Shed Matters 3

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

A pleasure to help Kev. Tell him if he breaks that I shall be very surprised!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

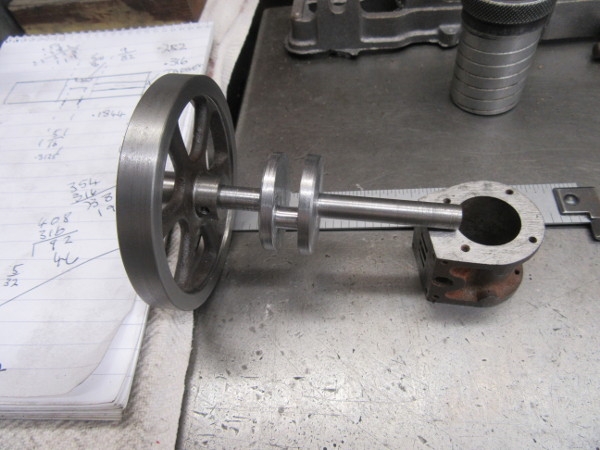

Two hours fiddly work fitting the engine up. Not easy because I have to overcome inaccurate work by me because of age and also the problems caused by the lousy castings. Suffice it to say that it's been difficult. I have the crankshaft and crosshead coupled to the piston and I am ready to put the lid on the cylinder.

I have to admit I'll be glad when this one is finished!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

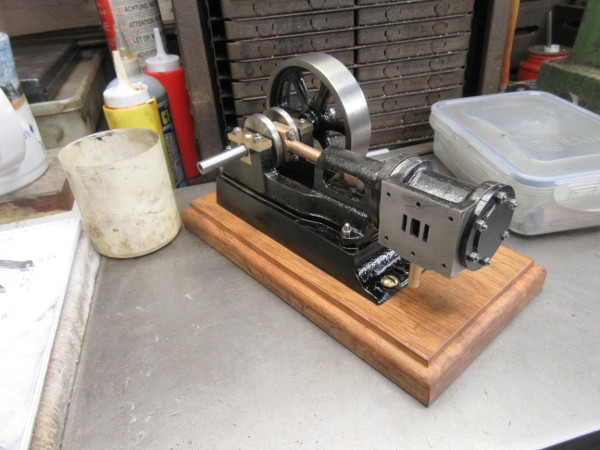

Only one pic today, the engine now has a flywheel and a lid on the back of the cylinder. The crankshaft turns smoothly and by tomorrow morning the shaft lock will have set and the flywheel will be a permanent fixture. I am ready now to make the eccentric and that will be tomorrow's task.

That's the good news but there is bad news as well. As you know I have struggled with this build because of the pot hard castings, the miracle is I have managed to work with it and get to this stage. But I have to tell you it will never be a runner because it has no piston. The reason for that is that although it's a good fit the bore is not aligned with the rest of the engine due to the fact the cold shops in the metal have diverted the bore. There was only one cure, a new cylinder, but I have no confidence that will be any better. The engine is intended to be a toy for a young lad called Fred and I don't think he will worry about the piston!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

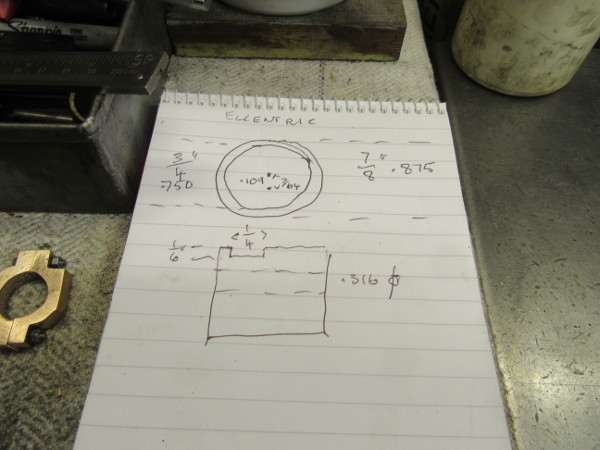

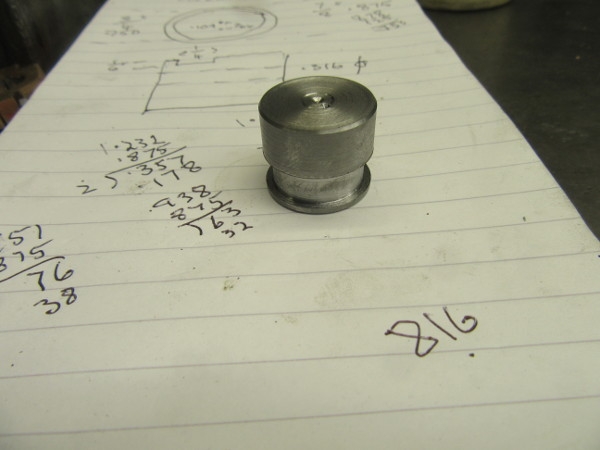

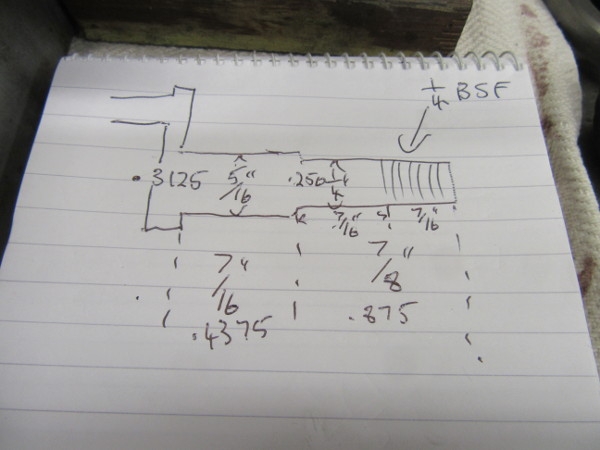

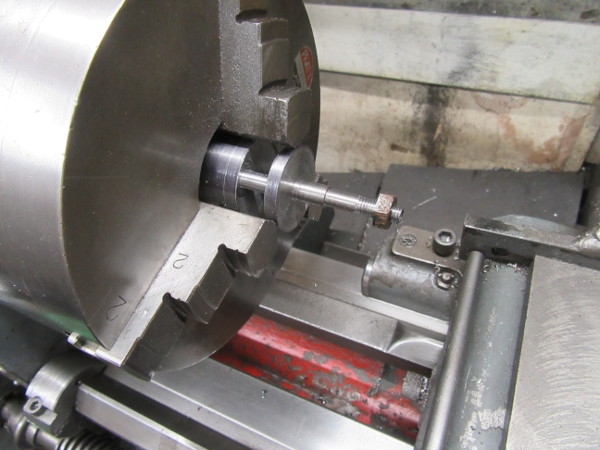

My next job is to make the eccentric and fit it to the rod. First job as always is to check the measurements and do a fag packet drawing which is my adjusted interpretation.

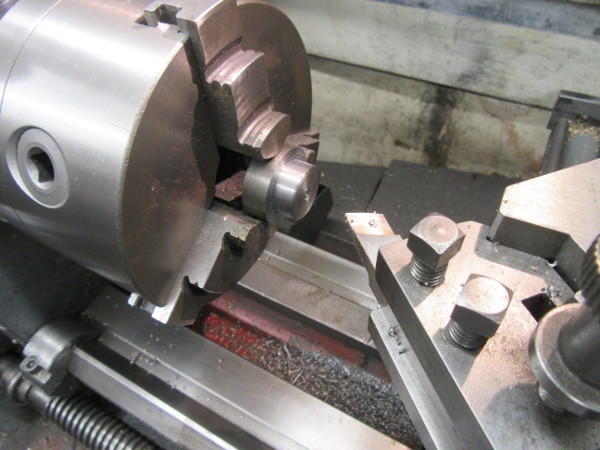

You may have noticed that every now and again I like to have a fresh start with my HSS tool. Today felt like a good day to do it. I tend to stray away from the classic form as I touch the tool up on the wheel. So here we are ready to start on the eccentric with the stock in the chuck and a nice fresh cutter in place and checked for centre.

I've started turning the stock and Here I'm marking the PCD of the bore, 7/64" offset.....

Here is where I got to. The eccentric is cut to size and the channel for the eccentric rod is cut. I have marked the position of the offset centre with the punch and tomorrow will drill it with a centre.

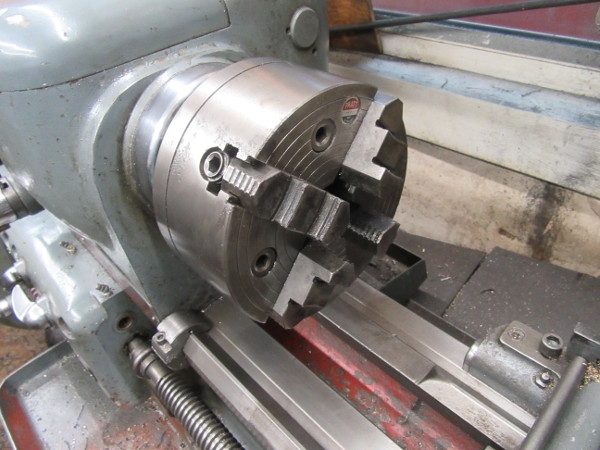

Last job was a quick clean of the lathe and change to the 4 jaw independent chuck so I can mount the eccentric for boring. Nice easy morning, no rushing and some careful work. The way I combat age is to be even more careful and check everything two or three times. I know my limitations.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

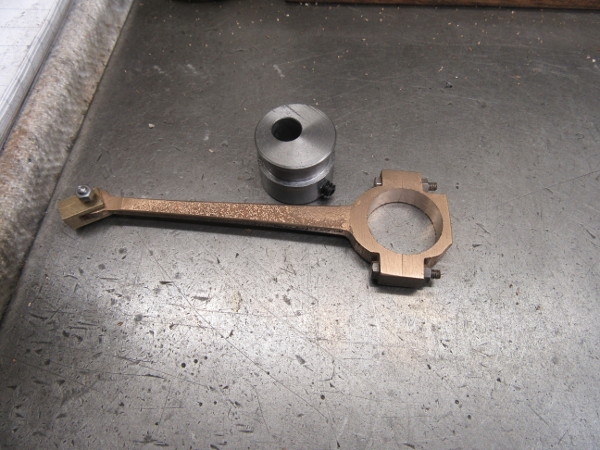

Today we have to finish the Eccentric and fit the eccentric strap.....

I cheated. I remembered that I did the last eccentric without turning down the body concentric with the bore and decided that was far better because it gave me plenty of meat for drilling and threading to fit the Unbrako set screw that fixes the eccentric on the shaft. That being the case all I had to do was bore the eccentric under the pillar drill. I automatically ensured it was vertical by capturing it in the vice using a vee block.

It worked fine and here is the eccentric on a trial fit on the shaft after drilling with a letter 'O' drill.

Then under the drill again and drill and tap for a 3/16" Unbrako set screw.

Here we are on the shaft.

I tidied up at this stage, put the 3 jaw back on the lathe and fixed the boring head in the VM. Then some measuring up and decisions, straightening the strap up and boring it.

I think those two pics cover that.

Here we are at closing time. The strap is ready for an oil hole and fitting and my last move was to put the boring bar away and replace a normal cutter on the mill. Two hours nice work.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

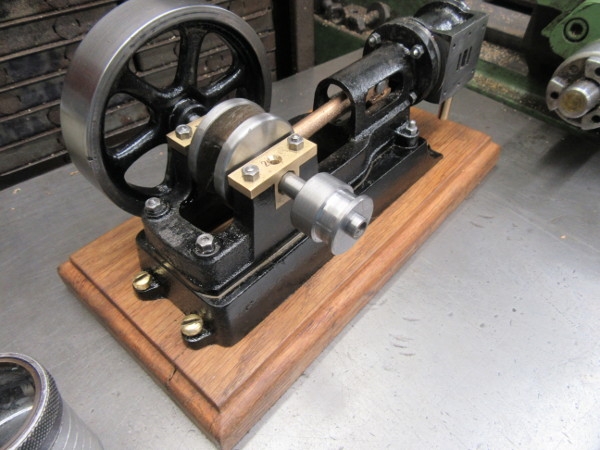

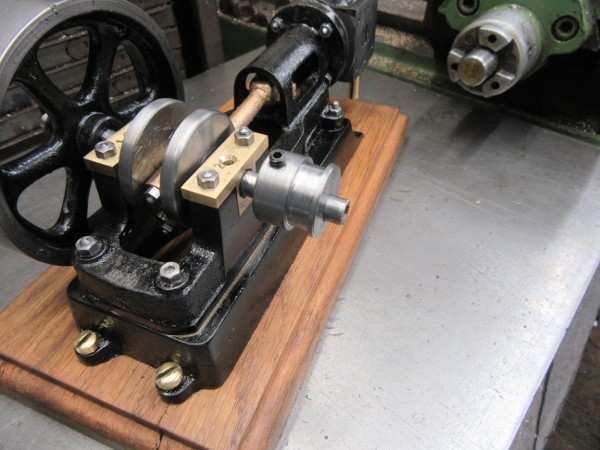

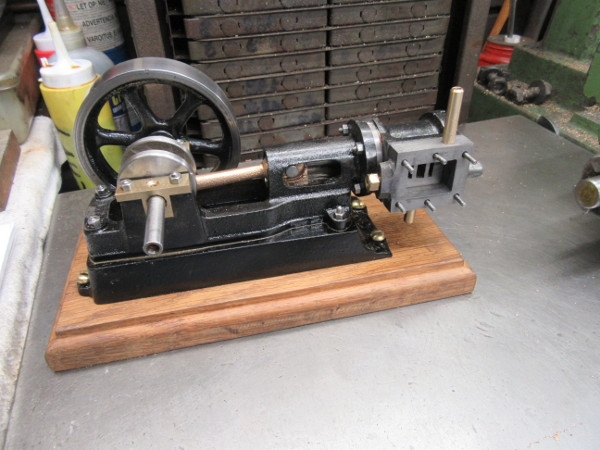

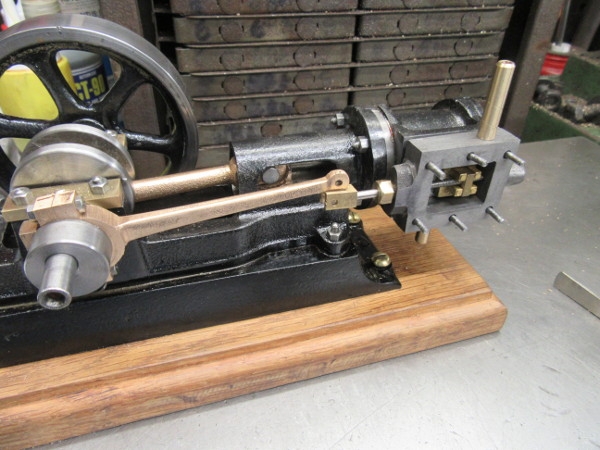

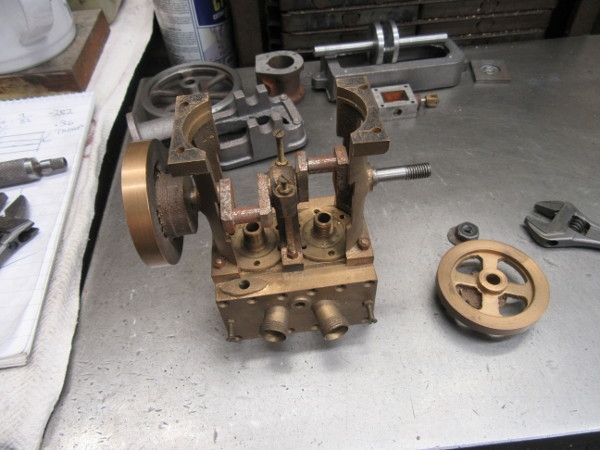

We're on the last lap. I have all the parts made and what I want to do today is fit the valve gear and eccentric and get close to the final touches.

Some quiet fitting, all is well so far.

Closing time, (I had to pop to the Co-op for some milk) The engine is built and all I have to do now is the finishing touches, tightening all fastenings, cutting off excess thread and tomorrow some polishing of nut heads etc.

Not my finest hour, this was the worst casting set by far I have ever had from Stuarts. I'm glad to see the back of it.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: Shed Matters 3

Still can't understand why you have given up on making it a runner. ie : no piston. Surely the bore alignment can't be that far out that lapping in or a modified knuckle joint wouldn't cure. I know you are offering it as a toy but remember there are some old kids in that house.

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Because the castings are so horrible Ken. I don't want anything to do with them. You have no idea what a struggle it's been to get it this far. I shall titivate it and send it on its way.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

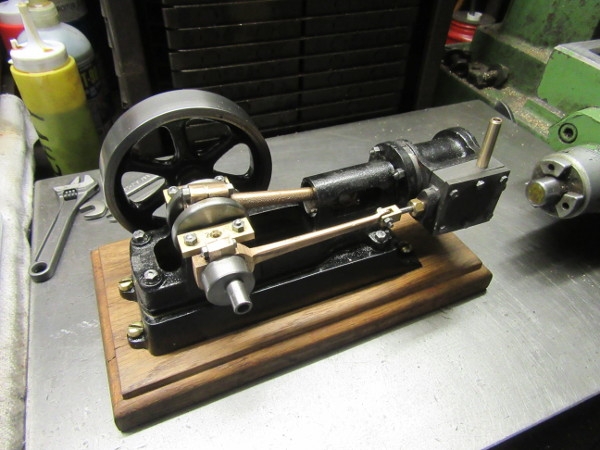

Today is titivating day. One of the jobs is grinding off the excess thread on the fastenings on the engine. I took the easy way out and did it with the Dremel. If any of you have ever wondered what the chain and the spring hung above the bench were for, here's your answer. It means I can support the weight of the Dremel and make it easier to control the grinder on small jobs. I've done all I am going to do with the engine. As you know, I regret ever seeing these castings and will be glad to see it go out of the door.

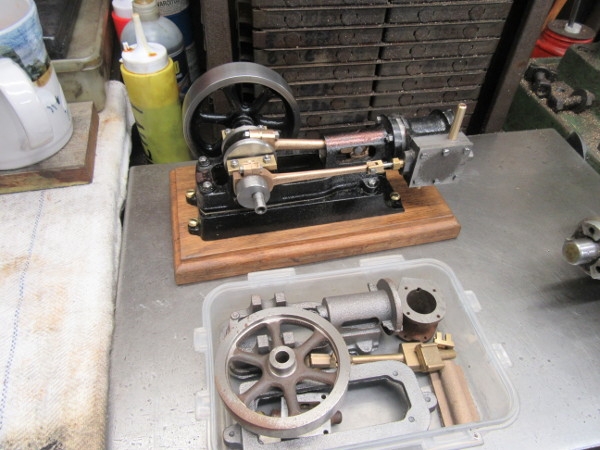

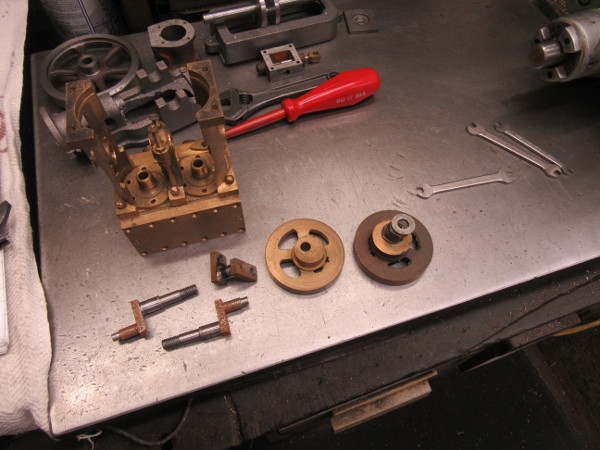

Then I had a clean up, first Mrs Harrison and then re-arranging the storage of my spare engine parts and the next job. Here we have the outgoing engine and the next set of castings for a 10H. This started with the castings that Keith gave me and I got the castings I needed to make it up to a full kit from Stuarts. I have the drawings of course from making previous versions of this engine. I won't be in the shed tomorrow but I am ready to start on the next engine on Saturday.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

No shed today, shopping, end of previous project and a gallivant to Colne with Susan all conspire against the shed.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: Shed Matters 3

It looks good and as you said, that's all that matters and it doesn't need to be a runner. You should talk to Stuart's and maybe ask for some credit against future purchases as it couldn't be completed satisfactorily. Stuart's have always sounded reasonable in your dealings with them.

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I already have Graham and got a couple of free castings out of them but nowhere near enough to recompense me for the aggro, The new engine is mainly old castings that Keith gave me, some I had in stock and made up with modern castings from Stuarts. The later castings are nowhere near as food as the old ones. They seem to have lost the knack of casting small parts with no chills, they used to turn like butter!.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

This is an overall view of the piste. I raided a second hand tool stall on Colne market yesterday and spent £20. So as well as the finished engine and the castings for the 10H I have the loot to deal with. I scored a pair of 10" Gilbow straight snips, an air-powered drill and three milling cutters, 2 of them brand new and unused.

The first job was to install the No. 8 engine on the kitchen table as eye candy. It will stay there until Stuart picks it up.

Here are the three cutters, two brand new and one that needs a bit of attention.

I tried the cutter, found it needed sharpening and gave it a good going over in the T&C grinder. I put it back in the mill. It was better but not there yet, It was seriously out of kilter and will take a while to get in good shape. I tried it as a side cutter and the flutes are good, very sharp.

here's where I finished up. I fitted the air drill with a modern fitting that matches mine in the shed. I tried it out and it works fine, intended more as a drill but fast enough to use with stones or burrs. Next I sorted out my small grind stones and burrs, I need a box for these now. Part of the clearing up entailed dumping a block drilled with holes and that meant that I have an assorted bunch of 1/4" Whitworth cap screws that are looking for a home. Another plastic box perhaps.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

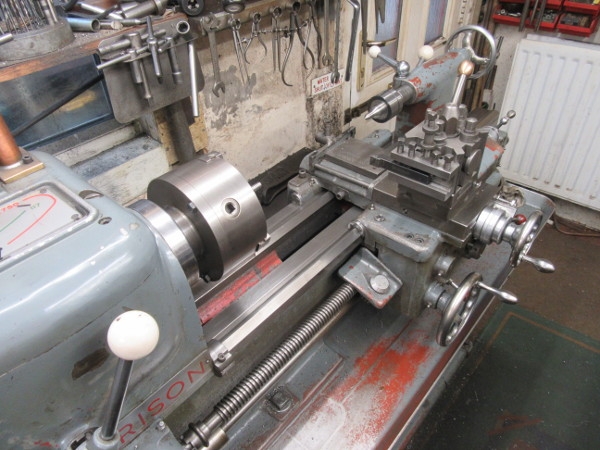

After my tidy up yesterday I had another clean up and after oiling my CI surface plates, I put a clean tablecloth on. I was ready to start the pleasant task of making a 10H engine with mostly old castings.

The flywheel had been turned and bored but I decided to make it a bit better, Here we are, I have skimmed the face, turned it round and done the other face, a very light skim. The periphery was a bit further out so I gave that a skim with the HSS cutter. This is the point where it all went wrong. There was a squeal and the cutter stopped cutting. The edge had been knocked off it by a band of pot hard CI! I tried indexed carbide tools but couldn't make any improvement.

I retrieved the situation by using some Norton honing stones I happened to have about my person. I have got rid of most of the shattered edge but would have been much better just polishing it. Whoever turned this in the first place did much better than me!

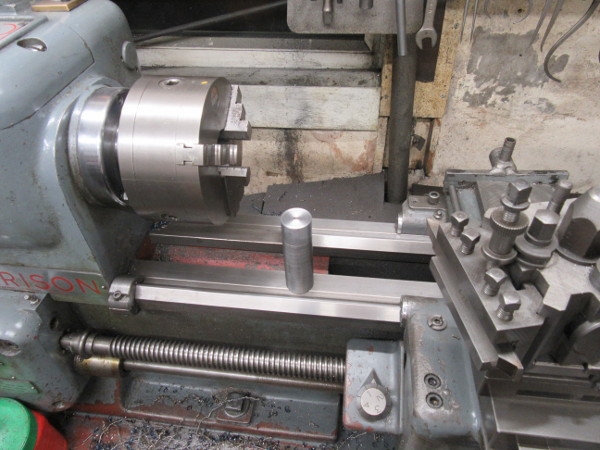

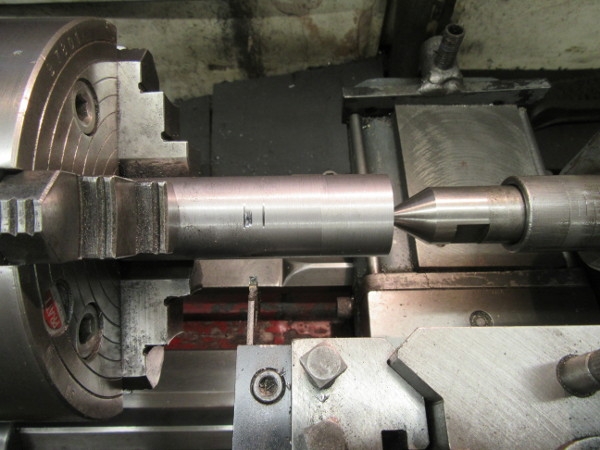

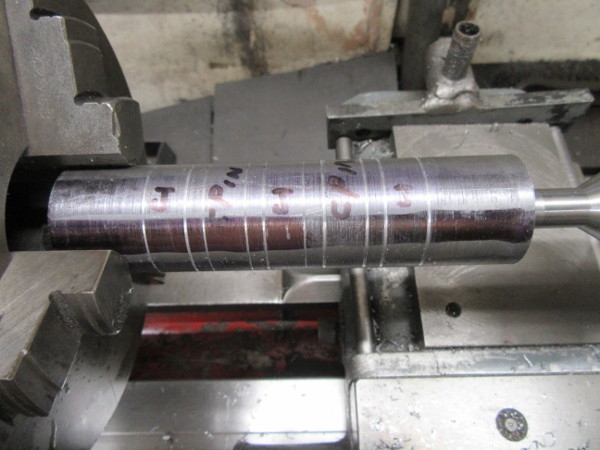

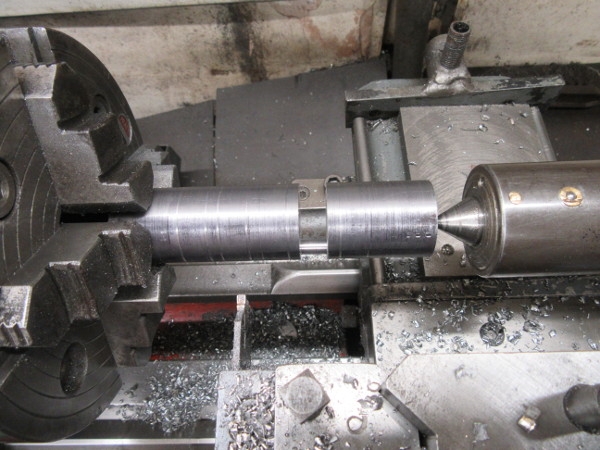

I had a good read of the drawings and a measure up, good job I did because the flywheel is bored larger than the drawing. No problem because I am going to chop the shaft out of the solid and can make it to suit the bore. Here we are enjoying Mrs McMaster quietly chobbling through a piece of stock for the shaft.

The stock needs reducing to the size needed for the blank so I got stuck in with a big carbide cutter.

This is where I finished up, the shaft is almost down to stock size. I have put the larger original three jaw on so the stock can get in the bore through the mandrel, It makes things much better later. That was it for this morning's two hours in the shed. I know where I am starting tomorrow.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

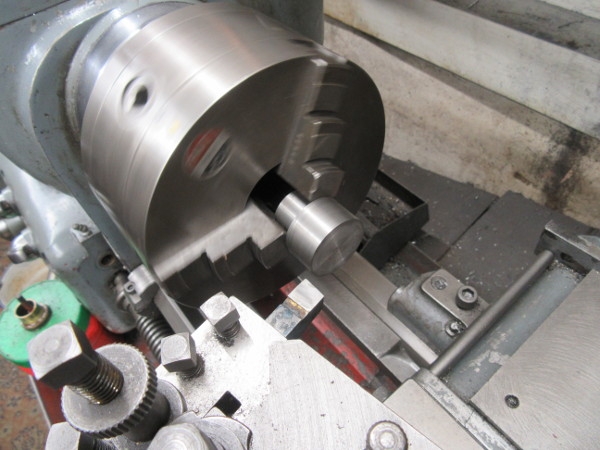

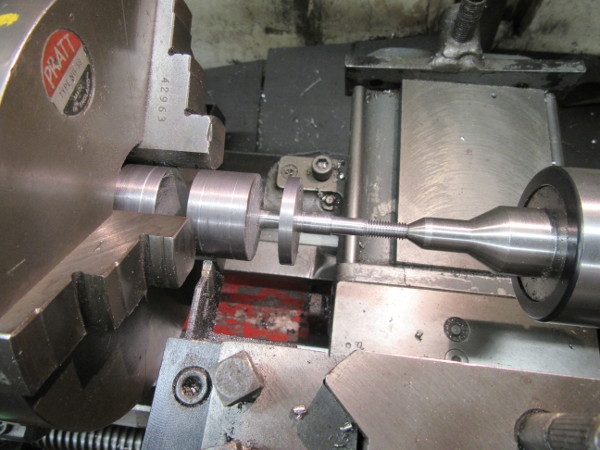

I started the morning by finishing roughing out a slug 4" long and the correct diameter to get a crankshaft out of it. Always bigger than you think to allow for the offset, in this case 3/8". Then I cleaned up all the nasty blue swarf I made cutting the stock out.

Some last minute measuring and checking led to a PCD for the crank pin centre and a mark for the centre to aid setting up. I didn't bother with drilling for a centre, I just used the pop mark and had no problems. In truth I could have cut the pin without the centre.

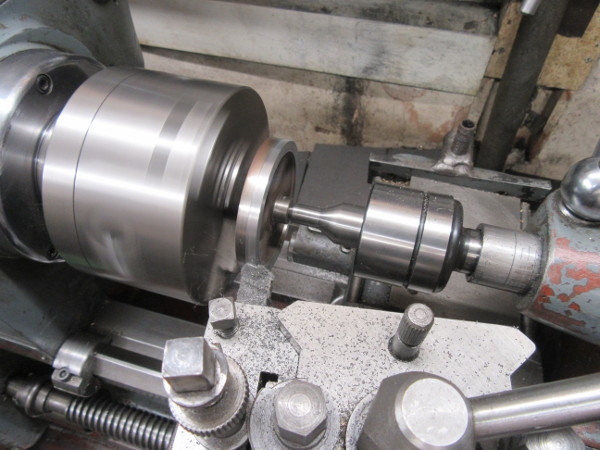

Here we are, marked and set up, all we need now is some careful turning.

After a good two hours in the shed we have a crank pin and it's been polished. It's within a thou of the recommended size so that's all right. Not a bad morning's work.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

As I was ripping stock off my lump of scrap with negative rake indexed carbide tools I thought about old fashioned carbide cutters like Wimet which are the same geometry as high speed steel tools, take less energy and on an old lathe like mine, can give a better finish. That's what is going on here. I am finishing sharpening a small Wimet cutter by honing it on an 80 grade diamond hone.

I've mounted it in a quick change block in place a a big negative rake tool and here I am making sure it's exactly on centre. Now we can get on with the job in hand.

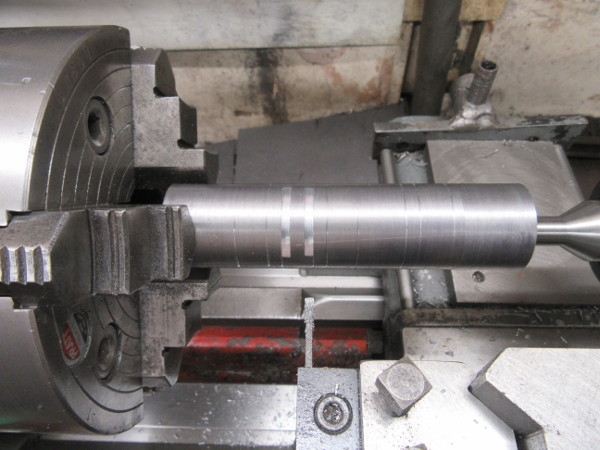

Here we are getting started. Both webs of the crankshaft have been marked and now it's simply a matter of patience and muck shifting.

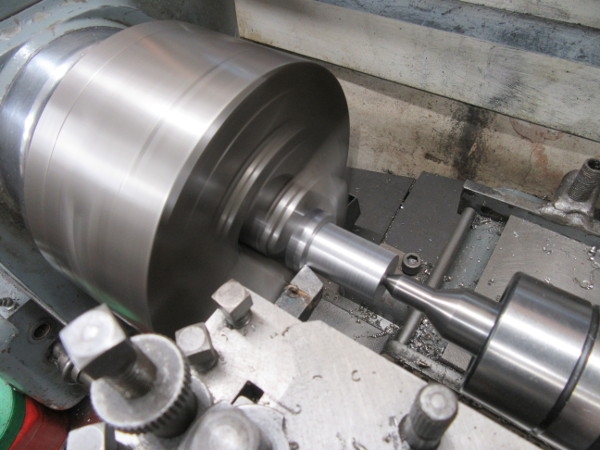

A bit later and we have an exact fit in the flywheel the bore of which is slightly over the design size.

I resharpened the cutter giving a bit more angle so it will be closer to missing the centre when we get down to that size. Then into patient turning again.

This was knocking off time, well on the way to getting the other leg of the crankshaft to size. Notice by using this larger chuck I can still hold the shaft securely so as not to be transmitting the cutting forces through the crank pin. That can be done but only with very light cuts. This way I can take 40 or 50 thou a side which speeds things up. (I'm being conservative and careful here and only taking 25 thou cuts. No rush!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

The first item of business was finishing the crankshaft for the 10H engine and I had a clean up. Now I can be distracted.

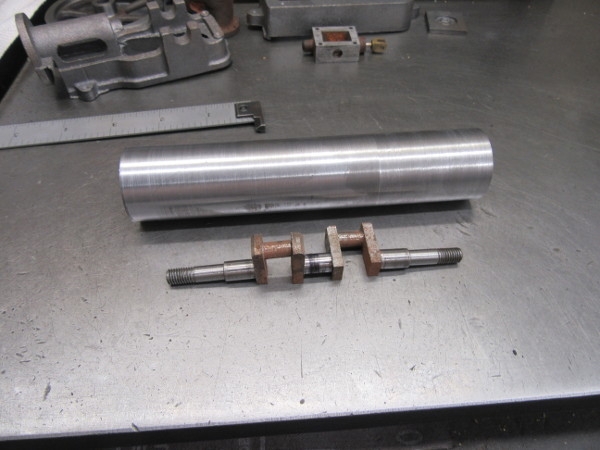

Remember Keith giving me the partially built Reeves kit for the Shand Mason fire pump? I remember noting it had a Crankshaft in it but it was built up and unfinished. I got it out and had a look.

I stripped the shaft out of it and it fell to pieces. As you know I am not a good man with building crankshafts so the choice was to either send it to Bob or to chop one out of the solid. I measured up, photographed the drawing and went looking for some scrap. I found a piece and cut it off in Mrs McMaster, Now we have to clean it up and get it to size.

Into the lathe and some hard turning with a little carbide cutter to get the crust off and then back to the tool I used for the other shaft and here's where I ended up. The slug is the exact diameter of the eccentric discs that carry the crank pins and a bit too long but that can be adjusted when it's being finished. It's always surprising how much waste there is. So tomorrow I need to measure and mark the three journals on the shaft for the two crank pins at 90degrees and the main bearing on the centre. Then get on to shaft turning....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: Shed Matters 3

Stanley, I’m sure that I could solder those parts up but getting the shaft straight would be a different matter entirely. I would normally leave the main shaft as one through piece to guarantee straightness and cut it at the webs after soldering.

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I don't think it has been very competently done Bob. It will take a while but I shall enjoy making a new shaft out of the solid. Very satisfying work, slow but I have plenty of time!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

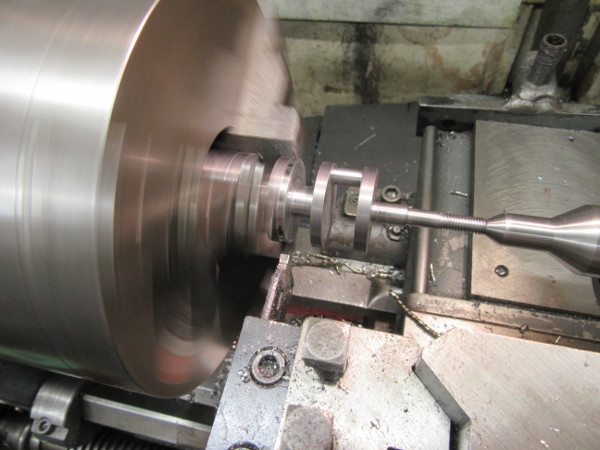

his pic sums up the problem and the job. The existing built up crankshaft has too many deficiencies and I am no go0od at silver soldering anyway. My way out of the wood is to chop a new crankshaft out of the solid. This morning is all about that.

The diameter of the slug is correct. The length needs reducing to 5" so I'm parting it off. I can remember a time when this would have frightened me to death. Today I did in on auto cross feed. (Really grown up!) Once I had it to length I centred it again and marked the PCD of the offset for the crank pins on each end.

Then I marked one of the crank pin centres on one end of the slug. And drilled it to put a centre on.

Once I had a centre on one end I had to mark the slug so I could set another line at 90 degrees and then transfer that to the other end. All I had to do then was put the centre for the other crank pin in the other end. Then I put the slug back in the lathe and used the cross compound to accurately measure the divisions on the slug which are the two crank pins and the three main bearings. There will be other mods that are needed but they can wait until we have a lot of metal removed from the stock.

My last move was to put the 4 jaw independent chuck on. I am ready now to set the stock up and start actually cutting metal. The first two cuts will be the nerve racking ones, the eccentric cutting to get two crank pins. More quiet and careful cutting.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: Shed Matters 3

Having struggled most of the morning yesterday changing the battery in my car's key fob - I stand in total admiration of the scope and ambition of this project. The book said "insert small screwwdriver into the slot". There is no slot ! Then I lost the plastic prising tool which I have for one of my phones. Got there in the end. Goes almost without saying I put the battery in upside down and had to do it all over again.

Respect. . . .

Respect. . . .

Born to be mild

Sapere Aude

Ego Lego

Preferred pronouns - Thou, Thee, Thy, Thine

My non-working days are Monday - Sunday

Sapere Aude

Ego Lego

Preferred pronouns - Thou, Thee, Thy, Thine

My non-working days are Monday - Sunday

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Look at it this way David. I do two hours in the shed each morning as a sort of 'brain gym' to keep my head exercised (As well as the two hours light exercise of standing at the bench and the lathe and the results which people seem to like.) I'd never really thought about this until one day, when I was staying with Janet in Oz I happened to say that I supposed she thought I was wasting my time playing Solitaire on the computer and she said no, it was valuable brain gym and I should keep doing it. I'm still here working out my problems so perhaps she was right.

(Cool the respect though David, I am nowhere near as good as I was, time is inevitably taking its toll!)

(Cool the respect though David, I am nowhere near as good as I was, time is inevitably taking its toll!)

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

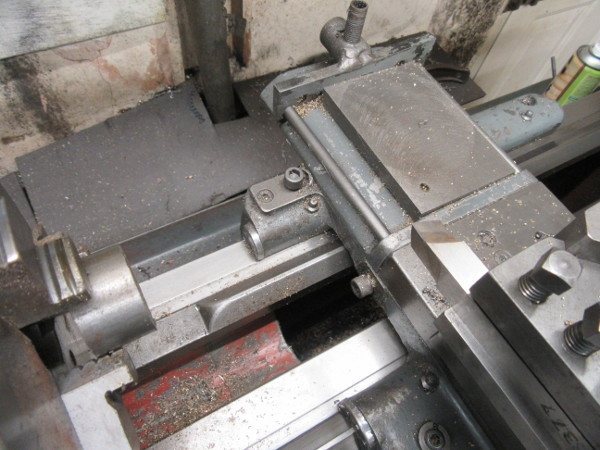

Only one pic needed for today's hour in the shed before shopping. I set the stock up in the 4 jaw independent chuck and by trial and error made sure it was running as near dead parallel as I could manage, I have it within a worst error of 2 thou. This is within the margin of error in the stock and the jaws of the chuck.

Once it was installed I set the cutter up and made sure the top slide was set on 0 degrees because I shall be using it to move the cutter from side to side in the cut which is 7/16"wide for the pins. Then I took two of the 100thou cuts that will be used to cut down to the finished thickness of 1/4" for the crank pin.

That was a good hour and I am pleased. I am ready for some patient cutting tomorrow!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

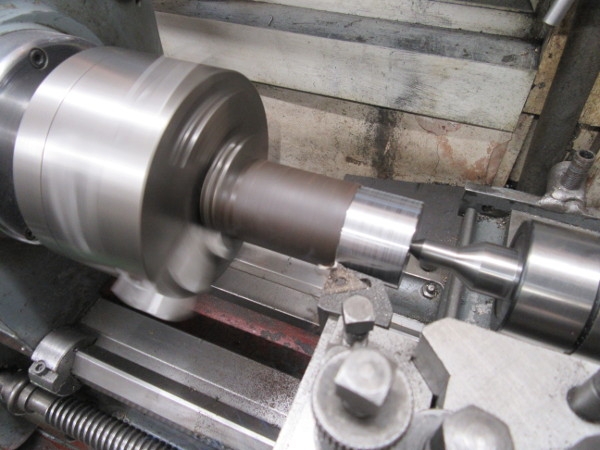

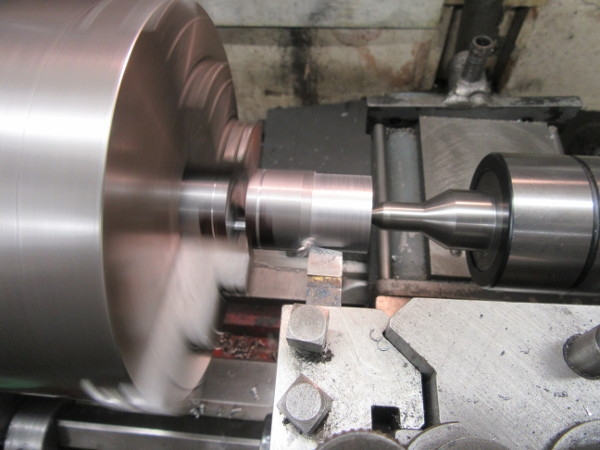

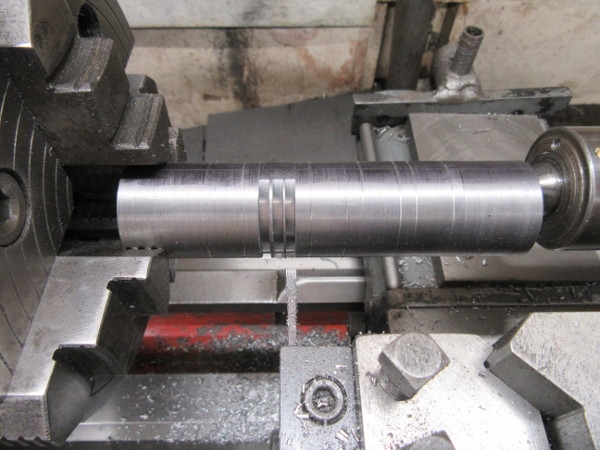

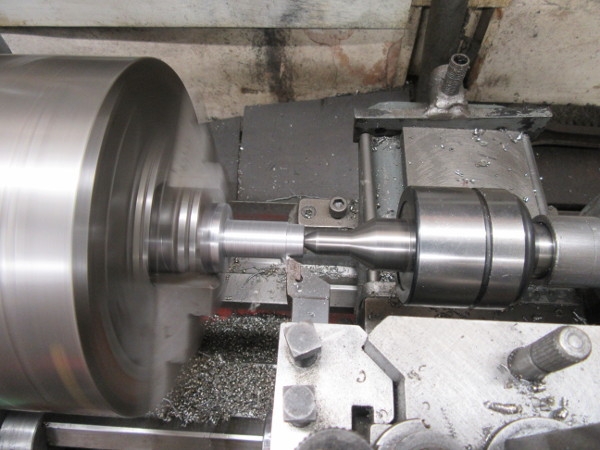

I left the stock set up ready for a start yesterday so after checking everything once more I started turning. If I'd been brave enough I feel sure that I could have done the cutting on auto feed but I took the safer way out of doing the cutting by hand.

It took about 30 minutes careful work to find the first pin, 1/4" diameter.

Then I reversed the workpiece and set it up again cutting on the chuck side so that there was no pressure put on the completed pin. Notice also that I am using my old heavy duty live centre as it is more rigid, having less stick out.

Here's where I was after just over an hour, I have two crank pins at 90 degrees to each other and am ready to turn the three main bearings.

I put the three jaw back on, Mounted the stock in a way that didn't put any strain on the crank pin and resharpened the Wimet cutter as I shall be muck shifting. It won't be as good a finish as HSS but that can be the last cut. As you can see, I have started the cutting of the end of the shaft.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90293

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

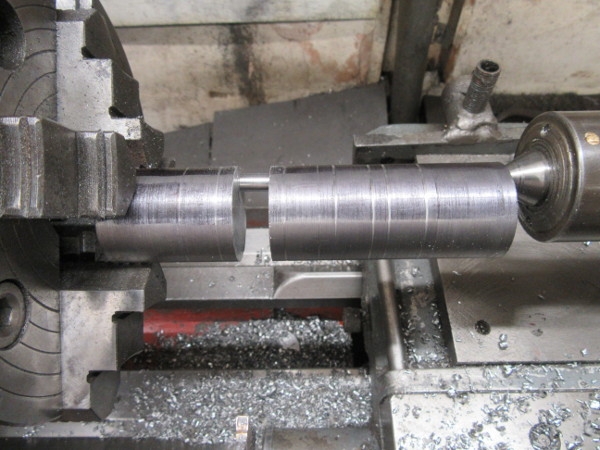

First job was to do a fag packet drawing of the end of the shaft and find a 1/4"BSF die.

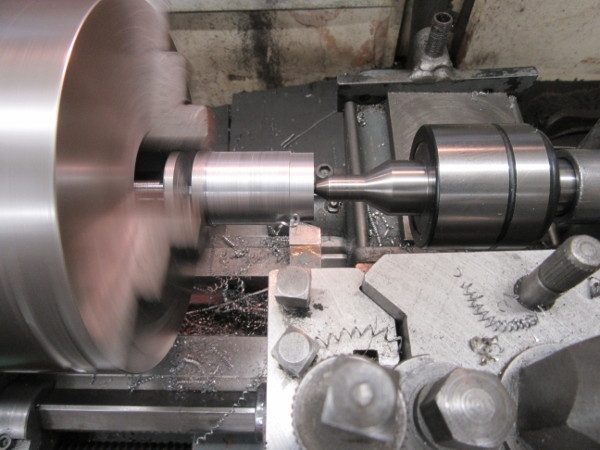

Then back to turning. I changed over to an indexed cutter as it will give me a better finish and it's the right shape for getting into the corners.

A bit later we have a shaft end threaded and with a test fit of the nut.

Working back down the shaft observing the rule that cutting torque must always be taken by the webs of the shaft I am ready to cut the centre bearing.

The bearing is cut and if you look carefully there is one low shop in the middle where I wasn't paying attention! It is of no account and won't spoil the fitting.

Here I have reversed the shaft and started cutting the other end. I have stopped here a shade before the journal size because the workpiece is hot and I'll get a more accurate measurement tomorrow when it's cool.

I cleaned and oiled Mrs Harrison as that's the end of heavy turning for the time being. I swept the floor as well. A nice clean shed for tomorrow's finishing touches to the shaft.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!