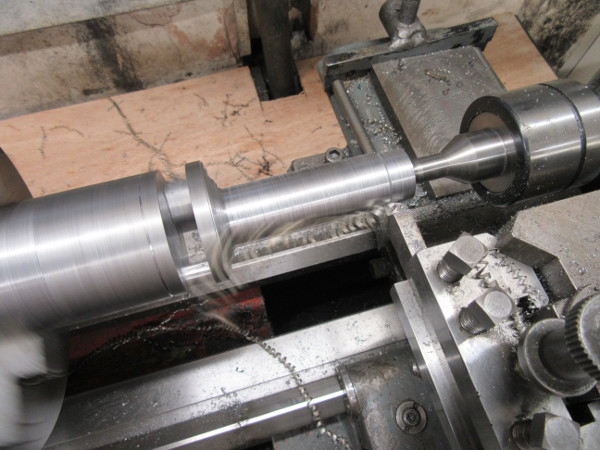

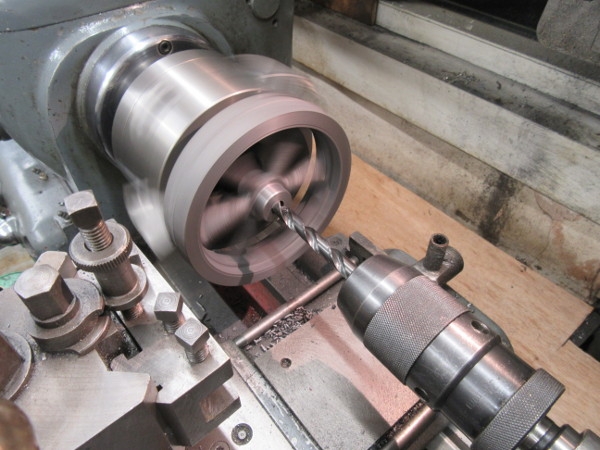

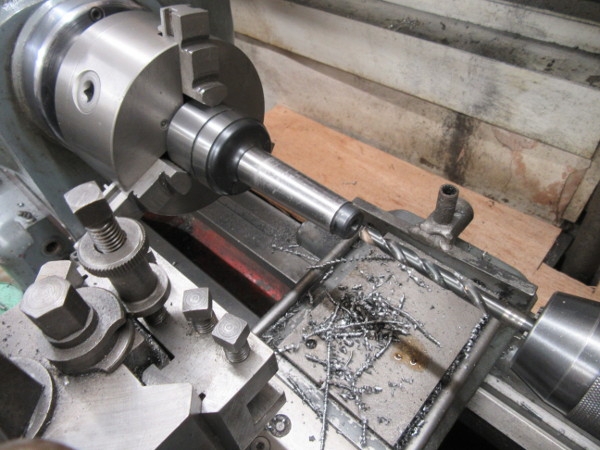

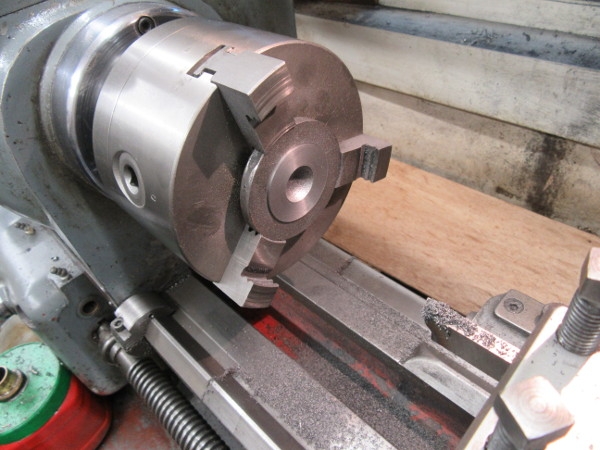

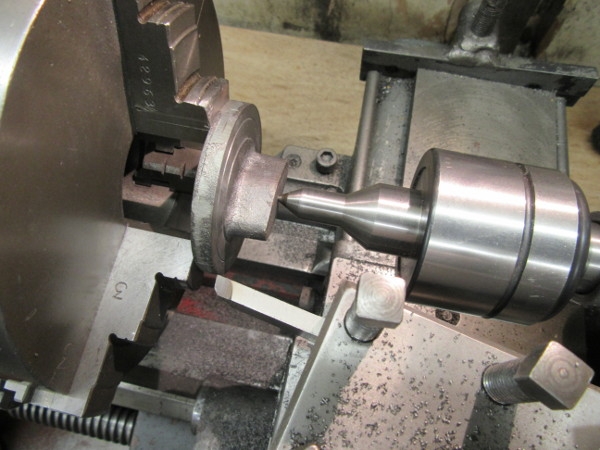

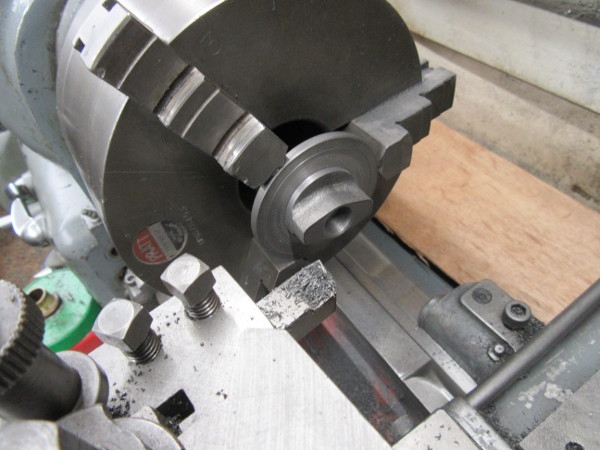

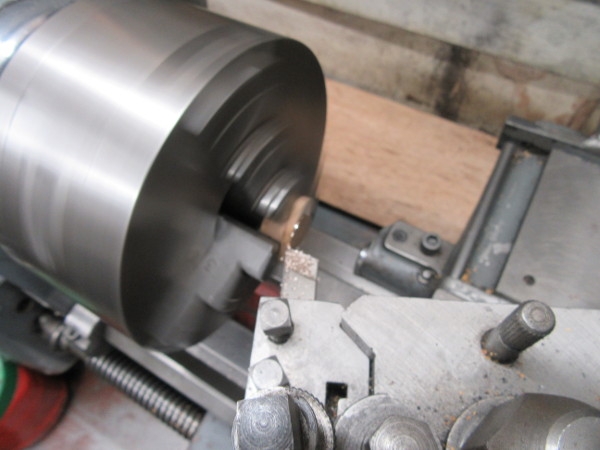

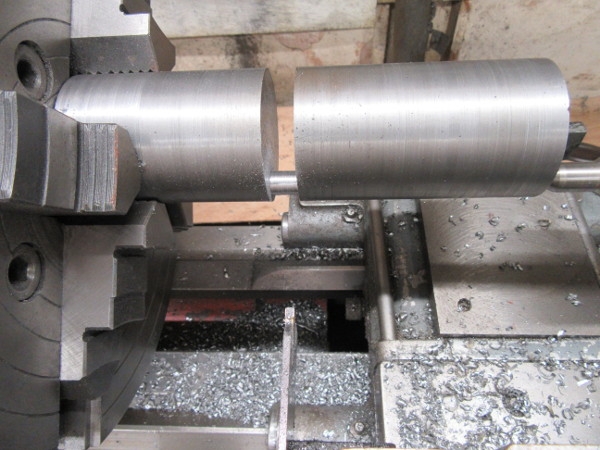

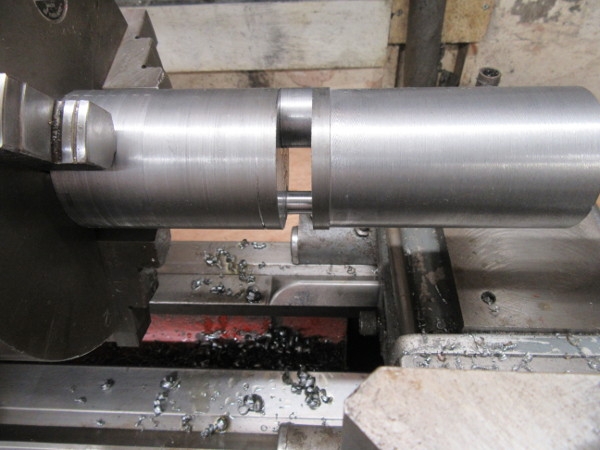

I considered using a different cutter but in the end carried on with the parting tool. You can see it has a quite ridiculous amount of stick out!

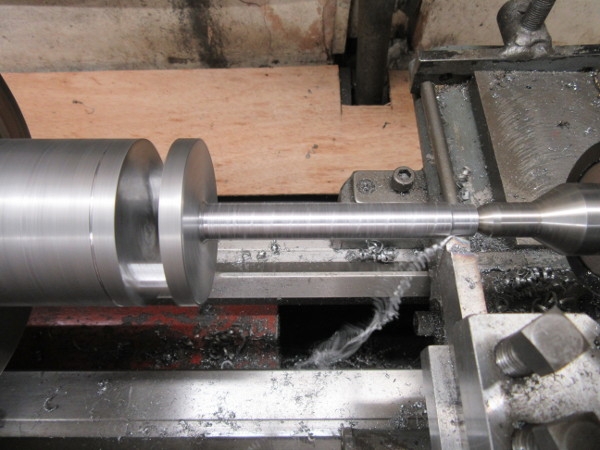

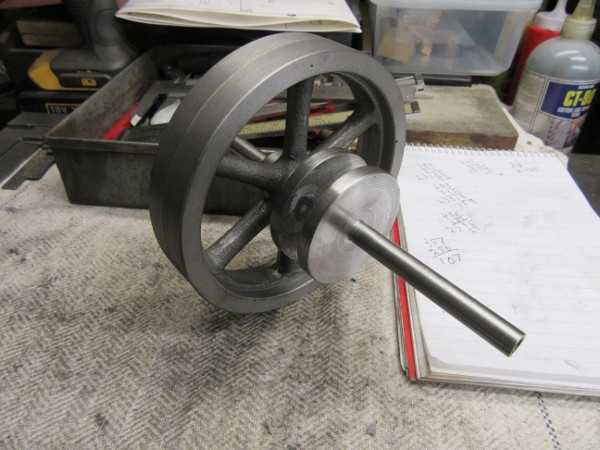

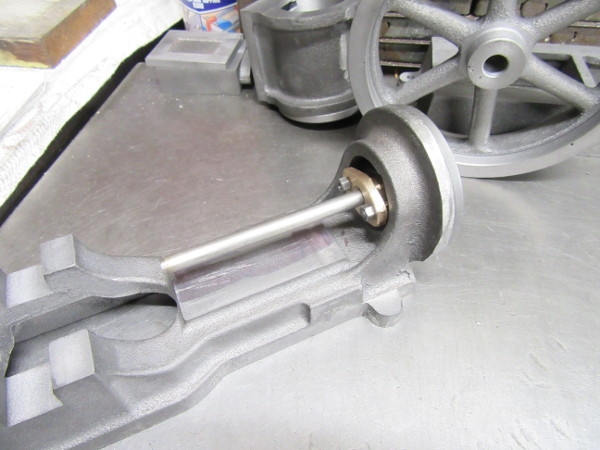

Another hour of very careful turning and I have a crank pin. I polished it with emery cloth. It's actually 10 thou over size but I had reached the limit of my stick out and so left it at that, no problem accommodating that in the con rod.

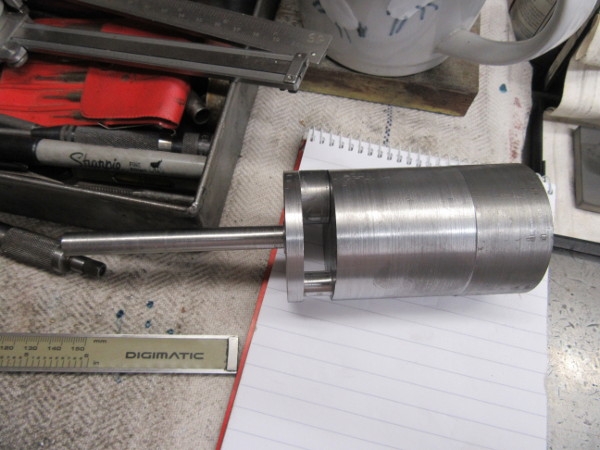

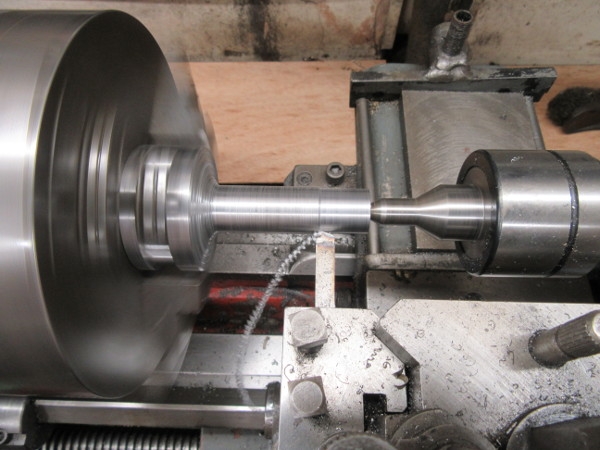

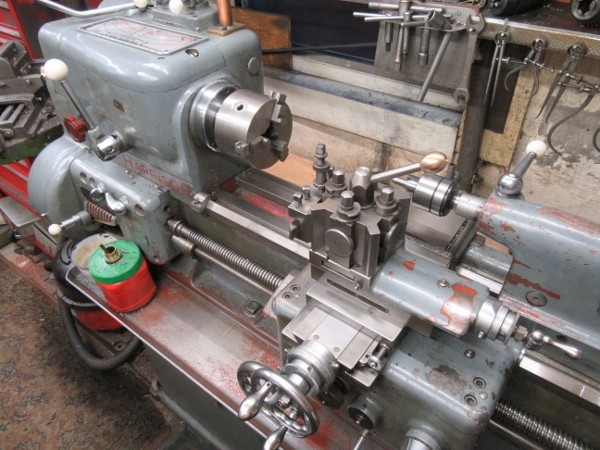

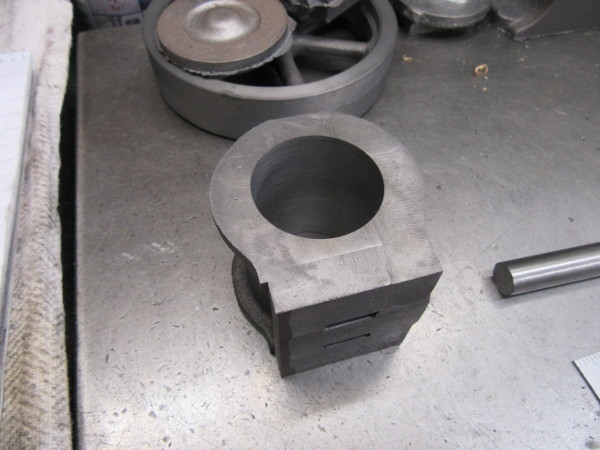

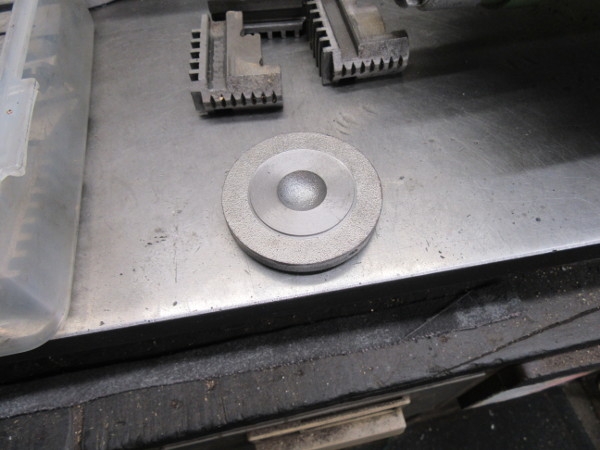

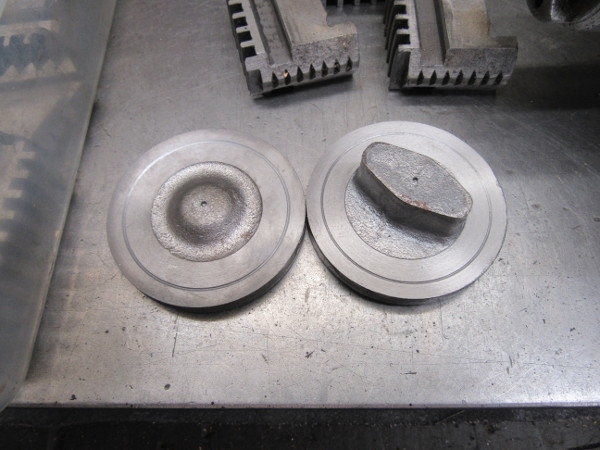

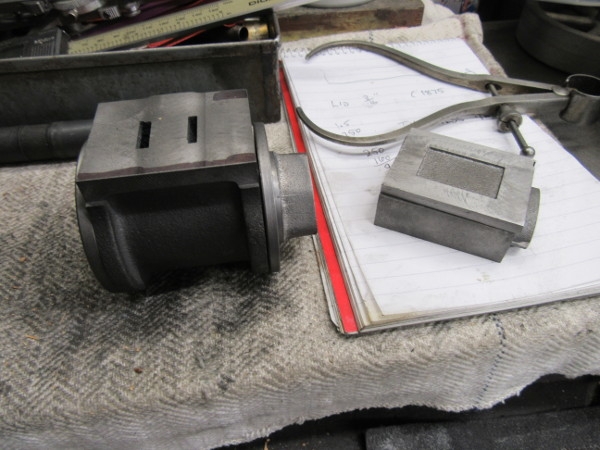

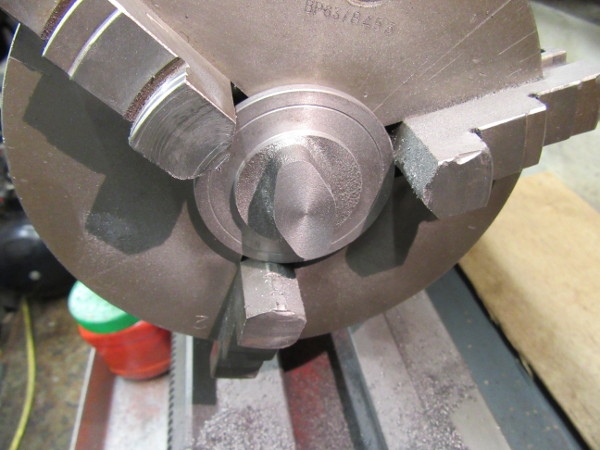

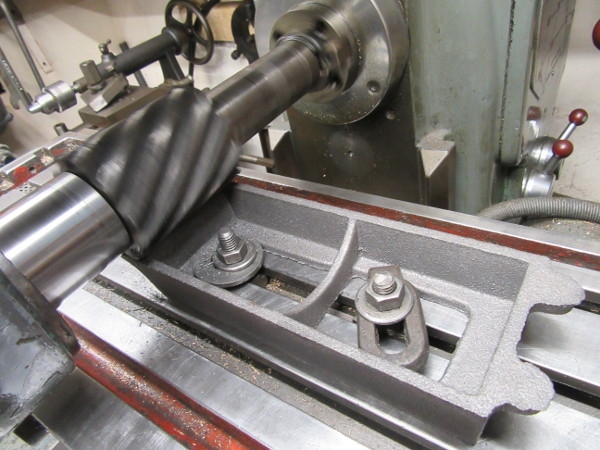

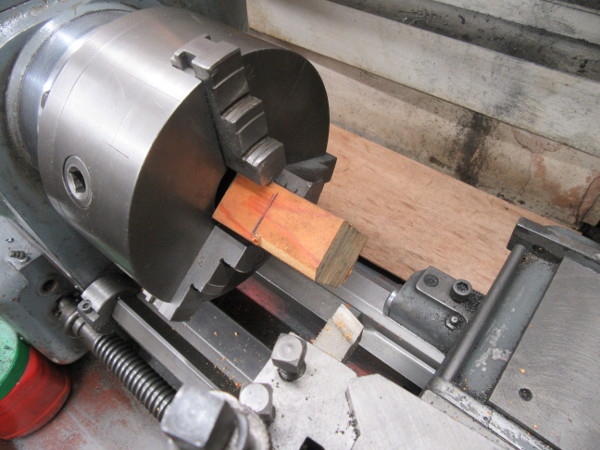

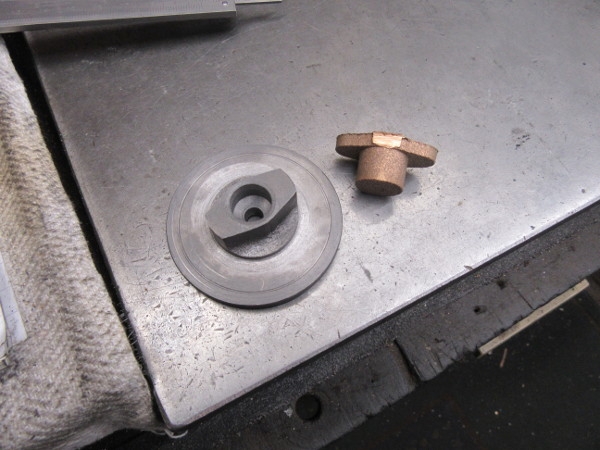

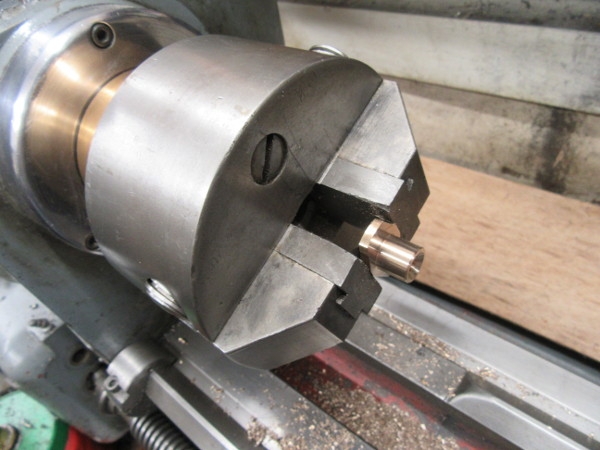

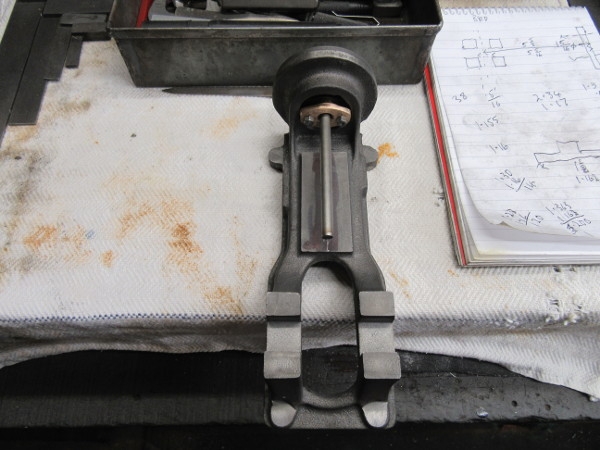

Closing time, I've put the big 3 jaw SC chuck on again, cleaned Mrs Harrison and marked the 1/4" flanks of the crankshaft webs and made a small slug which I have put in the gap in the shaft to take the pressure from the Centre. It's got a bit of superglue on it but didn't really need it. Tomorrow I can go muck-shifting again.