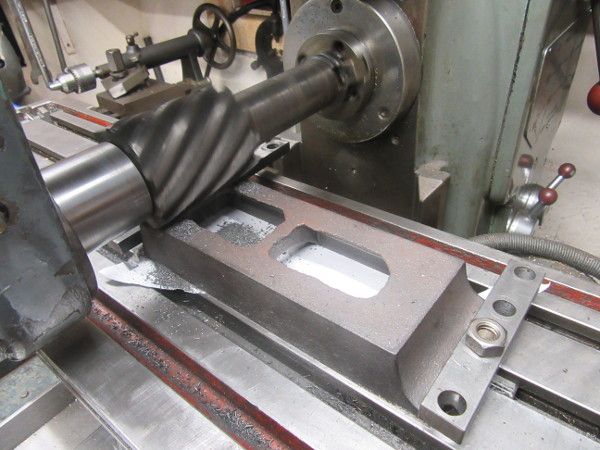

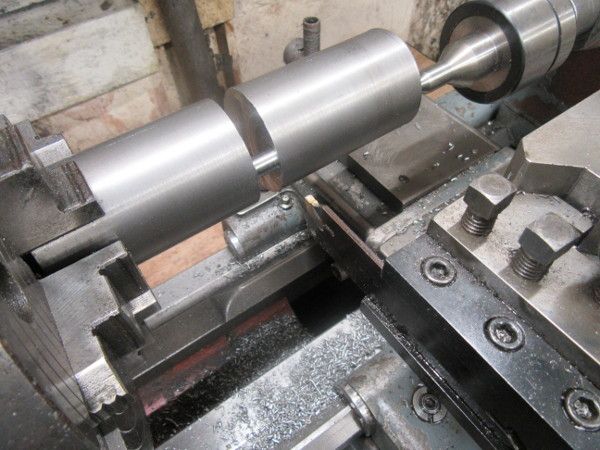

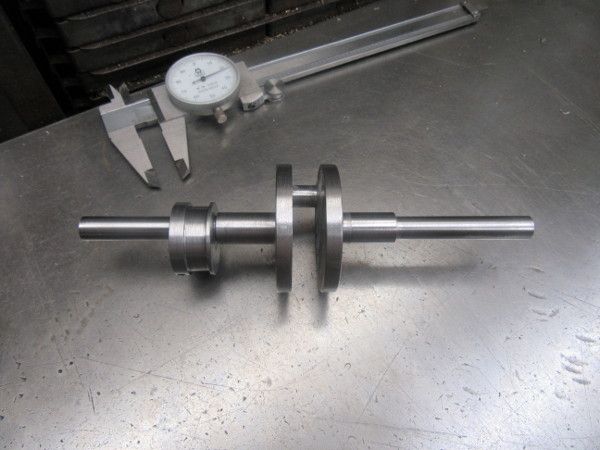

Once again, two pictures tell the story. I measured up and decided on the size of the stock. Then I went into the scrap box and picked two rusty candidates. Then I centred and cleaned both of them and cut one to size. The first pic shows the use of the steady rest to face the ends and get an accurate centre. The second is closing time, two pieces of clean stock, the front, shorter one is for the crankshaft, the larger one goes into stock cleaner than it came out! I cleaned up Mrs Harrison and cleaned the floor. I'm ready to oil the lathe and set up for crankshaft turning. A nice productive morning.

.

.