Page 8 of 103

Re: SHED MATTERS 2

Posted: 01 Sep 2014, 21:20

by micktoon

Hi Stanley , I think that sort of sounds like good news but a shame it was not just the cateracts done and hey ho its the vision you had when you were 21 again, but as you have mentioned it could be a lot worse so just fingers crossed and keep positive

Hopefully the scarring will improve and once the lens is scrubbed off you should be able to apply for a snipers job

I know you will be finding things to keep busy in the meantime.

Cheers Mick.

Re: SHED MATTERS 2

Posted: 07 Sep 2014, 22:27

by micktoon

Hi Stanley and all, I have been car booting again today, its been lovely mild sunny day so they were busy.

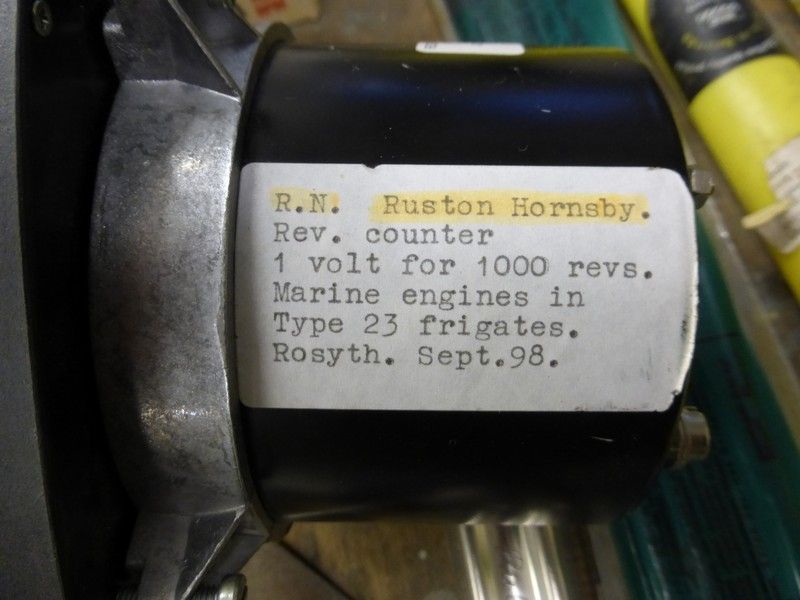

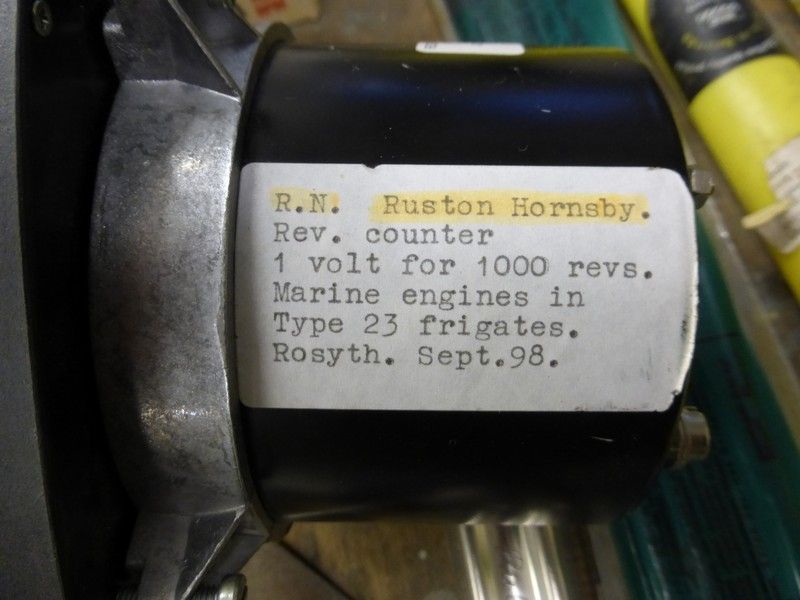

This is my haul from todays 2 bootsales, quite a varied catch again consisting of : A pasta making machine £2........???? what I hear them say , ..............aye don't worry no pasta making here its for rolling out polymer clay for making a prototype for a carving project , the herb chopping knife £1 this is to chop the clay up too. 3 boxes of good Wurth woodscrews £5, two good old fashioned hand brushes £2, 4mm Tee handle Allen wrench 50p, Refco pipe clamp £2, Maun safety 12inch rule £1, 2 tubes of BOC silicon bronze brazing rods, 1.6mm & 3.2mm £6, a thin tube of Cuprotic 3.2 welding rods for copper I think £1 , some 2mm Rothenberger S2 hard soldering rods for Copper £2 and last but not least a nice rev counter from a Royal Navy type 23 frigate, it looks like it will be good for future project especially at £3.

This is the rev counter

The Refco pipe clamp, the company seen to do refridgeration type stuff

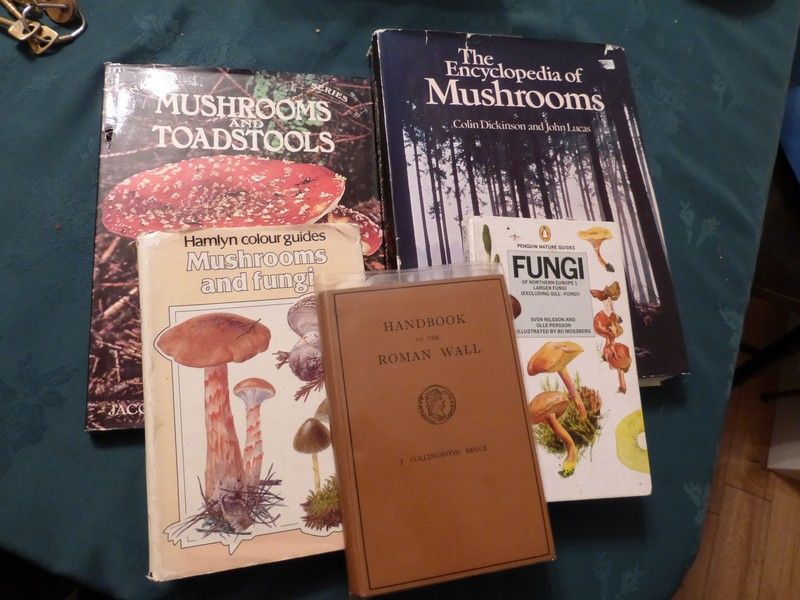

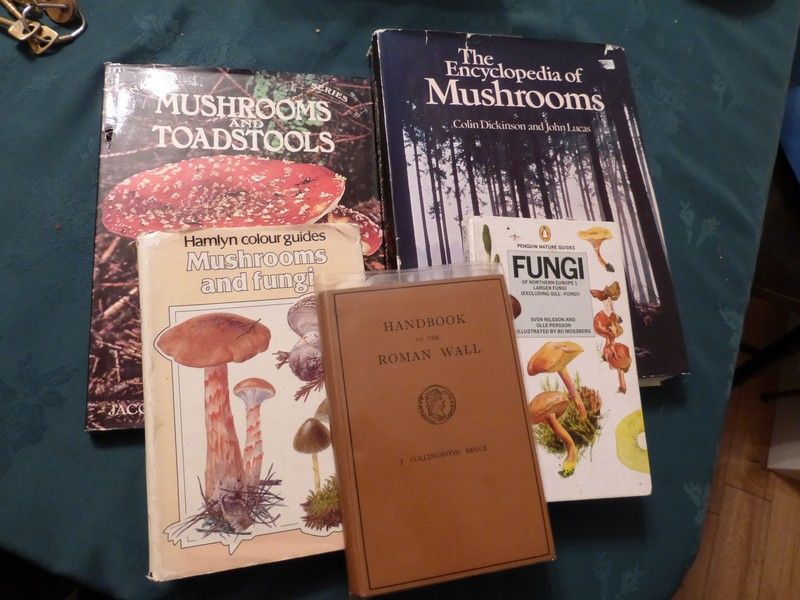

The other odd ball thing was some books on Fungi for my mates wife , she is interested in this sort of thing and is laid up after an operation on her foot so these should keep her amused, or get her off to sleep , one of the two ! The other book is off Doubleboost for an old friend of mine who loves all things Roman, its a good 1933 guide to Hadrians wall, cheers John.

Cheers Mick.

Re: SHED MATTERS 2

Posted: 08 Sep 2014, 03:58

by Stanley

I missed your Sept 1 post Mick, wasn't ignoring you.... Roll on the end of the eye saga! I've found the best way of passing what would have been reading time is watching videos on Youtube.... Some of the construction and demolition ones are hlarious if they weren't do dangerous. There are a lot of idiots in the world...

If your friends wife has had bog toe joint straightened, give her TLC, it's one of the most painful recoveries there is....

Re: SHED MATTERS 2

Posted: 08 Sep 2014, 23:22

by micktoon

Hi Stanley .........you cant beat Youtube now , anything you are interested in is there. Yes she has had problems with her feet so has ended up having several ops over time but this one had toes straightened and wires incerted to keep them in line until they heal, one foot first then once that is ok the other one to do............ like you say looks a nasty job Stanley.

Cheers Mick.

Re: SHED MATTERS 2

Posted: 09 Sep 2014, 03:50

by Stanley

Quite possibly more painful than your knee Mick! How's it doing now?

Re: SHED MATTERS 2

Posted: 10 Sep 2014, 23:26

by micktoon

Hi Stanley my thigh is healing but my knee still shot really but looks like not much can be done until I am mature enough for a replacement lol, they do not like to fit them too early

Cheers Mick

Re: SHED MATTERS 2

Posted: 11 Sep 2014, 04:04

by Stanley

So there are advantages in getting older! Don't worry, surprising how it creeps up on you.

Re: SHED MATTERS 2

Posted: 19 Sep 2014, 05:05

by Stanley

I've been watching videos on machining on Youtube. Interesting that there are some worse turners than me out there! Some of the instructional videos are not only wrong but downright dangerous. One bloke took the final cut when sharpening a drill by bending the post of his Picador jig!

I have a video of building a Stuart 5A bookmarked.....

Re: SHED MATTERS 2

Posted: 20 Sep 2014, 05:37

by Stanley

It wasn't the 5A but the 10A, a smaller engine. Interesting watching a man called Texas John making it. He made all the same mistakes I am guilty of! Amazing how you can learn from watching other people working and he reminded me that my old digital gauge, about 30 years old, is not reliable now as it loses readings because of bad contacts. I've asked Mick to look out for an old imperial 6" dial gauge for me. I saw one on the web, a good old Moore and Wright for £70 but thought I'd get Mick's advice....

Re: SHED MATTERS 2

Posted: 21 Sep 2014, 07:18

by Stanley

Red Letter Day yesterday! Mick will be pleased to know that watching the machining videos on Youtube seems to have done the trick. I have been getting the itch for a few days, looking for a dial gauge is one sign but yesterday I went in with a purpose. Interesting watching the videos, particularly a bloke who posts as Abom79 who is a bloody good turner, it's his day job but he has a big shed at home. His granddad and father were both in the same trade and it shows. Lovely watching him work and being reminded of certain things. What was on my mind yesterday was the fact that in my early days I always had a pot of cutting oil and a brush handy when I was cutting but got out of the habit. I had a sold brass rice measure that is just the job, the right size and heavy enough to stay where you put it! Another thing that struck me was the amount of cutting done with tipped tools. Newton hardly ever used them, he was a HS steel man and as I learned my turning from him I veered the same way. However, I did go out one time and buy a couple of tool holders, left and right hand, and a bunch of spare tips but never got on with them and they languished amongst the treasures. I got them out yesterday, made sure the tips were good and set them up on centre in two of my quick change blocks. A few practice cuts which on reflection aren't fast enough, and I'm set up. You can see them both mounted up at the same time and the brass oil pot.

I noticed something else as well, Abom frequently uses a dial gauge with a magnet glued on the back which he pops onto the front of the ways and uses to accurately measure lateral movement on the saddle. I have the usual dial gauge mounted on an Eclipse magnetic block which is good but not as tidy and easy as this. I have spare dial gauges and am going to have a look to see what I can lash up. I also have some very powerful magnetic plates that surprisingly enough came out of a paten window cleaning kit that used a magnet to hold the cleaner on the outside of the window. Anne across the street had it given but despite the power of the magnets it was useless so she gave it to me. They are so strong that the biggest problem is separating them from their keepers so I'm sure they'll do.

Another ting I didn't mention was the fact that despite Little John from Texas being on about the same level as me, his engines are better. Really pissed off about that but I can see where I have been going wrong... I can see me making another engine!

PS. I think I was frightened of finding out how bad my eyes are. Funny thing is I never noticed so they must be better than I thought. Nothing a magnifying glass can't cure.

Re: SHED MATTERS 2

Posted: 21 Sep 2014, 07:31

by David Whipp

That's all good to hear, Stanley!

Re: SHED MATTERS 2

Posted: 21 Sep 2014, 07:51

by Stanley

I'm pleased as well David... I think I was afraid of finding out I was worse than I am....

Re: SHED MATTERS 2

Posted: 21 Sep 2014, 09:07

by Stanley

This shed culture is compulsive! Thinking about the magnetic backed indicator I went and had a look in the box where I knew I had a spare dial indicator or two. One of them, an old Capstan made in Brighton of all places, had a heavy metal back into which it slipped and was held by three tiny Allen screws which protects it. This back can be easily milled flat to accept a magnet. Only problem was it had no glass! However, surprise surprise I just happened to have a small packet containing 6 Stability replacement pocket watch glasses which were almost an exact fit, just slightly too undersized to spring in. Another root in another place and sure enough I had some two part Araldite. Only problem was that it's so long since I used it the caps were frozen on so I used my head and clipped enough off the bottom to get some out. Found an old plastic cap, mixed some up with plenty of hardener because of the age and ran a thin string into the bezel (after cleaning the dial face with a cotton bud and WD40). I Popped a glass in and left it to harden. So I now have the dial gauge and a back to machine flat....

Re: SHED MATTERS 2

Posted: 22 Sep 2014, 05:21

by Stanley

First job was to cut the old stud off the backing plate.

Pop it into the lathe and take a skim across the back.

The next bit was the most difficult! Here are the four magnets inside their keepers. I can't stress too much how powerful they are and separating one block out was a pantomime. They fight you whatever you want to do! Big does and little does and I managed. No need to glue the magnet on to the indicator back, the grip is more than sufficient.

Here's the finished job, we now have an accurate depth gauge on the slide ways. By the way, it will fit on any of my lathes.

Mick came up with the goods for me. He found me a Moore and Wright dial gauge and I've ordered it. Saved me £30. Good lad Mick!

Re: SHED MATTERS 2

Posted: 22 Sep 2014, 21:42

by micktoon

Hi Stanley, Well what can I say , after almost giving up on seeing any action .................. I log on to see I have been missing all the action

Well very glad to see you back in the shed and glad the eyes seem to be not holding you back too.

Abom79 (Adam) has good videos , there are a few others you might like too Stanley the same sort of thing , OXTools (Tom Lipton ) has good stuff as does my mate John who goes by the name of Doubleboost on Youtube, he has machining videos, casting, patern making etc and does the odd videos on local places of engineering interest too as well as his car boot sale finds. He has a few videos showing the making of a dial gauge like you have and other lathe and milling extras.

Glad the M&W dial caliper info helped you out and saved you a few quid. What do you use as cutting oil Stanley ? , I have tried some hydraulic oil, thinned with burning oil , that looked to have similar properties to proper Shell Ilocut cutting oil but it smokes like mad and looks like the lathe is actually on fire

so I will have to drain it off and find another alternative , the reason for that trial was I got the oil free

Keep up the good work, I will be checking back every day now !

Cheers Mick.

Re: SHED MATTERS 2

Posted: 22 Sep 2014, 22:26

by micktoon

Hi Lads, this is my haul from Sundays car booting, I was with John and had a good day too.

As you can see quite a good engineering related batch today, the lathe tools are 25x25 type for the big lathe some with spare tips too and a parting tool with spare blades and tips, the boring bar is 25mm and a good length, a couple of decent DTI's and a Noga mag base plus various taps, calipers etc.

Ther is a nice old Weller 100w soldering iron and a Burgess Vibro tool engraver, a good old powerful heavy duty thing not like the Sh** you get today , its even in the original box !, a couple of de burring tolls with spare blades.

This is the best DTI , a Rambold German made 2 inch travel guage, I have never heard of them but its good quality and feels heavy. I think everything in total came to £60 or a few quid less, so well happy with the days goods.

Cheers Mick.

Re: SHED MATTERS 2

Posted: 23 Sep 2014, 04:32

by Stanley

I bought a ten gallon drum of neat cutting oil (not soluble) many years ago and about 8 Gallons of it is in this tank. Gravity feed to the lathe and manual return to the tank when bed tank is full. I only use it on flow when I'm doing heavy turning on things like chopping crankshafts out. You'll note no doubt that the magnetic dial gauge is parked on the end of the angle iron support. The thin edge means you can remove it by hand. The magnet is so strong that if it was on a large flat metal surface it would be a major job getting it off.

Nice lot of stuff. Funnily enough, playing with the tipped tools reminded me that I had a tipped holder and threading set so I looked them out. I also have a big boring bar but not sure if I didn't give that away. If not I shall find it.

The tips are all Unified but near enough to Whit and BSF for a bum turner like me!

Re: SHED MATTERS 2

Posted: 23 Sep 2014, 08:00

by Stanley

Just watched 4 videos of your mate John breathing new life into an old Manus vacuum pump. Pure fitting and what I did most of my life. Nothing nicer than bringing a good piece of kit back from the grave! It had echoes for me as well because I learned my machine milking on a Swedish Manus set-up and our pump was exactly the same as this one. Nice.....

Now, where's that boring bar.....?

Re: SHED MATTERS 2

Posted: 23 Sep 2014, 23:18

by micktoon

Hi Stanley , looks like you have had another day in the shed , I hope you find your boring bar . The tipped threading tool looks nice, good how the one tool does the various pitches. John had done some really good videos, check on his channel as some are quite old now with good machining on them, making a dividing head etc I am sure you will enjoy them.

Cheers Mick.

Re: SHED MATTERS 2

Posted: 24 Sep 2014, 03:55

by Stanley

Not a full day... After so long out of it a couple of hours on my feet is enough. I will improve.....

Re: SHED MATTERS 2

Posted: 24 Sep 2014, 08:17

by Stanley

Mick, during my furtle looking for the boring bar.... (I'm giving up on that one, if I trip over it OK but it's displacement activity!) I have found this David Brown adjustable reamer. Two and three sixteenths to two and three quarters. No 4 Morse taper which doesn't fit any of my lathes now since I got rid of the big one when I moved in here. It's a good tool and I'm sure you can find a home for it. It's a freebie of course. Someone would love to have it somewhere!

Re: SHED MATTERS 2

Posted: 24 Sep 2014, 22:26

by micktoon

Hi Stanley , you are better off taking it slowly and getting back into things bit by bit, like you say a few hours at a time will be enough to get you started

, What sort of size boring bar do you need ? , I will keep my eyes open. I dont know how oftern or when I would use the reamer but will give it a good home until the day its needed

, I have a MT3-MT4 adaptor that I use on the Binns and Berry lathe, saying that if you though you would ever use it you could get an adaptor sleeve too ?

Any sign of your new dial calipers eyt then ? .

Cheers Mick.

Re: SHED MATTERS 2

Posted: 25 Sep 2014, 04:18

by Stanley

I thought about a 3 to 4 adaptor but it would be too cumbersome. I'm OK for boring bars but if you come across any small offset tools rather than bars they would be welcome. Usual terms.... The David Brown Tools boring head is yours.

The dial gauge arrived yesterday and if it isn't an import I'll stand locking up! However, I've tested it on standards against my micrometers and it is accurate to less than half a thou so that's all right. Heavy weight, in a fitted case and a good finish but not quite Moore and Wright if you know what I mean. I got my old Mitutoyo digital out and gave it one last chance. I cleaned all the contacts up and lo and behold it works. Not sure what will happen in practice

but we'll see. I tripped over my Verdict lever point indicators, one metric and one Imperial, that were given to me by my old mate Arthur Entwistle years ago. He was a tool room man so they are good ones! Got my magnetic base out and cleaned the base up. It's a good tool but I could do with a slightly heavier one with a bigger reach, the one I have has a .475 diameter post 6" high. If you trip over a bigger one that's cheap, grab it for me.

That was about it for yesterday.... I need to have a clean up and sharpen and actually get round to doing something rather than sorting out! My mind is active....

Re: SHED MATTERS 2

Posted: 25 Sep 2014, 22:06

by micktoon

Hi Stanley , I know exactly what you mean about the M&W calipers, I think it always looks worse in the modern plastic cases too, the actual tools seem to look better with a bit of use somehow. I will keep my eyes out for a bigger mag base and also offset tools, do you mean the tiped type where the actual tip is set off to the side and sort of juts out from the holder body ?, you have a bigger tool post on your lathe so what size tools will it take 25x25 ?.

I have found some of the digital calipers , if you can clean the battery contacts with say fiberglass pen brush then just tweak the bend a little so it makes better contact has done the job for me in the past

Good to see you back in the shed anyway Stanley, sounds like you have the urge to make something again

Cheers Mick.

Re: SHED MATTERS 2

Posted: 26 Sep 2014, 04:28

by Stanley

I think the thing is that the sharp edges are more broken on old tools and they feel soft in the hand. That's what I did with the digi calliper. Got a new battery and found I had a spare pinned up in the shed! The one that's in it is functioning well so I have three now! When will I learn.....?

Not thinking of anything ad big as that Mick, not bothered if they are tipped or welded HSS but I was thinking of small side cutters for bores up to say one inch.

Pent time yesterday having a good clean up and deciding that rearranging shelves and storage over the lathe was displacement. Bottom line is I have too much stuff in too small a space!

I have to rewrite a big article over the weekend so don't expect any significant activity.

Re the base, the post is 12mm of course and I'd like a slightly heavier one than normal so it will sit on the suds tray on the Harrison and reach the chuck. If you saw a ball jointed flexible arm slightly heavier than the usual El Cheapo that would be good. No push, It was just a thought....

David Brown Boring head is in the Mick corner with the gas set.... Remind me to give you a bunch of HSS as well, I have more than you can poke a stick at!