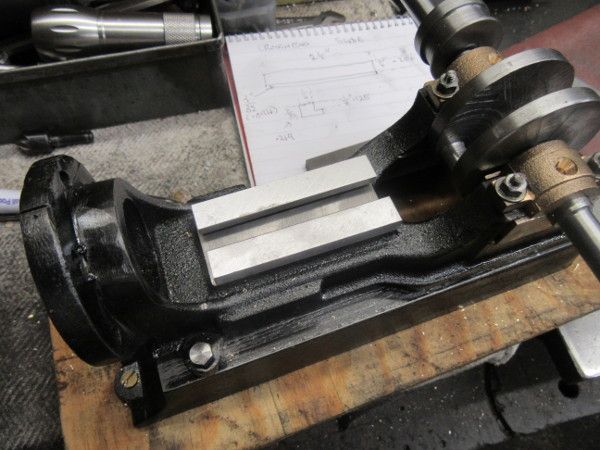

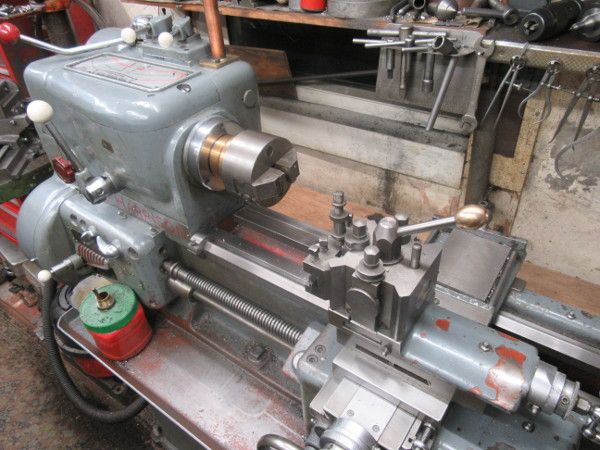

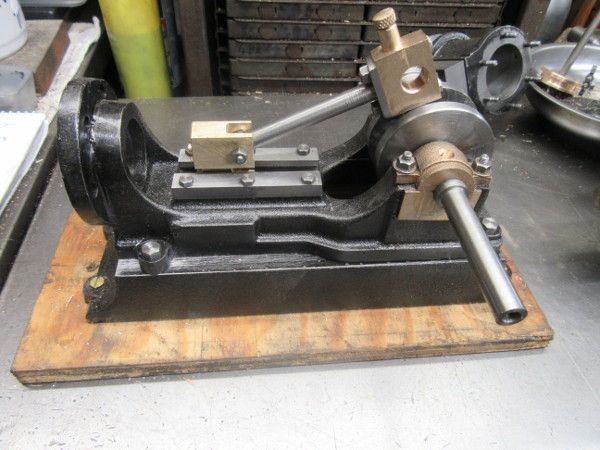

This is the task this morning, finish fitting the steam chest and lid to the cylinder so that they are an easy push fit and make and fit the gland for the valve rod. Just like that! The first thing to say is that there is nothing wrong with opening up the drillings in the chest and the lid to give more clearance and accommodate any slight misalignment of the studs. The chest and lid drop into place nicely now.

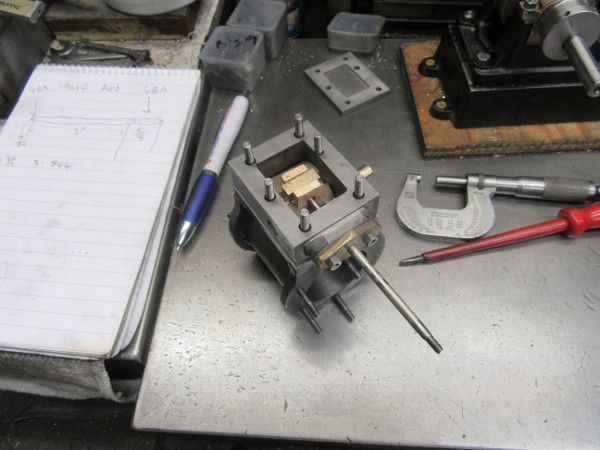

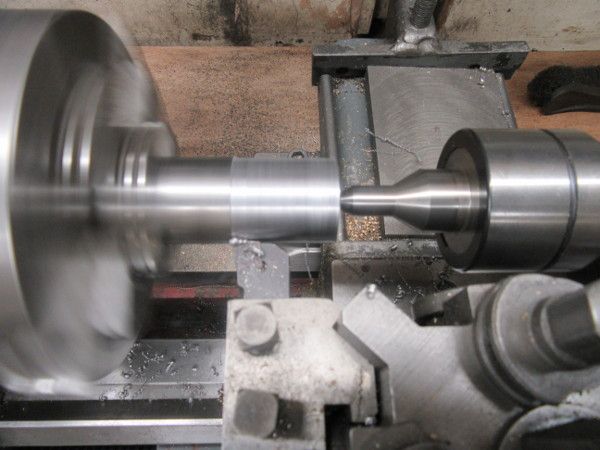

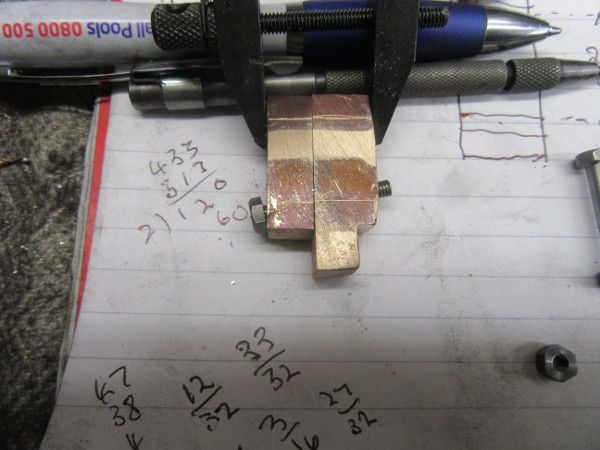

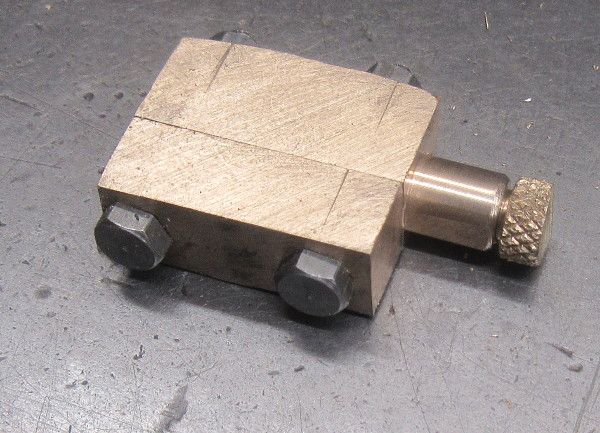

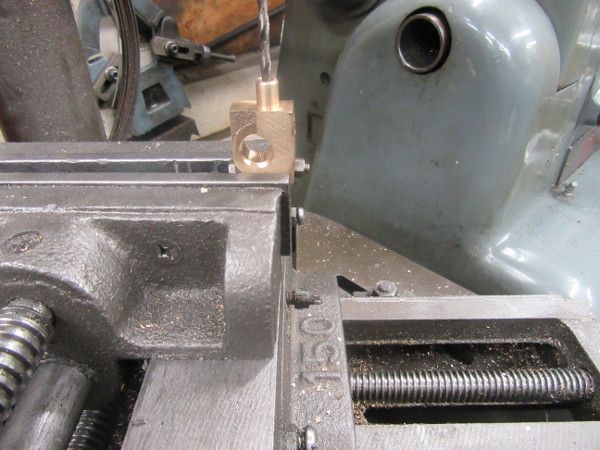

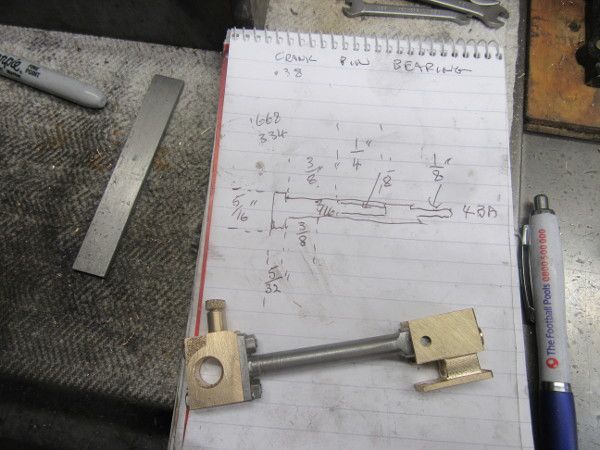

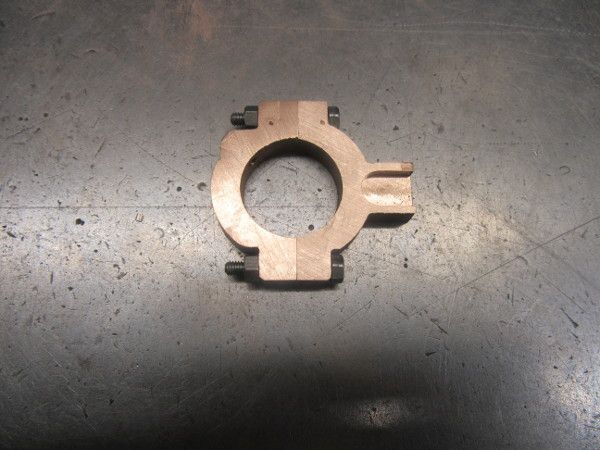

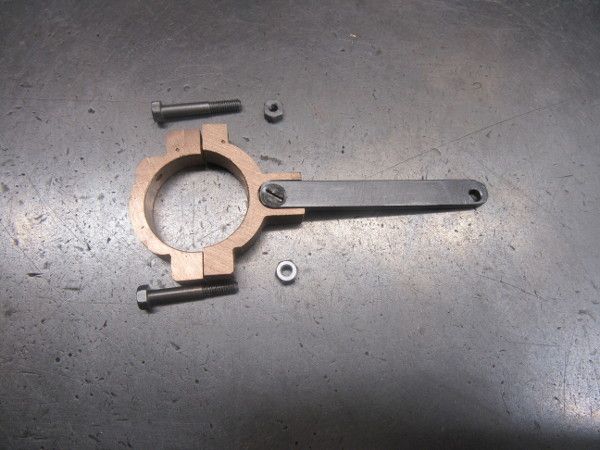

I thought it might be worth while to show how I machine an awkward little shape like the gland for the valve rod. You have the the stem of the gland on the casting so that's a good thing to grab while you face the gland and drill it for the rod. Then Put the valve rod in the chuck and use it as a mandrel to locate the hole you have drilled. Then push the casting against the chuck with the live centre. That will give enough friction between the gland and the chuck to allow light cuts and all you do is centred. Notice that I put a PCD in for the stud holes.....

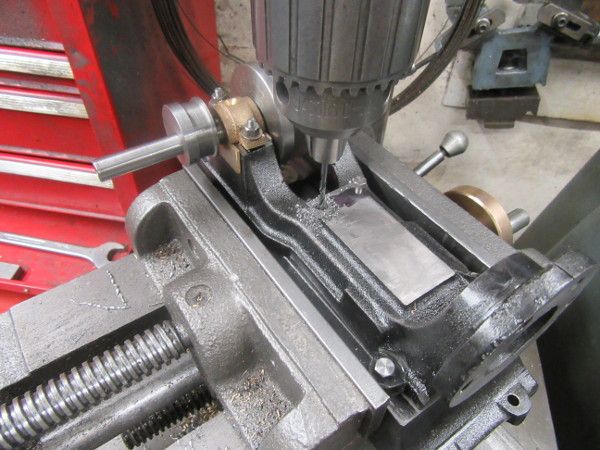

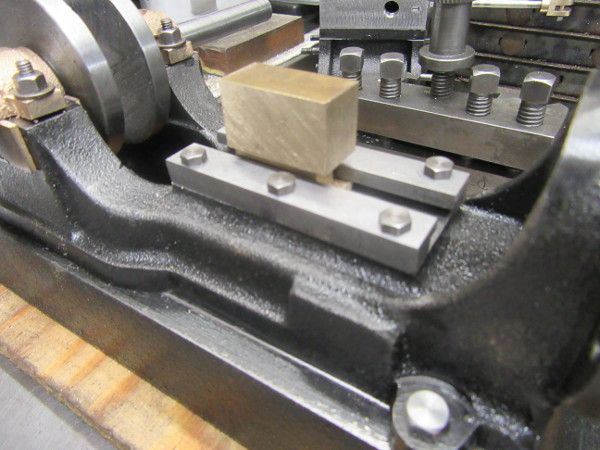

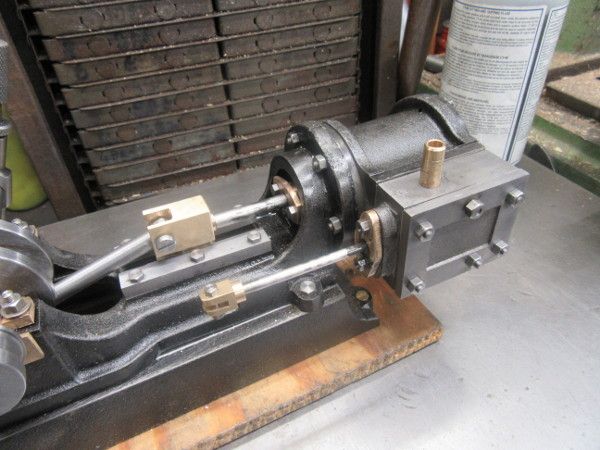

Once I had the gland finished I used it to mark the steam chest, put witness marks on and drilled for the studs. Here I am tapping the holes in the cylinder.

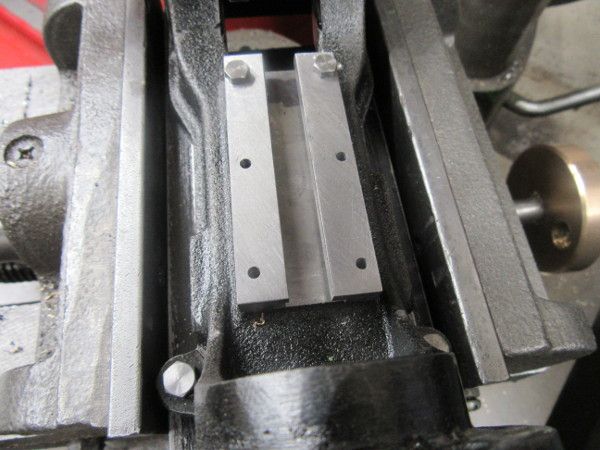

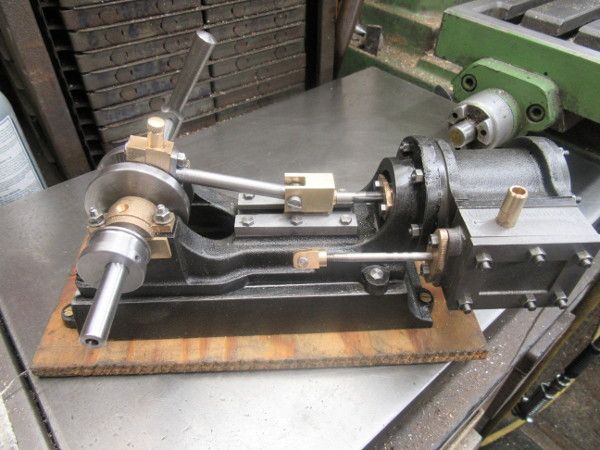

Closing time, the lid and chest are fitted and the gland is made and fitted. Another step nearer an engine! Nice morning, good work and no overriding fear of what the doctor was going to say. Just what I want and definitely the best thing for me.