Shed Matters 3

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Unusually, Shed Matters spilled over into the kitchen after my second sleep.

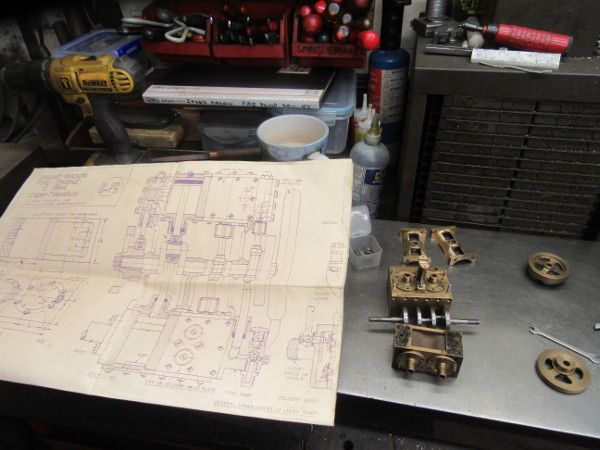

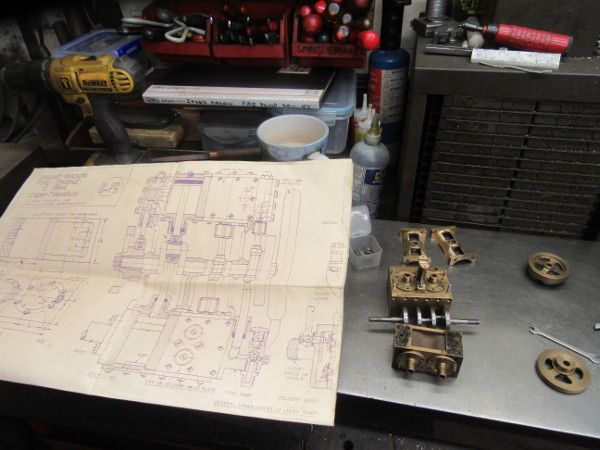

I have spent an hour and a half trawling the ME volumes 133 and 134 and have scanned and copied 40 pages. I had about my person some pocket files and one of them is now my workshop manual, all 40 pages protected by plastic pockets.

As for what I have learned.... the answer is not a lot, as they are very general articles and most of the drawings I already have on a larger scale. However, it will have clues that will repay careful reading, in short, I have better resources now than before.

One thing I have learned is that this project will never result in a practical pump as some elements of it are fiendishly complicated. The best I can aspire to is get it closer to completion than it is now.... Believe me, even that lowly ambition will be a bit of a bloody triumph if I pull it off.

I shall have a spot of lunch now and a rest!

I have spent an hour and a half trawling the ME volumes 133 and 134 and have scanned and copied 40 pages. I had about my person some pocket files and one of them is now my workshop manual, all 40 pages protected by plastic pockets.

As for what I have learned.... the answer is not a lot, as they are very general articles and most of the drawings I already have on a larger scale. However, it will have clues that will repay careful reading, in short, I have better resources now than before.

One thing I have learned is that this project will never result in a practical pump as some elements of it are fiendishly complicated. The best I can aspire to is get it closer to completion than it is now.... Believe me, even that lowly ambition will be a bit of a bloody triumph if I pull it off.

I shall have a spot of lunch now and a rest!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I spent an hour on ensuring that the crankshaft was a good running fit in the standards. I started by putting a 5/16" reamer through the bearings and the rest of the time on repeated fittings and easing of the castings. At closing time I still hadn't got the fit I wanted but at least I know exactly where to start tomorrow morning!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

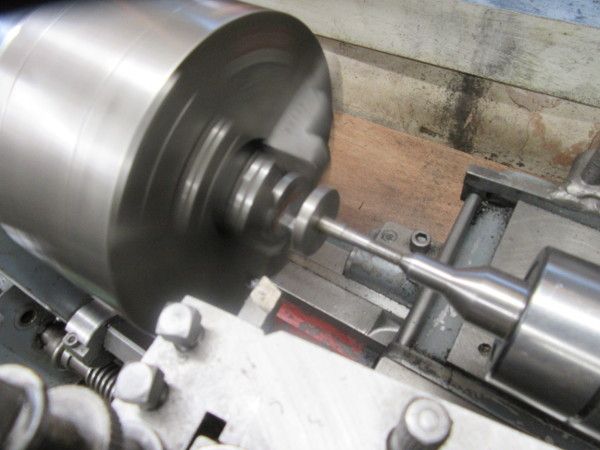

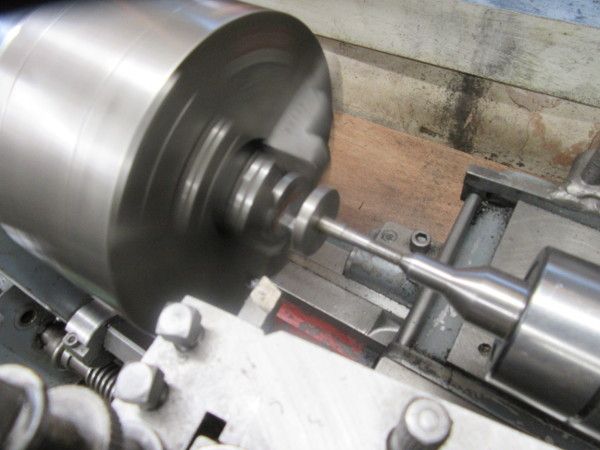

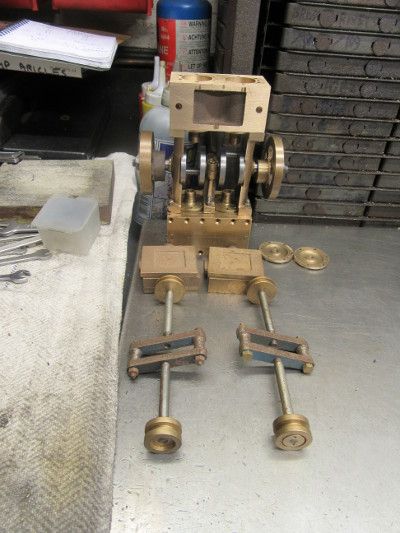

This morning I finally cracked the fitting of the shaft into the supports and then fitted the centre bearing, the shaft runs free now. Lots more fitting to be done on it of course but definite progress. You can see clearly that the right hand flywheel needs finishing and that's probably the next task.

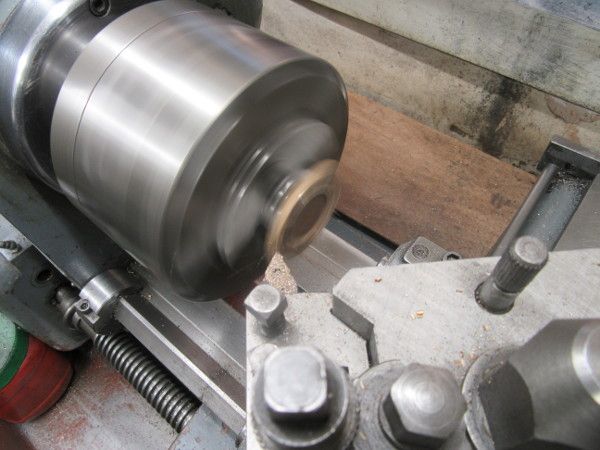

When I was looking at jeweller's tools I was reminded of the goldsmith's anvil that I have and decided it needed some TLC so this morning I mounted it in the lathe and trued the top face, it was hardened and I had to use an indexed carbide tool. The last pic shows where I finished and the piece of very hard plastic which will become the base.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

As you can see the process of fitting the piece of plastic to the jeweller's anvil didn't go well. It was far less malleable than I had assumed and shattered. So, into the bin and I accepted that the way to use the anvil is to capture it in a vise. I also noted that there is a trademark on the vise, a fish.

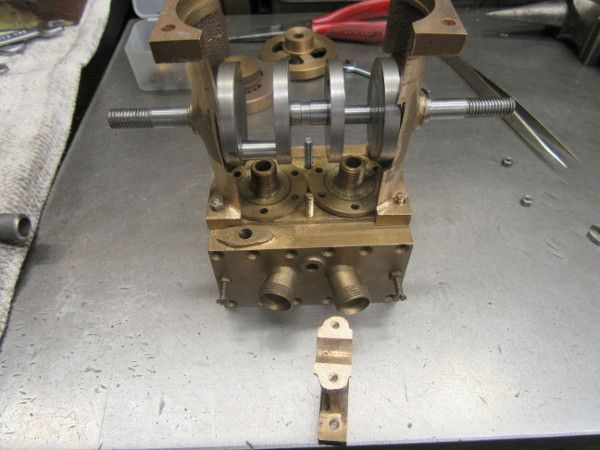

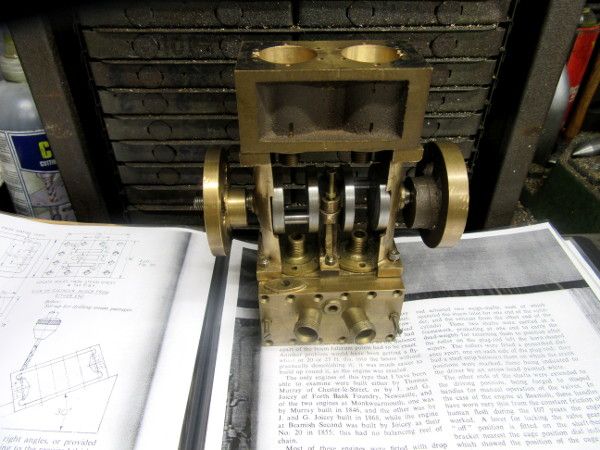

So then I switched my attention to the fire pump. I found the relevant drawing in the ME files and did some preliminary investigating. What I found is bad news, the shaft and the standards are going to need a lot more fitting, the engine block is nowhere near a fit. It means a complete strip down and basically re-make what i have so far. I told you this pump was going to be a bugger!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I went in the shed and surveyed the piste. I confirmed what I had to do, strip the pump and cylinder block down and check everything again, adjusting to make it fit properly. I also realised it was warmer than I thought in there and came out. Sorry lads but I shall give it a while longer.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

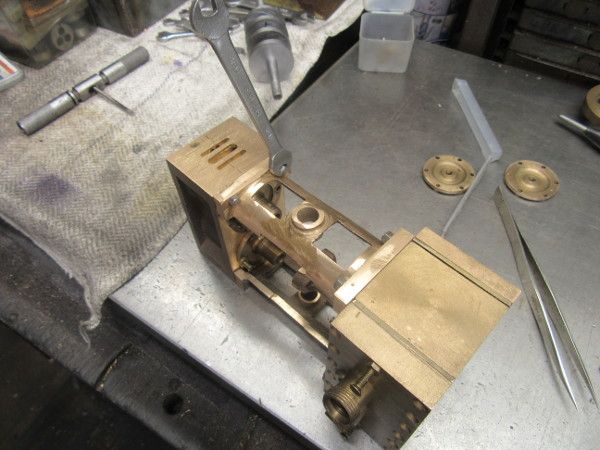

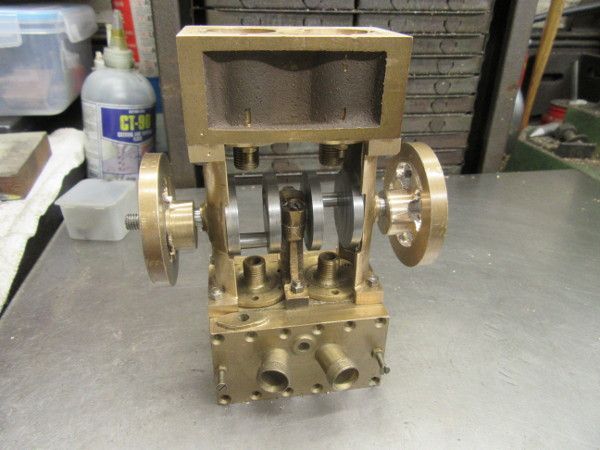

Normal service has been resumed and I have been in the shed for almost two hours....

My primary focus was to strip the steam cylinder end of the pump down and address the faults in the fitting. One of them was the crankshaft I made out of solid, it needed 10 thou taking off one web..... Then I spent the rest of the time addressing the two standards which needed improving and easing. In the process of doing these clear tasks I wanted to get it clear in my head how the pump can work when the rods for the steam cylinders and the pump bores are all working in fixed planes and there had to be a way of allowing the oscillation produced by the crank pins to be absorbed. I think I have cracked it, it's a version of the Scotch yoke mechanism that uses die blocks captured in yokes to convert the motion. If you want more detail go to Google and do a search for 'Scotch Yoke motion' and try to get your head round it.

You can see from the last pic where I finished, I shan't know how much good I have done until I build it up again. All I can say is that it is better than it was this morning.....

My primary focus was to strip the steam cylinder end of the pump down and address the faults in the fitting. One of them was the crankshaft I made out of solid, it needed 10 thou taking off one web..... Then I spent the rest of the time addressing the two standards which needed improving and easing. In the process of doing these clear tasks I wanted to get it clear in my head how the pump can work when the rods for the steam cylinders and the pump bores are all working in fixed planes and there had to be a way of allowing the oscillation produced by the crank pins to be absorbed. I think I have cracked it, it's a version of the Scotch yoke mechanism that uses die blocks captured in yokes to convert the motion. If you want more detail go to Google and do a search for 'Scotch Yoke motion' and try to get your head round it.

You can see from the last pic where I finished, I shan't know how much good I have done until I build it up again. All I can say is that it is better than it was this morning.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I think you can see my problem in the first image. My Standards are still not pe4rfectly square and so cannot line up with the base of the steam cylinders at the top. So I decided to take the shaft out, force the standards into a correct position and measure for the dimensions of the crankshaft. As you can see from the second image I can't get them in far enough because they are fouling on the bottom lids of the cylinders. These are going to need reducing in diameter. Then I cleaned all the parts and lids so that I can read the witness marks that will keep me straight. So tomorrow I shall be into some very careful turning again but this time the lids. Then a refit and measure to see how much room there is for the shaft. It's going to need reducing again. The third image is where I finished up, all my parts identified and ready for another attempt to get a fit.

I'm not interested in how it got like this, the real root of the problem is that there are many important dimensions missing off the original drawings so I'm working in the real world, making the parts fit!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

The first thing I did was reduce the diameter of the lids so they don't interfere with the standards. Then I assembled the standards with the pump and the steam cylinders and measured the space I had for the crankshaft which was approximately 25 thou less then what the drawings indicate so I reduced the width over the outside flanges by 15 thou on each side. I finished with the standards fitting properly and the shaft definitely going to fit. I put more witness marks on and tomorrow I'll strip it all back again and refit with the crankshaft in place. Theoretically it should fit now but I won't be satisfied until it is in place and running freely.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I've had a good hour and a half in the shed. First thing was to re4sharpen my HSS cutter, make sure it was set on centre and take a skim off the two faces of the crankshaft to get a better finish and give me another 5 thou of fitting room. You may wonder why I have suddenly got into tomato soup.... Every time I go to switch the compressor on I think "Must drain the condensate from the reservoir." This morning I did it and yes, it's always the colour of tomato soup! Then I marked drilled and tapped the holes on the bottom side of the steam cylinder so I could fit it and make sure the crankshaft runs freely. I finished up looking for studs. I shall finish that process tomorrow.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

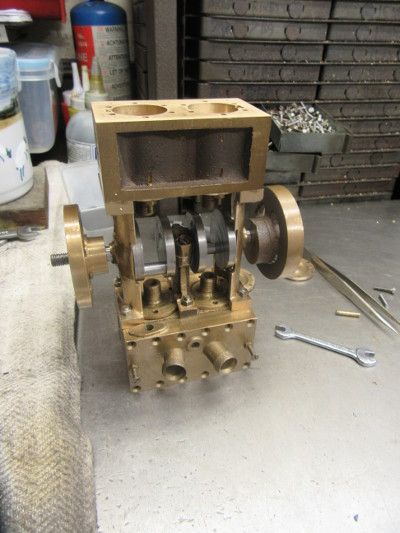

A fiddly morning. It took me over an hour to get to the stage where I could use the drill to turn the shaft in all three bearings. No point detailing all the things I had to do but it was all classic fitting. The last pic shows where I am now, I can choose now where I go next as all the problems with the fitting of the shaft have been solved. That makes it a very good morning......

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

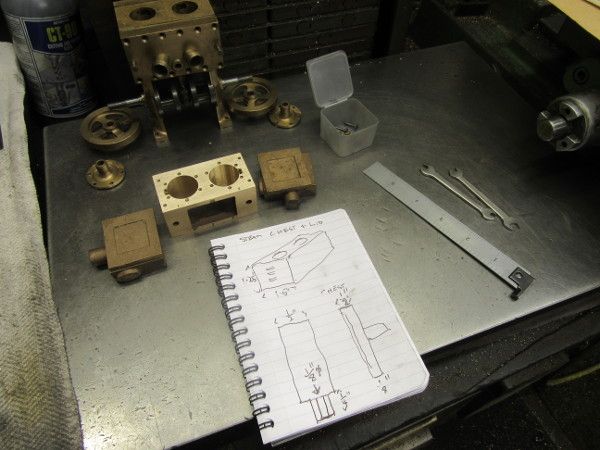

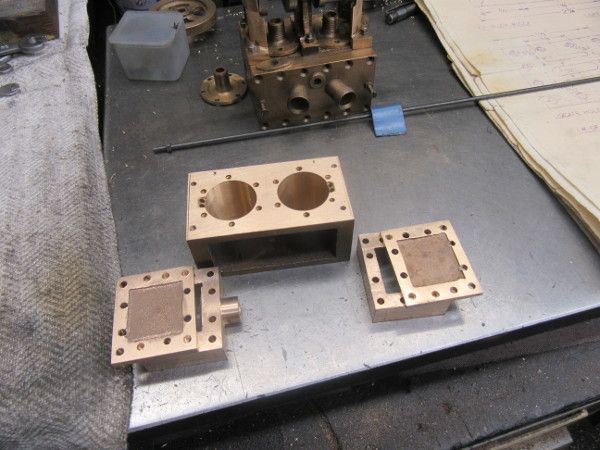

This morning was simple. I trawled through all the bronze castings I have to identify which belong to the pump. I have found enough to persuade me what we can reasonably hope to achieve. It will basically be what we have here but with the addition of the cylinder and pump pistons and the valve chests and eccentrics. So I know now where to go next. Finish the flywheels and make the eccentric straps then make the steam chests and lids. That's more work than it looks and I don't get any better at staying the course in the shed!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

This morning I started on the first element of what I had to do to complete the rescue of the pump. If you look at the first pic you'll see that one flywheel has been worked on but the other hasn't. My problem is that the centre of the eccentric is not marked on the casting so I shall have to reverse engineer it from the other. The other pics show my first moves towards creating a replica. Not ideal, but it will work with care....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

As you can see from the pics this morning was complicated but went well. I now have two flywheels that are reasonably well finished and match each other. I can now think about the eccentrics.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

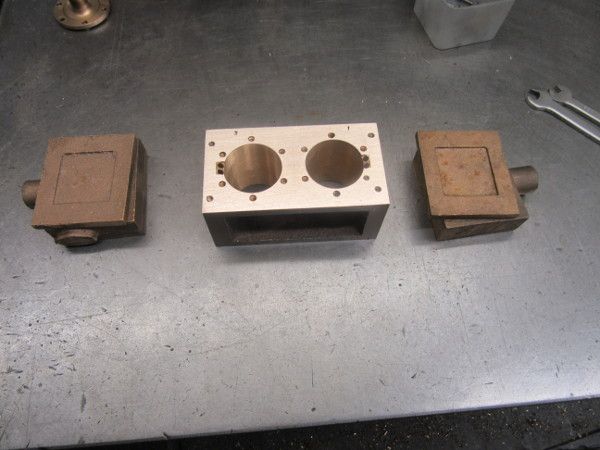

The task is to make the steam chests and lids and fit them to the cylinder block ready for making the eccentrics and valve rods. First I had to strip the block out and measure up for the lids and the chest and check these measurements with the drawings. Bit frustrating because the drawings are very faint in places and of course that was just where I need clarity. So a lot of thinking and measuring and I am satisfied I have the dimensions I need. One lucky circumstance is that whoever worked on this before didn't drill and tap for the chest and lids so I have a clean start there. I reached a point where I am ready to start cutting. That'll do for today.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Working on the lids. First use the spigot cast on the back to turn the front in the lathe. This looked easy but I found that it didn't quite give me a cut in the right plane so that had to be adjusted under the mill. I finished up with one lid flat and parallel. Tomorrow I'll do the other and then address the actual dimensions to make them match the cylinder casting. Slow but steady and no mistakes.... A good morning.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

More work on steam chest and lids. The lids still have to be reduced to dimensions but I'm leaving that until the steam chests are finished because that's what they have to fit. I have started the machining of the chests. Lots of dimensions and cuts. No Rush.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Only a short spell in the shed as I was late up but we now have both steam chests at the same stage, ready for further adjustments in the vertical mill tomorrow.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

More work on the steam chests. Not there yet but a lot closer and as you can see I haven't forgotten my witness marks.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

This morning has been all about steam chest lids. I have to make them square and the right size. Not as easy as it sounds and I spent an hour and a half doing it. They are somewhere near the right size!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

First job this morning was to make the steam chest lids a bit prettier. When I had done that I realised that I had to have a planning morning. First I needed to settle where the steam inlet was going to be as this dictates the hole pattern for the studs that will hold the steam chest and lid on the valve face. I did that and set out the hole pattern and then realised that I needed more 6BA studding and nuts than I had available so I had to adjourn to the computer and spend money on 2X12" lengths of 6BA studding and 100 full nuts. That sorts that out, tomorrow I can go on with the holes knowing that the 6BA fastenings are on the way! The firm is quite good and they will be delivered early next week.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Two pics tell the story, an hour and a half in the shed and all I did was drill 12 holes....

More to it than that of course and I have all I need to go forward tomorrow to drill the cylinder block for the holding down studs. I need to sort my witness marks out tomorrow, I got mixed up as usual with my opposite hands but nothing I can't sort out.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

As I said yesterday I cocked up the orientation of my castings yesterday so the first job was to get the orientation right and put another set of witness marks on all the castings. Then I drilled and tapped for 4 studs and fitted them. This means my lids are held tight in place and tomorrow I can mark accurately the the other 20 stud holes (!) through the clearance holes in the steam chest. An hour and a half to fit 4 studs.... but there was quite a lot to it.

It's growing slowly!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

The 6BA studding and 100 nuts arrived this morning....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: Shed Matters 3

Which supplier did you use for the 6BA studding and nuts Stanley? I have a couple that I use, both quite good at delivery.

- Stanley

- Global Moderator

- Posts: 90301

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

EKP in Barnstaple. Did they used to be Kenyons?

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!