SHED MATTERS 2

Re: SHED MATTERS 2

Handy in the shed if your stuck for space http://www.practicalmachinist.com/vb/an ... he-333301/

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

I already have one Bodge.....

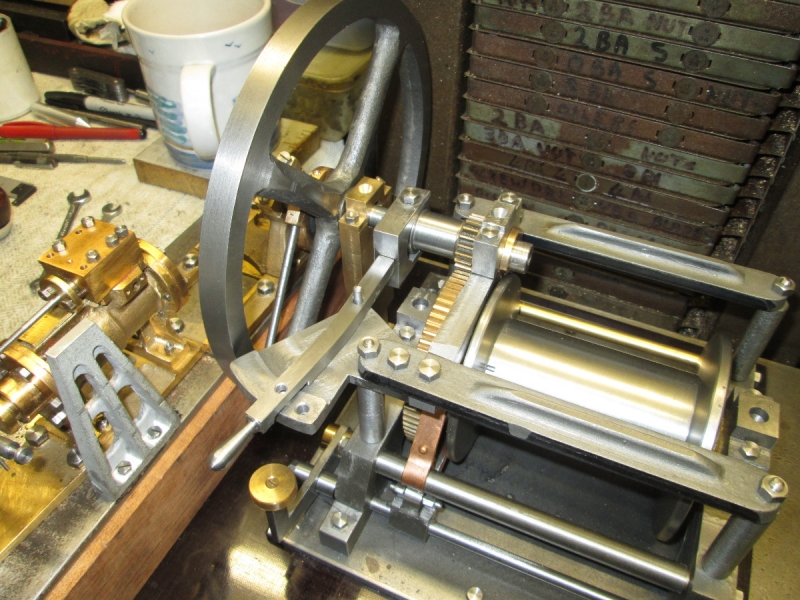

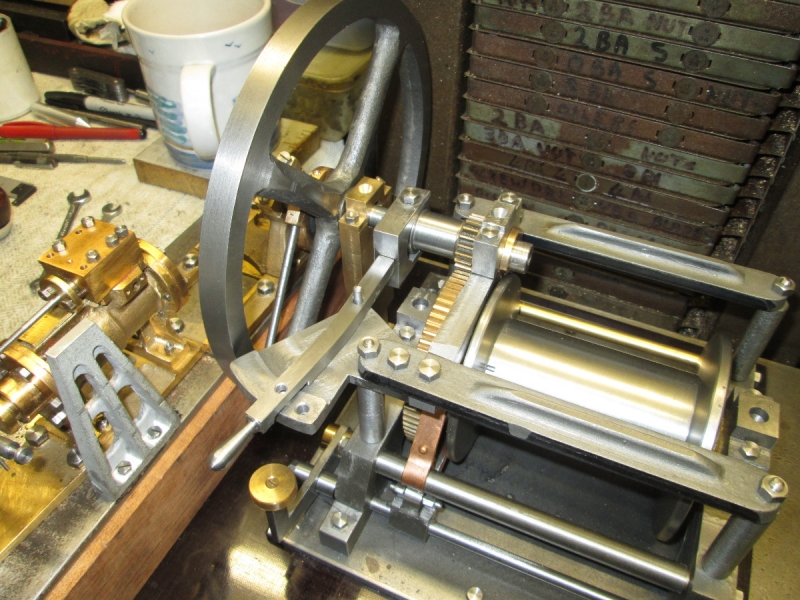

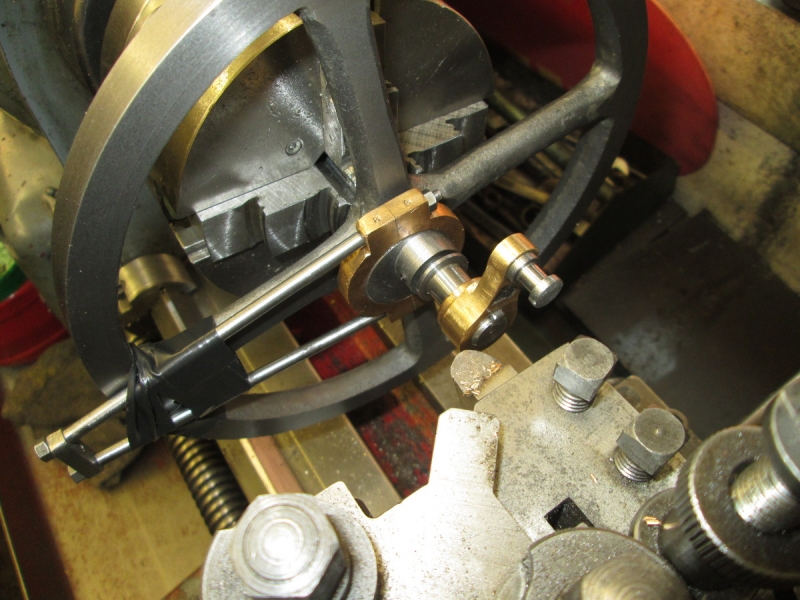

Today is prettification day..... I want to make the selector and gear lever look as though someone cares.....

Notice that we now have a handle and I have drilled the 5/32" hole for the pin which will locate the lever on the quadrant. All edges broken and offered up to fit.

Looking good but there are a couple of things that need sorting. I need holes in the quadrant for the gear lever pin but when I came to look, the in gear position was too near the end of the quadrant. I had to do the highly dangerous job of putting a bend in the gear lever. It's key steel so its tough. I did it in the vise using an 18" Stillson to put the bend in. Then I marked the quadrant took it off the winch once more and drilled and countersunk the holes in their proper positions.

Knocking off time.... I shall make the pin for the quadrant tomorrow. In addition I have gone through all the bearings on the shaft and identified the tightness as being generated by the top cap of the crank bearing. I eased that and its fine now. I also realised, once the shaft was free, what the source of the tightness in the selector is. I had been assuming it was misaligned but now I can see it is in the mesh of the pinion gear with the bull gear on the drum. I could adjust this but have decided to leave it. The bronze gears will soon argue out an easy sliding fit when it is run in. Another nice morning.....

Oh, by the way, I did another little job.

I cobbled up a bracket for the door to the cellar glory hole and the steps can live there handy but taking no room. And yes, I know that plywood needs a coat of paint!!

Today is prettification day..... I want to make the selector and gear lever look as though someone cares.....

Notice that we now have a handle and I have drilled the 5/32" hole for the pin which will locate the lever on the quadrant. All edges broken and offered up to fit.

Looking good but there are a couple of things that need sorting. I need holes in the quadrant for the gear lever pin but when I came to look, the in gear position was too near the end of the quadrant. I had to do the highly dangerous job of putting a bend in the gear lever. It's key steel so its tough. I did it in the vise using an 18" Stillson to put the bend in. Then I marked the quadrant took it off the winch once more and drilled and countersunk the holes in their proper positions.

Knocking off time.... I shall make the pin for the quadrant tomorrow. In addition I have gone through all the bearings on the shaft and identified the tightness as being generated by the top cap of the crank bearing. I eased that and its fine now. I also realised, once the shaft was free, what the source of the tightness in the selector is. I had been assuming it was misaligned but now I can see it is in the mesh of the pinion gear with the bull gear on the drum. I could adjust this but have decided to leave it. The bronze gears will soon argue out an easy sliding fit when it is run in. Another nice morning.....

Oh, by the way, I did another little job.

I cobbled up a bracket for the door to the cellar glory hole and the steps can live there handy but taking no room. And yes, I know that plywood needs a coat of paint!!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

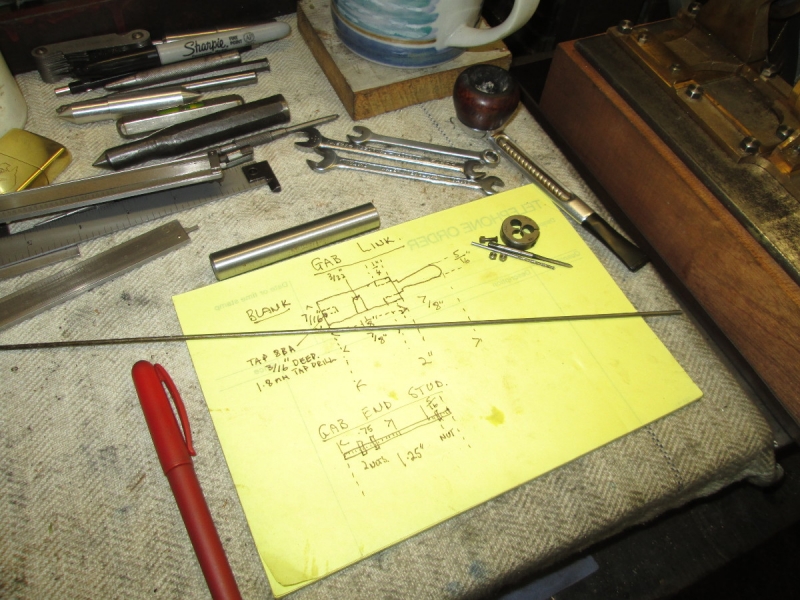

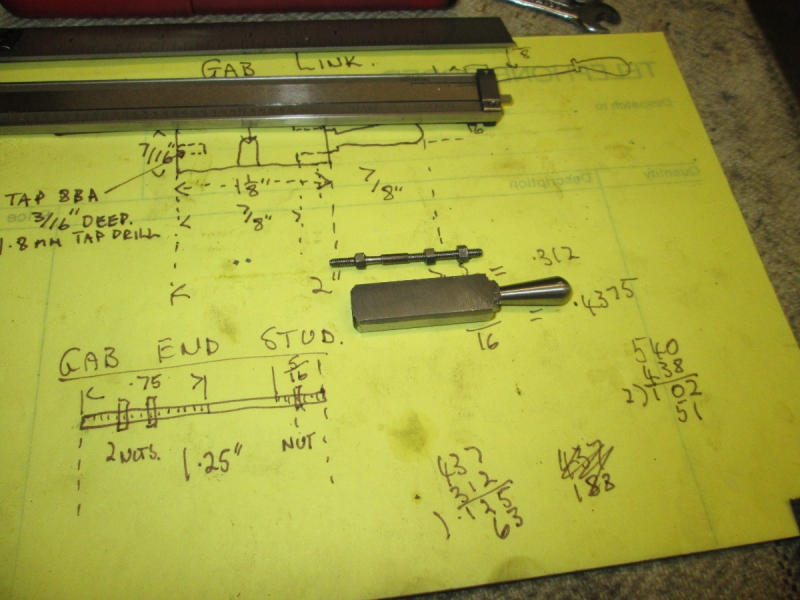

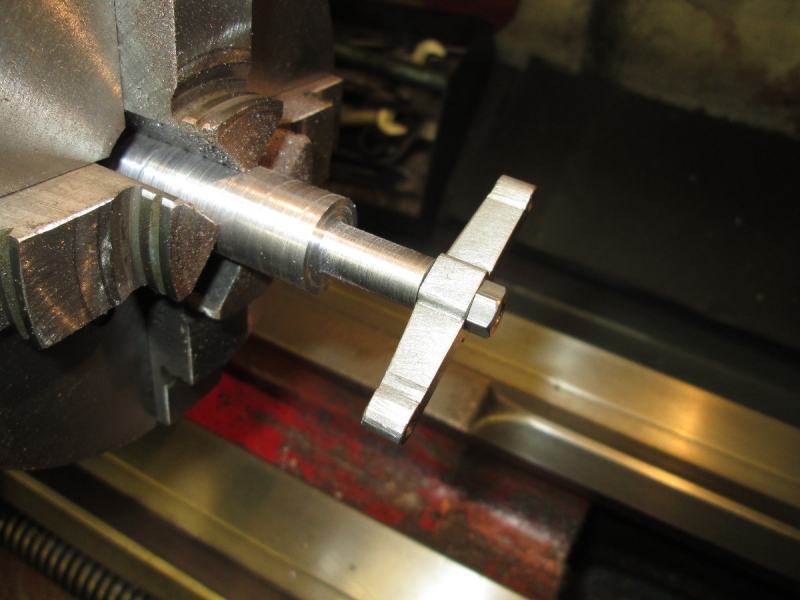

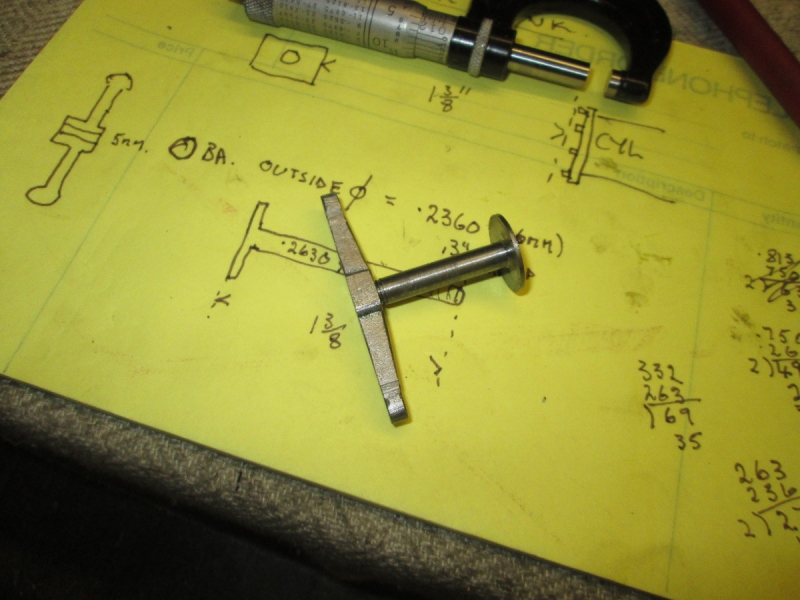

Today we need a peg to retain the gear lever in place on the quadrant. So a bit of simple but small turning.

Here it is made and fitted.

There was no more actual machining. I decided I might as well bite the bullet and make yet another fiddly item, the hooked end for the eccentric rod which is the gab link, made so that the valve gear can be lifted out of gear if necessary. Used on a full size engine for disconnecting the eccentric while the engine is rotated by hand to a starting position. Complicated little bugger and it needed fathoming out, a bit of re-design to make it easier to make and identifying 8BA nuts and threading tack;le which I need for the connection to the eccentric rod. I looked up the stock I need, silver steel rod for the stud and MS for the gab itself.

I had to go into the 1927 lathe, the three jaw on there is the only thing I have that will hold this thin rod for the stud.... Ready for tomorrow.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

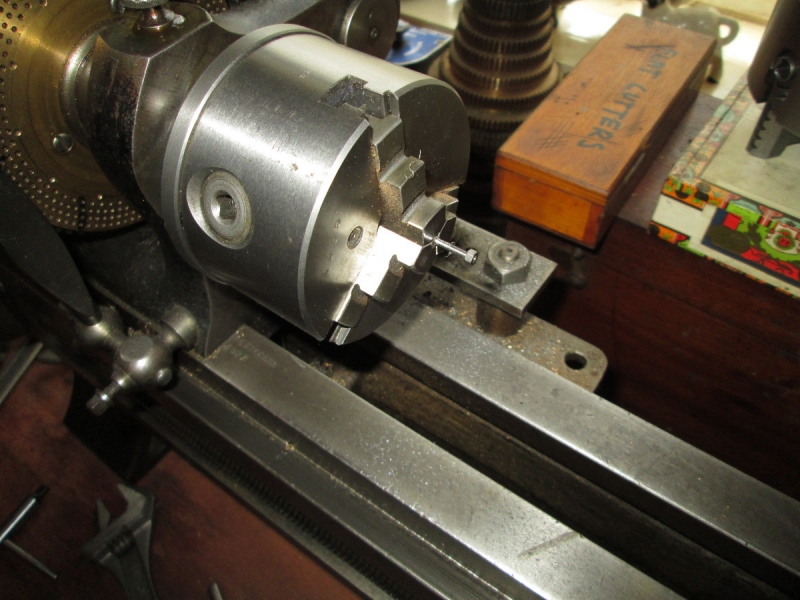

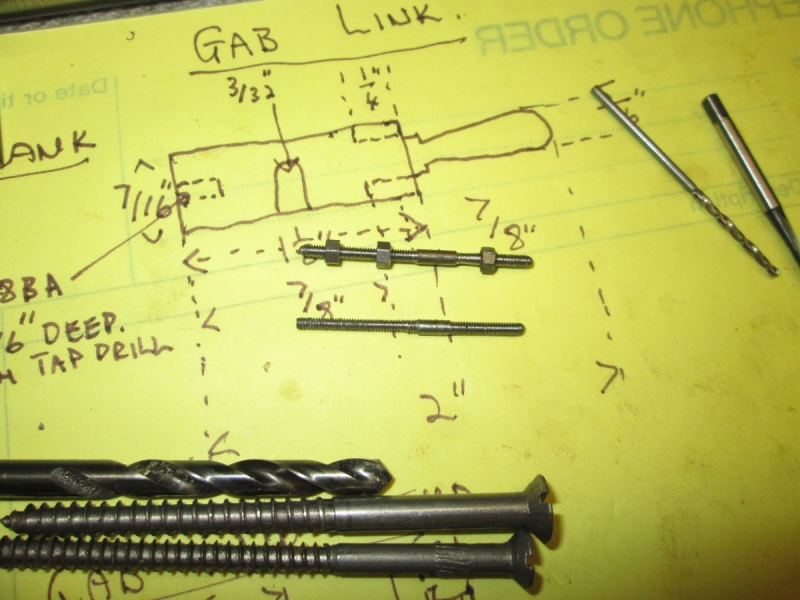

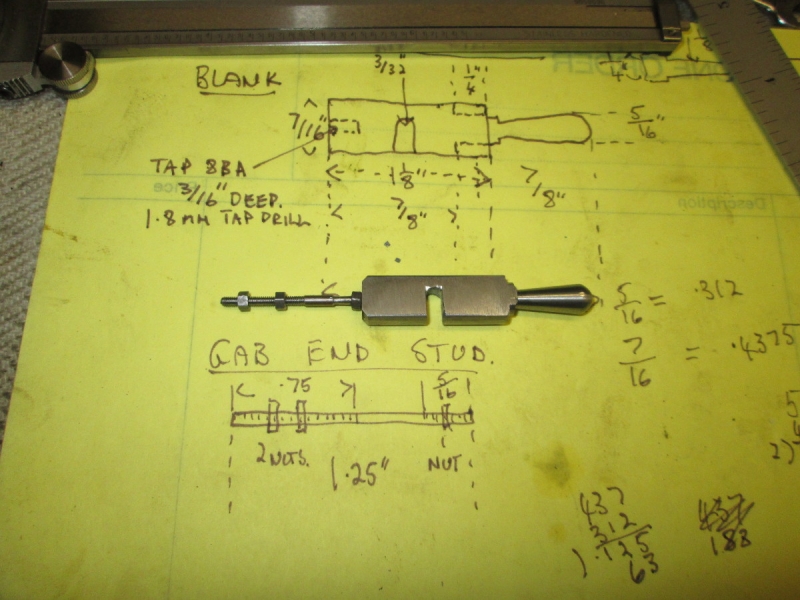

I started the morning on Johnny's 1927 lathe making the 8BA stud.

Not as easy as it looked. It took two goes to make a perfect stud. The thread is so fine I had the adjustable die ever so slightly tight and made the stud too small. I did some experimenting and finally got it right with a good tight fit for the nuts.

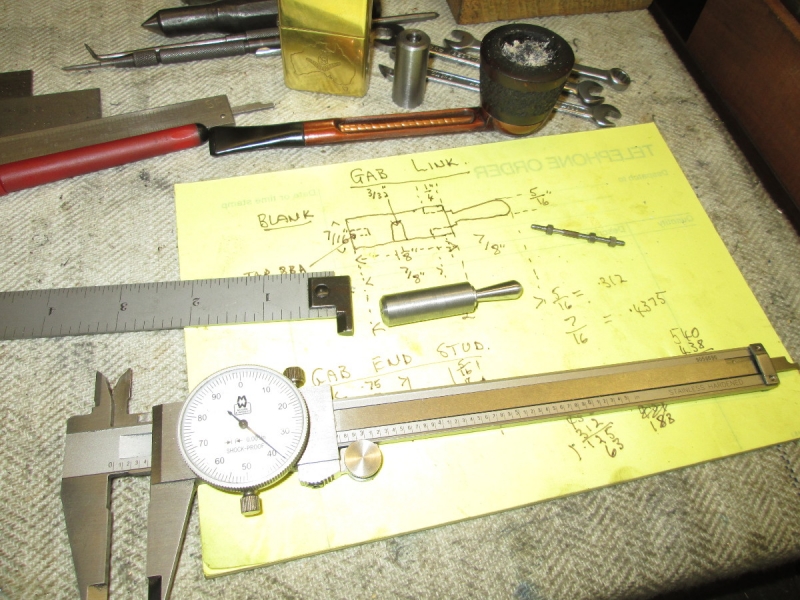

I started on the body of the gab arm. The first thing I did was face the end and drill and tap it for the stud. A trial fit and it's a good fit. So I went on with making the blank body.

By knocking off time I had the body finished as far as turning goes, the rest of the work is milling and hand work. If you're thinking I was a bit slow this morning the reason is that I had another small job to do which was to put two more screws in the bracket on the cellar door so it doesn't swivel. This entailed using my Metabo cordless drill and after I had gone to the trouble of charging the battery I found that it had gone the same way as its mate, the chuck had given up the ghost. I have decided that they have to go and when I am in funds again I will get myself a new one. So if anyone fancied obtaining and fitting new chucks to the drills you're welcome to them. I am too old and too busy to do the job. They are, apart from the chucks, good drills and even though the batteries lose their charge if not used regularly they are perfectly serviceable when freshly charged. Each has two batteries and of course a charger. So if you feel like having a crack, just ask me!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: SHED MATTERS 2

I'm asking if no one else wants them  . I have a small chuck in the drawer somewhere. I need to come round with a bit o' paper to make a template too.

. I have a small chuck in the drawer somewhere. I need to come round with a bit o' paper to make a template too.

Kev

Stylish Fashion Icon.

Stylish Fashion Icon.

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

They are yours Kev, both of them. You know how to grab me.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

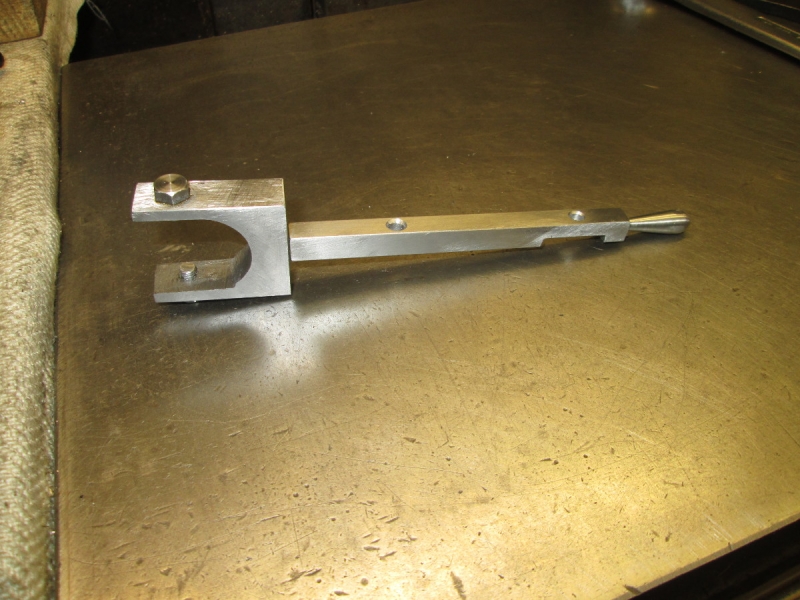

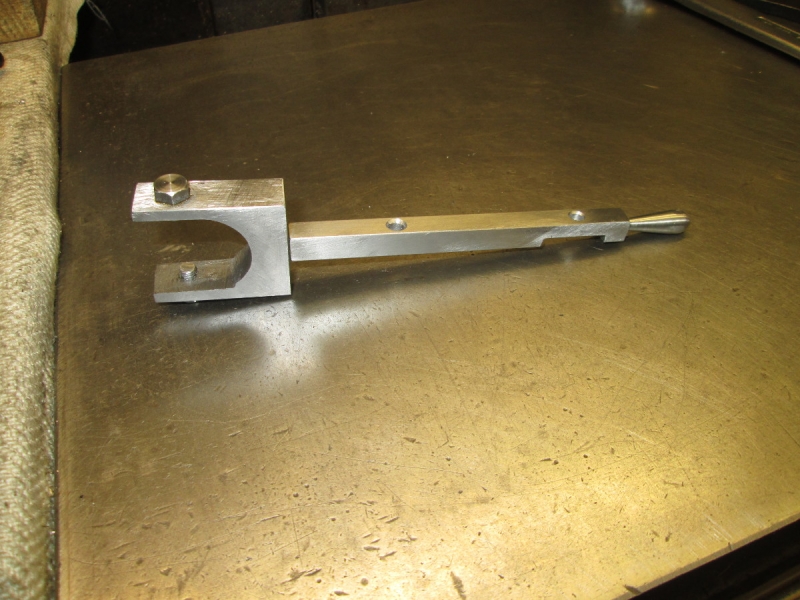

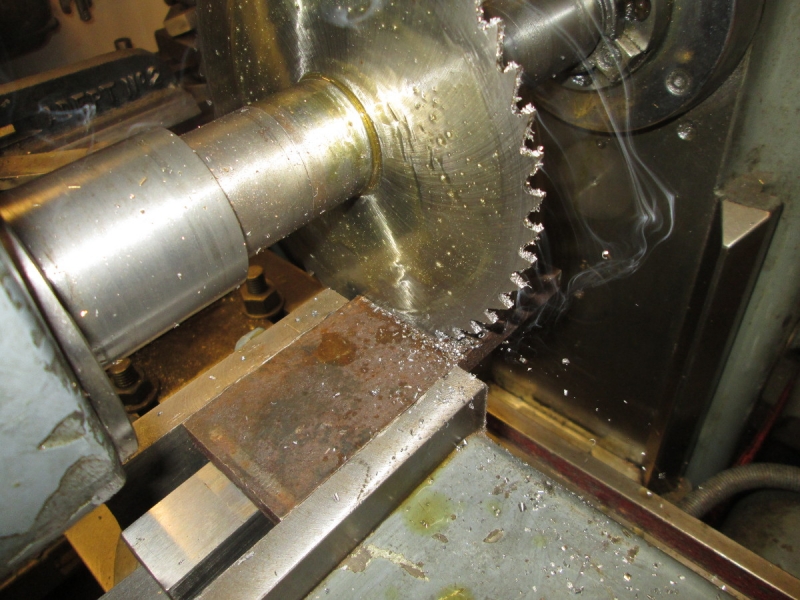

Not a lot of metal shifted this morning, shopping and cooking got in the way but that means more time in the shed over the next two days! What I wanted to do was carry on getting some shape into the gab link and this morning that meant reducing it to 1/4" thick, flattening the body if you will. Very careful setting up and even more careful cuts as I hadn't much hold on it.

It took an hour to get here at knocking off time. The body is 1/4" thick now and all the edges are broken and surfaces filed and polished. Next job is to cut the slot in it to grab the pin on the valve rocker arm. Progress and no cock-ups, my idea of a good morning.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

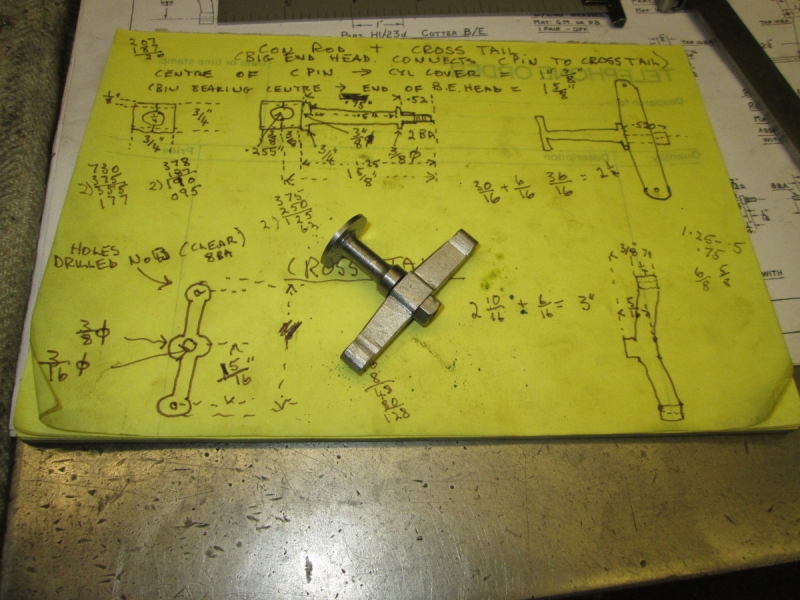

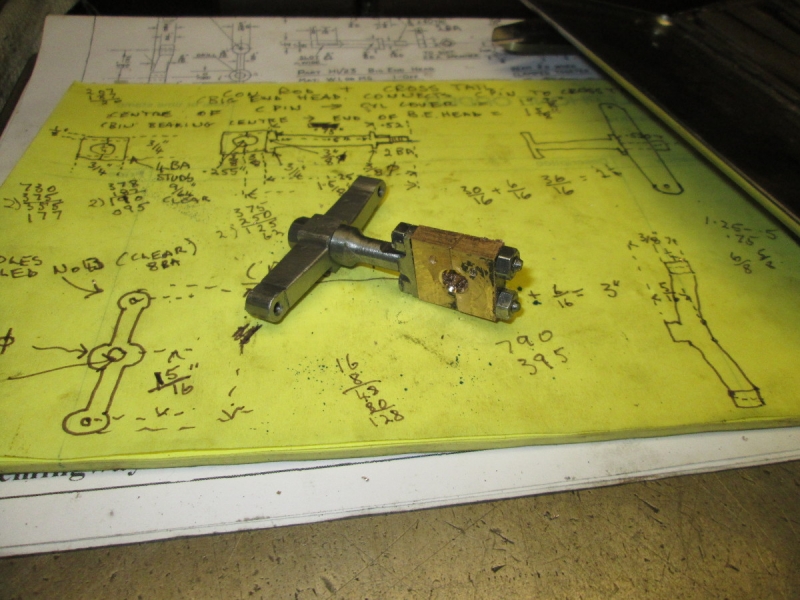

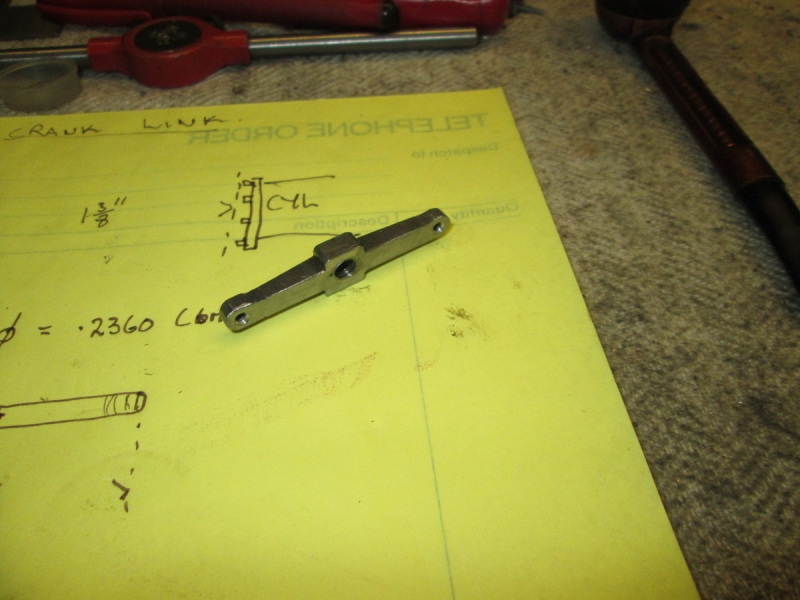

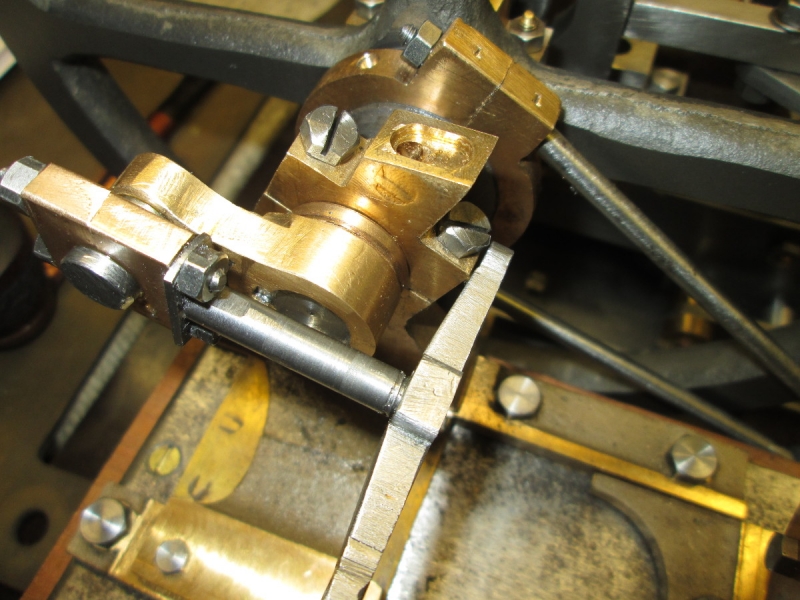

My first job was to finish the gab link. It needed a slot cutting in it so it can hook on the valve arm.

Here it is fitted on the end of the eccentric rod. The lighter is there to support it of course. That's another bit made and fitted, on with the next piece....

I needed a piece of 3/8" MS to make the next piece which is the cross head that is the connection between the connecting rod and the two connecting rods that go down the sides of the cylinder to connect with the crosshead on the tail rod. (I still can't fathom why the engine was designed like this, it's crazy! But this is how it has to be..... )

Here's where we are at closing time. The blank is the right size, squared and I have started putting some shape in it. There's a lot of metal to come off it yet. One thing to note is that when I cut the main piece of stock off I had measured what I needed at 3". As soon as I had it cut I realised it was far too big! I went back to the drawing and found I had read 15/16" as 1 5/16" and after doubling it and adding the spare on the end had arrived at 3" when it should have been 2 1/4"! If you look at the fag packet drawing you can see all the wrong working out. Never mind, just as luck had it the smaller piece of stock left over was exactly the right size. There is a providence that looks after drunken men and idiots......

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

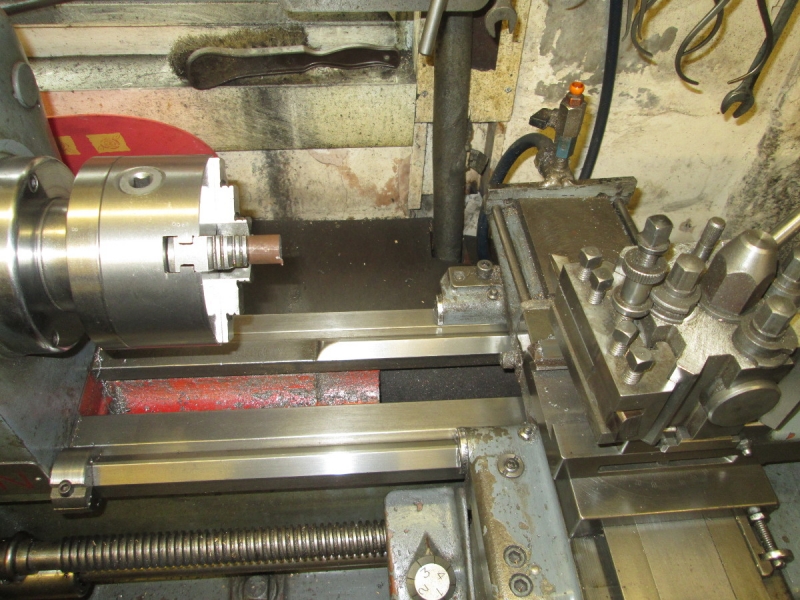

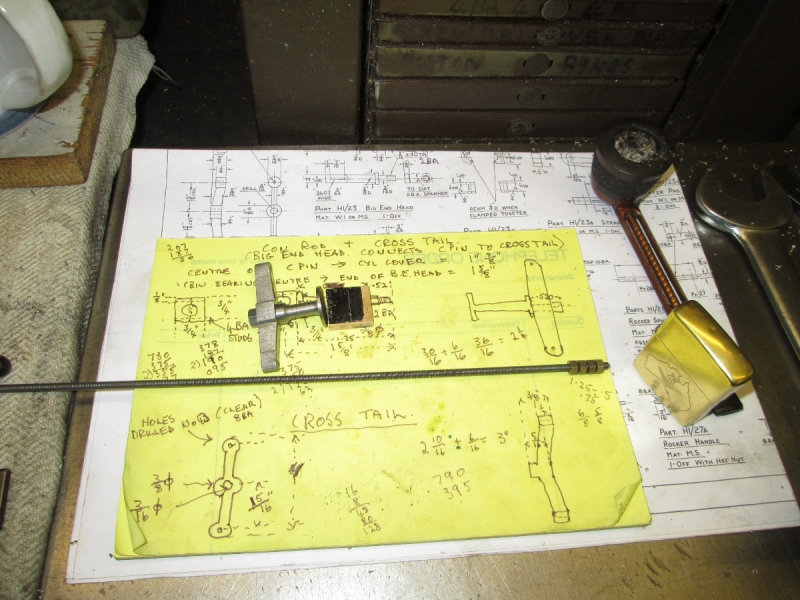

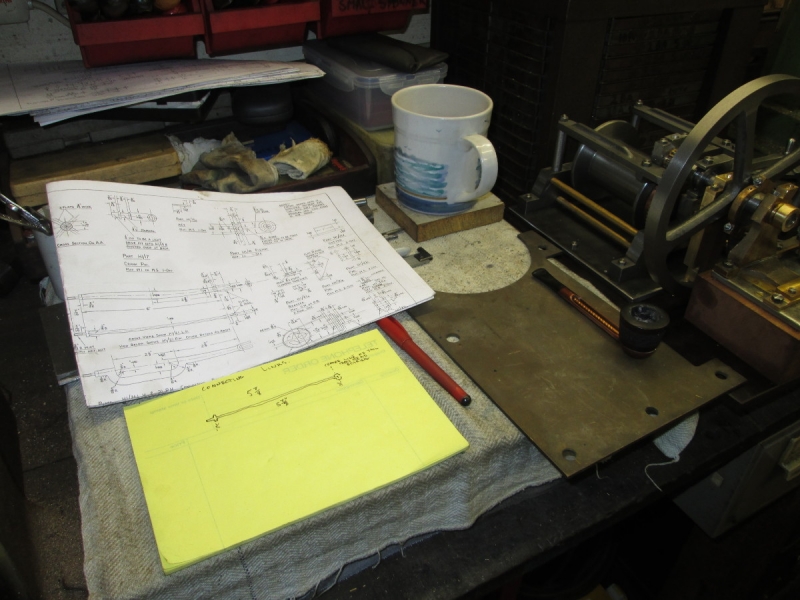

I won't bore you with all the tiny milling jobs as I got some shape into the blank I made yesterday but I couldn't resist doing a pic of the trick I learned on Youtube for milling a curve on the end of something as long as it has a hole in it! It's a brilliant little trick and I recommend it to you.

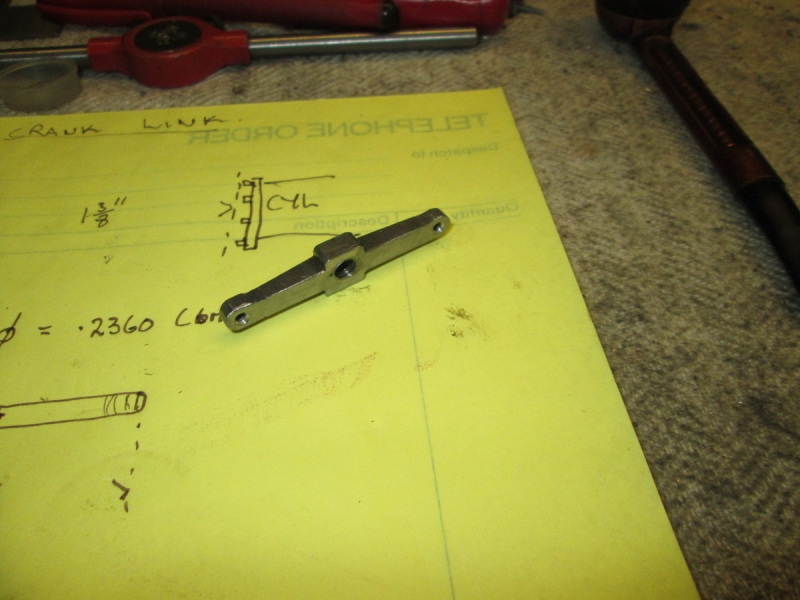

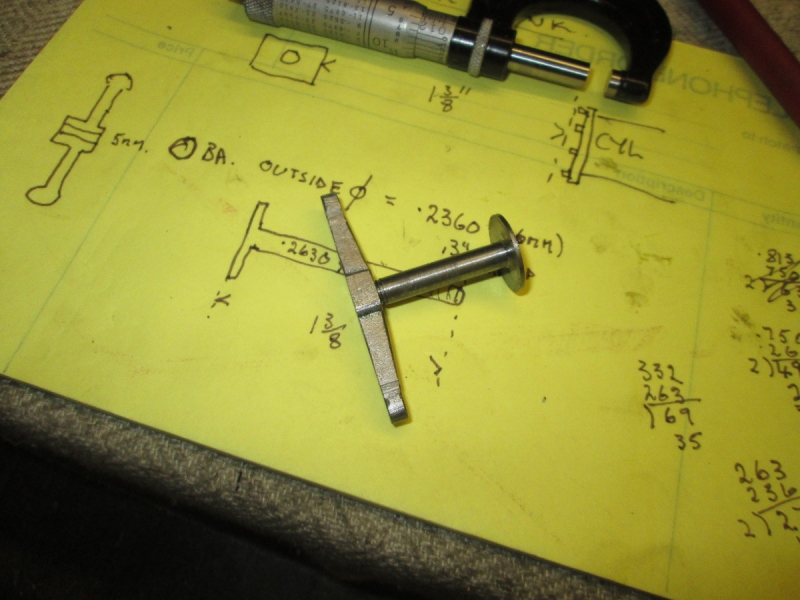

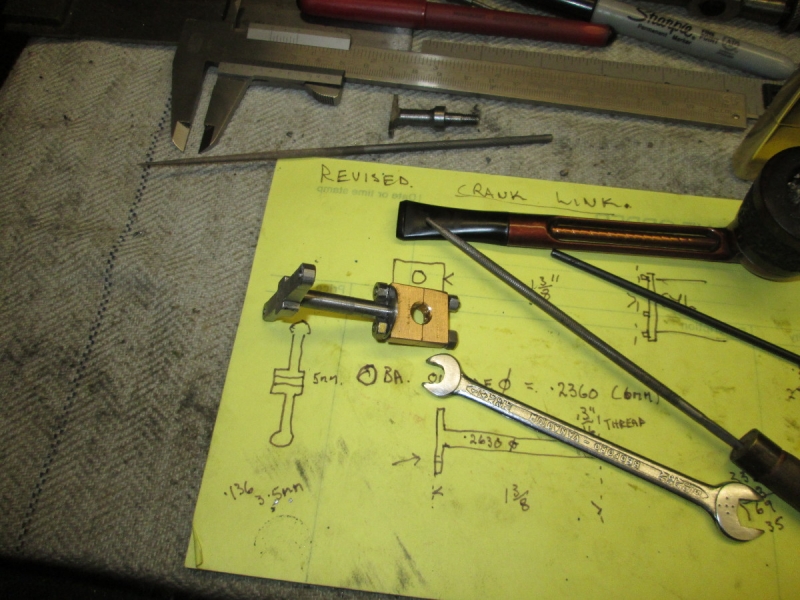

Much later I had the crosshead finished, all the edges broken and as much polishing as I could bear to do! Then I had to re-design the link between the crosshead and the crank. I refuse to do it the way it says on the drawing as it is an incredibly complicated end, just the same as you'll see full size on most engines with a curved strap, wedge and adjusting screw. I'll do it my way which will be just as effective and much more simple! (The purists will write me off yet again!) So I had to go to the engine and do a completely different set of measurements. Here you see the fag packet drawing.....

I needed a small piece of 3/4" stock so I cut a good size lump off a longer bar. I couldn't resist doing a pic of my favourite woman, Mrs McMaster! I bless Mick and John every time I press the start button. Thanks Lads!

It was getting close to knocking off time and I didn't feel like starting a completely new part so I cleaned Mrs Harrison,sharpened my cutter and set up ready for a flying start tomorrow. I do like a nice clean lathe when you are starting on a job!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

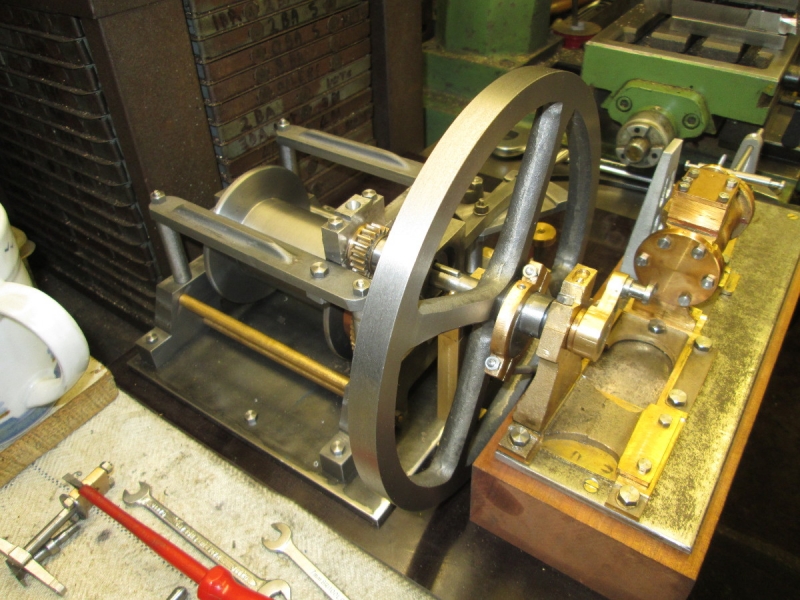

Well, you might wonder why I am taking the winch to bits when I am all set up for making the short connecting rod link and bearing. The answer is that I have been nagged for a while by the fact that there is nothing to retain the gear selector lever in place on the pivot pin and quadrant and until I rectified it the winch can't be said to be properly finished. So I did something about it.

Here's the solution, I threaded the top of the pivot pin and installed a retaining nut and washer. I feel better now!

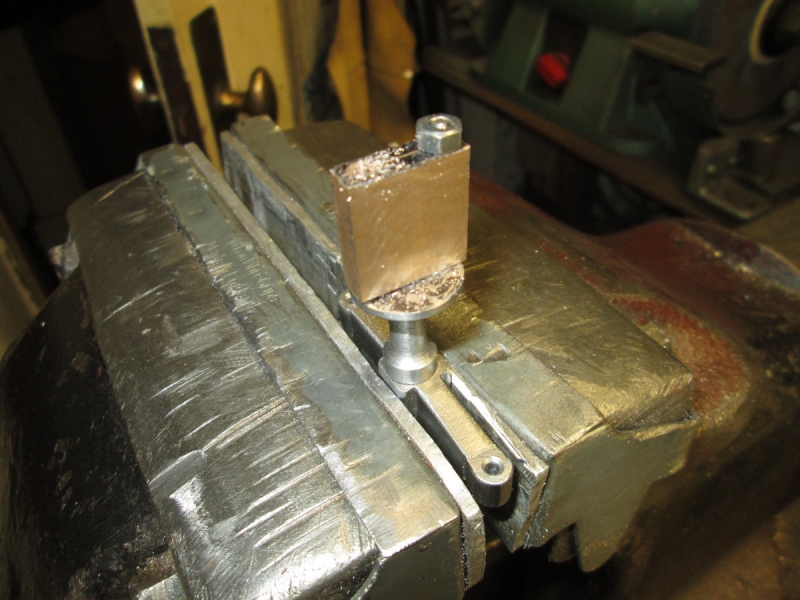

I got stuck into the con rod. Here's the end of the first stage, the tail end crosshead is a good fit and has its retaining nut fitted. Then I got on with finishing the rest of it.

Here's where I finished up a while later. All I ever do is make bits of metal smaller.... And there is more to come of it yet but for the moment that's it, I need to concentrate on the crank pin bearing now.....

I found a piece of bronze that will do nicely in one of my treasure chests....

Here's where I was at closing time after three hours on my feet. I have the bearing ready to drill for the holding studs before splitting and boring 1/4". I've made allowances for the saw cut, it should finish up very close to 3/4" square and 1/4" thick. Another nice morning.......

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

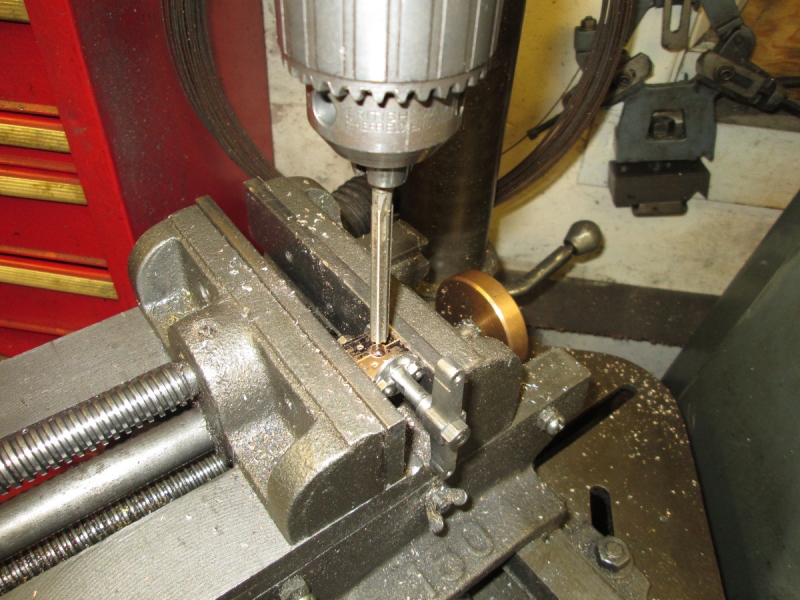

I'd decided to use 4BA studs so first job was to mark and drill the blank for the studs. Then fit one to the link and mark for the other hole, that way I know they will be in line and the correct spacing.

Once I had them fitted I marked the centre for drilling the bearing and splitting it, bits of fitting all the time. The perennial problem is having enough clearance for the nut, they always foul the con rod so you have to file out a recess.

Once I had that done I split the bearing. Because of my bum right eye I can't saw straight these days but it doesn't matter a lot as these faces will always be matched. Just to make sure I punched a witness mark on each half. As long as they are matched up the bearing is fine.

Reassemble and then into the pillar drill. Check the diameter of the crank pin, a shade over 1/4" so drill it out a 64th shy and then ream it 1/4". It will still need slight adjustment when fitted but that's OK.

Last job this morning was to mill off the excess on the con rod foot and countersink each side of the bronze bearing. It needs to be made pretty and fitted, that's the first job tomorrow. In case you hadn't noticed, we are getting serious now. I have to make the con rods from the tail-piece down the cylinder sides and connect to the other crosshead.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

I spoke too soon..... It was all going nicely this morning, I spent about an hour prettyfying the rod and drilling an oil hole in it. Then I carefully fitted the bearing to the crank pin and then I turned it over and found I had got it wrong, the crosspiece fouls the stand for the flyshaft bearing and also on the slightly protruding end of the shaft beyond the crank. We have to withdraw, convene and consult! What it means is that I shall have to remake the rod again but modify it. Not all the work is wasted, the bearing and the crosspiece are OK. No great sweat but a slight annoyance....

As I was coming to terms with this Kev turned up for his drills and a drawing of the plinth. Nice to have him there commiserating with me. So, tomorrow we do some very accurate measuring and re-make the rod. Onwards and upwards!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: SHED MATTERS 2

I'm sure it'll just be a couple of minor adjustments. Thank you again for the drills, I'll get stuck into them once the visitors have gone home.

Kev

Stylish Fashion Icon.

Stylish Fashion Icon.

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

I have a cunning plan.......

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

Even better, see below.

I started by slimming the crosshead down......

The slimline version, threaded in the boss for 0BA.

Knocking off time, I've made the new link, the crosspiece fits nicely and it should be the right length. Tomorrow I'll fit the bearing...... It looks better, a lot less metal in it.

I started by slimming the crosshead down......

The slimline version, threaded in the boss for 0BA.

Knocking off time, I've made the new link, the crosspiece fits nicely and it should be the right length. Tomorrow I'll fit the bearing...... It looks better, a lot less metal in it.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- PanBiker

- Site Administrator

- Posts: 18080

- Joined: 23 Jan 2012, 13:07

- Location: Barnoldswick - In the West Riding of Yorkshire, always was, always will be.

Re: SHED MATTERS 2

Coming along nicely Stanley. I have something that I will relay here in Shed Matters.

I have been effecting a repair to our food processor, well the bowl attachment. The processor comes with two attachments a jug style liquidiser and a bigger bowl attachment that has tools with it for chopping, mixing, slicing etc, it's a multifunction jobby. A common feature of both attachments is that they have a motor defeat mechanism to kill the motor if the lids are off. I can see some slight point to this if you have a completely stupid person (or a small child who knows no better) who will shove their hand onto rotating knives or attachments while all the stuff in the bowl or jug is being flung around the room if operated without the lids. The method of achieving this safety feature would also be great if it was a good design but here is the problem, it's not.

Lids on both units lock on and at the same time trigger a micro switch on the motor control housing that effects the defeat. This is done via a spring loaded plastic actuator within the handle assemblies of both units. The one on the food processor bowl is effectively a "C" shaped bit of plastic that the lid presses down on, this force is transferred to an actuator lever in the base of the bowl that engages with the micro switch when it it locked onto the motor, removing the bowl or the lid kills the power to the motor. The weak point is that you are trying to use a curved bit of plastic to apply downward force. The handle is transparent and I could see that the plastic bit was fractured in the middle at the maximum stress point, it is a repeat mechanism that is bound to fail.

I pulled it apart and removed the offending bit of plastic and glued it up with epoxy adhesive. Rebuilt it when dry but found I was still not out of the wood it would no longer give the required downward force to actuate the micro switch. Looking at it again the plastic has loads of micro fractures on the curves which has probably weakened it beyond repair. This is an internal part of the the mechanism of the bowl so the part is not available separately. A new jug is over £60 as a replacement part, there is no way I am paying that to replace a bad design with another bad design. A new processor with the same features is rocking on £200. The jug and all it's tools works well so I have elected to defeat the lid mechanism. A simple plastic spacer inserted in the base of the jug to wedge the plastic actuator always in place and the job is done, not the most elegant fix but very effective. It will still kill if the bowl is lifted off the motor and I think we will remember not to operate it without its lid.

I have been effecting a repair to our food processor, well the bowl attachment. The processor comes with two attachments a jug style liquidiser and a bigger bowl attachment that has tools with it for chopping, mixing, slicing etc, it's a multifunction jobby. A common feature of both attachments is that they have a motor defeat mechanism to kill the motor if the lids are off. I can see some slight point to this if you have a completely stupid person (or a small child who knows no better) who will shove their hand onto rotating knives or attachments while all the stuff in the bowl or jug is being flung around the room if operated without the lids. The method of achieving this safety feature would also be great if it was a good design but here is the problem, it's not.

Lids on both units lock on and at the same time trigger a micro switch on the motor control housing that effects the defeat. This is done via a spring loaded plastic actuator within the handle assemblies of both units. The one on the food processor bowl is effectively a "C" shaped bit of plastic that the lid presses down on, this force is transferred to an actuator lever in the base of the bowl that engages with the micro switch when it it locked onto the motor, removing the bowl or the lid kills the power to the motor. The weak point is that you are trying to use a curved bit of plastic to apply downward force. The handle is transparent and I could see that the plastic bit was fractured in the middle at the maximum stress point, it is a repeat mechanism that is bound to fail.

I pulled it apart and removed the offending bit of plastic and glued it up with epoxy adhesive. Rebuilt it when dry but found I was still not out of the wood it would no longer give the required downward force to actuate the micro switch. Looking at it again the plastic has loads of micro fractures on the curves which has probably weakened it beyond repair. This is an internal part of the the mechanism of the bowl so the part is not available separately. A new jug is over £60 as a replacement part, there is no way I am paying that to replace a bad design with another bad design. A new processor with the same features is rocking on £200. The jug and all it's tools works well so I have elected to defeat the lid mechanism. A simple plastic spacer inserted in the base of the jug to wedge the plastic actuator always in place and the job is done, not the most elegant fix but very effective. It will still kill if the bowl is lifted off the motor and I think we will remember not to operate it without its lid.

Ian

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

Thanks Kev, we shall see later this morning if I have it right this time. I still have to deal with the protrusion of the shaft beyond the face of the crank, I have another cunning plan to effect that!

Ian, I have a Kenwood food processor and that feature has always annoyed me. I can see the point of it but it is so hair trigger you have to hold the jug in place to stop the jug rotating slightly and stopping the motor. I have taken your comments on board!

Ian, I have a Kenwood food processor and that feature has always annoyed me. I can see the point of it but it is so hair trigger you have to hold the jug in place to stop the jug rotating slightly and stopping the motor. I have taken your comments on board!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- PanBiker

- Site Administrator

- Posts: 18080

- Joined: 23 Jan 2012, 13:07

- Location: Barnoldswick - In the West Riding of Yorkshire, always was, always will be.

Re: SHED MATTERS 2

Mine is a Hotpoint which is now owned by Indesit. I would think most will have a similar mechanism. It would have made sense to make it out of bit of formed metal rod or something rather that a plastic moulding. Maybe weight, cost, dishwasher compatibility comes into the mix?

Ian

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

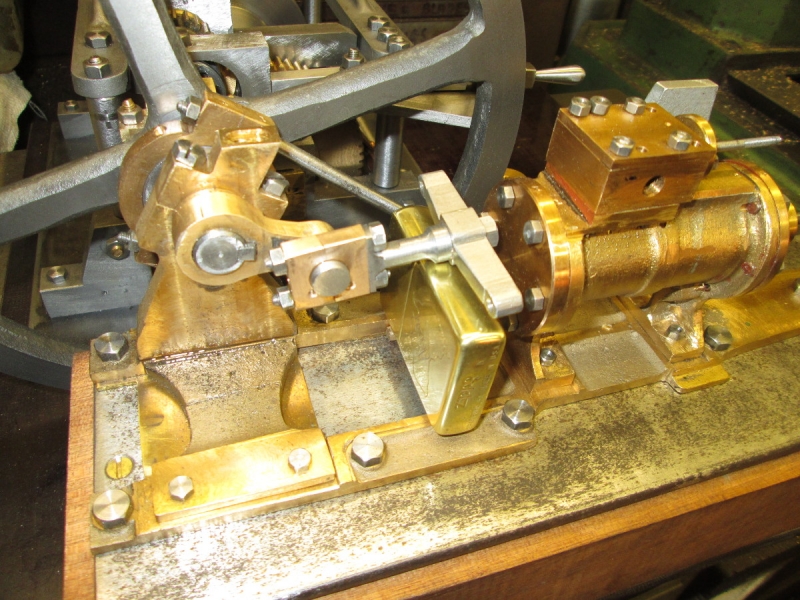

A bit of quiet, careful fitting of the bearing to the link. Apart from trimming the excess off the foot of the link, it's finished and ready to fit but there is some work to do on the flywheel shaft! So I set to and dismantled it.

Once I had it in bits I addressed the pinion. I reckon it's too tight a mesh with the bull gear on the winch so I turned a bit off the face and cleaned out the teeth with a triangular file. We'll see soon if this has done the trick.

I told you I had a cunning plan. I was able to mount the shaft in the chuck without taking the feather key out which was a blessing. I dealt with the eccentric by taping it to the flywheel and using a slowish speed as it is imbalanced. It worked well and I soon had it looking pretty.

At closing time I was half way through re-assembling the shaft. The relieving of the pinion has worked like a charm, it's free on the feather key now. The two main bearings have gone back together nicely fitted, no play but running free. This has been a good morning and I shall finish knitting it up again tomorrow. Then I can fit the modified link and see if we have got it right!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104283

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS 2

I finished re-installing the shaft and then re-fitted the link and the cross piece. As you can see, it is still tight but I think we can get away with it. It just clears the back end of the cylinder so that's all right..That's the end of the good news! The next job was to get an accurate measurement of the distance from the face of the crosspiece to the tail rod crosshead. I set the crosshead with enough clearance from the end of the cylinder, put the crank in the right position and got an accurate measurement. While I was doing this I realised that I had a problem. The cross piece wasn't central to the cylinder.

While I was mulling this problem over I went and had a dig in the treasure chest for the material for the rods. They are flat and 1/8" thick. I found this which will do nicely. It's a horn plate for the traction engine that newton was building but abandoned when his father criticised it. Then I had another look at my problem....

This pic illustrates the scale of the problem.... I've taken the link off the crank and the crank off the end of the shaft. I can put things right by altering the crank pin. It's Loctited on but I can soon get it loose tomorrow and then make another. This phase, making the motion on the engine, is not going to be unadulterated pleasure!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: SHED MATTERS 2

A bad design is a bad design and surely makes it unfit for purpose? Is this built-in obsolescence?PanBiker wrote: ↑10 Apr 2017, 07:44 Mine is a Hotpoint which is now owned by Indesit. I would think most will have a similar mechanism. It would have made sense to make it out of bit of formed metal rod or something rather that a plastic moulding. Maybe weight, cost, dishwasher compatibility comes into the mix?