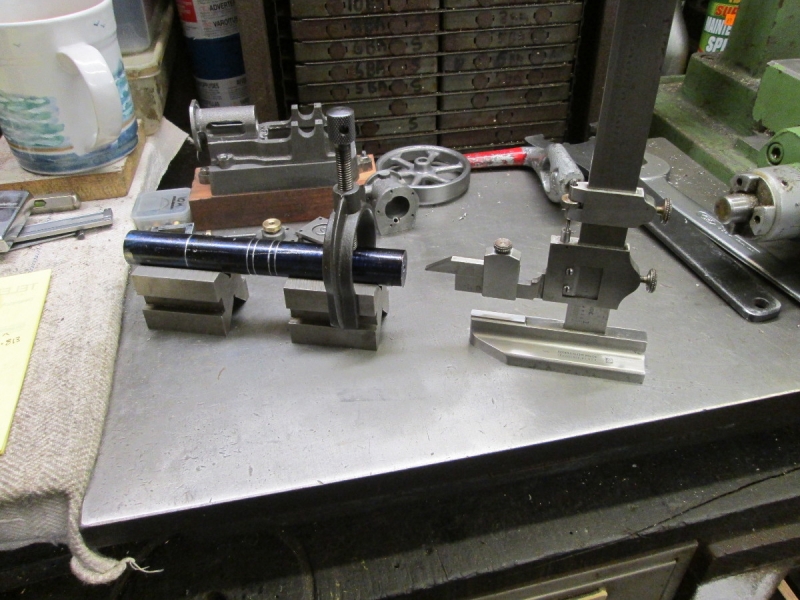

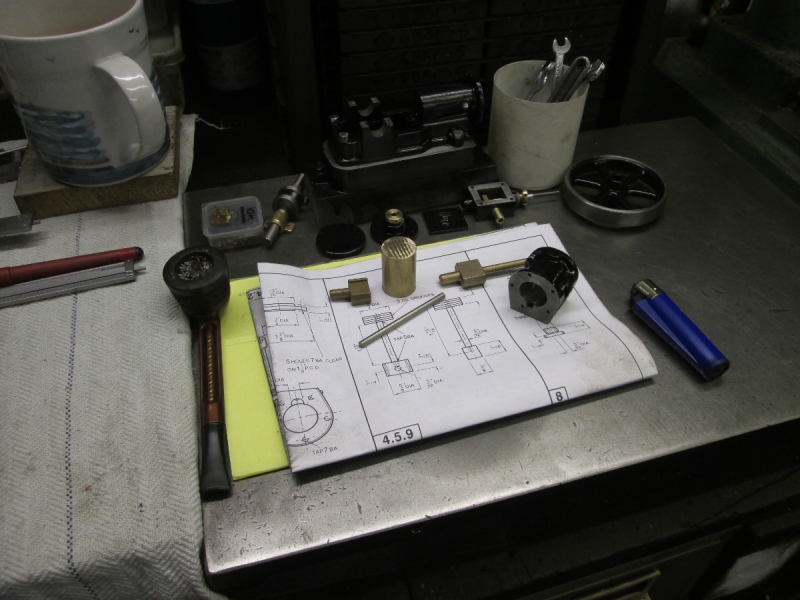

All right, I'm doing the same thing as yesterday but this is because I am paranoid about my ability to get mirror images wrong. I realised this morning that I wasn't sure whether I had turned the right boss off the template so I popped it back in the lathe and modified the other side as well and then did my checks all over again.

I'm not going to bore you with all the steps, all I can say is that the new DeWalt drill is a godsend, just the thing for popping little holes through hard to clamp work pieces. Here's where I finished up, both lids drilled for clearance and on (hopefully!) the right register. Notice I have put witness marks on them.

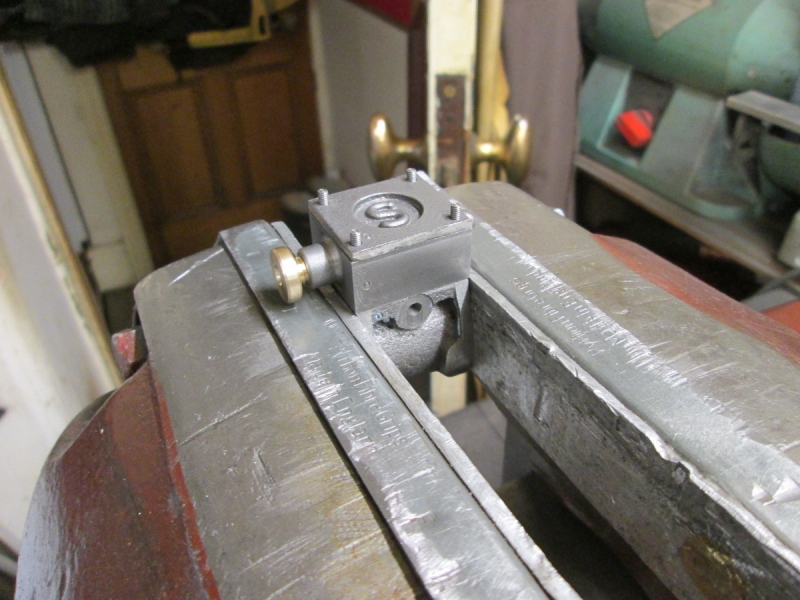

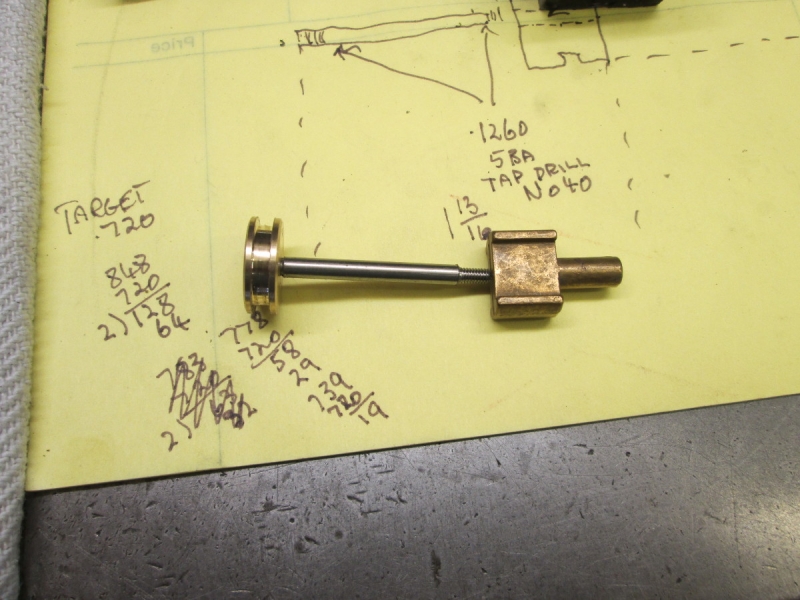

The next thing I addressed was the ports in the valve face because I have to screw myself up to doing something I hate, drilling the steam passages. Before I do this I have to get the 'as cast' ports cleaned up and the correct depth. So the first job was the exhaust port and I had to make sure I was accurately lined up.

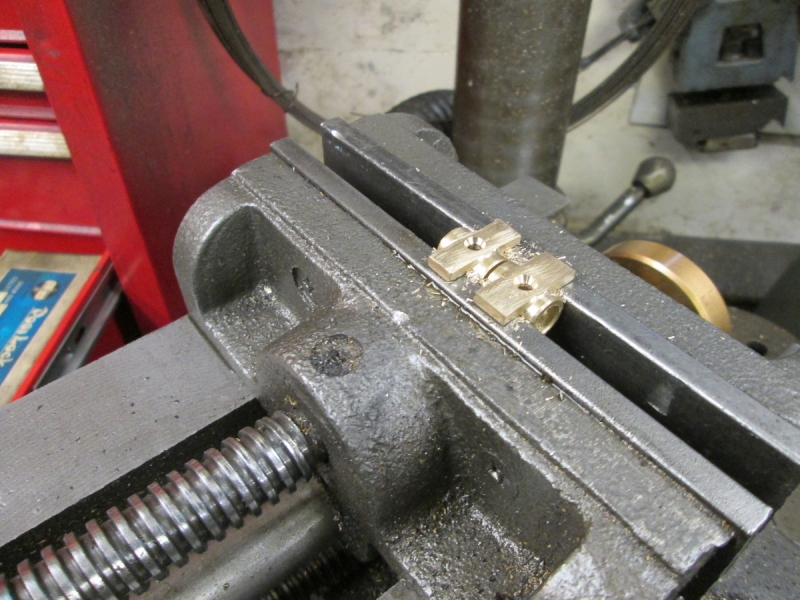

The 1/8" slot drill chucked up, the mill put on top speed and after some careful cutting a check with the depth gauge. That's one port out of the way! The steam ports were a bit of a problem. They are 5/64" wide and I haven't got a mill that size so I improvised with a 5/64" drill in the DeWalt drill and I cleaned those up by hand. God knows how the old lads with far less equipment did this!

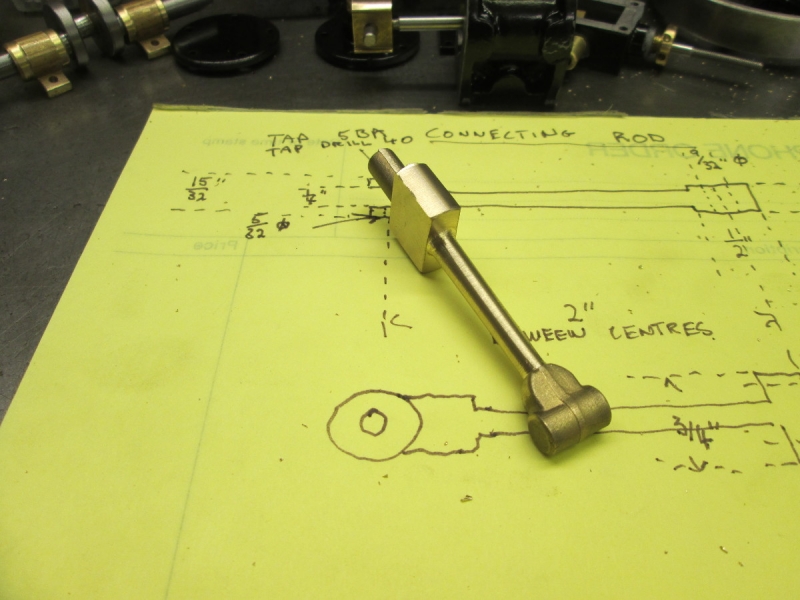

For my next trick I needed a 3/8" slot drill and when I got it out it was dull so the first thing to do was sharpen it. No short cuts!

I wanted to drill the exhaust port and before I did this I wanted a clean face on the boss where it emerges.

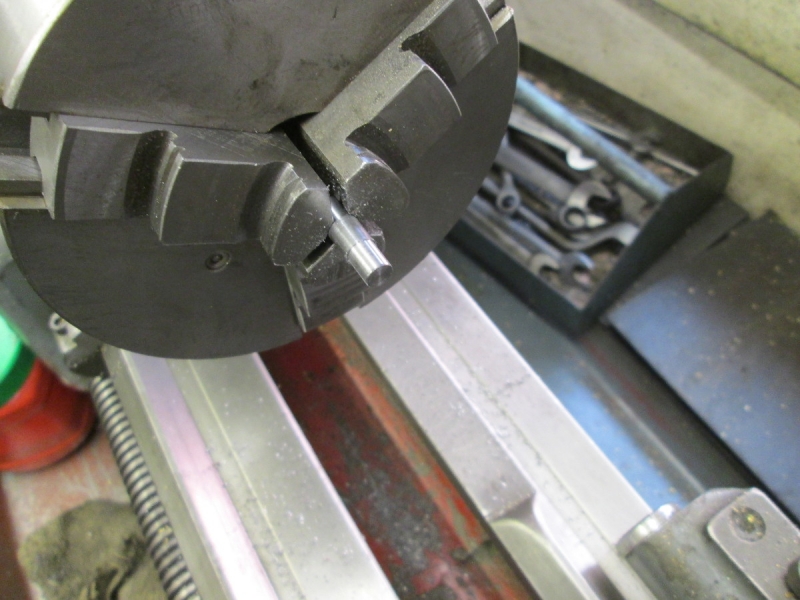

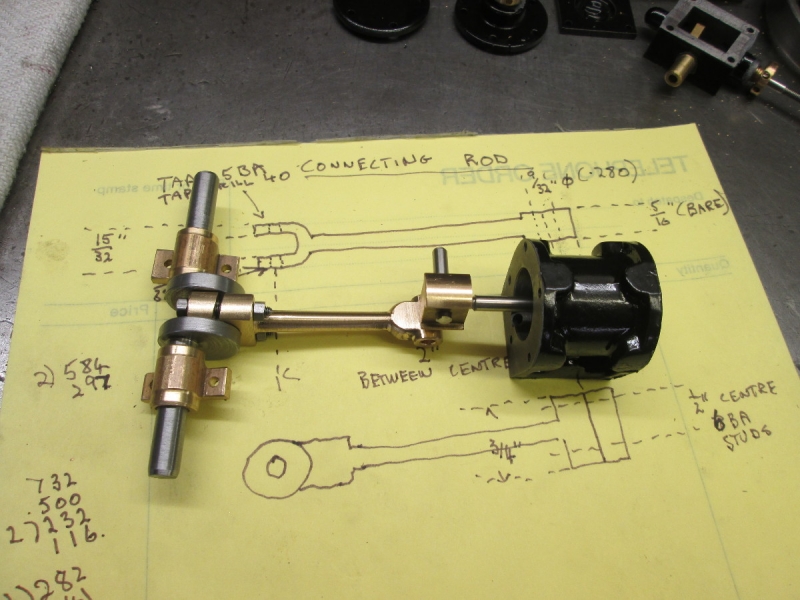

Here we are with an 1/8" hole drilled in just the right place and breaking into the exhaust port satisfactorily. I'm ready to attack the steam passages now but this needs some careful measuring and setting up. As it was coming up to closing time I knocked off early. I'll come to my bete noire fresh in the morning!