SHED MATTERS. MARINE ENGINES.

- PanBiker

- Site Administrator

- Posts: 16447

- Joined: 23 Jan 2012, 13:07

- Location: Barnoldswick - In the West Riding of Yorkshire, always was, always will be.

Re: SHED MATTERS. MARINE ENGINES.

Nice job Mick, to say you were hampered somewhat with the "one off" you made a damn good job of it.

Ian

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

You're a better welder than I am! Think seriously about putting a separate 60amp cooker supply into the shed from the meter. Makes things a lot easier when you're welding....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: SHED MATTERS. MARINE ENGINES.

Hi All , just a couple of photos of the finished rail fitted in its final position , it seems to match in ok and all fitted first time so everyone is happy .

I still have two brackets to make that will bolt onto the rails that are used for storing some wood batons , more alloy welding , so I will try to get better photos of the process next time.

Thanks Panbiker and Stanley , I sort of have a seperate supply Stanley for the welder but its the breaker that supplies the garge in the house main board that is the weak link , its overhead supply here so I cant really push it more as the main fuse in is smaller due to the overhead situation, just one of them things really , its ok up until thick stuff , say 10mm which I hardly ever do anyway.

Cheers Mick.

I still have two brackets to make that will bolt onto the rails that are used for storing some wood batons , more alloy welding , so I will try to get better photos of the process next time.

Thanks Panbiker and Stanley , I sort of have a seperate supply Stanley for the welder but its the breaker that supplies the garge in the house main board that is the weak link , its overhead supply here so I cant really push it more as the main fuse in is smaller due to the overhead situation, just one of them things really , its ok up until thick stuff , say 10mm which I hardly ever do anyway.

Cheers Mick.

Re: SHED MATTERS. MARINE ENGINES.

Good Evening All , Well at long last I have got a bit more done to the Harrison. I have done various things without photos , like diamond filing the burs off every single cog tooth in the whole gearbox ....... not a five minute job , I have all new bearings for the spindle and new oil seals and generally cleaned and inspected everything. I managed to get the gear cog I needed to replace because of chipped teeth, thanks are due to Peter ( Bacup Hillbilly ) who had a spare gear cog and shaft , the holes in the clutch plates are oval and the pins worn, this was making the clutch grab and sometime not disengage , I have got new roller bearing pins and Rob Wilson is kindly going to drill and press the new pins in ( I was not confident of doing a good job of it ) Cheers Rob. The other part that was worn was a brake pad disc that is operated by the clutch lever, I did not even know it was there so have never used it ! It had wore down to the countersunk fixing bolts was was steel on steel not bronze on steel. The original was made of a bronze type brake material with particles inbedded in it, I could not get any of this so have made one out of bronze, it should still do the job.

This is the worn out part, the three holding coutersunk set screws had just been rubbing.

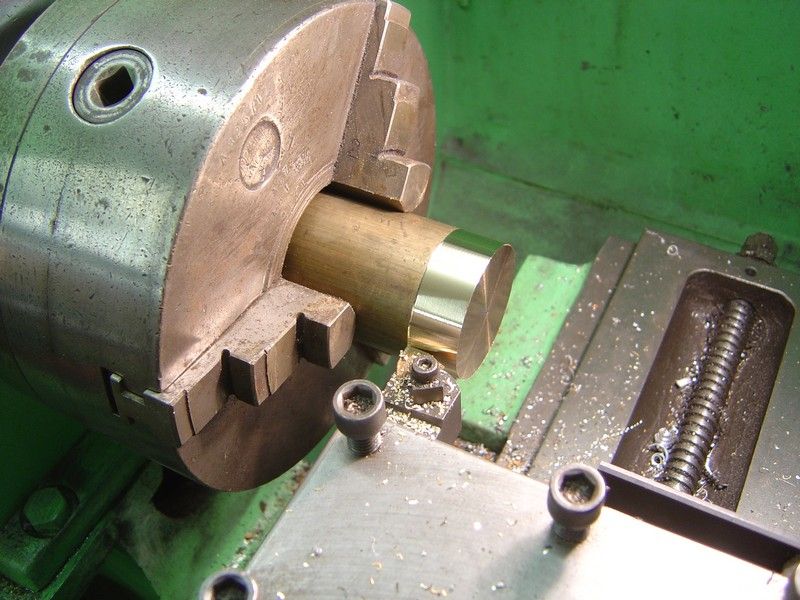

2 inch bronze bar, skimmed to size.

Drilled out in a couple of stages to almost the right ID , the drill is car boot job , rusty but sharp where it counts !

I marked out the three holes and drilled them on the Bridgeport.

I then skimmed the top surface so it was the right depth to the countersink s, then parted off.

The new disc in place along side the old one, its only after looking at this photo I think I might mill the three recessed flats into it as per the original so it has even contact with the steel collar it presses against , as it is it might wear uneven around the holes ? it wont do any harm to do it anyway.

Cheers Mick

This is the worn out part, the three holding coutersunk set screws had just been rubbing.

2 inch bronze bar, skimmed to size.

Drilled out in a couple of stages to almost the right ID , the drill is car boot job , rusty but sharp where it counts !

I marked out the three holes and drilled them on the Bridgeport.

I then skimmed the top surface so it was the right depth to the countersink s, then parted off.

The new disc in place along side the old one, its only after looking at this photo I think I might mill the three recessed flats into it as per the original so it has even contact with the steel collar it presses against , as it is it might wear uneven around the holes ? it wont do any harm to do it anyway.

Cheers Mick

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

As usual, beyond impressive! Now get it all stitched up in the box. Which lathe are you using to do the job?

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: SHED MATTERS. MARINE ENGINES.

Hi Stanley I have just seen your reply now, I have used the Binns and Berry big lathe to do the job , to be honest it seems big and clumsy doing small parts on it , it also needs the compound etc fettled as too much backlash and slack. Keep watching this space for re assembly but I have tham alloy brackets to do for the railings first and am also going to Harrogate model engineering show on Friday too

I have milled that disc so its like the original part , not much else done but hope to get more done this week.

Cheers Mick

I have milled that disc so its like the original part , not much else done but hope to get more done this week.

Cheers Mick

Re: SHED MATTERS. MARINE ENGINES.

Evening all, Well after a bank holiday of serious car booting, 3 sales visited in all, with my mate John Doubleboost, we both come back smiling  The sun was shining as we set off with our usual arrangement (he goes one way around and I go the other) , to save any ugly incidents where we both spot the same item at the same time lol.

The sun was shining as we set off with our usual arrangement (he goes one way around and I go the other) , to save any ugly incidents where we both spot the same item at the same time lol.

This is my collection at the end of the day, all in all £32.50p spent ..............not bad at all , even a Yorkshireman or Scotsman would be proud

Its not that clear to see some of the stuff , but amongst it are 25 reamers , some tapered , an 18V Dewalt drill , a Makita 18V battery , an old heavy duty soldering iron , ideal for doing leaded glass work, a remote car alarm , a 5 lever mortice lock with 3 keys, a pull saw for wood , scraper for wood , hole saw arbor, feeler gauges , calipers , 3 files , couple a ratchet wrenches, a leather hole punch , milling cutter , couple of taps , a few drill bits, two pairs of safety goggles , 10 heavy duty rawl bolts, a tube of evostick glue , a tube of pvc weld glue ..... not bad haul :thumbup:

We both had a good laugh too , especially when I bought the reamers John had offered the bloke £15 for and the guy said no , he must have then regretted it , I then saw them , and said how much for them all he said £15 ........... I said I will give you £10 ..he must have been thinking he didnt want to regret missing a sale again so said £12 and I took them ..... much to John's dismay when I told him lol ..............there are several doubles so he will still be getting some of them anyway.

We drove back with the sound of all our bounty rattling away in the back of the car with smiles like Cheshire cats on out faces .......................Mission Acumplished

P.S before everyone rushes out to boot sales next weekend .................. normally its one blunt drill or something you already have three of , this was a good day indeed !

Cheers Mick.

This is my collection at the end of the day, all in all £32.50p spent ..............not bad at all , even a Yorkshireman or Scotsman would be proud

Its not that clear to see some of the stuff , but amongst it are 25 reamers , some tapered , an 18V Dewalt drill , a Makita 18V battery , an old heavy duty soldering iron , ideal for doing leaded glass work, a remote car alarm , a 5 lever mortice lock with 3 keys, a pull saw for wood , scraper for wood , hole saw arbor, feeler gauges , calipers , 3 files , couple a ratchet wrenches, a leather hole punch , milling cutter , couple of taps , a few drill bits, two pairs of safety goggles , 10 heavy duty rawl bolts, a tube of evostick glue , a tube of pvc weld glue ..... not bad haul :thumbup:

We both had a good laugh too , especially when I bought the reamers John had offered the bloke £15 for and the guy said no , he must have then regretted it , I then saw them , and said how much for them all he said £15 ........... I said I will give you £10 ..he must have been thinking he didnt want to regret missing a sale again so said £12 and I took them ..... much to John's dismay when I told him lol ..............there are several doubles so he will still be getting some of them anyway.

We drove back with the sound of all our bounty rattling away in the back of the car with smiles like Cheshire cats on out faces .......................Mission Acumplished

P.S before everyone rushes out to boot sales next weekend .................. normally its one blunt drill or something you already have three of , this was a good day indeed !

Cheers Mick.

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

Good haul! Shed was up at 64F yesterday with no heat. No excuses now!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: SHED MATTERS. MARINE ENGINES.

You will have to get in there quick Stanley . . . . . . . or next thing we know you will be saying its too hot to go in there  I look forward to seeing your next project.

I look forward to seeing your next project.

Cheers Mick.

Cheers Mick.

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

Perhaps some light cleaning up today? I've finished my book so no more excuses!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: SHED MATTERS. MARINE ENGINES.

Stanley, you could have a go at one of these, note the ladders down into the sump!

http://images.gizmag.com/gallery_lrg/3263_03.jpg

http://images.gizmag.com/gallery_lrg/3263_03.jpg

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

We had the pics of that engine on the old Marine topic. Bit too big even for me!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Re: SHED MATTERS. MARINE ENGINES.

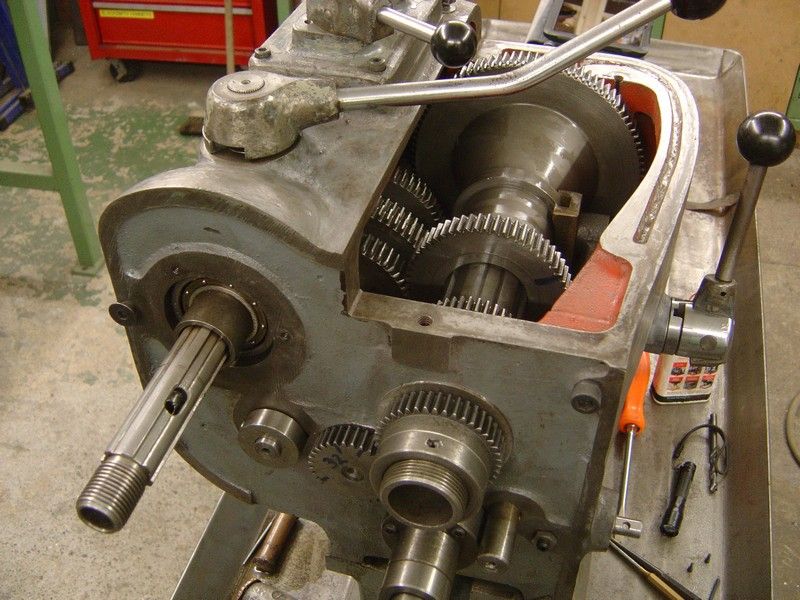

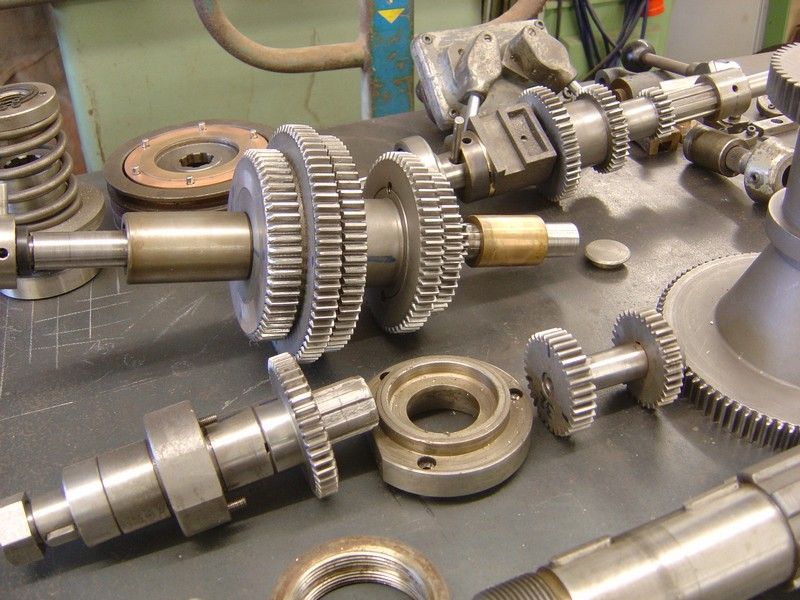

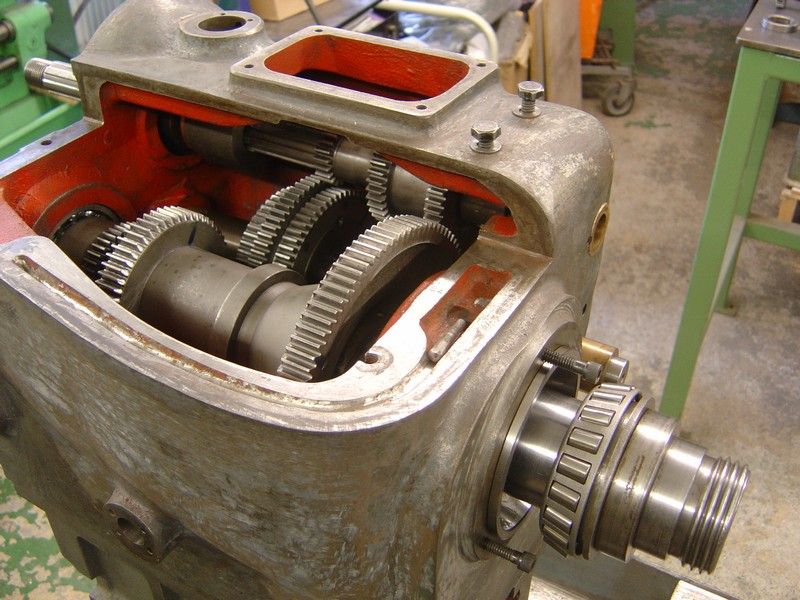

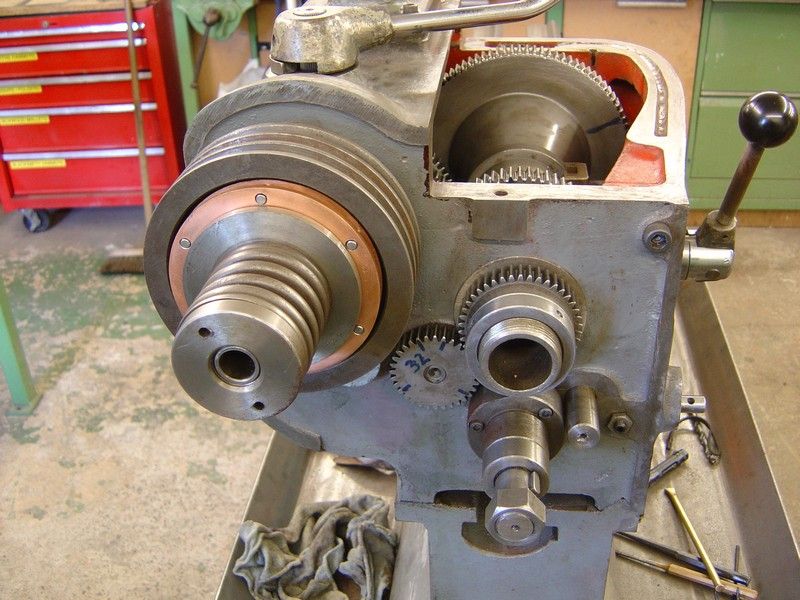

Well at last some real progress on the lathe.

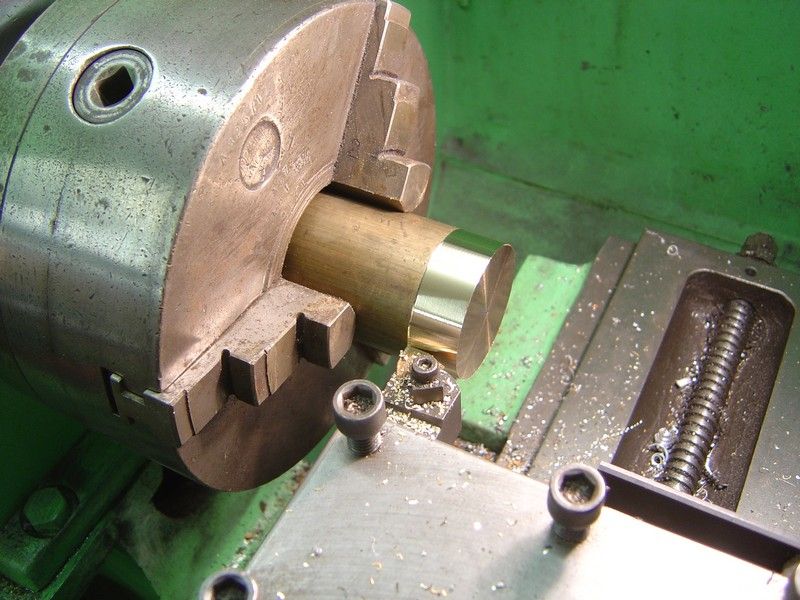

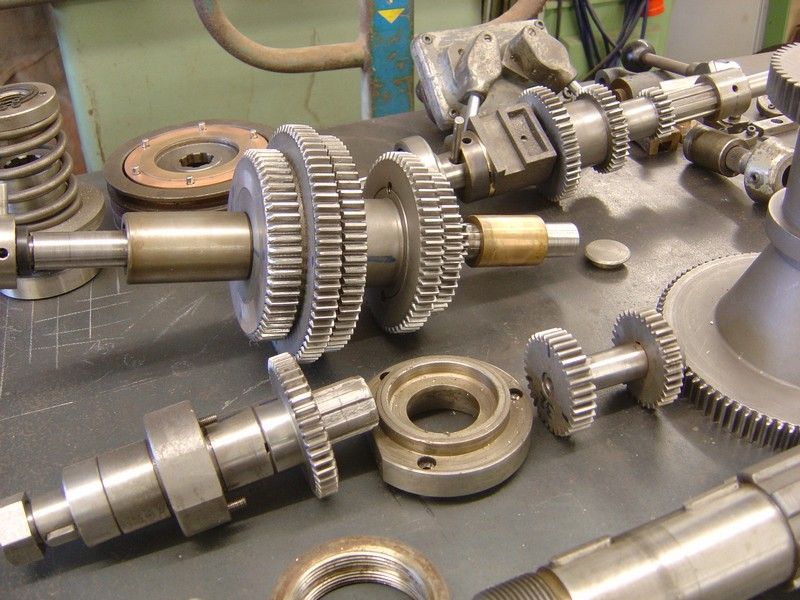

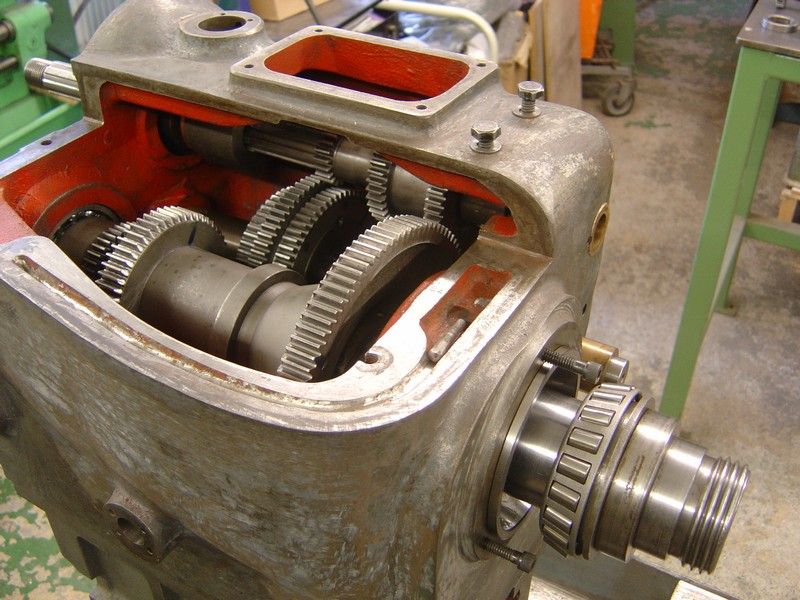

From looking pretty much stripped right down again.

The mission was to get this lot back inside the headstock

All the gears have been de burred, new spindle bearings and new oil seals, a couple of gears that had chipped teeth replaced and everything cleaned and checked over. The main problem with getting all the parts in seems to be most bits have to be inside the casing in their rough position but not actually in position and held there so that other things can be lined up at the same time, its a good job I had took plenty photos as my two manuals both have drawings that show several things that are not as this actual lathe so can do as much harm as help sometimes. Anyway after much struggling and trial and error , it all went back together and gears select and turn ok.

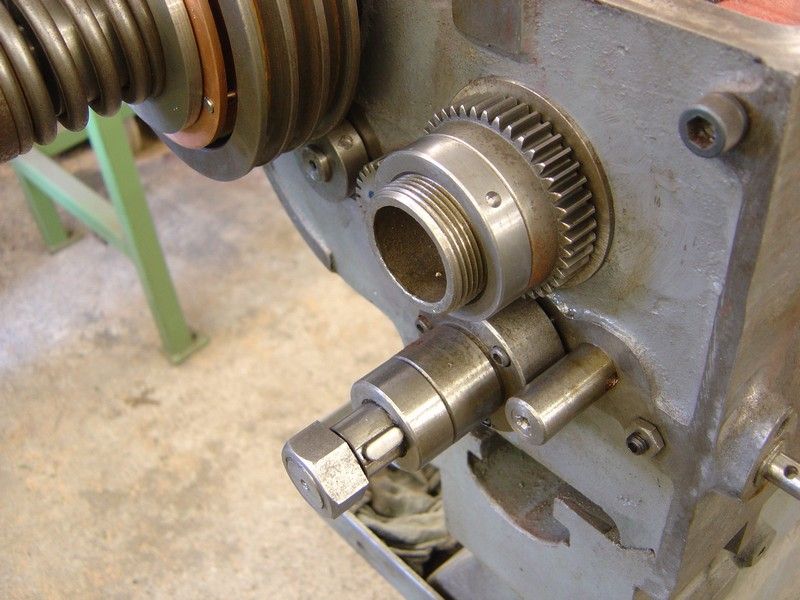

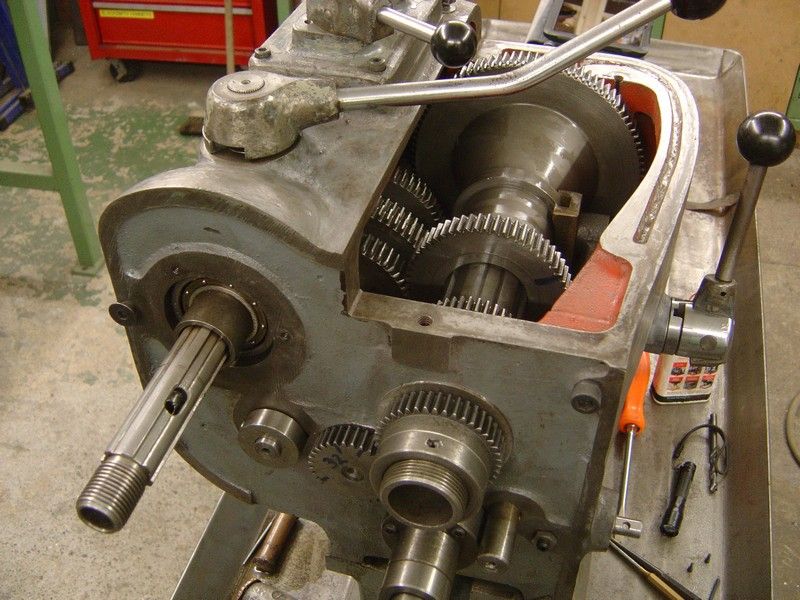

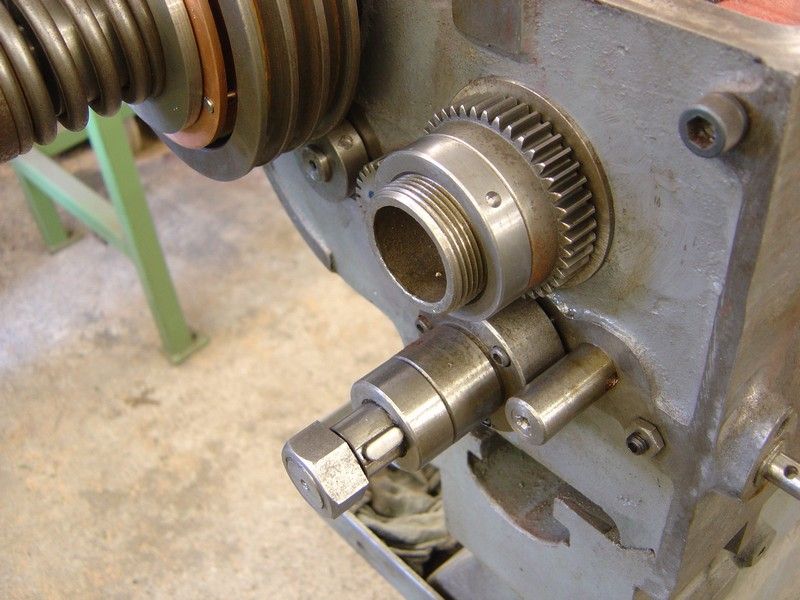

The next bit was the clutch , before the clutch used to snatch and sometimes not disengage, this was due to the pins in the vee pully that the clutch plate slide on having had notches worn into them and the clutch plates holes being worn oval. I was not confident of replacing the pins and drilling the plates spot on myself but Rob Wilson kindly did them for me , as you would expect Rob, he did a cracking job of them, cheers again Rob . You can see the pins in this photo, they have been fitted with slightly larger diameter roller bearing pins.

These are the plates with the new slightly larger holes drilled to match the new pins.

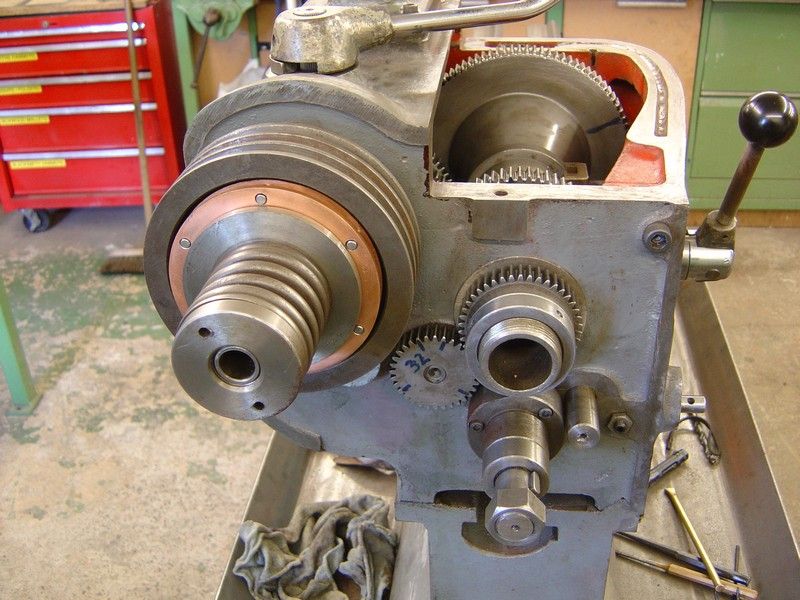

The clutch was then assembled, both the drawings were wrong and I could not remember at all how things went ! good job I had marked things as they came off, everything facing outwards received two small dot punch marks as you can see on second photo down at 12 O'clock , the steel clutch disc is flat one side and had a raised center on the other side as seen in third photo, it would have fit on either way but one way would be the wrong way , these marks ensured I put it in the correct way around so well worth taking the time to do this.

The next thing was a threaded collar on the end of the spindle has the holes chewed up so I drilled some new holes in the collar on the mill, lucky I already had the vee block and angle plate set up from doing something else on the mill as it would have taken longer to set up than do the holes.

This is the collar back on the spindle.

The clutch was then trial and error assembled, but would not seem to work, after looking at it really carefully I noticed witness marks inside an adjustable collar and remembered that I had put a small pin in a separate place in case it got lost , this was the missing link and once fitted it all seems to work ok.

The next stage is to prepare things for painting , a good bit of sanding , filling and priming needed, at least things should look as if they are progressing once some paint goes on.

Cheers Mick.

From looking pretty much stripped right down again.

The mission was to get this lot back inside the headstock

All the gears have been de burred, new spindle bearings and new oil seals, a couple of gears that had chipped teeth replaced and everything cleaned and checked over. The main problem with getting all the parts in seems to be most bits have to be inside the casing in their rough position but not actually in position and held there so that other things can be lined up at the same time, its a good job I had took plenty photos as my two manuals both have drawings that show several things that are not as this actual lathe so can do as much harm as help sometimes. Anyway after much struggling and trial and error , it all went back together and gears select and turn ok.

The next bit was the clutch , before the clutch used to snatch and sometimes not disengage, this was due to the pins in the vee pully that the clutch plate slide on having had notches worn into them and the clutch plates holes being worn oval. I was not confident of replacing the pins and drilling the plates spot on myself but Rob Wilson kindly did them for me , as you would expect Rob, he did a cracking job of them, cheers again Rob . You can see the pins in this photo, they have been fitted with slightly larger diameter roller bearing pins.

These are the plates with the new slightly larger holes drilled to match the new pins.

The clutch was then assembled, both the drawings were wrong and I could not remember at all how things went ! good job I had marked things as they came off, everything facing outwards received two small dot punch marks as you can see on second photo down at 12 O'clock , the steel clutch disc is flat one side and had a raised center on the other side as seen in third photo, it would have fit on either way but one way would be the wrong way , these marks ensured I put it in the correct way around so well worth taking the time to do this.

The next thing was a threaded collar on the end of the spindle has the holes chewed up so I drilled some new holes in the collar on the mill, lucky I already had the vee block and angle plate set up from doing something else on the mill as it would have taken longer to set up than do the holes.

This is the collar back on the spindle.

The clutch was then trial and error assembled, but would not seem to work, after looking at it really carefully I noticed witness marks inside an adjustable collar and remembered that I had put a small pin in a separate place in case it got lost , this was the missing link and once fitted it all seems to work ok.

The next stage is to prepare things for painting , a good bit of sanding , filling and priming needed, at least things should look as if they are progressing once some paint goes on.

Cheers Mick.

- PanBiker

- Site Administrator

- Posts: 16447

- Joined: 23 Jan 2012, 13:07

- Location: Barnoldswick - In the West Riding of Yorkshire, always was, always will be.

Re: SHED MATTERS. MARINE ENGINES.

Fantastic job so far Mick, thanks for posting your progress. Images are displaying a tad smaller than the norm at the moment since the recent site crash. We are having a pow wow about this and other site issues next week.

I'm not particularly mechanically minded but I know a good job when I see one, your attention to detail is to be commended.

I'm not particularly mechanically minded but I know a good job when I see one, your attention to detail is to be commended.

Ian

- Stanley

- Global Moderator

- Posts: 90295

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

Brilliant Mick. You're a good man! It will run like a rice pudding now instead of a basket full of pots! Mind you, it's amazing how long they can go on with worn gears. I had Newton's old Wilson lathe and when I moved in here and hadn't got room for it I took it over to Rochdale and used it in John Ingoe's shop to refurbish valves. Despite having horribly worn gearing it did a good job until I left John. One thing is certain, you're going to have a very impressive lathe in good condition by the time you're finished.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

- PanBiker

- Site Administrator

- Posts: 16447

- Joined: 23 Jan 2012, 13:07

- Location: Barnoldswick - In the West Riding of Yorkshire, always was, always will be.

Re: SHED MATTERS. MARINE ENGINES.

Thread is locked from further input, please use the new thread Shed Matters 2, link is below.

SHED MATTERS 2

SHED MATTERS 2

Ian