Man has been digging stone out of the ground and finding uses for it since the beginning of history. However, it wasn't until the mid 16th century that stone began to be used as a common building material. Before then the use of stone was confined to the church-building and the Crown for fortification, palaces and harbours. The great change came when Henry VIII dissolved the monasteries, by far the largest employers of masons who, deprived of their employment, shouldered their tools and took to the road looking for work. By the 17th century stone was being used to build or rebuild houses constructed mainly of timber and as income levels increased, domestic building in stone became the norm. At first, mainly because of transport problems, houses were built of random stone quarried from small delphs or excavations on site and always uphill of the building to make it easier to move the stone. This method of building persisted into the 19th century where building took place in areas ill-served by roads. Plenty of examples of this if you look at the farmhouses built on the Waste after the 1830 Enclosures. As demand increased and roads in the villages improved stone-getting became more organised and we start to see deep quarries which produced dressed or sawn stone as well as rubble stone. You only have to look at the quality of the houses built with dressed stone to see how standards improved.

My problem is to try to give you some idea of when this change happened. I have no specific evidence but looking at the buildings and estimating the dates it looks as though, apart from dressed corner stones (quoins) and door and window jambs ordinary houses were being built mainly of random stone until the mid 18th century so that's the date I shall put on organised deep quarrying. It's worth noting here that the stone I am talking about is varying grades of sandstone. There was another type of stone, limestone, freely available in Barlick and Salterforth that was used for road making and burning in kilns to make lime for building mortar and spreading on the land to improve fertility. This lime-burning was being done on a small scale using wood as fuel for hundreds of years. Like sandstone, the volumes used increased enormously with the advent of cheap coal via the canal because it was economical to burn it in large quantities. If you walk the canal you'll find many small kilns in the fields next to the waterway. The quicklime was usually used very close to the kiln because it was aggressive stuff and dangerous to handle.

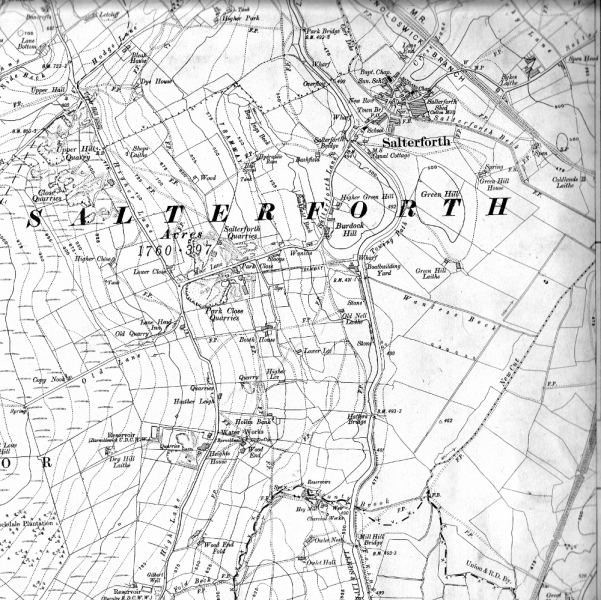

I think the first quarries producing dressed stone for building were all above the line of High Lane stretching from 'Loose Games' at Upper Hill south along the road as far as White House near the Black Brook (County Brook). As far as I can tell the development of the lower quarries on Salterforth lane happened after 1800 and the arrival of the canal. We can get some idea of the scale of these enterprises from evidence given to the Parliamentary Light Railway Commissioners in 1906 when the quarries were working at about the same level as they were in the mid 19th century. (The quarries described as 'Waterworks' were the ones above High Lane to the south of Lane Head.) Sagar Brothers, Tubber Hill (Loose Games), 20 men. Edward Smith, Tubber Hill, 20. John Sagar, Tubber Hill, 30. John Sagar Salterforth Quarry (On the left going down Salterforth Lane), 50. George Sagar at Waterworks number one and two, 30. Dalton and Higgins, Waterworks, 50. Salterforth Stone and Brick Company, Park Close (On the right going down Salterforth Lane), 50. 250 men in total.

There was only one significant limestone quarry in Salterforth and this was at Hollins. It included a large lime kiln and I have never been able to understand this or find any evidence. The only access was via Esp Lane into Barlick which seems totally inadequate. The other limestone quarries were to the east of Barlick at Gill Rock, Greenberfield and Rainhall Rock. Gill Rock was owned by a man called Farrand and at one point produced about 20,000 tons a year. Greenberfield was part of the Coates estate and was smaller. Rainhall Rock was leased by J W Wasney of Thornton in Craven to the canal company and even when the initial take had fallen was producing 15,000 tons a year in 1853 and shipping it out via the Little Cut. The canal company used limestone blocks from Rainhall for many of their building works on the canal and the new Barnoldswick Railway Company also used it. Next time you are in the Co-op car park take notice of the boundary wall on the east side.

At first the building stone from the quarries at Salterforth was mainly for local use and transported by road. Jack Platt worked for John Sagar in the latter days and told me that the stone in the Tubber Hill quarry was softer than that on Salterforth Lane. He used to work on the stone saws and they could cut 8” per hour in the top quarry but the stone from Salterforth Lane was much harder and had a blueish tinge which faded on exposure to the air. The most they could cut was 4” an hour and there was a good demand for this stone where harder material was needed for jambs, engine beds and road setts. Stone for Barlick from the quarries on the lane had to get onto the top road and the hill was too steep for the horses so a steam winch was installed on the triangle of land at the top and this assisted the horses up to the top road. This was in use until about 1930 when motor transport came in starting with the flood of ex-army vehicles onto the civilian market after WW1.

Looking at the census figures which include occupations we find that stone mason and quarry worker are common. Apart from the commercial opportunities open to the local entrepreneurs the quarries provided a lot of employment not only to their own workers but by the demand for horses and transport. I have no direct evidence but the farmers and small transport contractors would do well out of the trade and it's reasonable to expect that many of them would be based in the village of Salterforth.

I've run out of space haven't I! There is much more to tell about the quarries and how the use of the canal for transport benefited the village. I shall return next week.

The 1914 map shows the quarries, note the tramways! We shall look at them next week.