Page 14 of 97

Re: Shed Matters 3

Posted: 23 Apr 2019, 15:47

by Magnu420

Pm sent

Re: Shed Matters 3

Posted: 24 Apr 2019, 03:00

by Stanley

Re: Shed Matters 3

Posted: 24 Apr 2019, 09:18

by Stanley

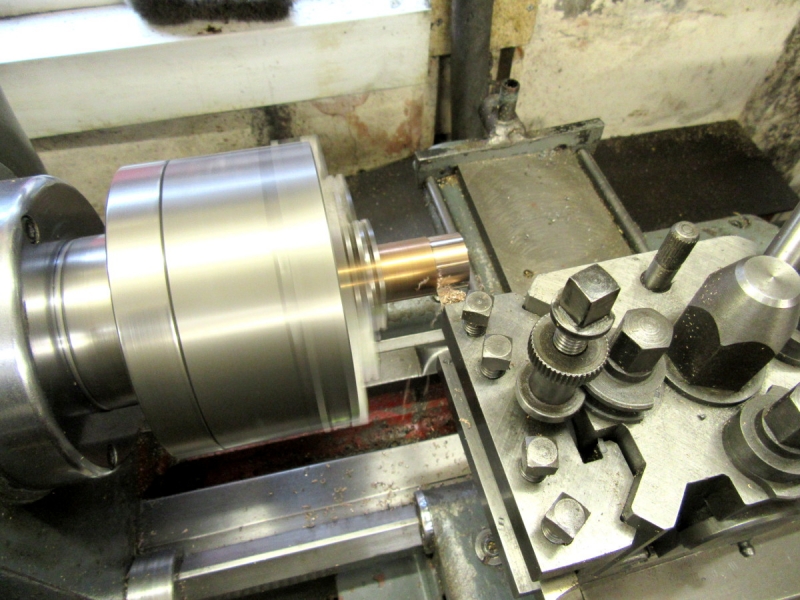

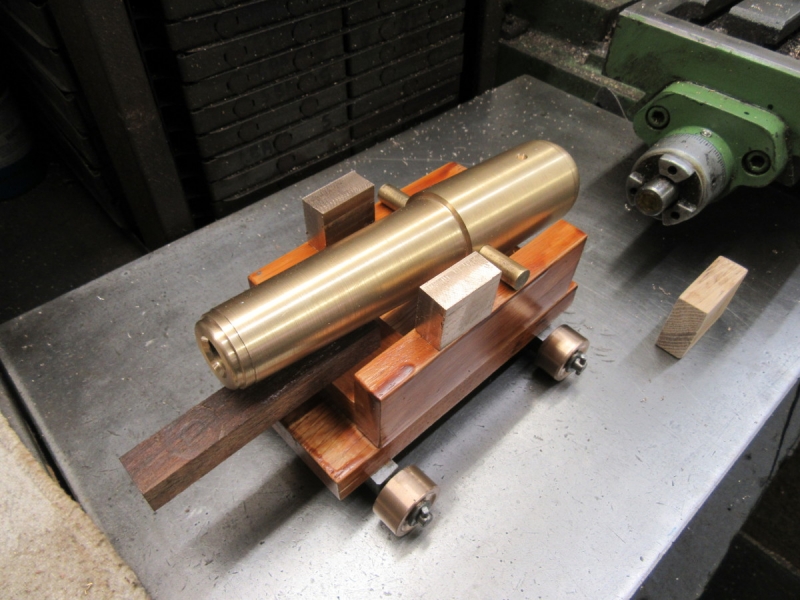

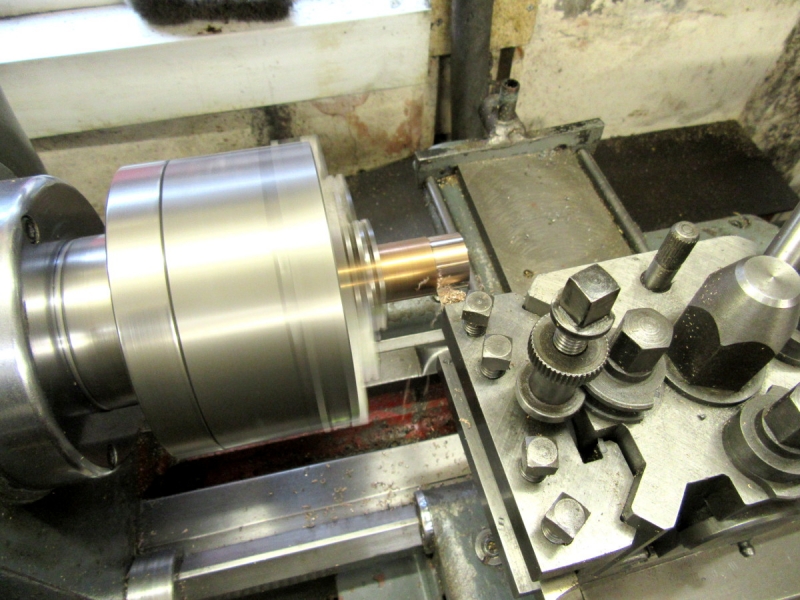

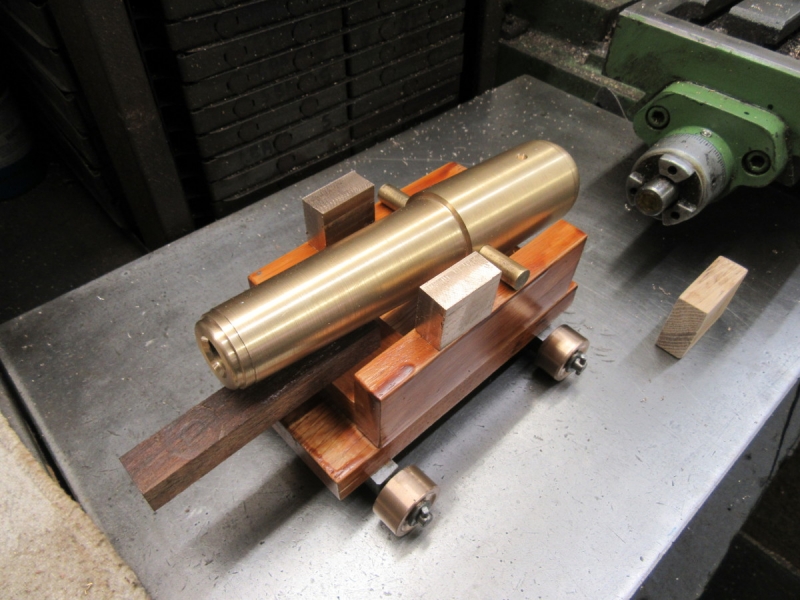

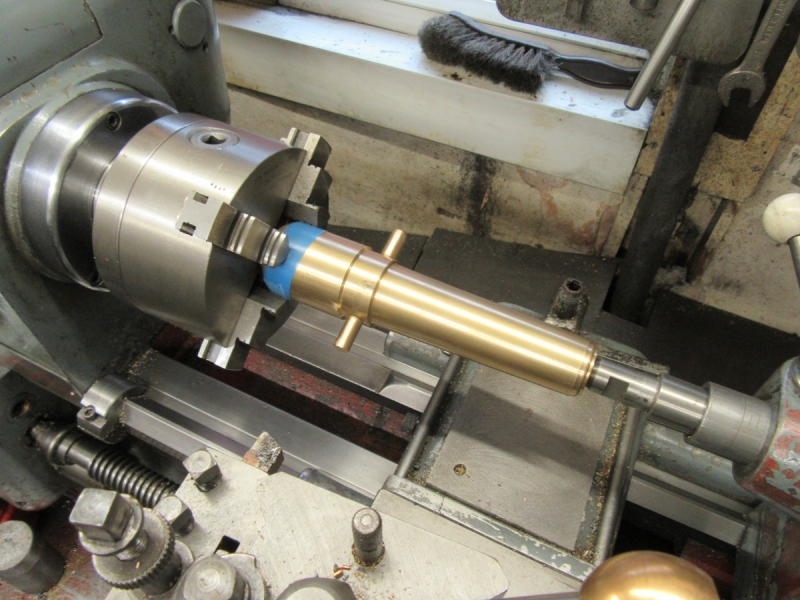

Life tried to interfere with the shed again but I fended it off. I want four wheels. A bit of measuring and I can get all of them out of this cast brass stock.

I haven't bored you with a straight turning job.

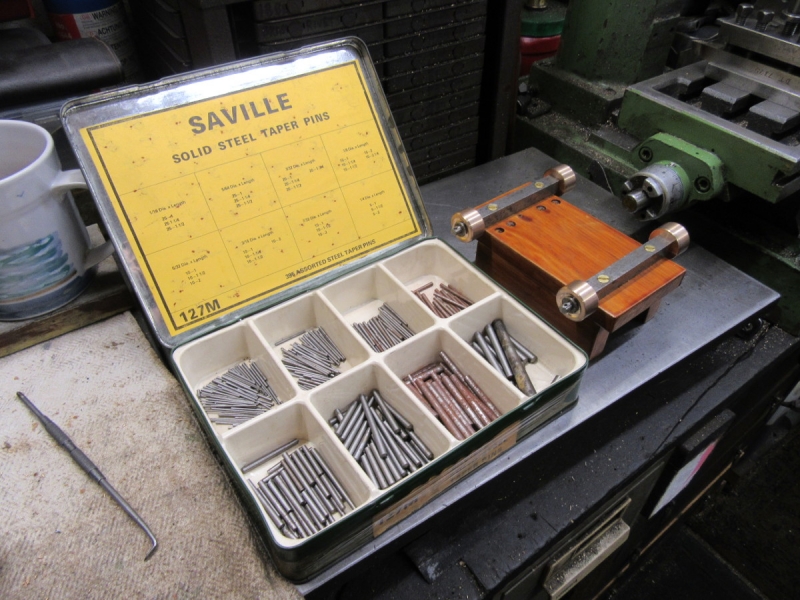

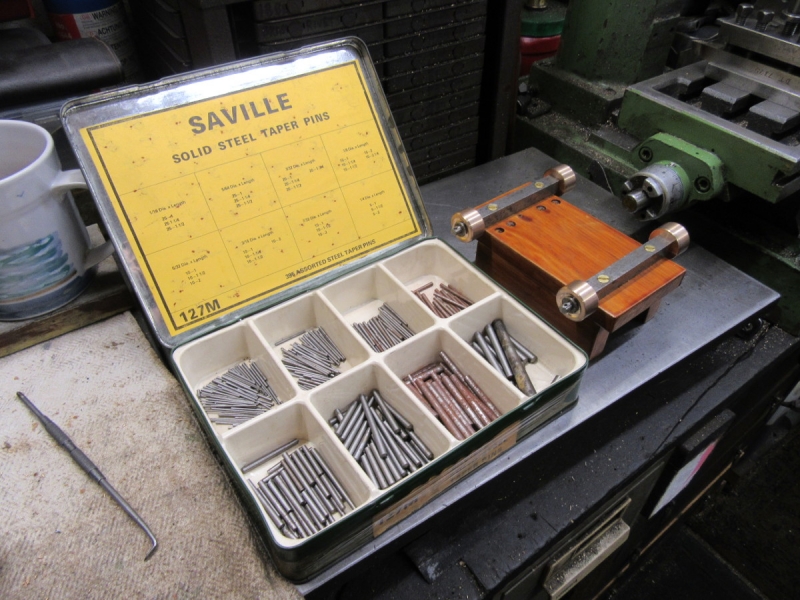

By closing time I had the washers drilled out and was ready to fit the taper pins that will act as cotters in the axles. No tree torn up but another little step forward.

Re: Shed Matters 3

Posted: 25 Apr 2019, 10:03

by Stanley

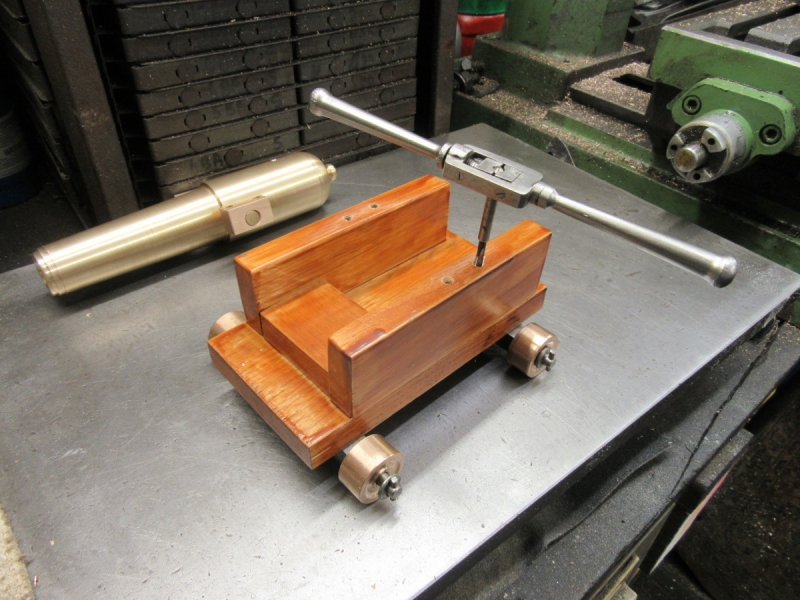

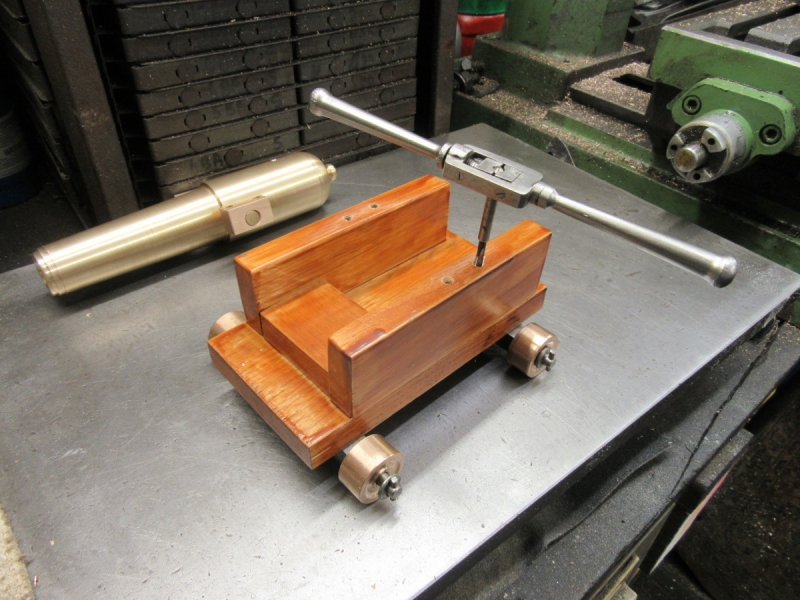

It didn't take long to Fit the cotters to the axles..... That's the wheels taken care of!

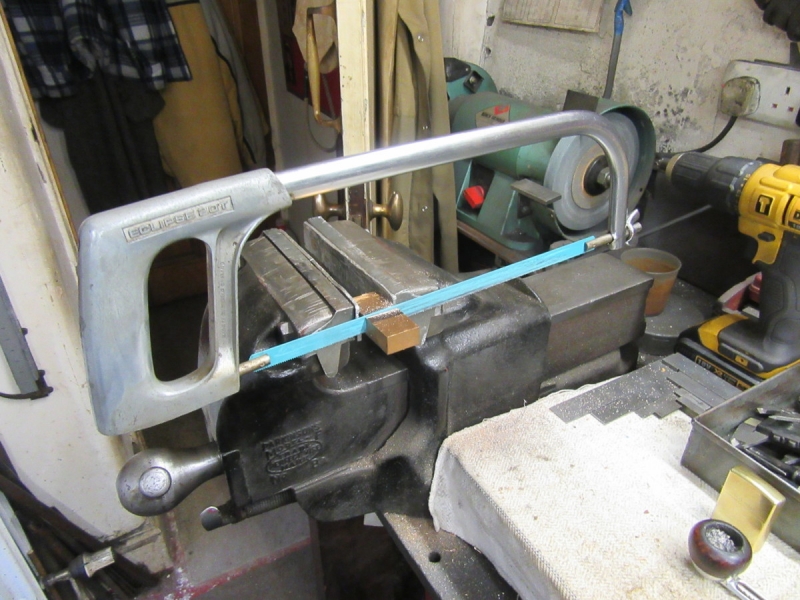

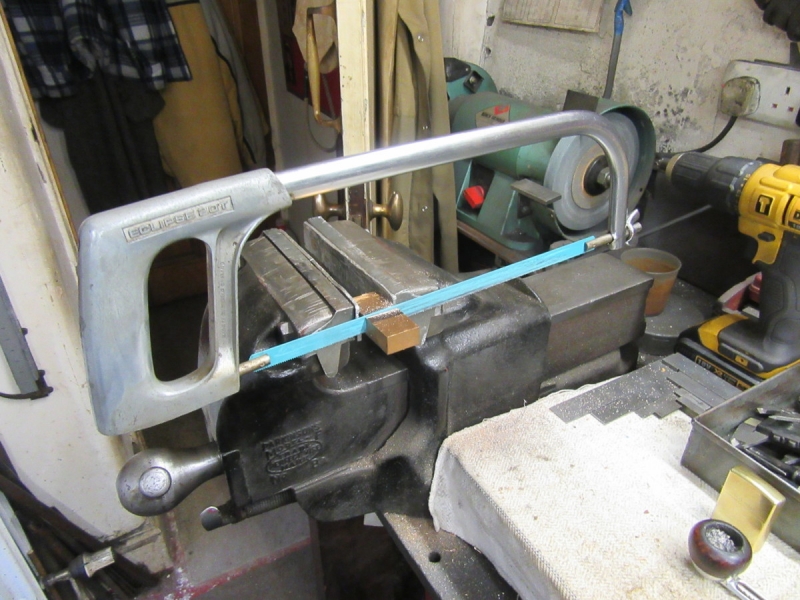

Next job is the trunnion mounts so I raided the brass ends box and found a piece I could split in two. Against my religion but I thought it would be quicker to use the hacksaw than change the cutter in the HM. Sharp blades make such a difference, especially on brass.

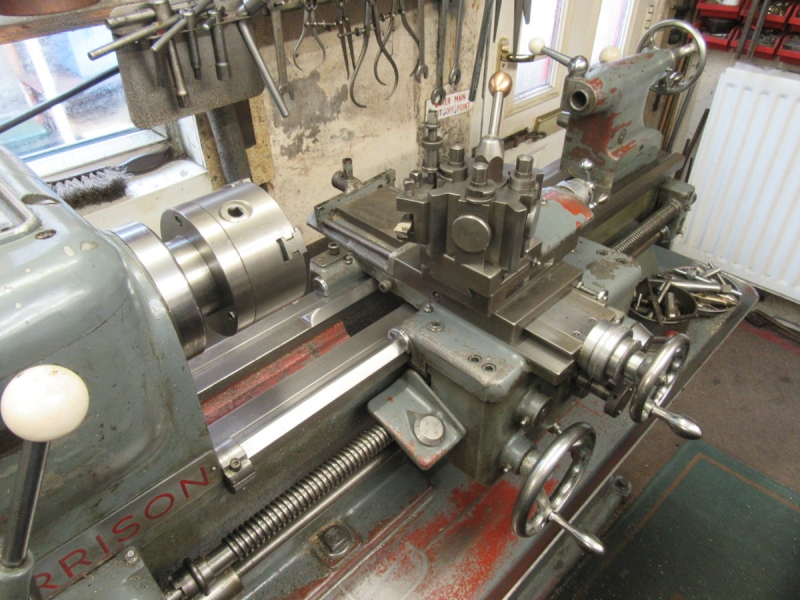

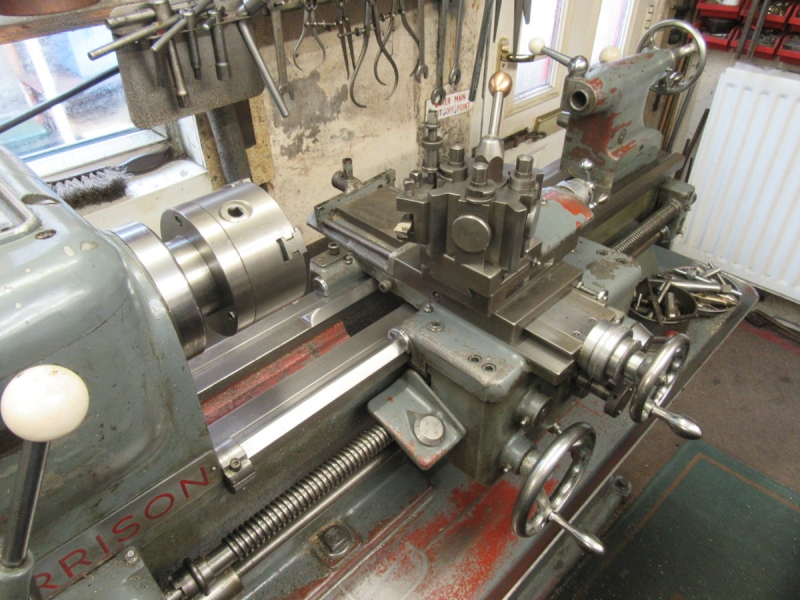

Before I went any further I cleaned Mrs Harrison up.... I work better if I have a tidy shed. Besides, I was expecting a visitor!

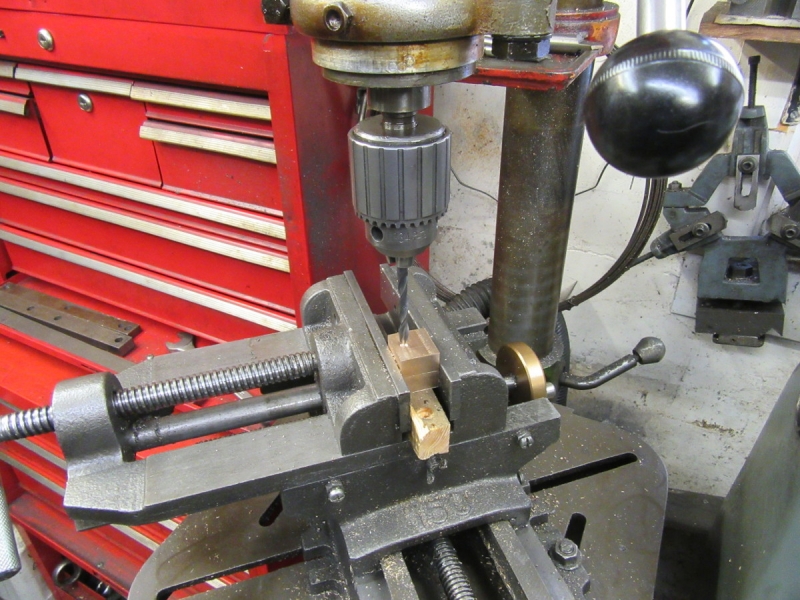

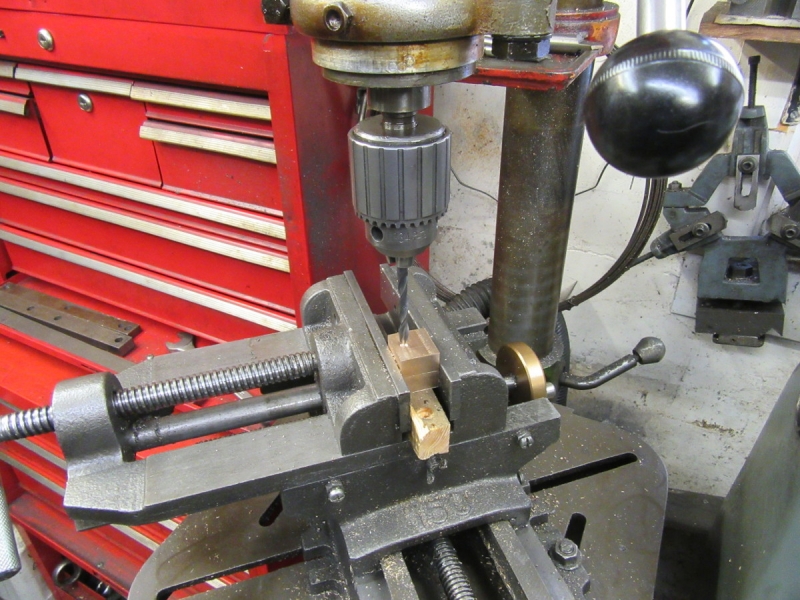

I needed to square the stock up and make sure both mounts were the same size so into the VM.

At knocking off time I am ready for some measuring and making the mounts into a good fit. That's the first job tomorrow.

I finished and took Jack for a pee and Dave turned up to take my jigsaw away.

Dave, here's a pic of the Adept No 2 mounted on the mill.

Re: Shed Matters 3

Posted: 27 Apr 2019, 13:26

by Magnu420

That looks good stanley but im afraid my wallet wont stretch that far or i would of took it of you ... i need to sort some work on my dads house first before i can buy toys again

Re: Shed Matters 3

Posted: 28 Apr 2019, 02:49

by Stanley

No worries Dave. Pass the word round your mates..... Thanks for the PM about the jigsaw. By-passing the bum speed controller will do, I can live with full speed all the time. I had an idea that was where the trouble was and almost bridged those two contacts with a link......

Re: Shed Matters 3

Posted: 28 Apr 2019, 08:42

by Stanley

Trunnion mounts today. I know I haven't got the design right yet so the best start is to drill the holes for the trunnions and go forward from there.

Then into the mill to get rid of the surplus stock. (More bloody brass chips! They get everywhere!)

If they look right they are almost certainly going to be right. These look a lot better now.

Then decide on the holding down bolts and mark for them. I also registered both blocks so that I had them right in regard to the muzzle.

Last blow before a walk, dinner and the Archers was to drill the 3/16" clearance holes for the holding down bolts. Next job is to make them look pretty.....

Re: Shed Matters 3

Posted: 29 Apr 2019, 09:03

by Stanley

Prettifying.... 20 minutes spent polishing and breaking edges.

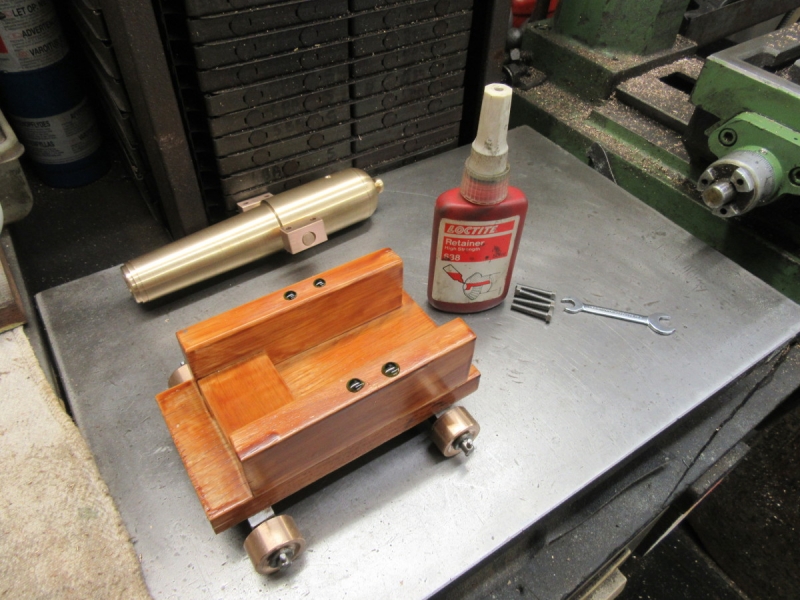

I transferred the holes to the carriage and drilled them out 3.8mm, .2mm less than the tapping size for 2BA in metal. Then tap the holes.

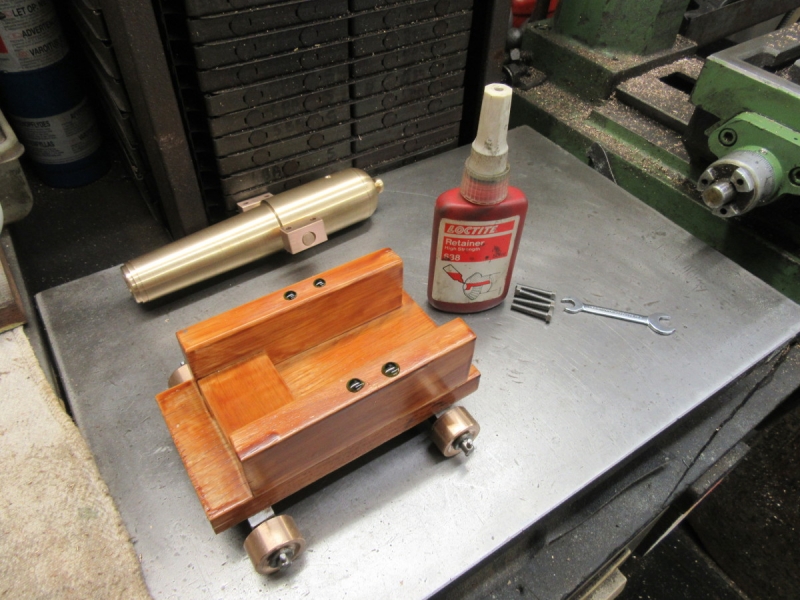

A drop of shaft grade Loctite in each tapping and we are ready for some assembly.

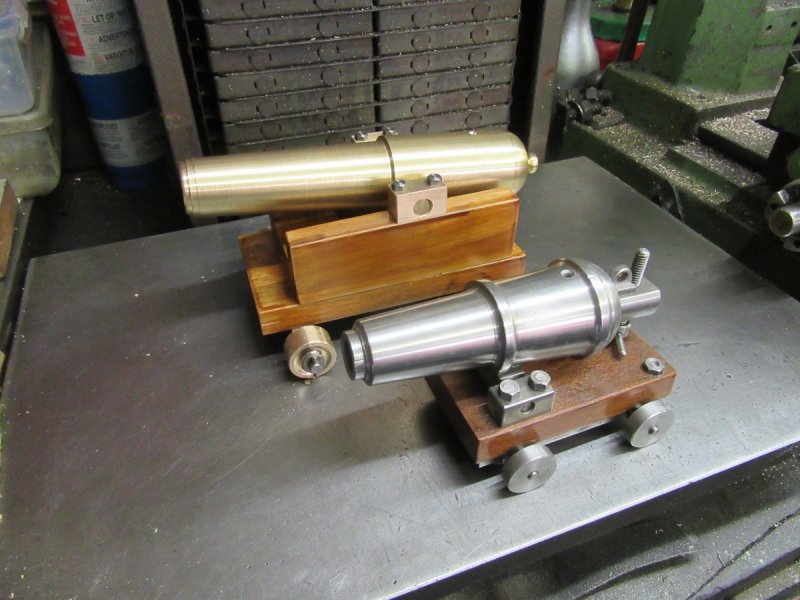

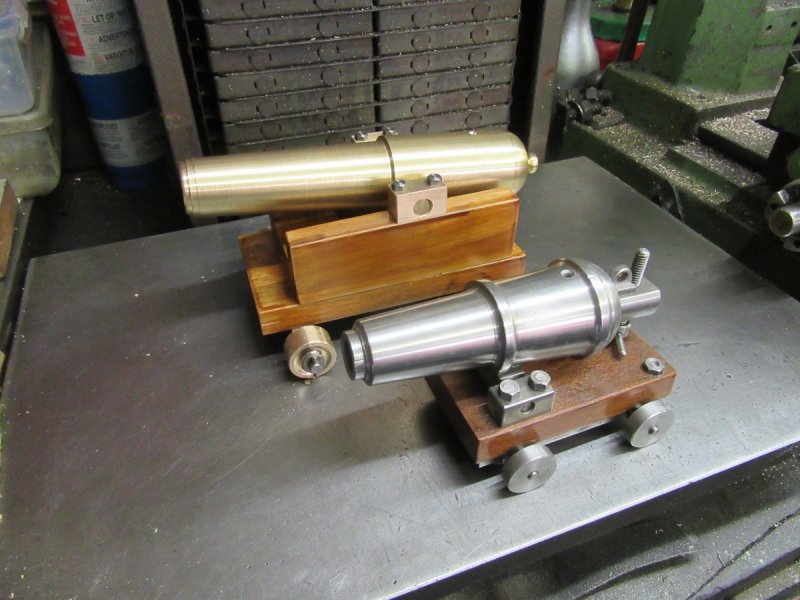

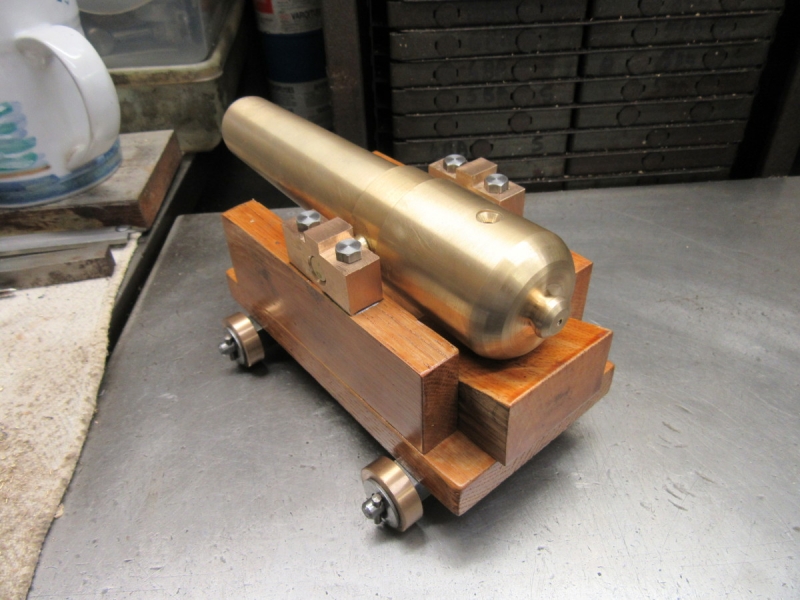

Knocking off time. We have a cannon on its carriage. In case you're wondering, the 2BA screws have a surprising hold in the wood, you can use this technique with confidence! The second pic is a comparison of the Carronade with the traditional cannon. Both to scale and both 18pdrs. You can see why the new compact cannon made at the Carron Ironworks was so popular. It was a short range weapon but most fighting was done at very short range and with a reduced charge the Carronade was so effective that it was nicknamed 'The Smasher'. Incidentally, this is where we get the expression 'smashing' from.

Now we need an elevating wedge......

Re: Shed Matters 3

Posted: 30 Apr 2019, 09:11

by Stanley

Today we are looking for an elevating wedge. I found a nice lump of oak in the wood bin, did some measuring and marking and got my Tenon saw out. The intention was to plane it to shape. This went p[ear shaped when I found that my plane needed some attention before it was fit to use so I sanded it to get it smooth and be a good fit.

Once I had the wedge to my satisfaction I had a look in the form tools for a cutter and found a stub of brass that will do for a knob.

I got the form tool wrong and my knob broke off so I made the knob the old fashioned way with a file. A hole in the wedge and a drop of Loctite and we are ready for some finishing tomorrow....

Re: Shed Matters 3

Posted: 01 May 2019, 06:32

by Stanley

This tells you everything you need to know about this morning's shed. I've oiled the wedge and declared this cannon finished. Now I have to get down to writing some articles for the paper..... I shall return!

Re: Shed Matters 3

Posted: 01 May 2019, 14:42

by Big Kev

Stanley wrote: ↑19 Mar 2019, 08:54

In the shed for an hour. First thing was a clean up all round including vacuuming the carpet!

Then I put the cannon in the lathe and gave it a spin while I cleaned it up a bit. Then a bit of fitting and adjusting. I have put some Loctite in the bolt holes and on the trunnions so I have got rid of the nod caused by the imbalance.

Here's where I got to. I have a couple of embellishments in mind and will think about them but essentially it's finished.....

Youngest grandson (nearly 5) has taken a shine to the cannon. One of the first things he does, before he's even got his coat off, is to lay down on the floor and look at it.

Re: Shed Matters 3

Posted: 01 May 2019, 14:52

by PanBiker

Get some black powder and ball bearings, that would really grab his attention.

Re: Shed Matters 3

Posted: 01 May 2019, 17:30

by Big Kev

Re: Shed Matters 3

Posted: 02 May 2019, 02:40

by Stanley

1/2" ball and 1/4 teaspoon of powder could do it.....

Re: Shed Matters 3

Posted: 03 May 2019, 16:31

by Big Kev

Stanley, you don't happen to have one of these in your box of tricks? It's a wiper arm puller

20190503_172951.jpg

Re: Shed Matters 3

Posted: 03 May 2019, 23:41

by Whyperion

Stanley wrote: ↑02 May 2019, 02:40

1/2" ball and 1/4 teaspoon of powder could do it.....

any chance of it becoming the most expensive pea-shooter of all time ?

Re: Shed Matters 3

Posted: 04 May 2019, 02:41

by Stanley

Kev, no but I have a track rod end puller which might do the trick for you...... Same principle but heavier. Worth a try?

Re: Shed Matters 3

Posted: 04 May 2019, 06:45

by Big Kev

I'll give it a go, thank you. I'll give it a go.

Re: Shed Matters 3

Posted: 04 May 2019, 13:52

by plaques

Kev Would a clamp like this be of use. Slightly larger than the one you have shown.

P5040127A.jpg

Re: Shed Matters 3

Posted: 04 May 2019, 18:05

by Big Kev

I don't think the shaft will be long enough but thanks for the offer.

I need to get the wiper arm off of the rear of my car, the motor has packed up.

Re: Shed Matters 3

Posted: 05 May 2019, 02:56

by Stanley

You're welcome to try the Puller. Alternatively, design a clamp/puller and I'll knock one up for you.....

Re: Shed Matters 3

Posted: 05 May 2019, 03:36

by chinatyke

Big Kev wrote: ↑04 May 2019, 18:05

I don't think the shaft will be long enough but thanks for the offer.

I need to get the wiper arm off of the rear of my car, the motor has packed up.

Unscrew the shaft on Plaques clamp and replace it with threaded bar? I'm sure Stanley will have something suitable in his treasures.

Re: Shed Matters 3

Posted: 05 May 2019, 05:04

by Stanley

Kev will decide, I will do anything he wants.....

Re: Shed Matters 3

Posted: 08 May 2019, 05:32

by Stanley

No actual work in the shed but a significant delivery. I have been threatening to get away from expensive cans of WD 40 for years. It is such a useful product, and at last I have done it!

Re: Shed Matters 3

Posted: 08 May 2019, 05:48

by Big Kev

Will you be up and about at 2:30 today?