Page 68 of 123

Re: Shed Matters 3

Posted: 20 Jun 2022, 06:34

by Stanley

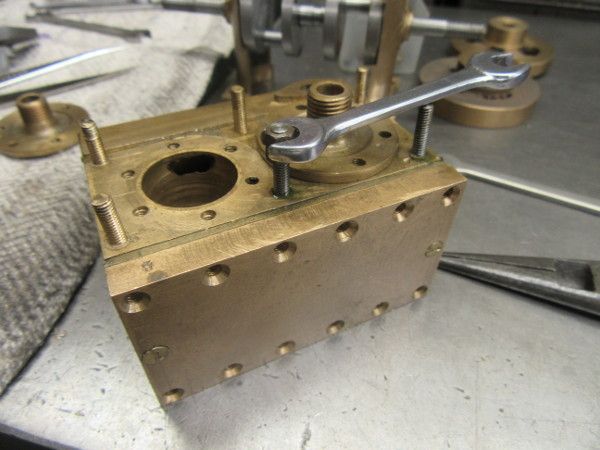

I started the day by cutting the spot faces for the bolts that hold the crank brass together, the brass isn't dead flat on this size. Then I made the screwed plug for the lubricating hole and fitted the bearing. Still tight but that can soon be adjusted when I have fitted the con rod. Then I measured up ready for making the rod, tidied up and knocked off. I know exactly what I am starting on tomorrow..... A good morning!

Re: Shed Matters 3

Posted: 21 Jun 2022, 06:43

by Stanley

Once more, one pic will do. I started making the con rod but wasn't satisfied with my HSS cutter to I found a new piece of tool steel and made a new one. Not the easiest task when you can't see properly but quietly away I got it done and you can see how far I got by closing time. Slow but steady and above all accurate!

Re: Shed Matters 3

Posted: 22 Jun 2022, 06:47

by Stanley

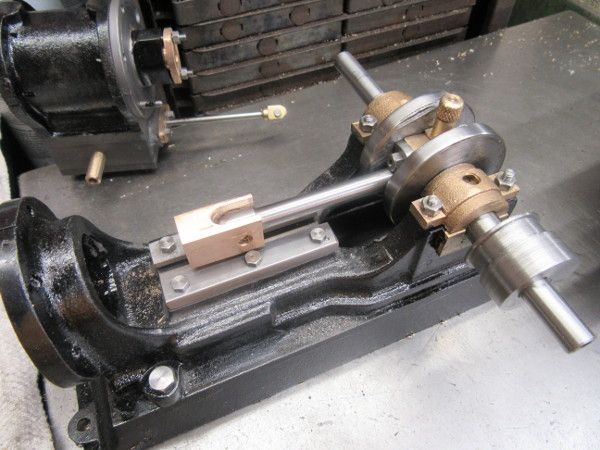

A good hour and a half in the shed. Two pics tell the story of how I got from a slug of steel to a con rod. It needs finishing of course and then fitting but this is another small step forwards and free from error....

Re: Shed Matters 3

Posted: 23 Jun 2022, 06:31

by Stanley

Re: Shed Matters 3

Posted: 25 Jun 2022, 07:02

by Stanley

I started the day by putting the two flats on the small end of the con-rod to get it to 5/16". Then I measured and marked the cross head, drilled the hole for the cross head pin and set up to mill out the slot for the rod. The second pic shows where I am at knocking off time. I am ready to make the cross head pin and finish the cross head.

Re: Shed Matters 3

Posted: 26 Jun 2022, 06:26

by Stanley

These two pics show what I did in the shed after I had given Mrs Harrison a good oiling, it has been crying out for some oil for a while but I kept crashing on. As you can see I made the crosshead pin and fitted it. Only a small thing but essential progress.....

Re: Shed Matters 3

Posted: 27 Jun 2022, 06:40

by Stanley

Re: Shed Matters 3

Posted: 28 Jun 2022, 06:47

by Stanley

Re: Shed Matters 3

Posted: 29 Jun 2022, 06:41

by Stanley

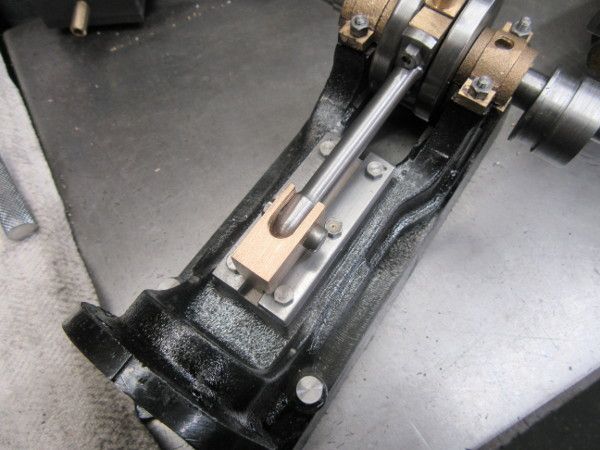

It's been a good morning after a bit of a set-back when I had to resort to Voltarol Emugel to calm down the pain in my shoulder. I always have pain but for some reason this morning it was much worse. Eventually I got in there and the pics tell the story, very careful measuring and recheck several times because My piston rod was about 3/4" too long! Don't ask me how that happened. I put the big three jaw on Mrs Harrison so I could chuck the rod without removing the piston and adjusted the length to what I believed was correct. It was, and the pic shows where I finished at closing time. I'm ready now to work on the valve motion and then install all the studs and build the engine. A dodgy start but then all went well.....

Re: Shed Matters 3

Posted: 30 Jun 2022, 06:54

by Stanley

Re: Shed Matters 3

Posted: 01 Jul 2022, 06:53

by Stanley

Re: Shed Matters 3

Posted: 02 Jul 2022, 06:44

by Stanley

Re: Shed Matters 3

Posted: 03 Jul 2022, 06:53

by Stanley

Re: Shed Matters 3

Posted: 04 Jul 2022, 06:36

by Stanley

Re: Shed Matters 3

Posted: 05 Jul 2022, 06:34

by Stanley

Not a lot of explanation needed this morning. The job was to convert the scabbiest casting in the box into a valve rod support, not made any better by the fact that it all has to be judged by eye, not my strongest department. However, as you can see I have managed to get somewhere near without actually destroying the casting. Tomorrow I shall finish it and fit it.

Re: Shed Matters 3

Posted: 06 Jul 2022, 06:44

by Stanley

Only one pic today after a fiddly morning. I have the valve rod support fitted and bolted to the bed. Now I am fine tuning the throw of the valve rod and I am having a difficult time. This isn't a problem, it's par for the course, making these small engines was never easy and difficulties like this morning's are par for the course. It's why we engineers are so patient.....

Re: Shed Matters 3

Posted: 08 Jul 2022, 07:01

by Stanley

An hour of fiddly things! First I sorted the valve rod, it is set for central stroke now and will not need altering again. As I had the lid off the steam chest I am tightening the studs in the cylinder castings by using two nuts on them. At the same time I have been sorting out my studs and nuts for installing the cylinder on the target on the bed. I have two out of the four fitted and tightened. I had to do that in order to get an accurate adjustment on the valve rod.

Careful work and good progress. Only an hour but a very productive one.

Re: Shed Matters 3

Posted: 09 Jul 2022, 06:47

by Stanley

Re: Shed Matters 3

Posted: 10 Jul 2022, 06:07

by Stanley

Re: Shed Matters 3

Posted: 11 Jul 2022, 06:36

by Stanley

Re: Shed Matters 3

Posted: 11 Jul 2022, 11:16

by Stanley

I couldn't resist going back to the engine and tidying up some stud lengths. All that is needed now is a piece of rubber cutting to go under the base so it doesn't scratch anything it sits on.

I shall reveal what comes next tomorrow....

Re: Shed Matters 3

Posted: 12 Jul 2022, 06:32

by Stanley

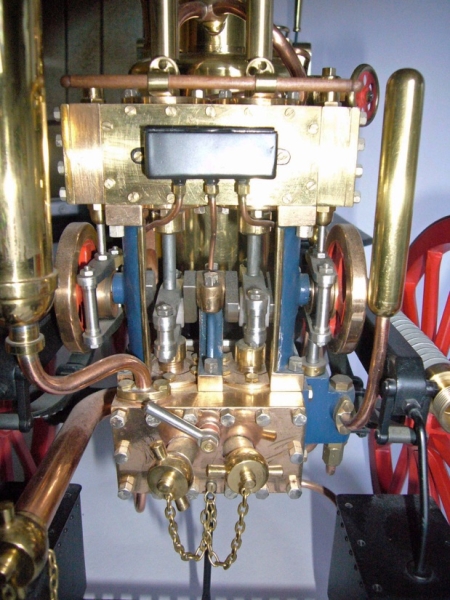

All change this morning. I put the rubber on the base of the No. 9 last night and this morning I touched the black paint up and then took the engine into the kitchen to sit on the table. It's good for my soul to be able to look at things I have made.....

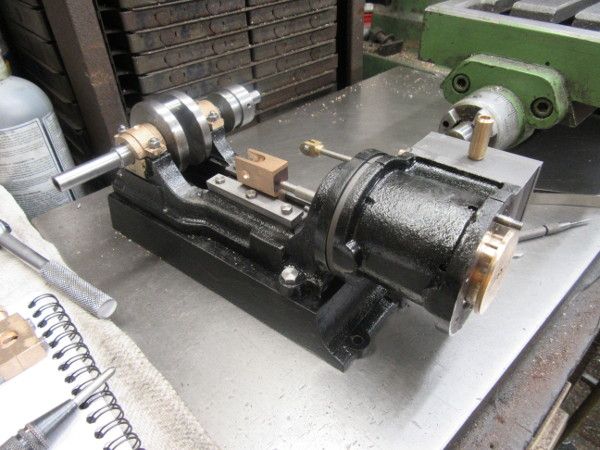

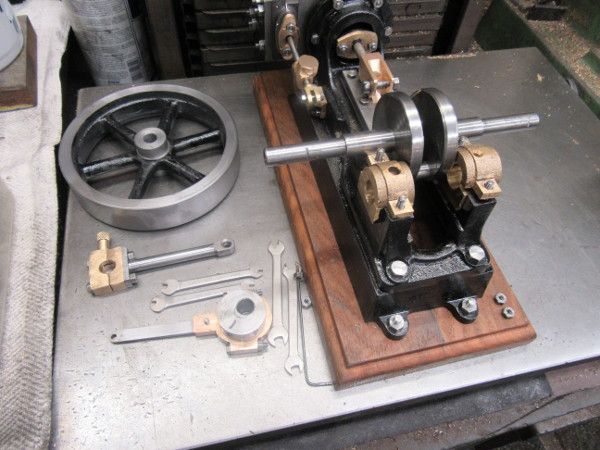

Then it was all change. A while ago, a friend of Bob's, Keith Sharp, gave me this set of Reeve's castings and a full set of drawings. Not all the castings are for the Shand Mason Pump but until I have a good study of the drawings I shan't be able to make any decisions. The castings have been partially finished by someone and you may remember me making a two throw crankshaft for it when I first got the castings. Tomorrow I'll have a look at the drawings and try to come up with a game plan.

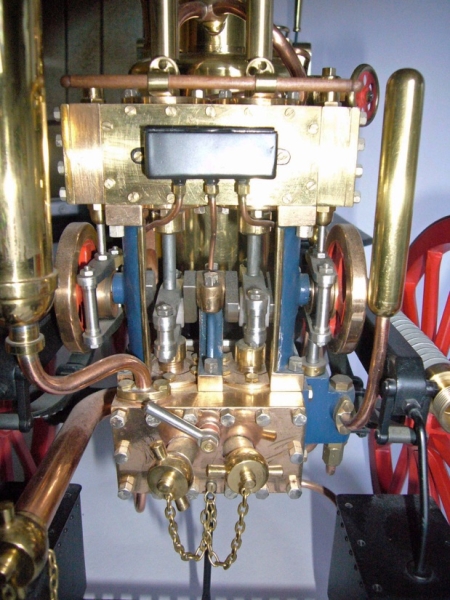

Here's a pic of a finished pump.

Re: Shed Matters 3

Posted: 13 Jul 2022, 06:21

by Stanley

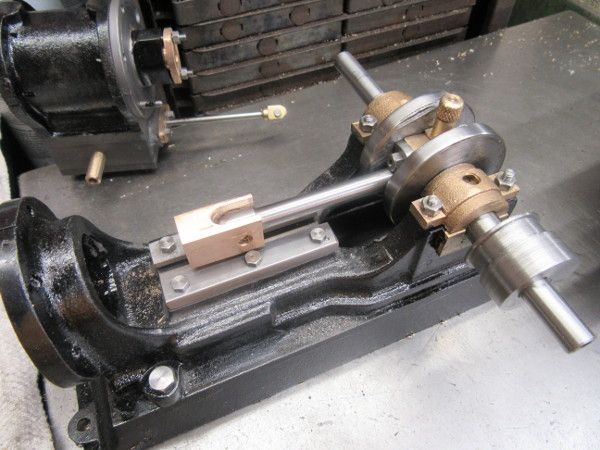

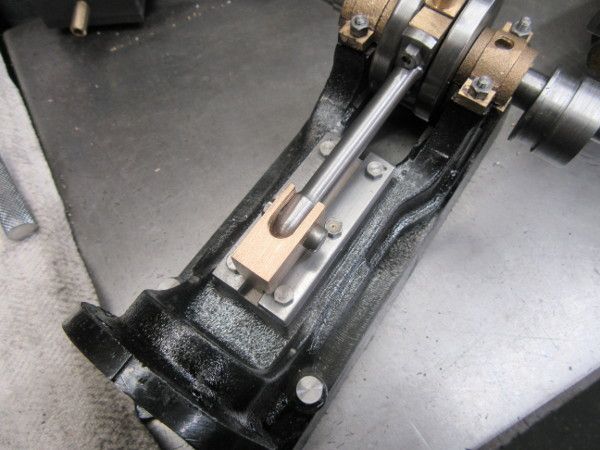

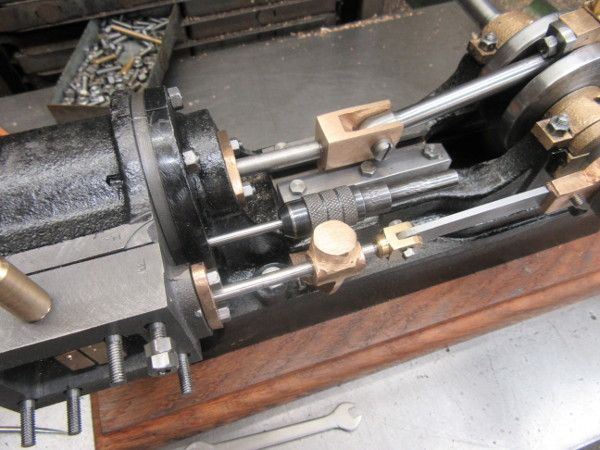

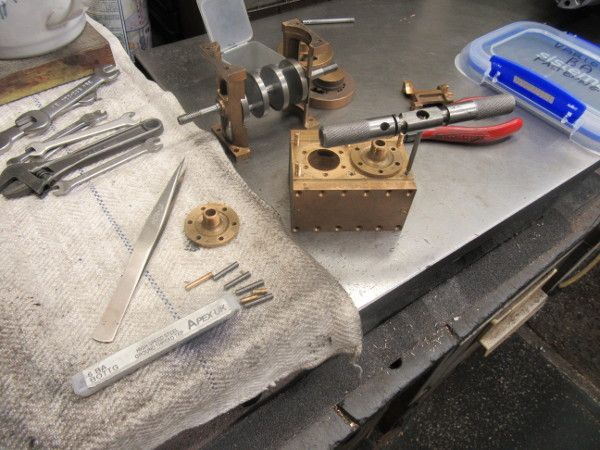

A busy and quite difficult morning. You may remember that I chopped a complicated two throw crankshaft out of a solid piece of stock rather than accept the horrible little built-up shaft that was already partially in place. It was too tight a fit so this morning the first job was to find out why. I stripped it out and found that the shaft was fine, it was the fit of the two standards and possibly the centre bearing that it is mounted in that is at fault. I spent a long time fitting and refitting the outside standards until I was sure they were a good fit.

That being the case my next suspect was the centre, main bearing. In order to prove this I set to to take the centre bearing support out, refit the crankshaft on its standards and see what it was like then. I suspected that I had to lower the main bearing housing slightly to ease the fit. If you look at the images you'll see that what I found was that one of the brass studs that holds the centre standard down was broken. It took me half an hour to get it out but the last pic shows I was successful and where I was at closing time.

Good stuff but not easy and I haven't even looked at the drawings. I shall finish chasing this rabbit tomorrow and then have a look at the drawings.... A stressful morning and my shoulder hurts but so far successful and good progress.

Re: Shed Matters 3

Posted: 14 Jul 2022, 06:32

by Stanley

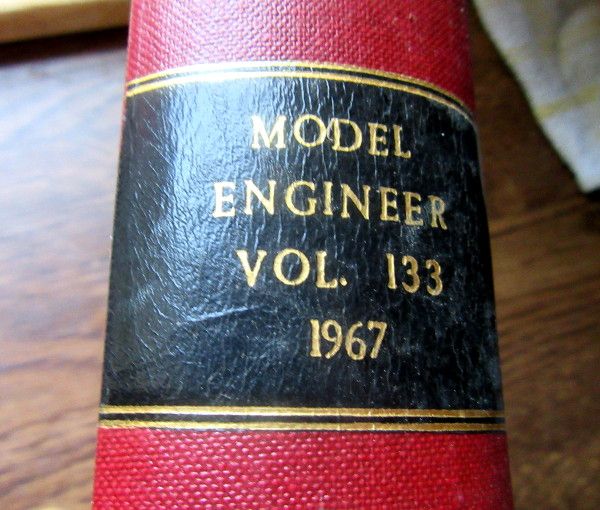

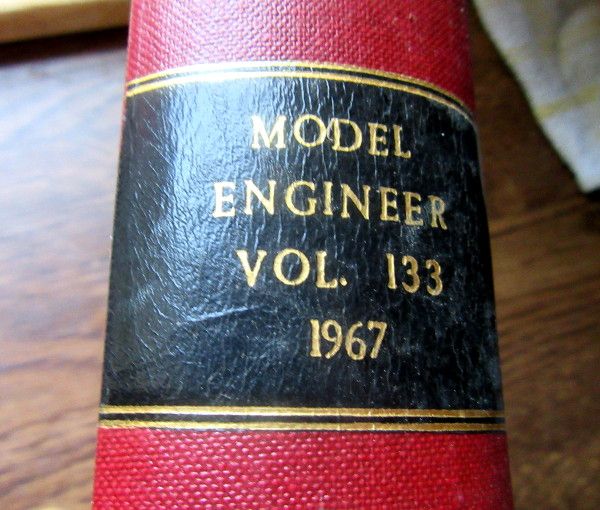

Our first business this morning is slightly different....

Yesterday I recounted the difficulties I was having finding specific information for the build of the Shand Mason pump.

25 Years ago I spent £300 with my bookseller George Kelsall at Littleborough on about forty year's worth of Model Engineers that had been professionally bound and were in as new condition. I went and had a look and Bingo!, I had the volume that I need. I haven't chased the references up yet and don't imagine for one moment that I shall have a complete answer to all my questions but it was a nice moment when I realised I had the information. I shall be reading today......

There is a moral here. When you see things like this, don't just walk past, grab them and wonderful things can happen.

Re: Shed Matters 3

Posted: 14 Jul 2022, 06:35

by Stanley