That's a different video than the one that opened yesterday afternoon when I clicked on it.

Joe is a very good engineer and machinist but gets a lot closer to perfection than I ever do!That's why to me he seems to go the long way round when he's machining something.

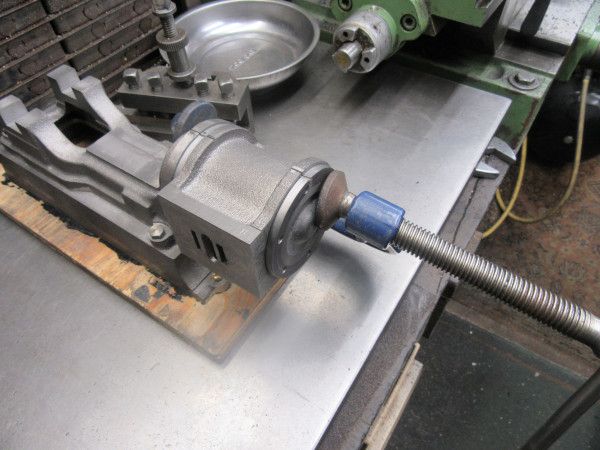

But this is different and he is good at explaining things. Funny how the engine he uses is almost exactly like my favourite Stuart Number 9.

This is a favoured route to PM and like all the others can't work because no energy is being put in to the system and if nothing else, wind resistance to the flywheel spokes would eventually stop it. (Sorry David......)

One other thing. Why like so many others does he demonstrate the engine running backwards? If you want I'll explain that but it takes nearly as long as explaining perpetual motion.