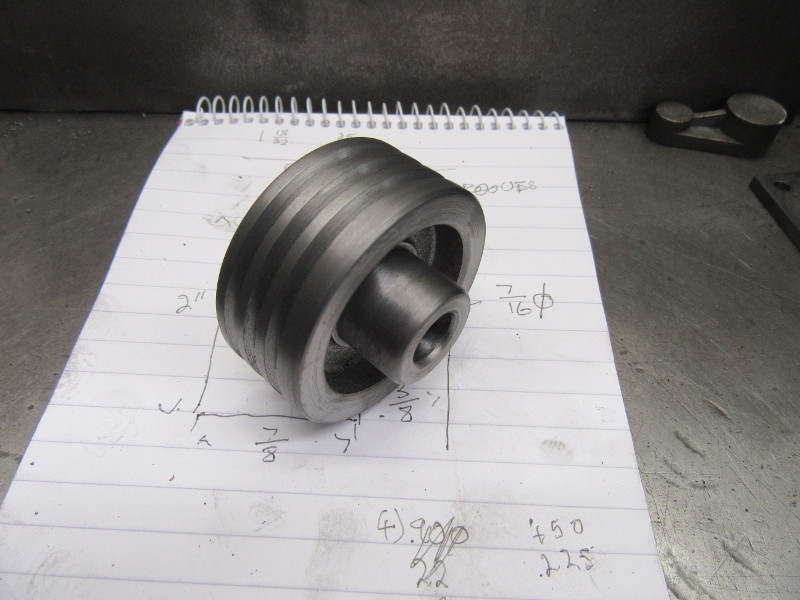

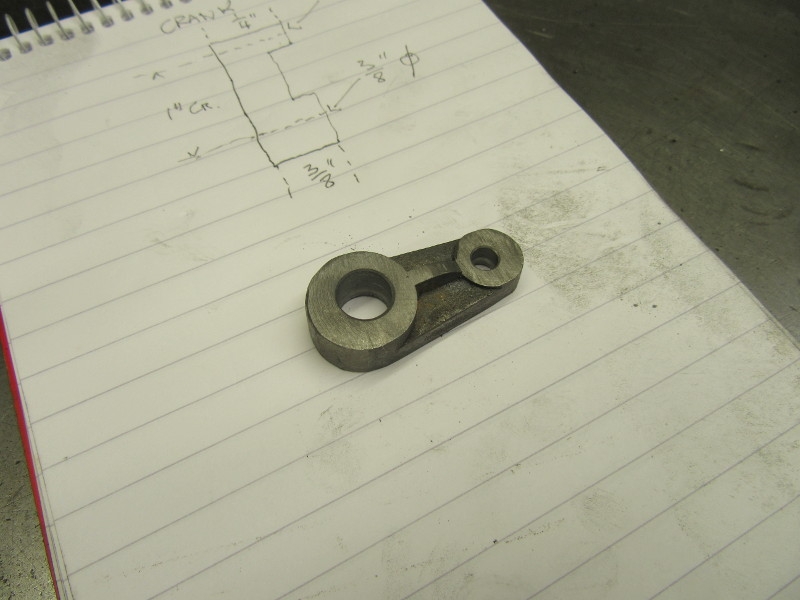

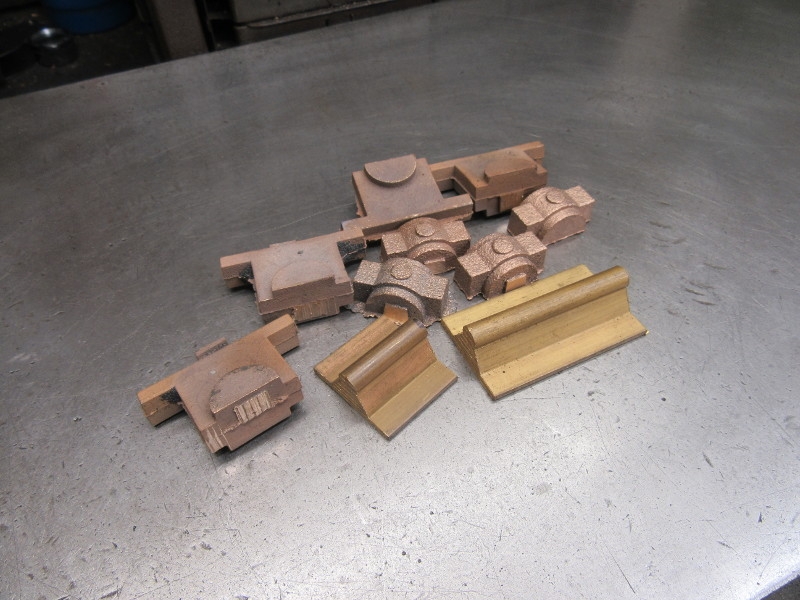

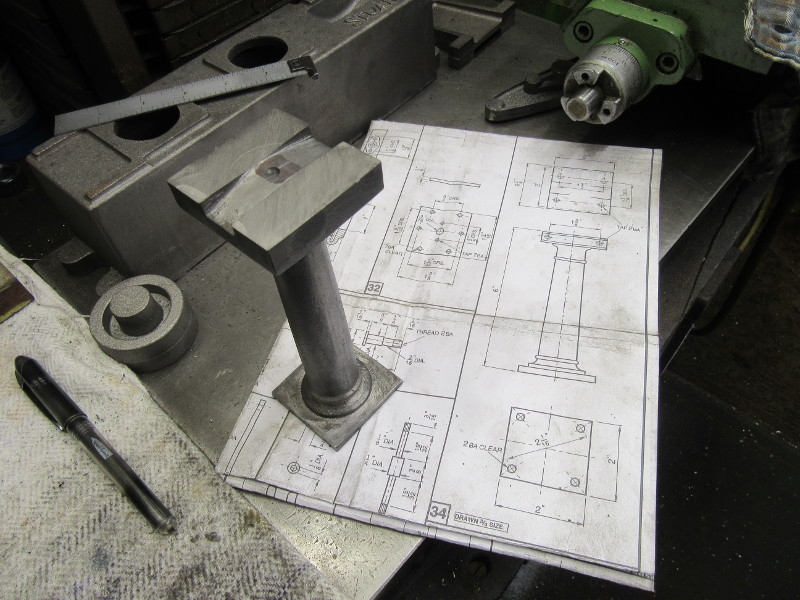

Back to my column. What we are doing today is sorting out the dimensions so first job was to get the drawings out and make sure I knew what they were!

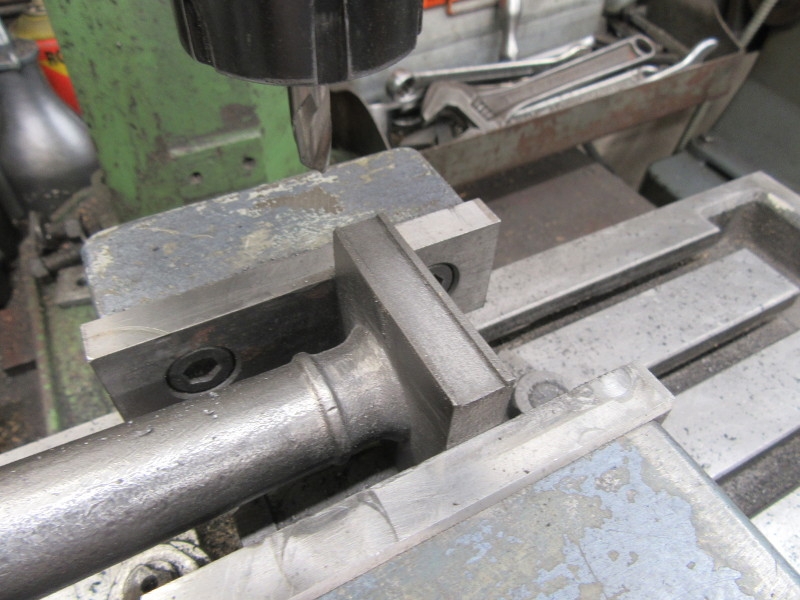

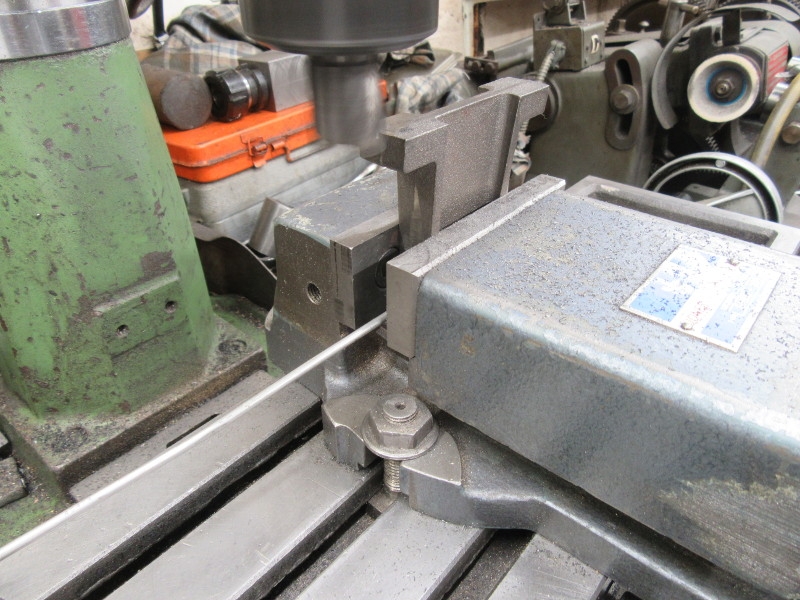

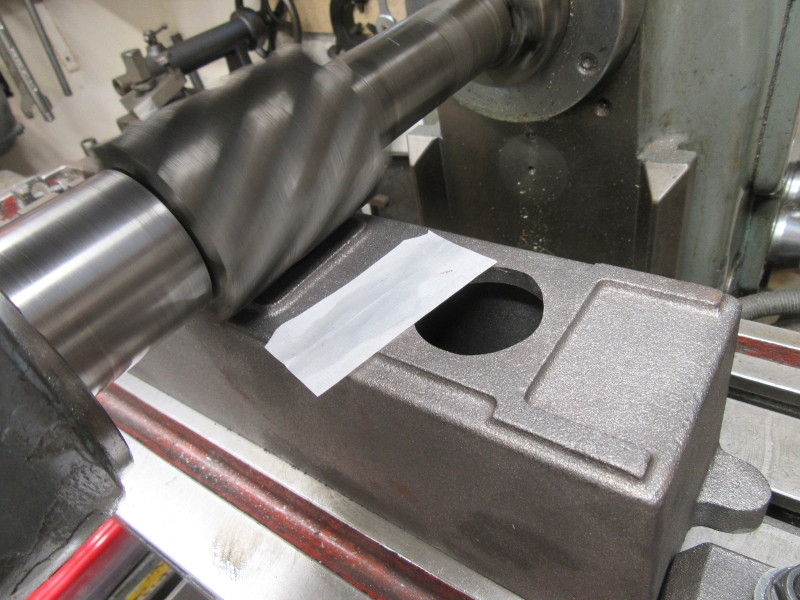

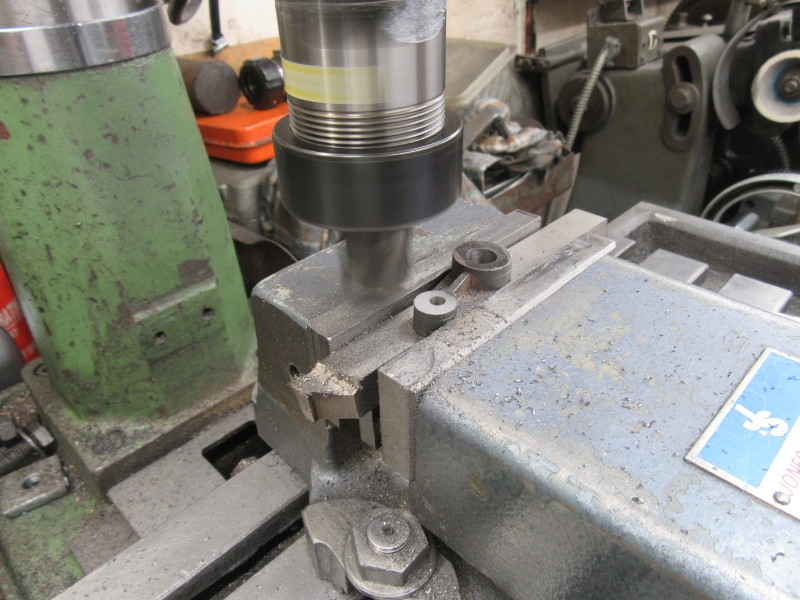

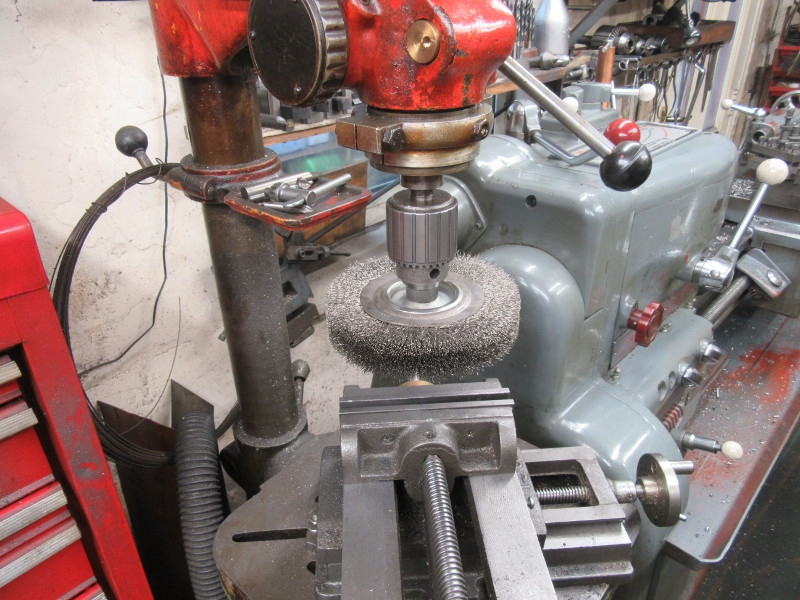

But first I wanted to check the tramming of my vise. I wasn't completely satisfied with the way I did it yesterday. The most accurate way is to actually mill an edge and measure the distance to the inside of the fixed jaw. So I fished out a piece of cast iron popped it under the cutter and took a cut across it then measured it. I was right, it was a couple of thou out so I put that right. We are under a thou now and that is good enough for me.

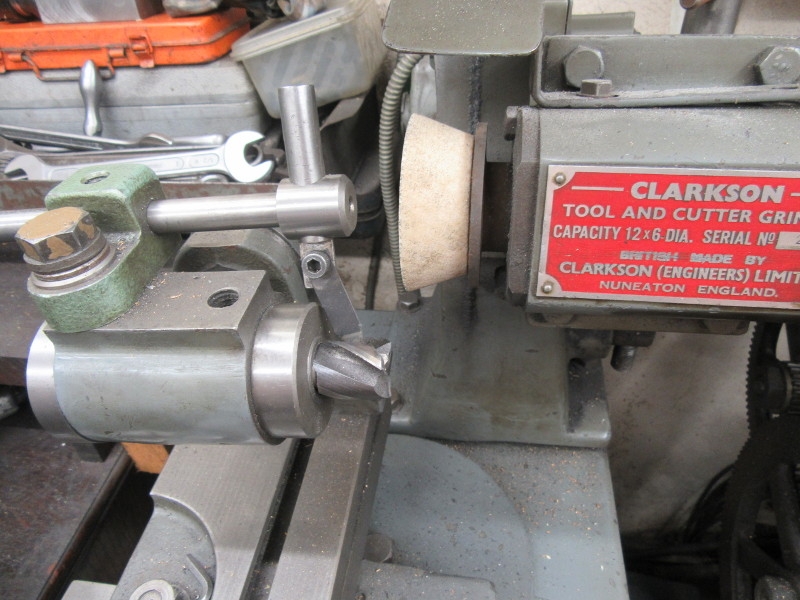

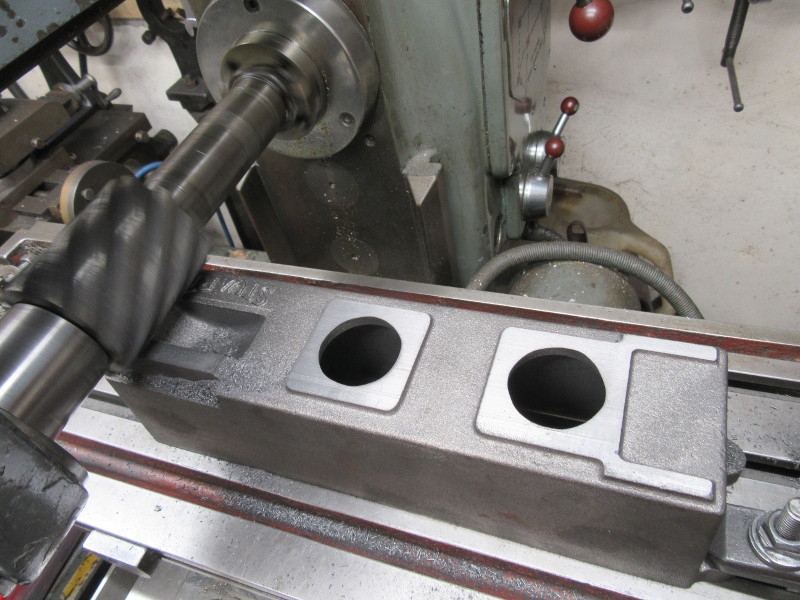

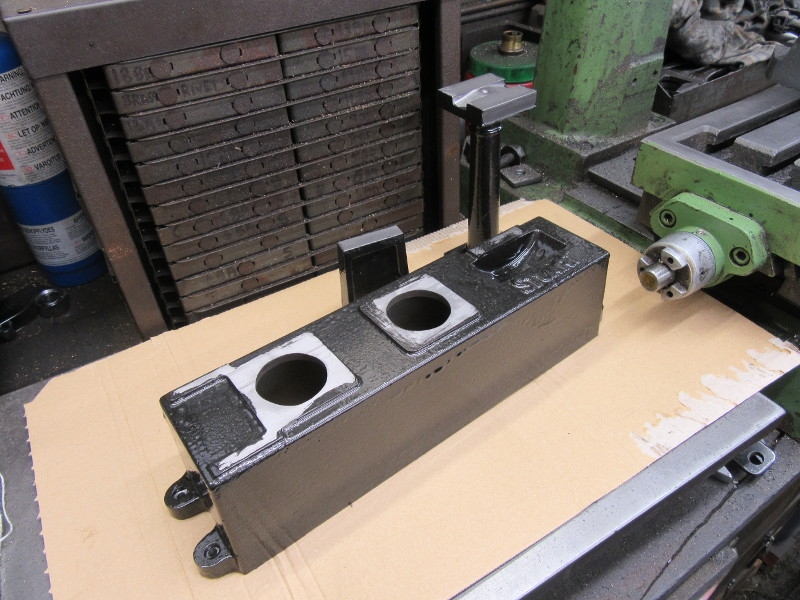

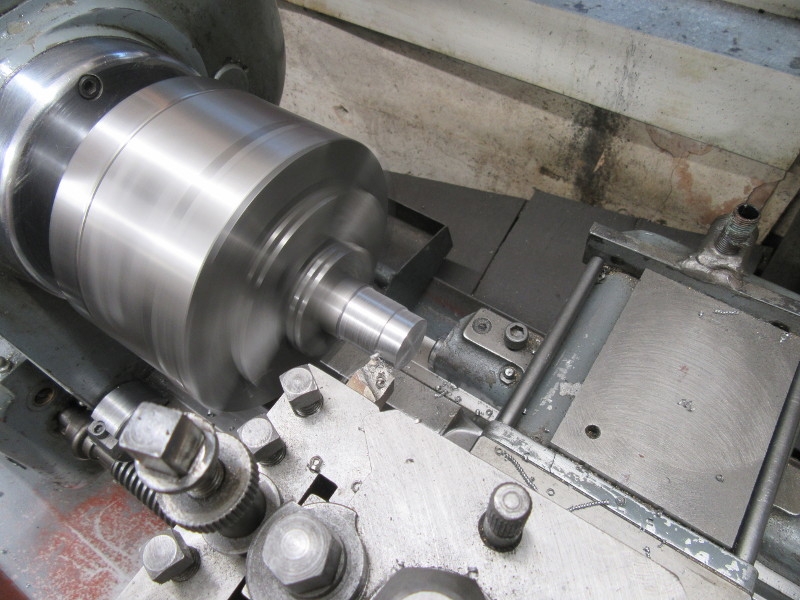

Next job was the overall length. I know from the last one I need as much metal in the head as possible so first job was to reduce the base to 1/6", funny figure I know but that's what it measures at.

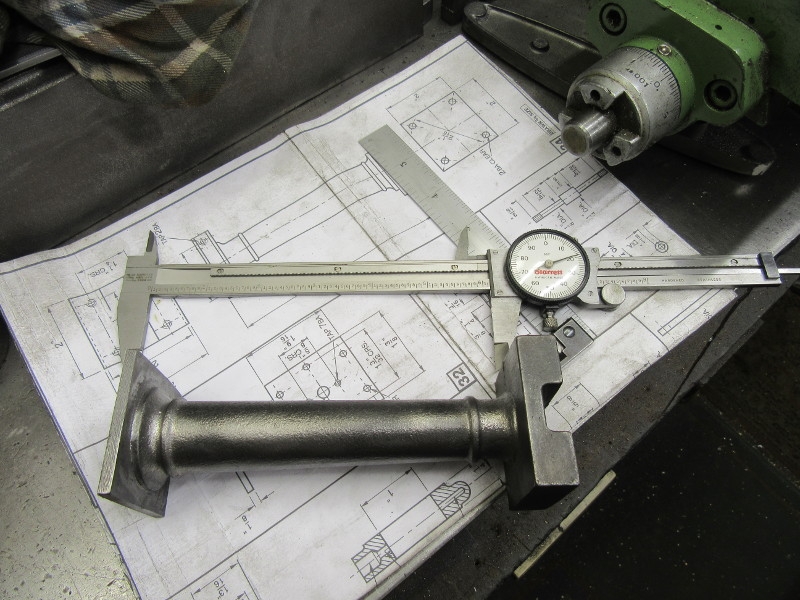

The drawing calls for 6" so I had to get the 9" dial calliper out that Mick gave me. Once I had the measurement I could work out the cut I needed and get set up and cutting.

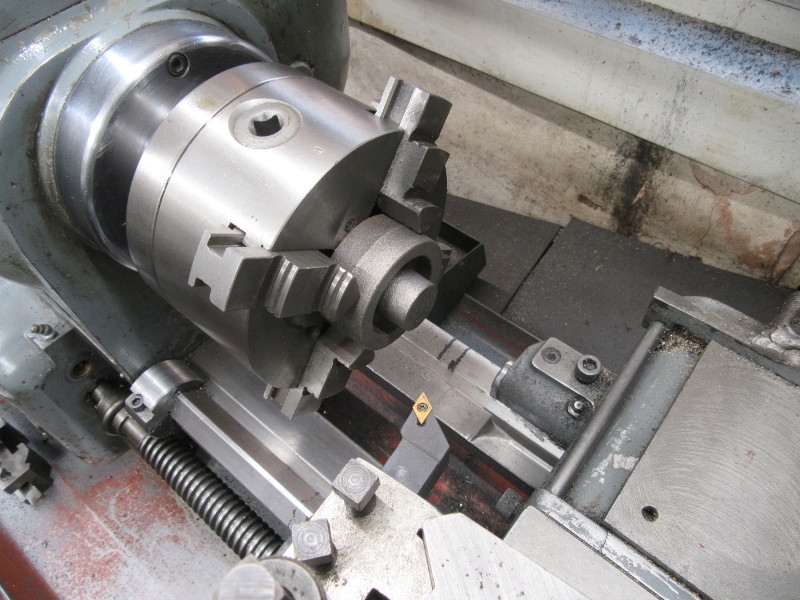

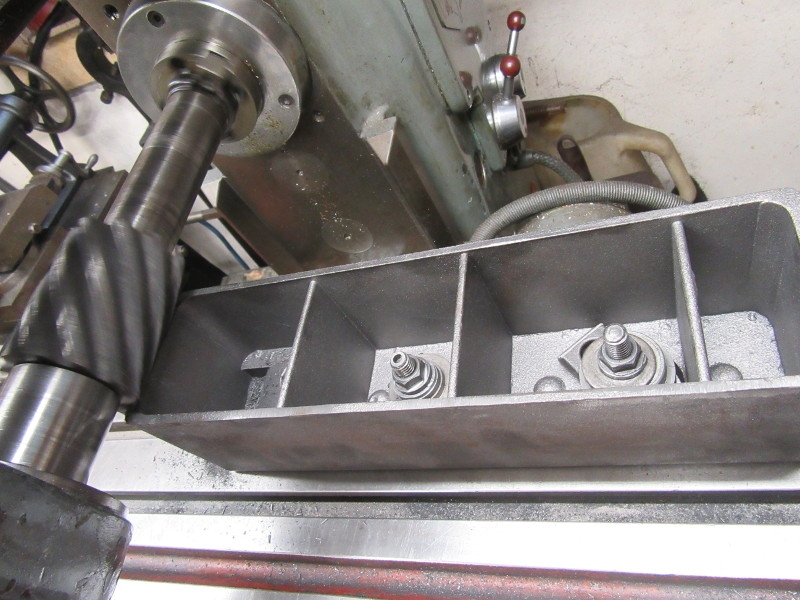

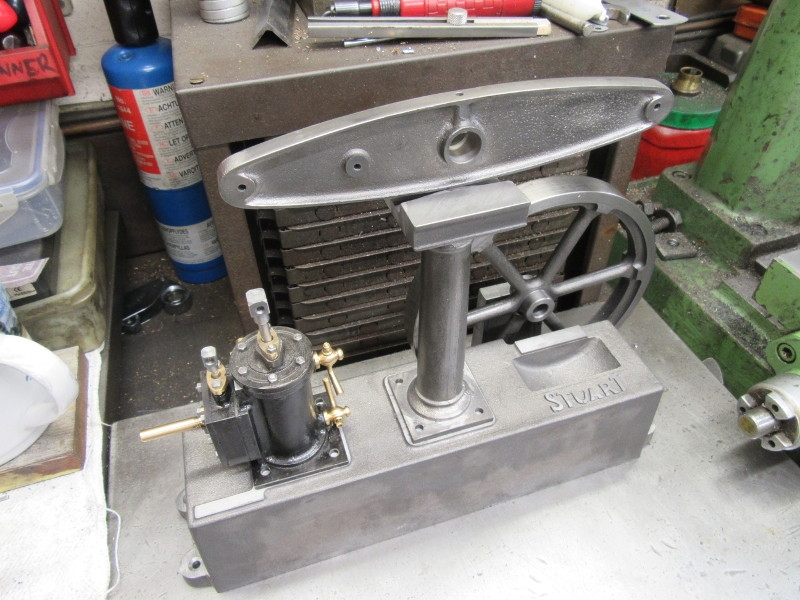

I couldn't get right into the centre so I had to get old fashioned and get a big rough file out. I ended up with a column that is exactly 6" long and has square ends. Next job is milling the sides of the head for the supporting bars for the parallel motion.

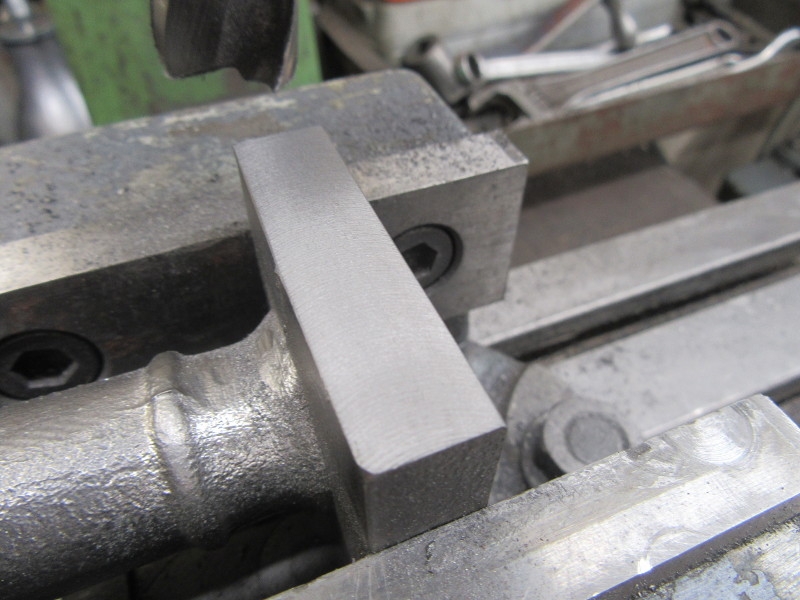

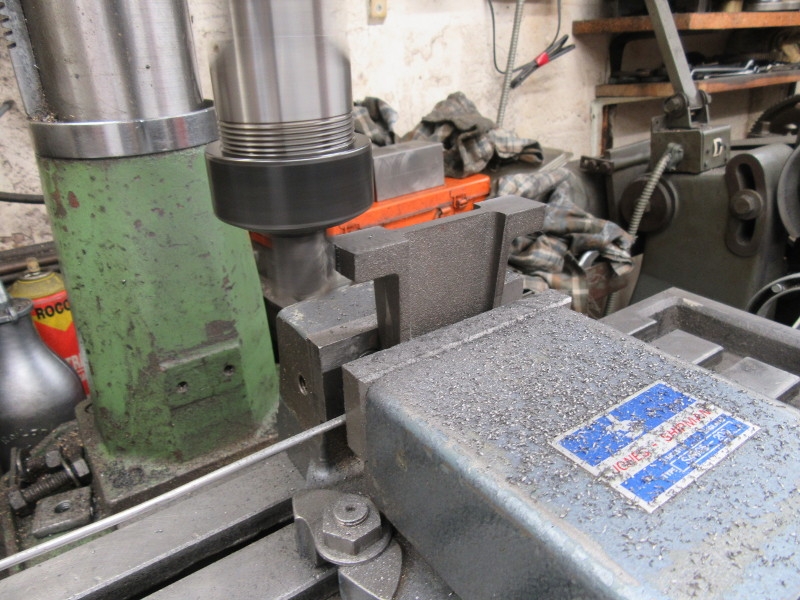

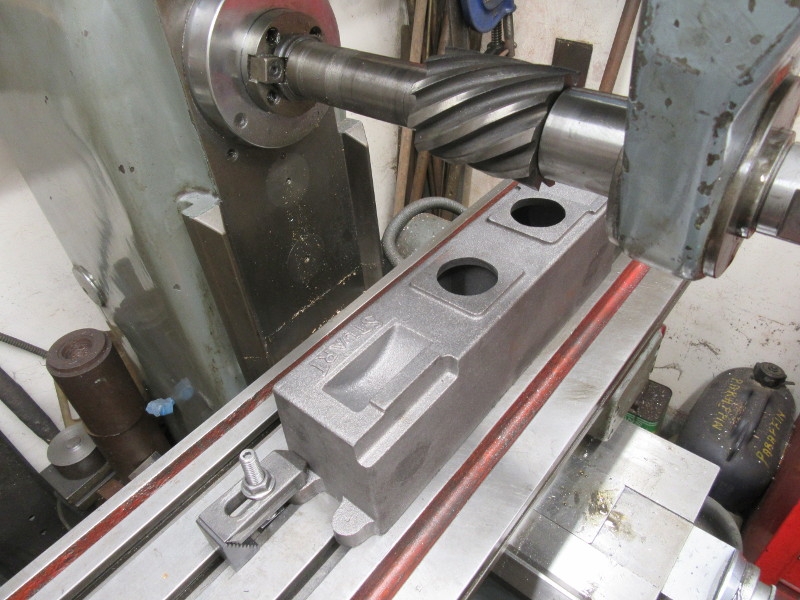

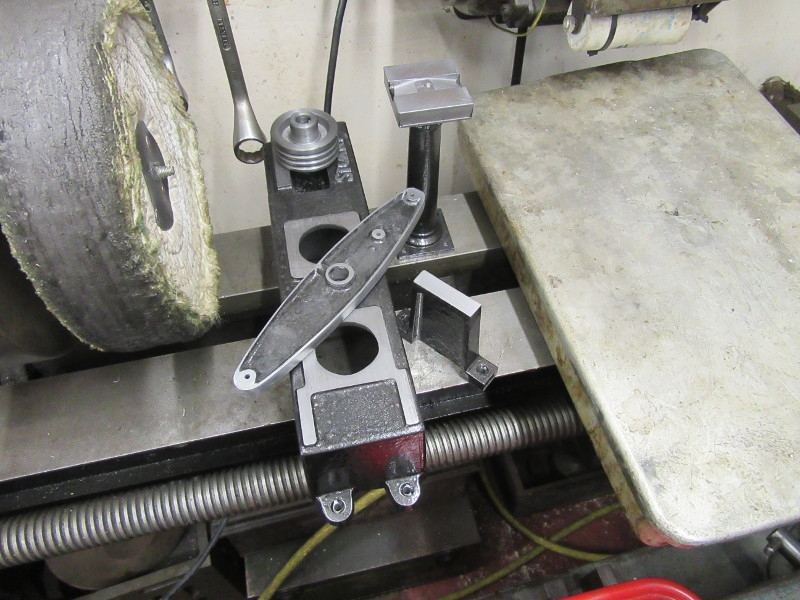

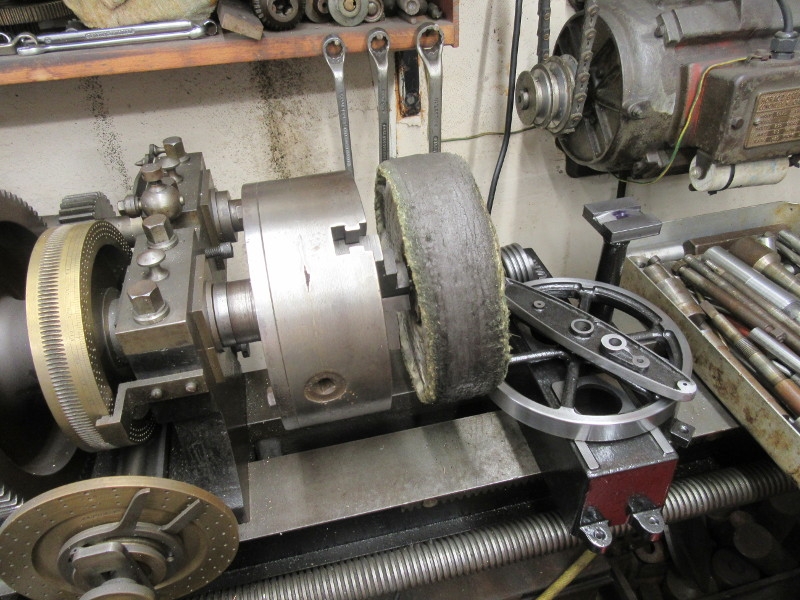

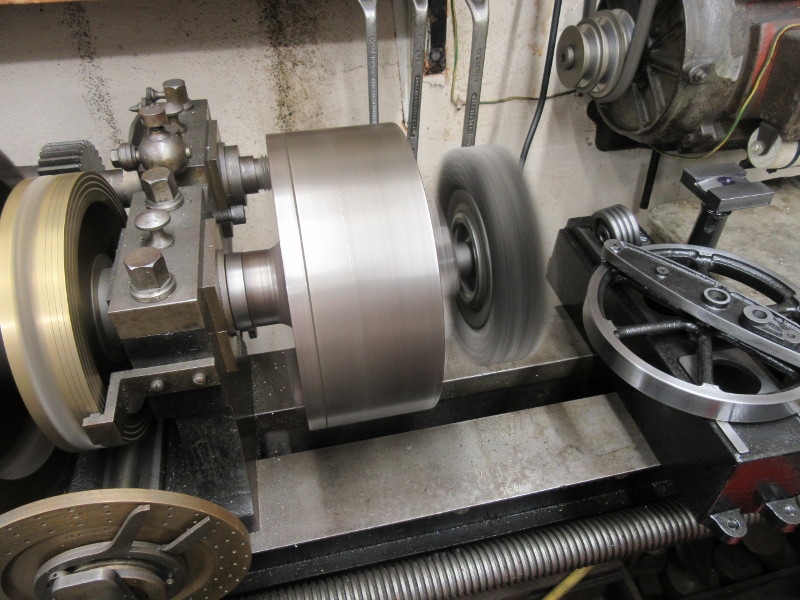

We need a good accurate stable set up under the cutter. It involves an adjustable parallel and some packing for the outside end. The last pic is knocking off time, we are ready to start cutting again.

Two hours careful work with plenty of checking, I think I have everything right so far!