Page 79 of 123

Re: Shed Matters 3

Posted: 03 Mar 2023, 07:47

by Stanley

Once again only one image needed. I did the small cuts on the blank I was working on yesterday and started cutting the main slot on the other. An hour and a quarter and slow but steady progress.

Re: Shed Matters 3

Posted: 03 Mar 2023, 15:49

by MickBrett

How deep of a cut do you take each time?

Re: Shed Matters 3

Posted: 04 Mar 2023, 03:20

by Stanley

Good question Mick and right to the point. To tell you the truth I don't know, I just put a bit on by feel but I'd guess at about 15thou. As you can see my El Cheapo mill is actually a heavy duty drill and you can't take heavy cuts. This has never been a problem because with light cuts and sharp cutters it does remarkably accurate work. That's why I am so slow but time is no object of course, nobody is breathing down my neck!

So I am slow and have to put up with it. I watch people like Brian Bloc hogging 1/4" cuts off with sparks flying out of the cutter but don't envy them. that's not for me. I may be slow but up to now I have always got there and get decent results.

In case you're wondering, yes I did think of doing the cut on the horizontal mill. That would have been a lot quicker but imagine the mayhem if the stock rolled during the cut! This way is foolproof as long as I take my time.....

Re: Shed Matters 3

Posted: 04 Mar 2023, 07:15

by Stanley

Only one pic this morning. I carried on quietly chewing the middle of the stock out but hit a problem. I only have two viable 7/16" cutters. One broke down and the other, pictured here, is too short to get to proper depth. I shall do my best tomorrow but it's a bit of a problem!

Re: Shed Matters 3

Posted: 04 Mar 2023, 15:40

by MickBrett

Stanley wrote: ↑04 Mar 2023, 03:20

Good question Mick and right to the point.

<snipped>

In case you're wondering, yes I did think of doing the cut on the horizontal mill.

Good grief, no! It never crossed my mind. I was thinking "if that were me I'd surely be taking small cuts, especially as I got nearer the bottom of the slot."

I was simply curious.

Re: Shed Matters 3

Posted: 05 Mar 2023, 03:14

by Stanley

Not having an adequate VM has always been the Achilles Heel for my shed but over the years, with care, I have done some good work with this early version of the Rongfu Taiwanese machine which cost £350 brand new. It was the price that drew me to it in the first place but later when I could have afforded to upgrade I hadn't the room.

So, I have to work within the limits the machine imposes on me but over the years have learned to live with it.

One thing is certain, I couldn't do what I do with it if it wasn't for the fact I have the Clarkson Tool and Cutter Grinder. A sharp cutter makes up for a lot of disadvantages!

Re: Shed Matters 3

Posted: 05 Mar 2023, 07:12

by Stanley

Only one image. Here we have the two blanks with as much of the metal taken out of the centre as I dare with the inadequate cutters I have. They are cleaned up and ready to go in the four jaw for eccentric turning. That's for tomorrow....

Re: Shed Matters 3

Posted: 06 Mar 2023, 07:16

by Stanley

The task this morning was to set the blank up for eccentric turning the crank pin of the crankshaft. I've done this and started the cut. That took an hour. Tomorrow I can get straight into turning.

Re: Shed Matters 3

Posted: 07 Mar 2023, 07:12

by Stanley

Re: Shed Matters 3

Posted: 08 Mar 2023, 07:11

by Stanley

Re: Shed Matters 3

Posted: 09 Mar 2023, 08:03

by Stanley

Nothing complicated about this morning. Mark both lumps of stock with the depth of the shaft on each side of the pin and then fit a piece of steel into the gap and stick it with instant glue. These are to stop the pressure of the centre in the end of the shaft from distorting the gap between the flanks of the crankshaft. We can start thinking about muck shifting tomorrow as we progress further forwards to two crankshafts and no mistakes.

Re: Shed Matters 3

Posted: 10 Mar 2023, 07:17

by Stanley

Only one pic needed. An hour's muck shifting..... Patience and slowly forward!

Re: Shed Matters 3

Posted: 11 Mar 2023, 07:13

by Stanley

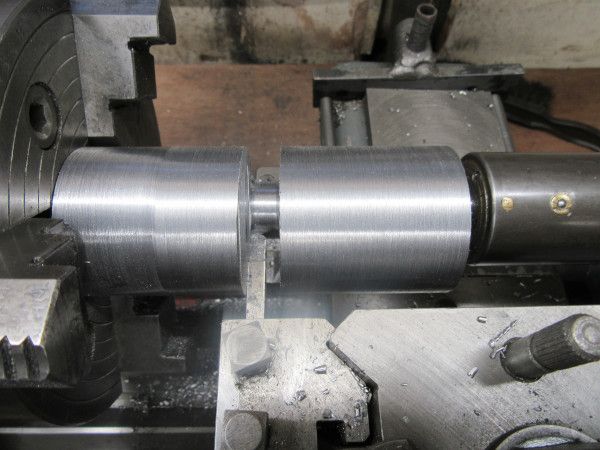

Only one image again. I have finish turned one side of the shaft. I shall reverse it and do the other side tomorrow.

Quietly forward.....

Re: Shed Matters 3

Posted: 12 Mar 2023, 07:10

by Stanley

Only one pic needed. I turned the other end of the shaft5 down to finished dimensions. I shall finish it off, polish it and clean the lathe tomorrow. This was a good hour in the shed....

Re: Shed Matters 3

Posted: 13 Mar 2023, 06:49

by Stanley

Re: Shed Matters 3

Posted: 14 Mar 2023, 07:18

by Stanley

Re: Shed Matters 3

Posted: 15 Mar 2023, 06:54

by Stanley

Forward with the flywheel this morning. I finished turning those surfaces ready for sizing then cleaned Mrs Harrison before getting into the Vise and round files to clean of all the flash and bring the as-cast surfaces to a condition ready for painting. Next I shall move onto the other castings. They all need bringing to this standard.

Re: Shed Matters 3

Posted: 16 Mar 2023, 07:17

by Stanley

Re: Shed Matters 3

Posted: 17 Mar 2023, 07:47

by Stanley

Just one image. I milled the top and bottom faces of the base and then set the engine bed casting up for work tomorrow. The first set up is to mill the target face that the cylinder will fit on. I'm ready for that tomorrow.

Re: Shed Matters 3

Posted: 18 Mar 2023, 10:00

by Stanley

Re: Shed Matters 3

Posted: 19 Mar 2023, 07:13

by Stanley

Re: Shed Matters 3

Posted: 19 Mar 2023, 14:41

by MickBrett

Stanley.

I want you to know that, as an ex machinist, I check this thread every morning.

Not only do I watch the work in progress but I monitor your clamping methods, use of tools and finished results.

I even study your work bench and the items on and around it

Keep up the good work

Mick

Re: Shed Matters 3

Posted: 20 Mar 2023, 02:49

by Stanley

That's nice to know Mick. Be sure to comment if anything comes to mind!

(I shall have to consider a 'pic for Mick'; an overall shot of the bench every now and again.)

Re: Shed Matters 3

Posted: 20 Mar 2023, 07:11

by Stanley

This morning I drilled and tapped for the 2BA bolts that fasten the bed to the base casting and once that was done, drilled the lugs in the base and fastened the castings down onto the temporary base that makes fitting easier. A nice quiet uncomplicated hour and a quarter with no errors..... Nice!

Re: Shed Matters 3

Posted: 21 Mar 2023, 07:15

by Stanley