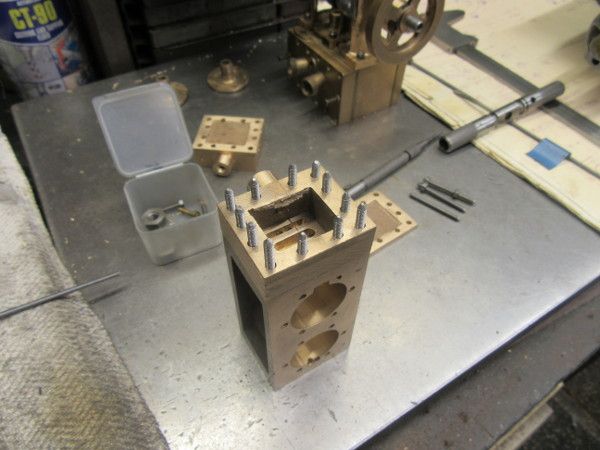

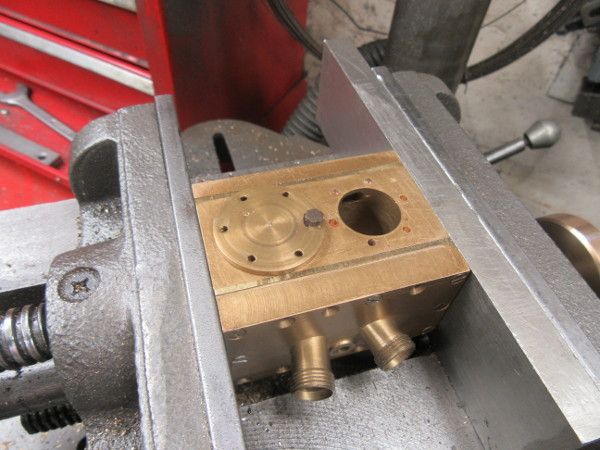

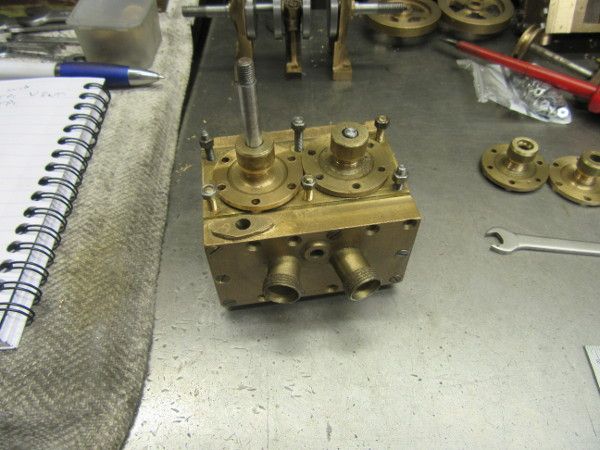

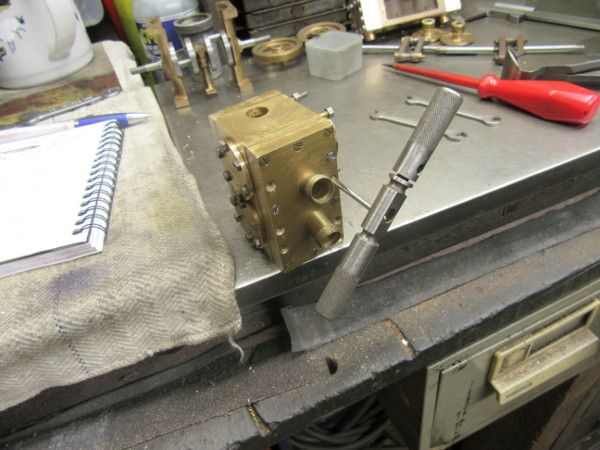

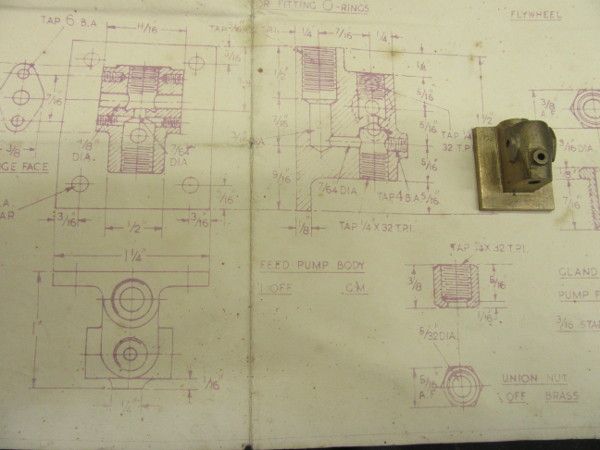

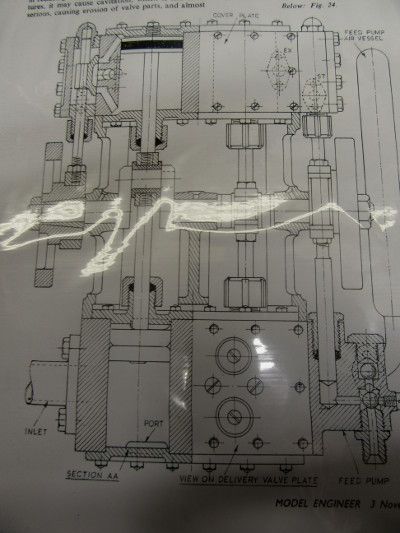

I started this morning by marking the stud positions I need by spotting the cylinder casting using a clearance drill in the steam chest holes as this is the most accurate way. Then I drilled and tapped 20 stud holes 6BA and that has taken up all the time I had in there. I think I have them right!