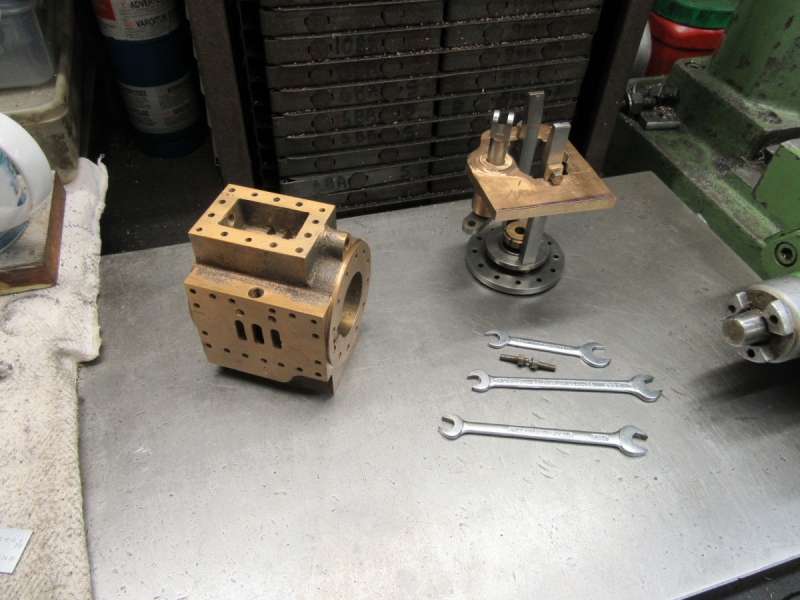

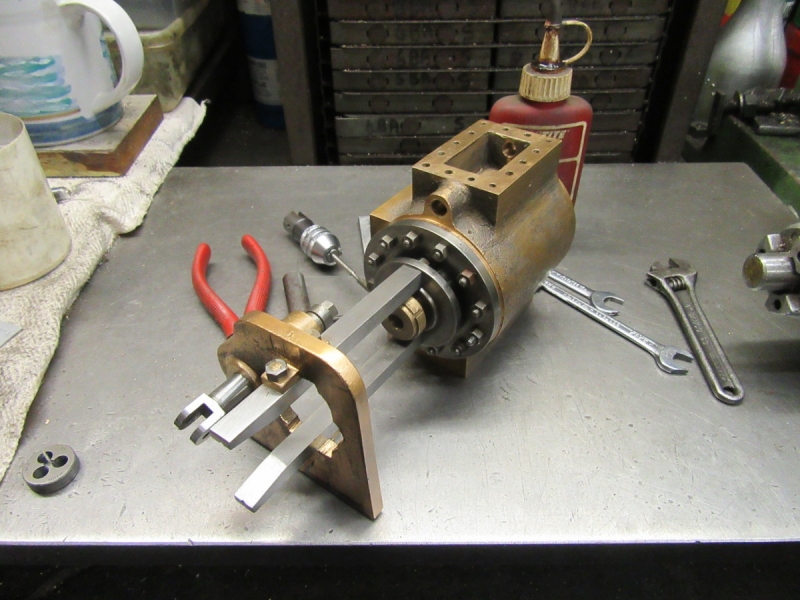

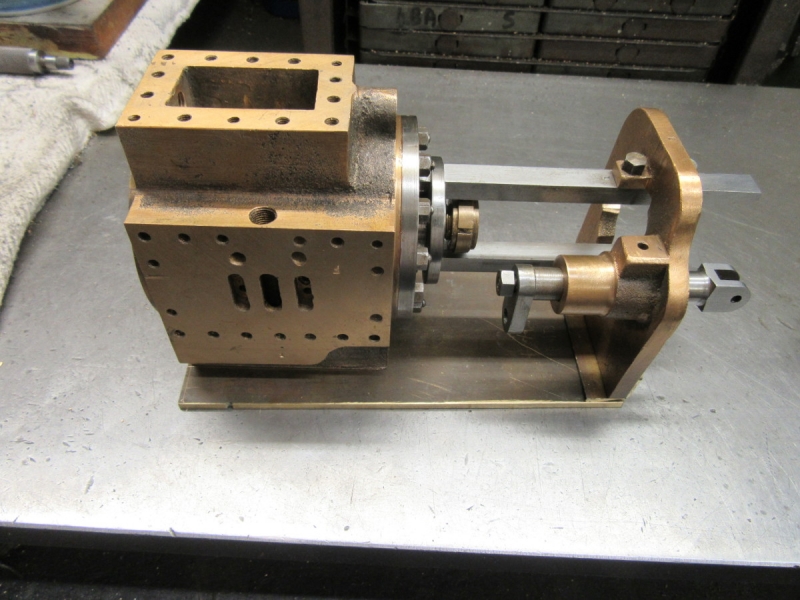

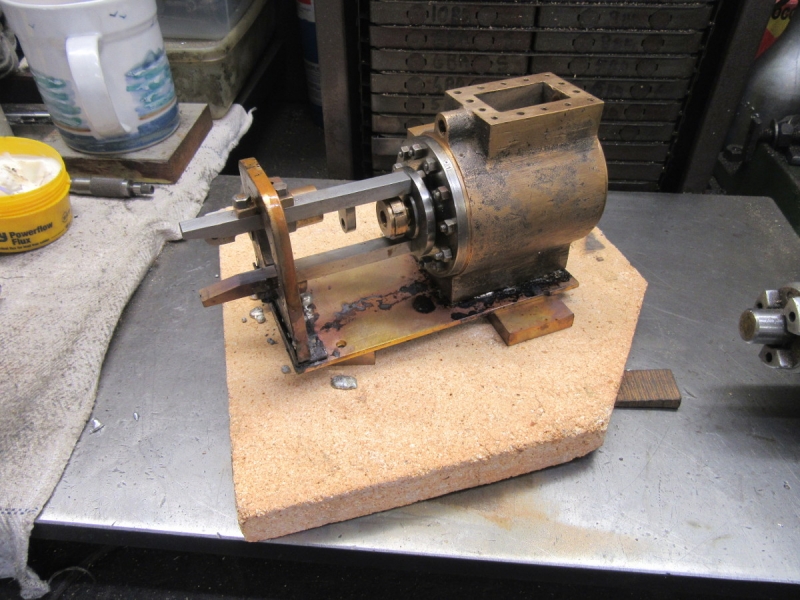

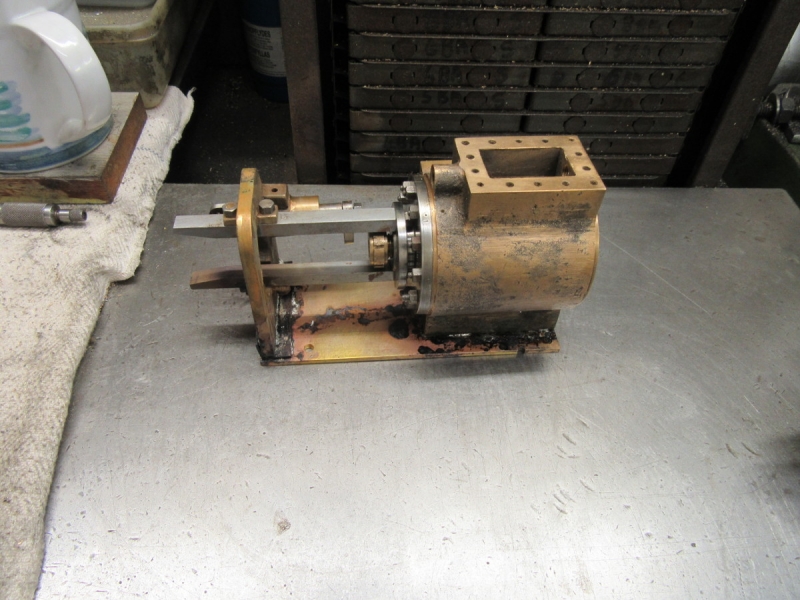

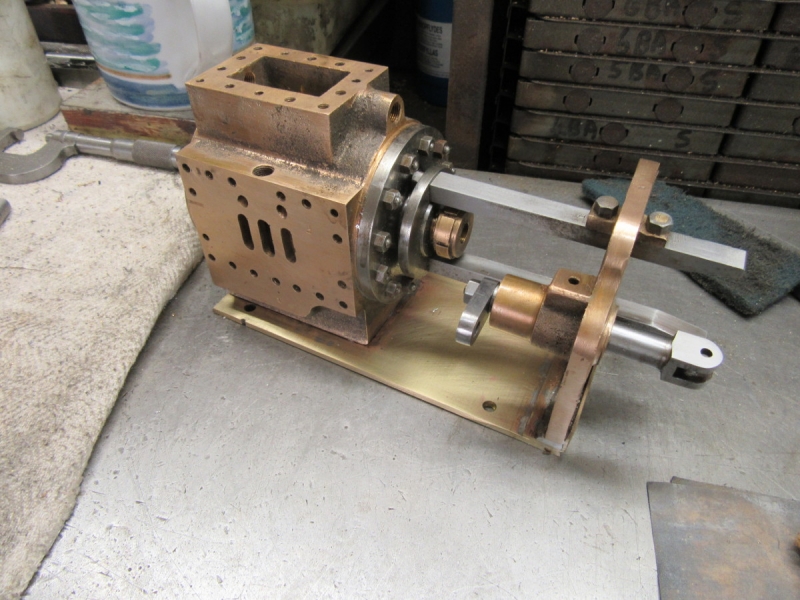

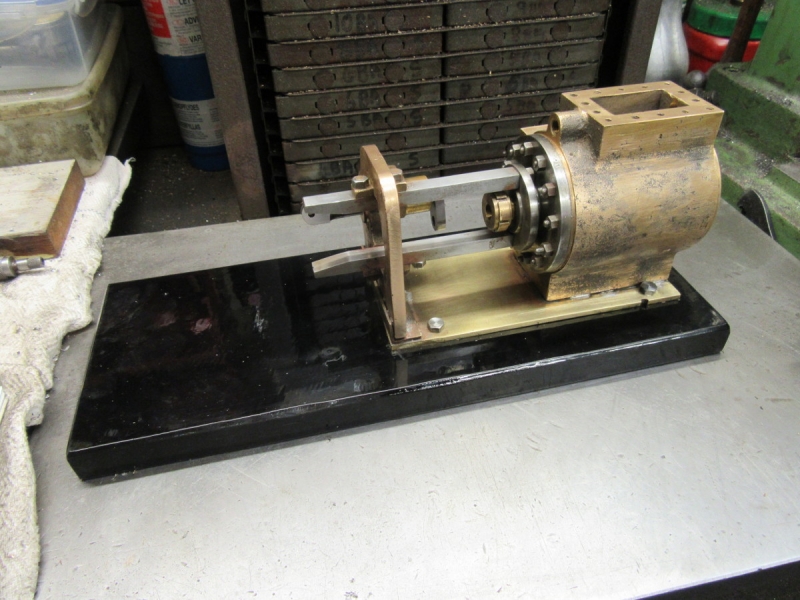

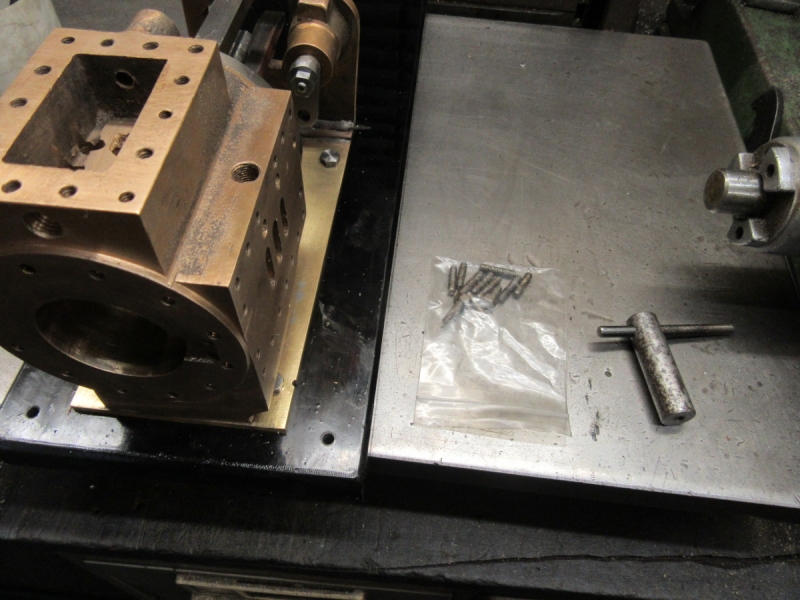

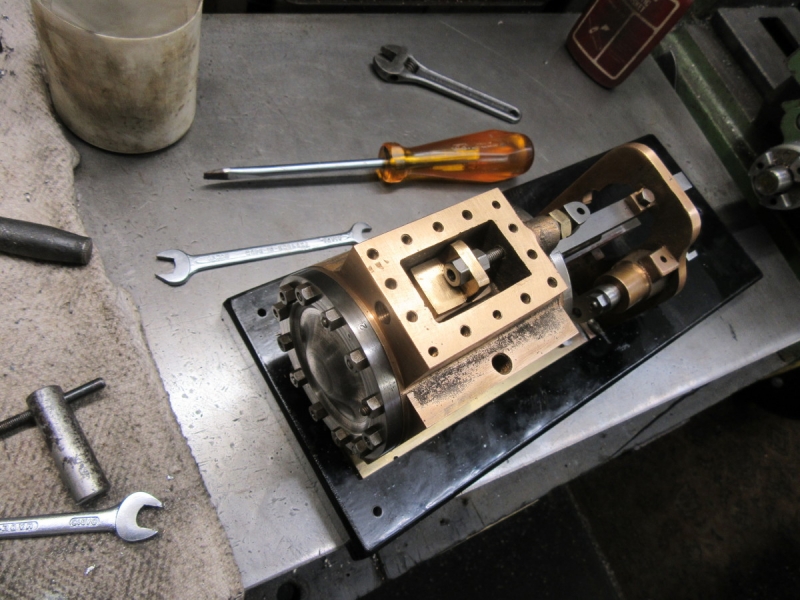

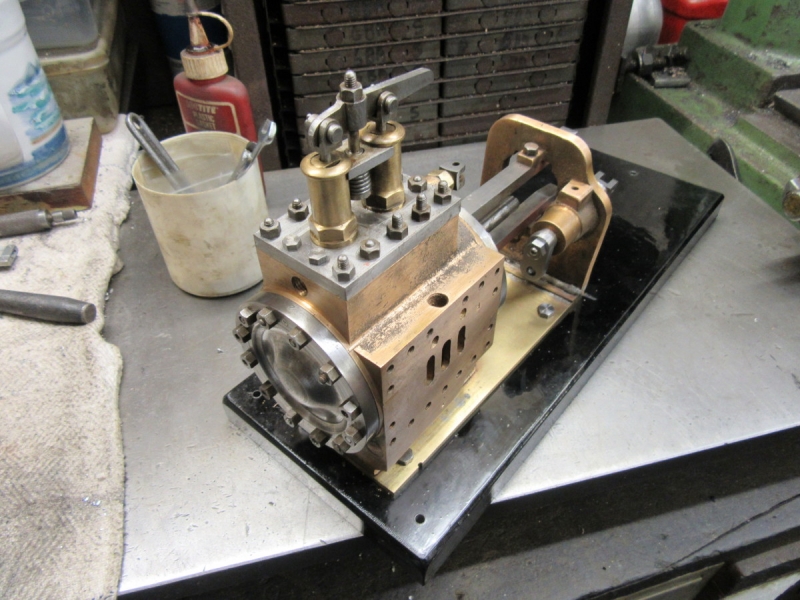

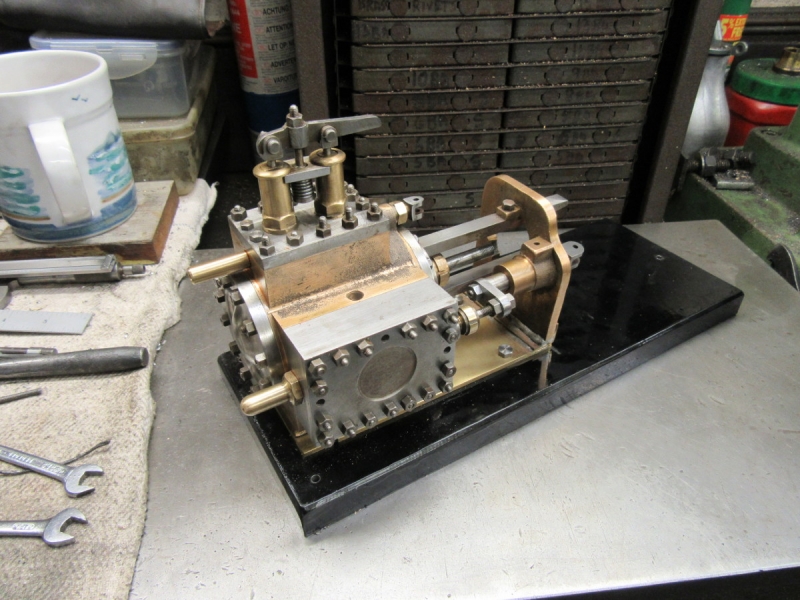

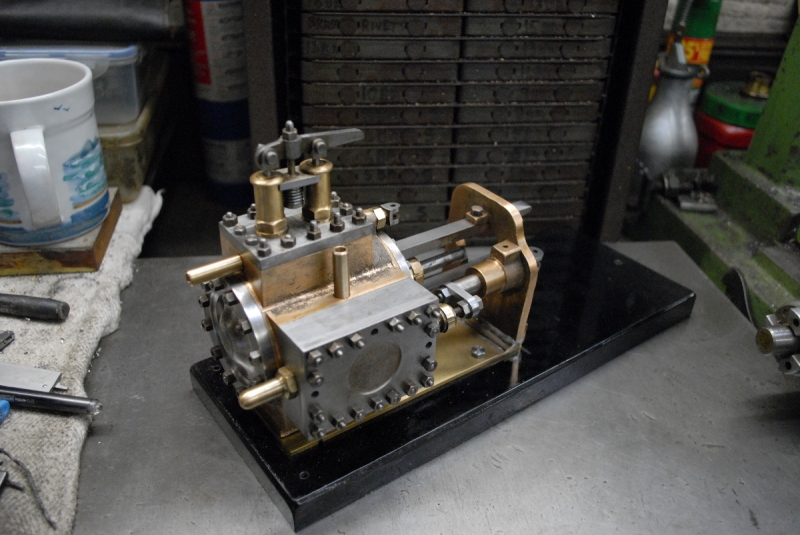

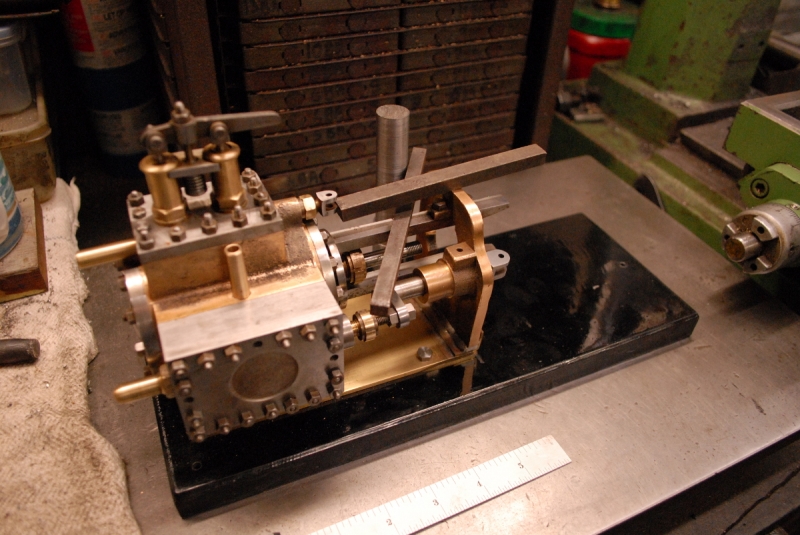

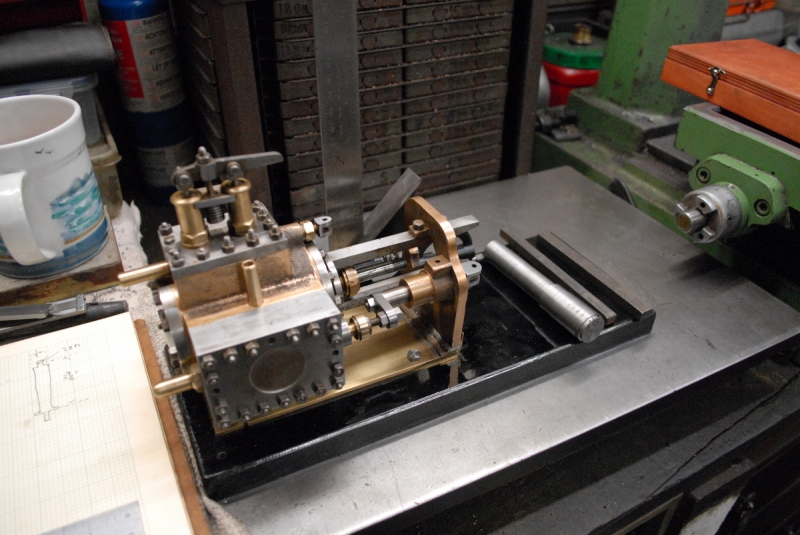

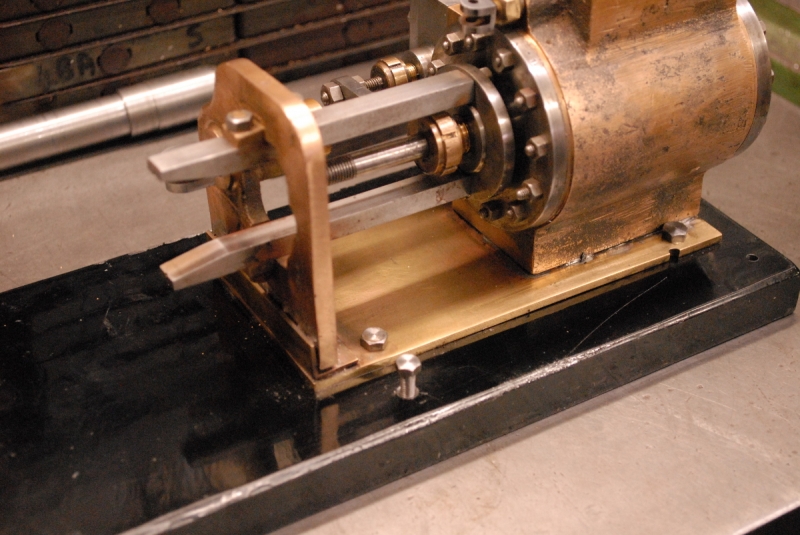

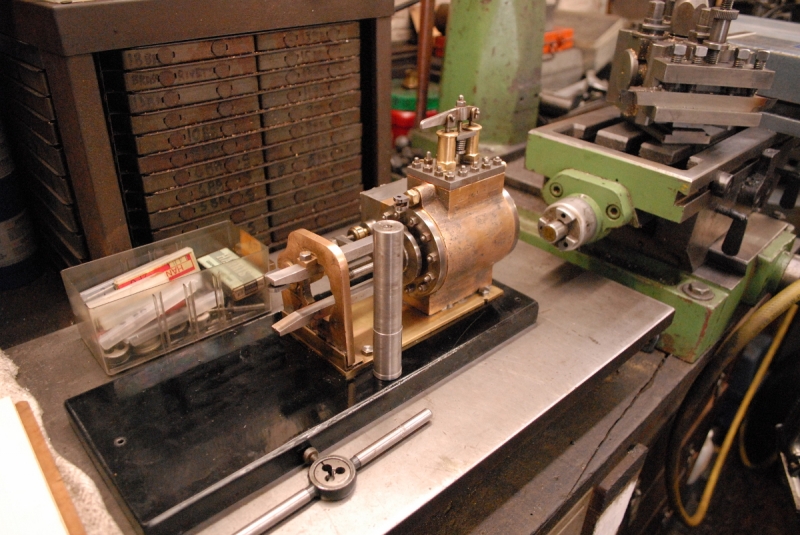

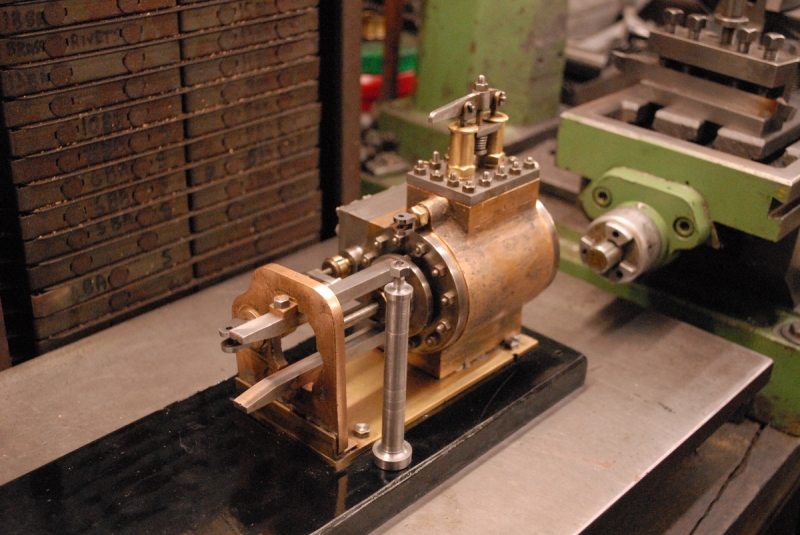

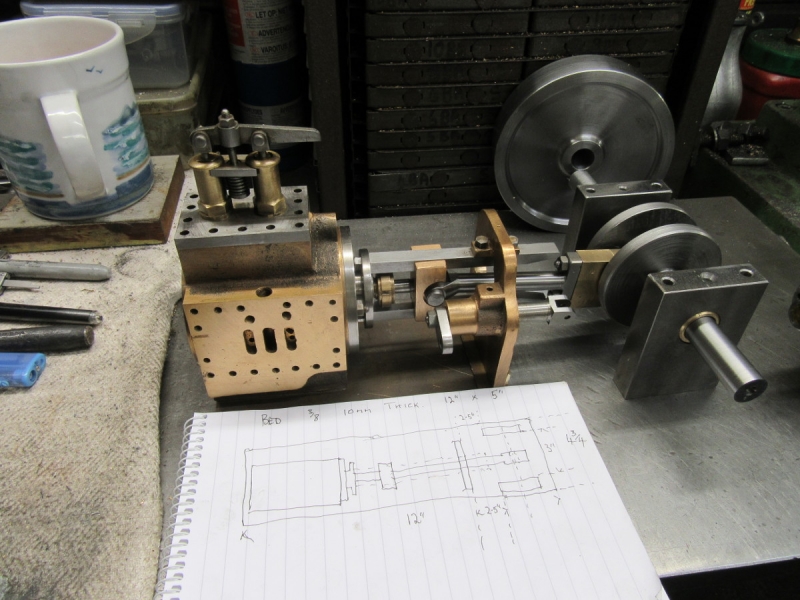

Only one pic this morning and no machining. What I wanted to do this morning is have a look at the rabbit and I function best when I have the evidence in front of me! As you can see I fitted the crankshaft and pedestals and laid the engine out after adjusting the piston on the back dead centre. Then I installed the brass base plate in its position and got some basic measurements. The main ones are the size of the large bedplate I need under the whole engine and the distance between the pedestals and the supporting bracket for the crosshead guides. I've got the size and thickness of the bed plate so I can now put the arm on my friend Terry Gissing.

Then I stood back and started to have a bit of deep thought. I say started because there are a lot of decisions to make. Remember that originally this cylinder was designed to fit directly on the boiler of a traction engine and get its steam directly through what was the curved base. It is going to be fed directly into the regulator box on top of the engine, the one that carries the safety valve. This means that eventually I will have to make a throttle linkage for it but at the moment that's not pressing. I can address that later when I come to it.

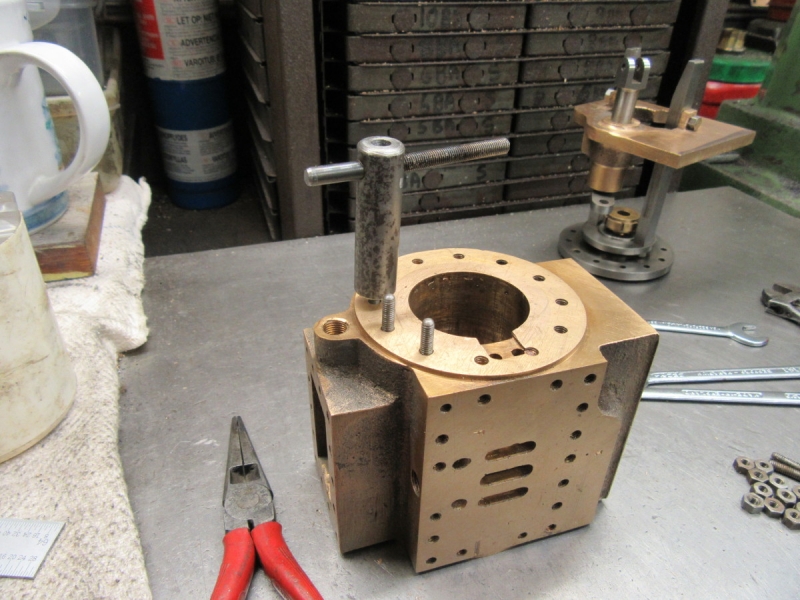

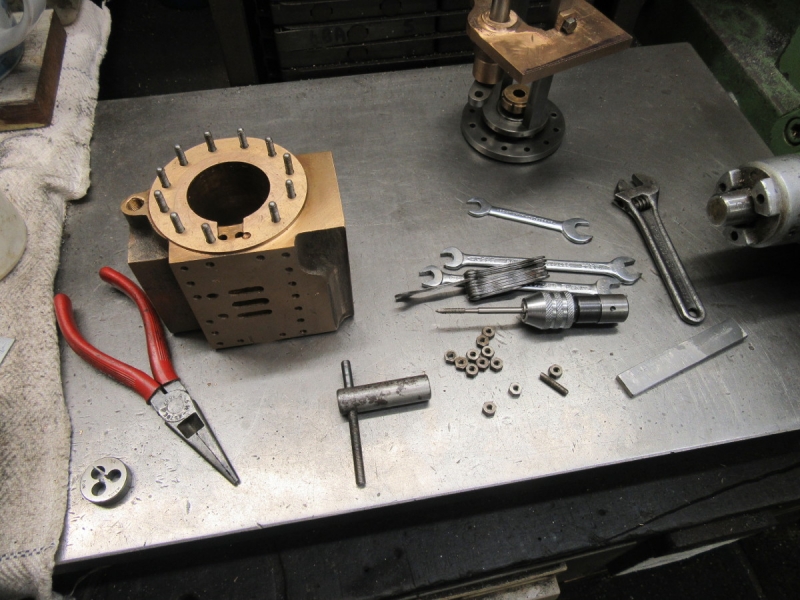

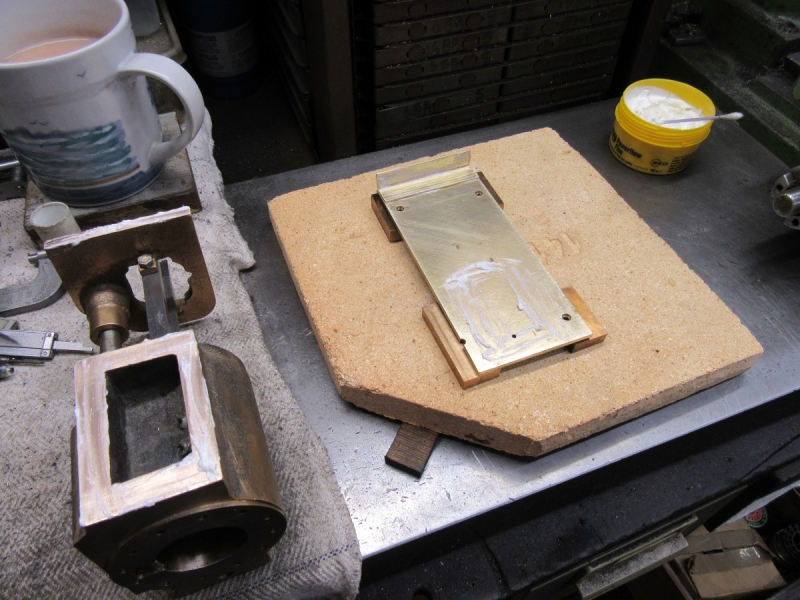

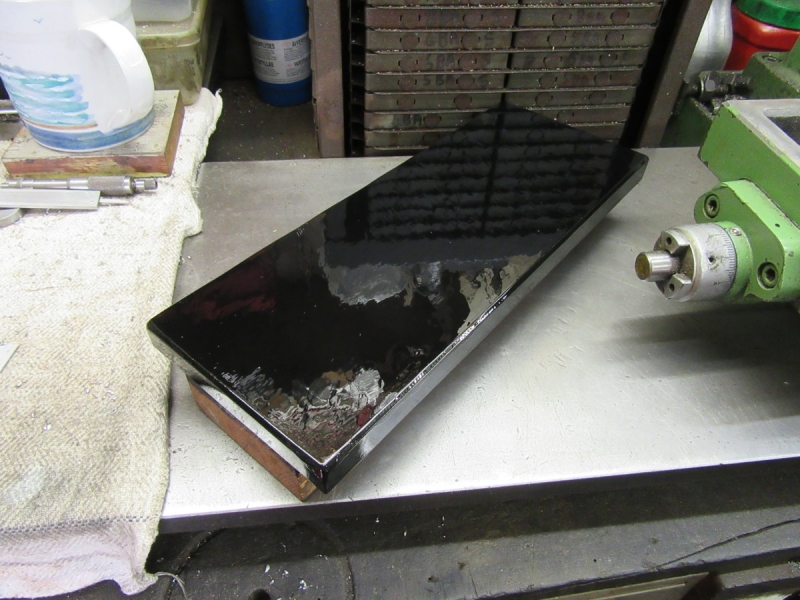

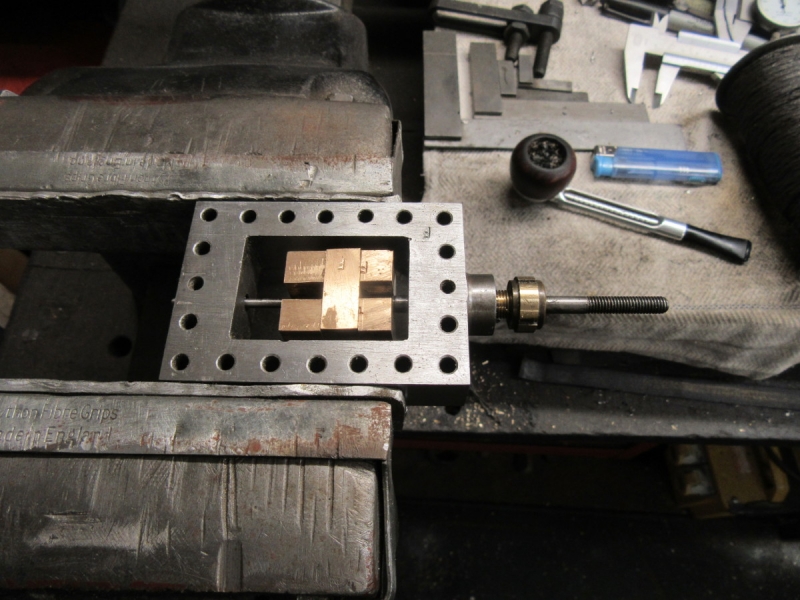

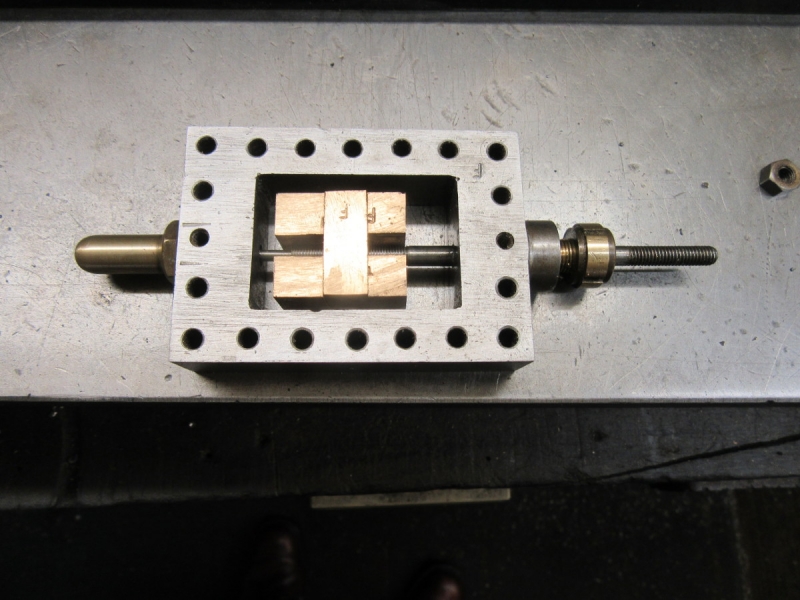

No, what needs to be addressed first is how I fix the brass sub-base to the cylinder and crosshead guide support and while I am doing that think about how I attach the whole assembly to the bed. Incidentally the flywheel isn't going to be a problem because the main bed will be mounted on a wooden plinth and that will give me clearance at the bottom of the wheel.

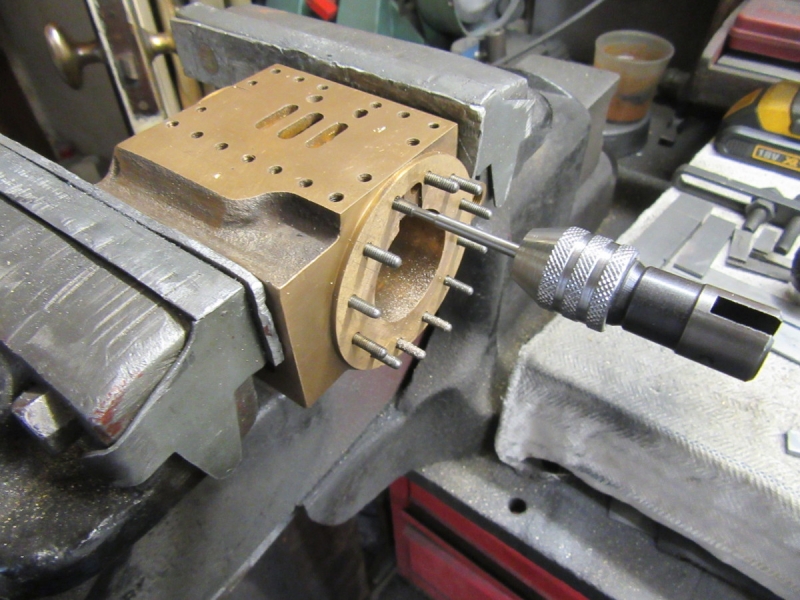

At the moment I am favouring 4 studs, one at each corner of the cylinder base, mounted on the brass base plate and taking care of the front support by sweating it on to the base plate and front angle. I might fit a couple of studs through the final assembly as well.

I don't see any problem in fixing the whole to the base plate, I have room under the guides to install 4 mounting bolts. What I really want now is to be able to slip the base plate under it all and see the full picture.

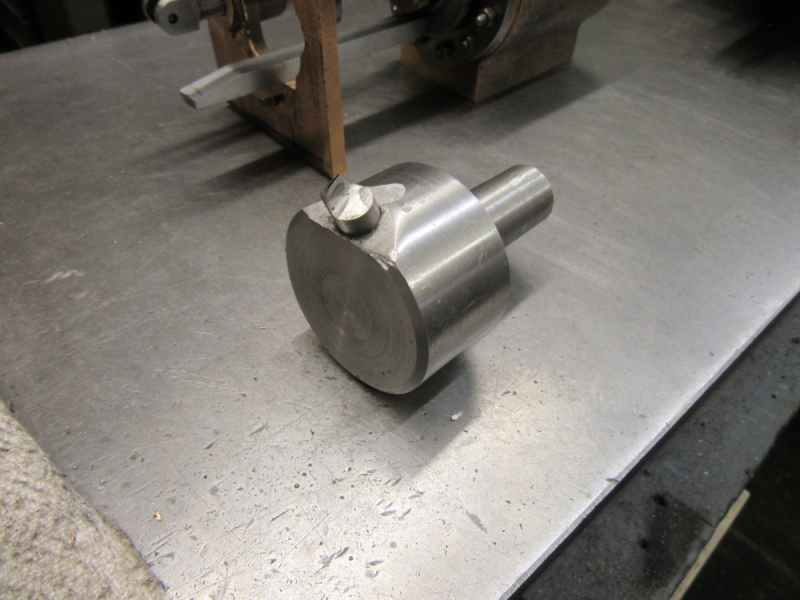

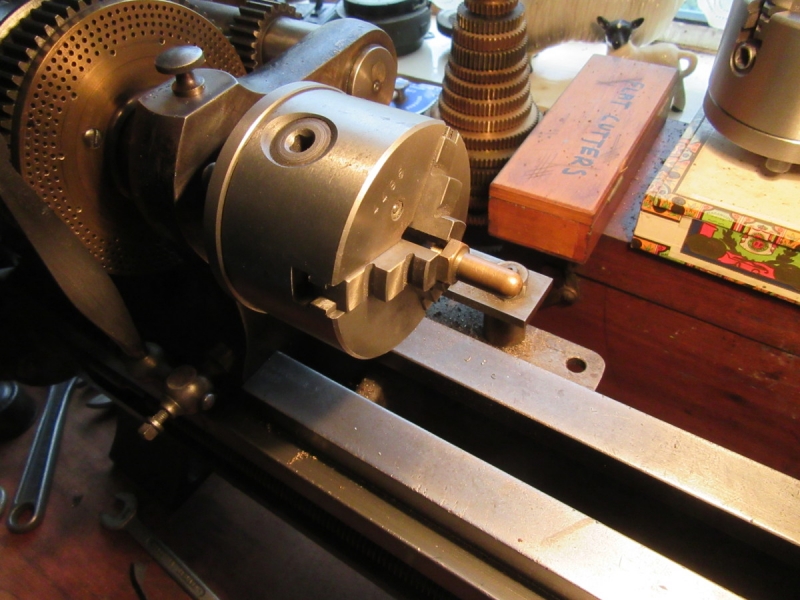

There is another small matter, the eccentric and rod. Because I have put the main bearings sufficiently far from the crank webs the Eccentric lines up well with the line of the original intended rod.

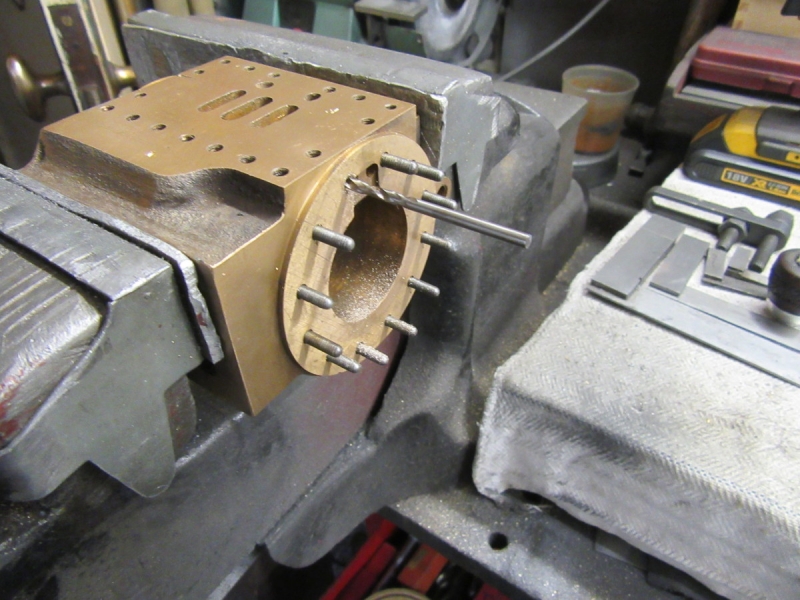

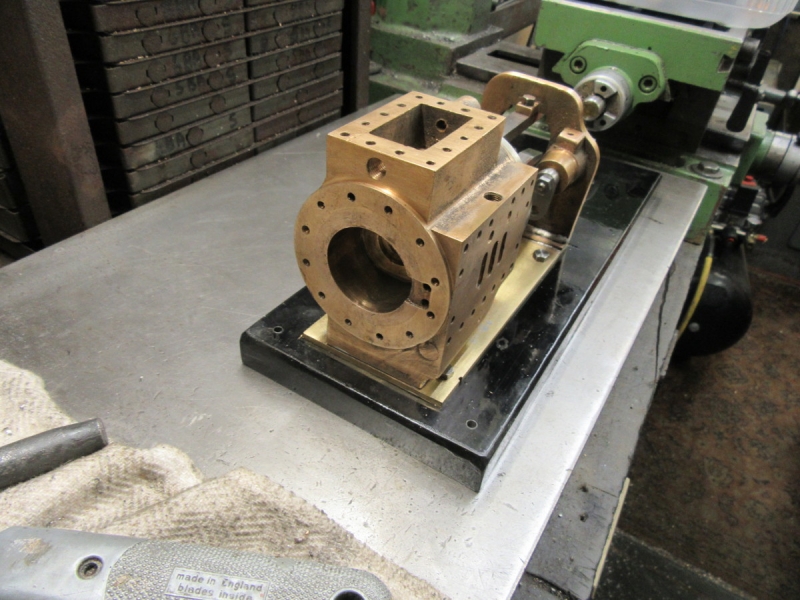

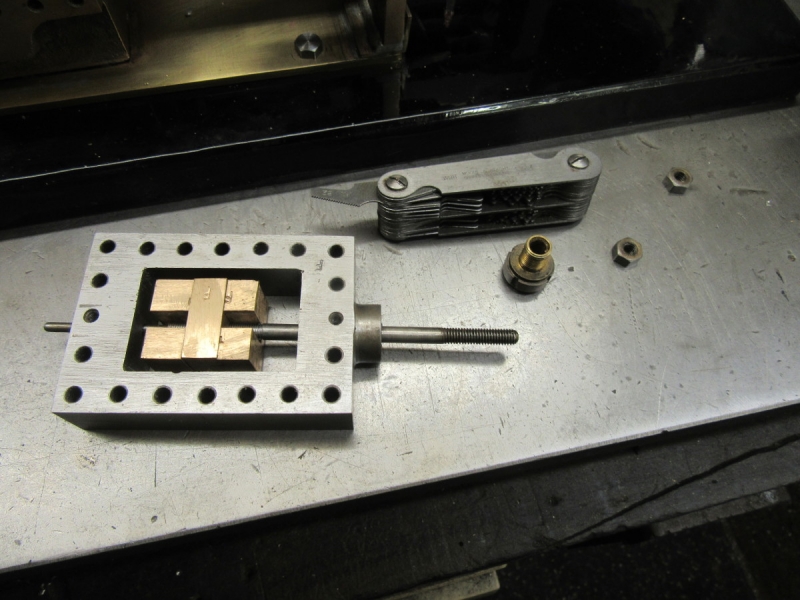

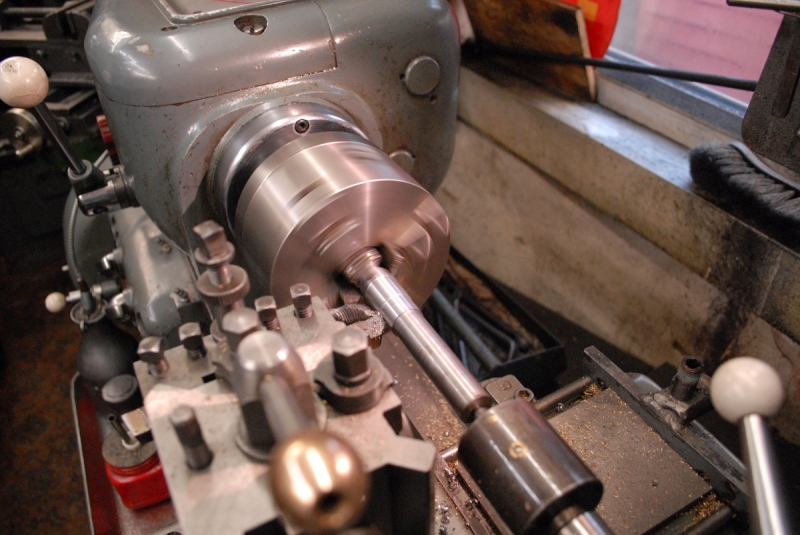

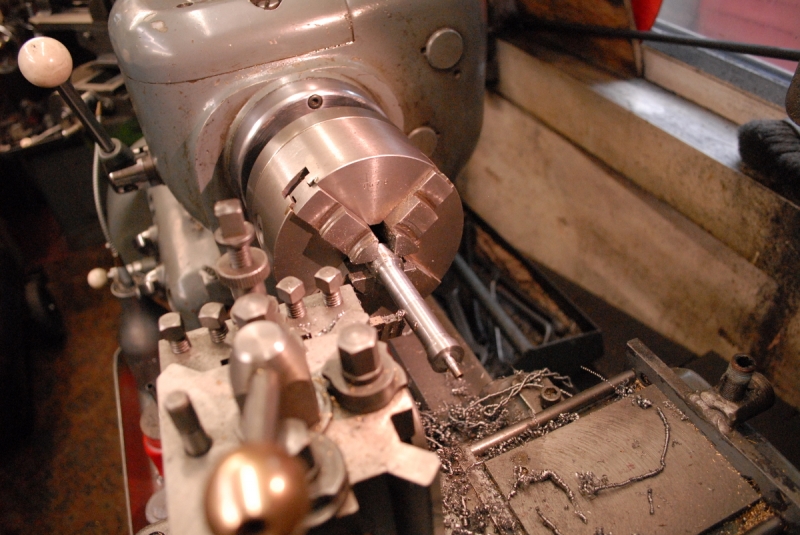

There is something that needs attention before I go any further. Because of the way the engine is designed I have to do the final fit on the front cylinder cover and the crosshead guides. It would be possible to do it later after the base plate is installed but would necessitate stripping it all down and I can avoid that.

So you can see I have a lot to think about. I always find that I do this best by running over the various points in my mind before I sleep and when I waken up everything is neatly sorted out. So I'll let the whole matter simmer away for a few hours. This is the bit I love about scratch-building without drawings. The design just grows as you go along. It's always worked up to now!