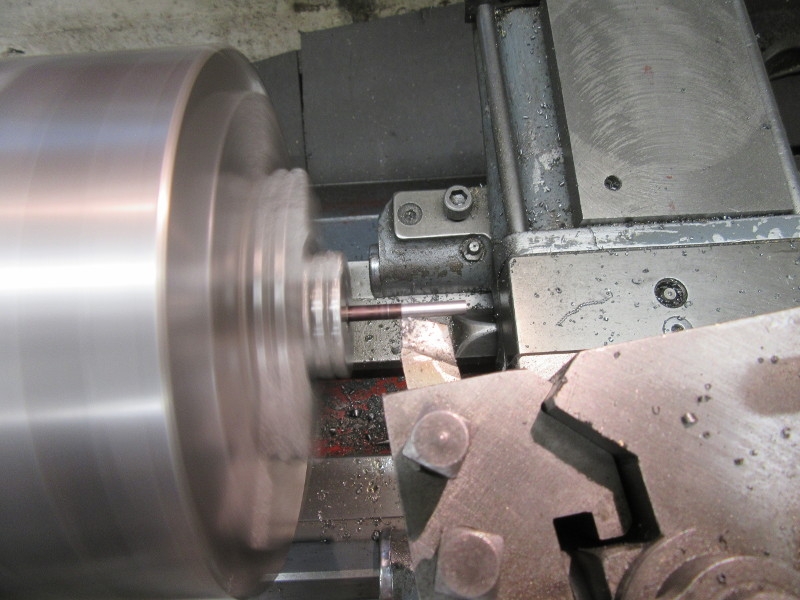

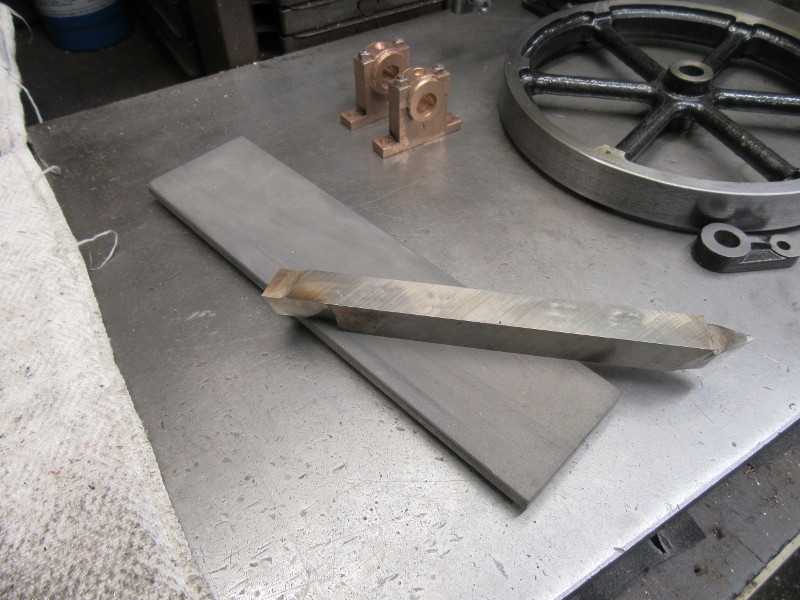

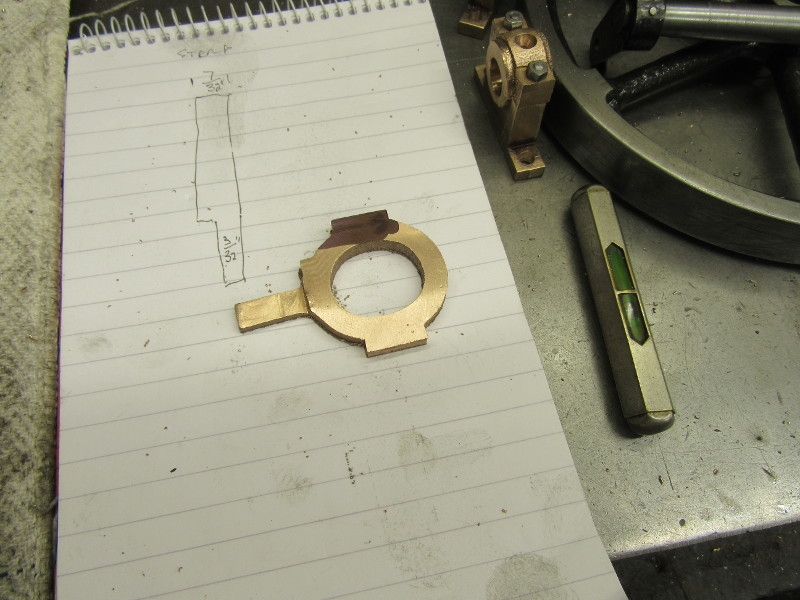

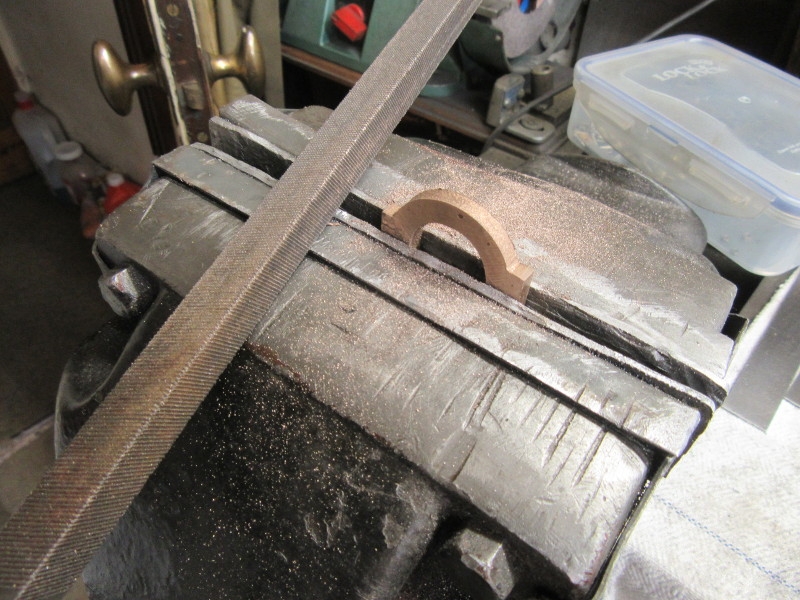

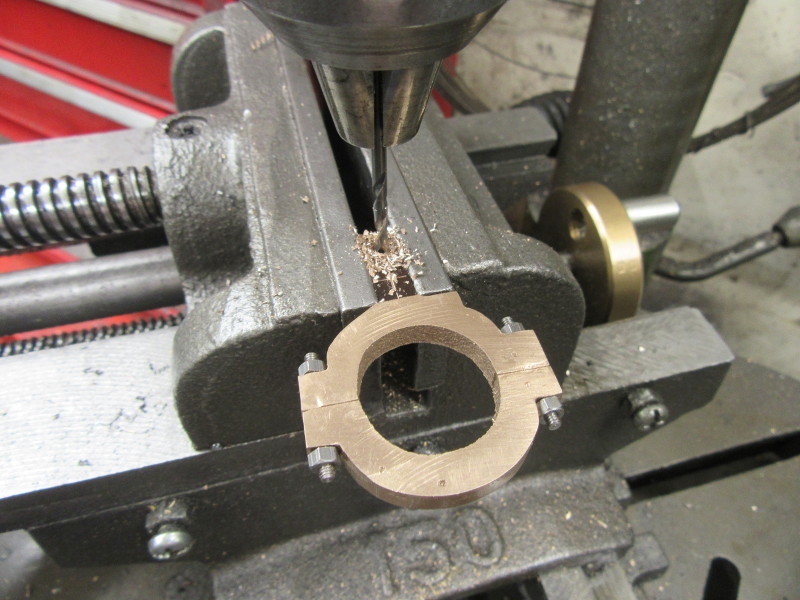

So... we move on the plan 'B' (after straightening the rod by eye, bending it in the vise.) I shall cut the slot with a 3/8" end mill.

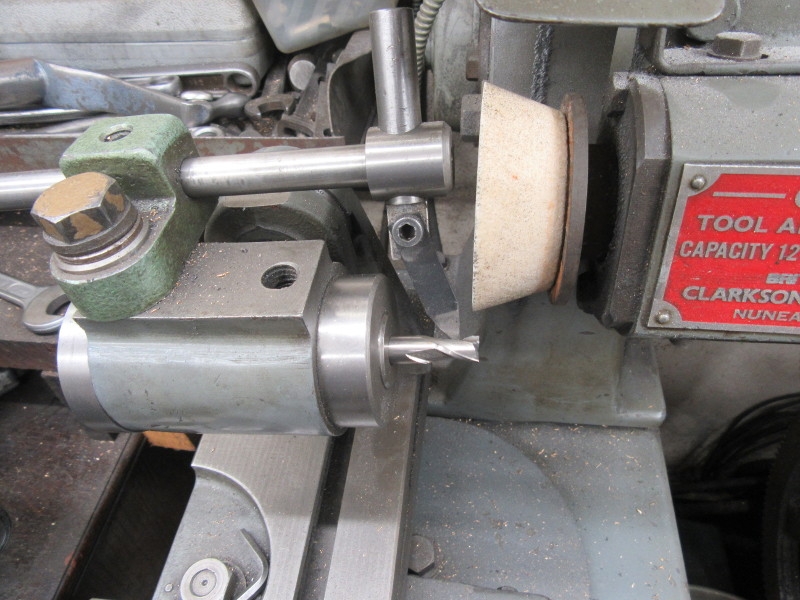

After a couple of passes I decided we needed to sharpen the cutter.

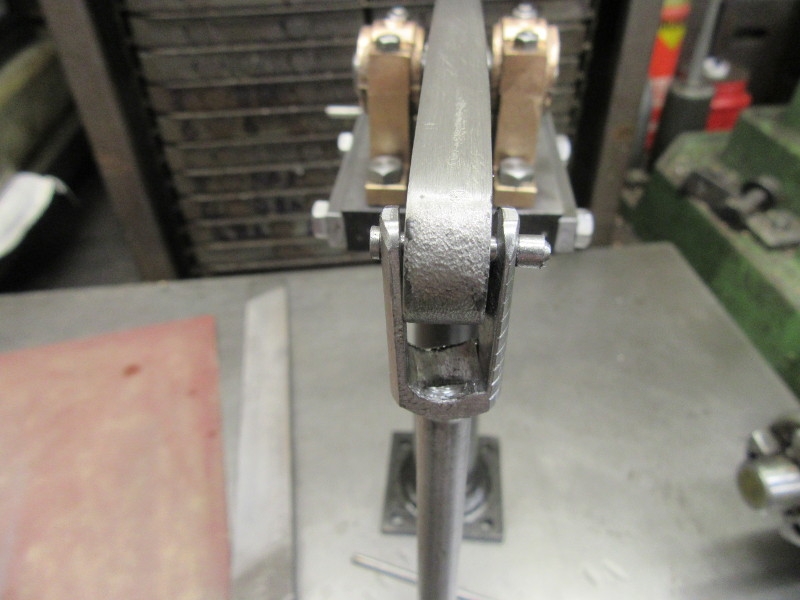

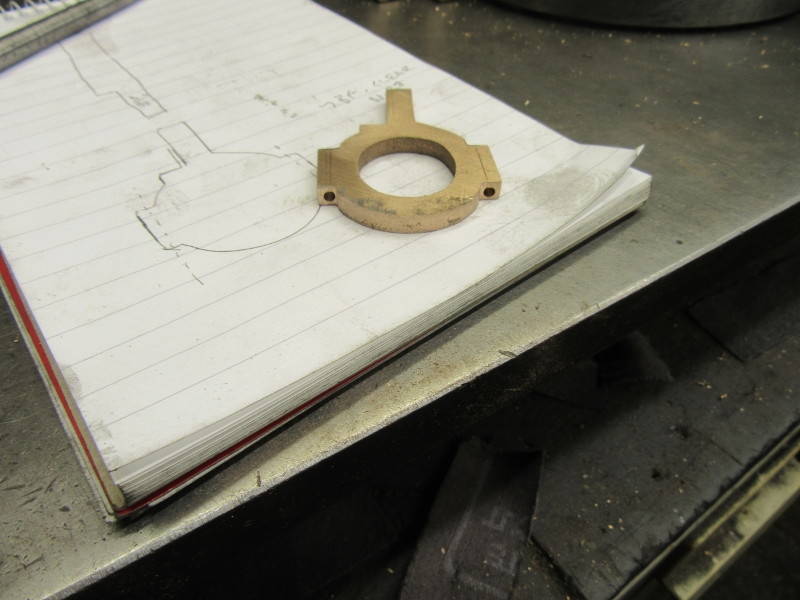

I cut as far as I could on the slant and tried it against the beam, it's a nice fit. So next job is to cut from the other side but that can wait until tomorrow. All that frustration for two hours has exhausted me. All right, I am a wimp but I don't want another cock-up. I shall come back to the problem fresh...