Page 88 of 122

Re: Shed Matters 3

Posted: 20 Sep 2023, 06:09

by Stanley

Re: Shed Matters 3

Posted: 21 Sep 2023, 06:15

by Stanley

Re: Shed Matters 3

Posted: 22 Sep 2023, 06:18

by Stanley

Re: Shed Matters 3

Posted: 23 Sep 2023, 06:21

by Stanley

I checked the valve for centrality and then set it for the position of the piston in the cylinder. I flooded it with oil and put the lid back on the steam chest. Then I fastened the engine down onto the surface plate, fired the compressor up and gave it a whiff of air. It went like hell! (This is the bit that China used to love, when the castings suddenly became alive!)

Then I tidied the stud lengths up on the cylinder cover and steam chest lid and took the engine to its new home on the kitchen table. A session putting tackle and spare engine parts away, a good clean up and both surface plates oiled and a clean tablecloth put on. Now I have to decide on what comes next......

Re: Shed Matters 3

Posted: 24 Sep 2023, 06:20

by Stanley

This is one of two compound marine engines I made to the design of Johnny Pickles (based on a design that had appeared in the Model Engineer but Johnny didn't like that.) I kept one for myself and gave this one to Susan. It is lodging with me now as there isn't room in their mobile home for a lot of stuff so I am taking care of it for her.

I noticed that her engine was very stiff and needed a bit of TLC so in the interim while I am working on the next engine I build I took it in the shed and have spent an hour on it this morning making sure that it is well oiled and cleaner. It is a lot more free now than it was. That was all I was aiming for.

Re: Shed Matters 3

Posted: 25 Sep 2023, 06:13

by Stanley

Re: Shed Matters 3

Posted: 26 Sep 2023, 06:18

by Stanley

This morning's task was clear. Start on reducing the two lumps of scrap I rescued from the bin yesterday to 6" X 2" blanks to make crankshafts from for the next engines. As you can see, I have made good progress. I put the original large 3 jaw SC chuck on and I have verified that these lumps are good metal, you never know what you're getting with anonymous lumps of scrap, there could be a good reason why it was discarded in the first place! Notice the colour of the chips. I have taken 50 thou cuts, a very heavy cut for a small lathe but Mrs Harrison handles it easily. No signs of distress at all. I'm very happy with progress and will carry on tomorrow.

Re: Shed Matters 3

Posted: 27 Sep 2023, 06:43

by Stanley

Back to muck-shifting. First I cleared up yesterday's chips including the ones on the floor. Then I simply carried on patiently with 50mm cuts until I had one end down to 2". Then I reversed it and cut the other end down to suit. You can see from the image where I ended up, the biggest lump of rusty scrap is now a very attractive 6" X 2" slug ready for making into a crankshaft. I'm an optimist so I am going to process two shafts.... I shall attack the other one tomorrow. This morning I expect FedEx to deliver my castings from Stuarts.....

There was one unexpected hold up. The cutters fell out of my electric shaver when I was cleaning it and I had forgotten how to put them back in. It took me half an hour because I was trying to do it like my old razor but that's wrong. All is well now.

Re: Shed Matters 3

Posted: 28 Sep 2023, 06:14

by Stanley

Re: Shed Matters 3

Posted: 29 Sep 2023, 06:25

by Stanley

First task was to turn the cool slug down to 2" diameter. Then mark the PCD of the crank pin centre on the end of the stock. Next I reversed it and cut the other end down to 2". It was here that I got my surprise and set back. I decided it was time I had a different centre drill so I changed it for another. Not sure what happened but when I went to use it it broke off in the stock! I haven't had a centre break for years. I managed to pick enough out to enable the blunt point o0f my old live centre to get a hold and ignored the slight error, I cut that end down to 2". I can get away with the bad centre. You can see I ended up with two 2" diameter slugs ready for putting under the mill to cut out the main of the dead meat that has to come out to get my crank pin.

I should mention that, mindful of the disaster I had when cutting the shaft about 9 months ago, I went back and checked on the correct and safe way to proceed. Big sigh of relief, I am all right. Tomorrow will be a clean up on the lathe, a marking of the PCD on the other slug and preparations for going under the VM.

Re: Shed Matters 3

Posted: 30 Sep 2023, 06:21

by Stanley

Re: Shed Matters 3

Posted: 01 Oct 2023, 06:20

by Stanley

Just one task this morning, to mark the crankshaft blanks with the position of the crank pin and crank webs. It took an hour because I had senior moments doing my calculations and had to retrace my steps several times.... That's why I have to check over and over again. I am satisfied now that I have the blanks marked correctly!

Re: Shed Matters 3

Posted: 01 Oct 2023, 09:44

by PanBiker

Probably a stupid question but doesn't pre cutting, marking up etc of these blanks confine you to making the same model of engine over and over again? Have you given up on different variants?

Re: Shed Matters 3

Posted: 02 Oct 2023, 06:40

by Stanley

I've already explained that Ian. I know my limitations and also know this design inside out so I want to make the same one over and over again. It's the Act of making them and the knowledge that there are not many blokes in their 88th year who could do it. This hour in the shed each morning is a life saver for me.....

Besides, I like this engine, it's one of Stuart's most handsome designs....

Re: Shed Matters 3

Posted: 02 Oct 2023, 06:42

by Stanley

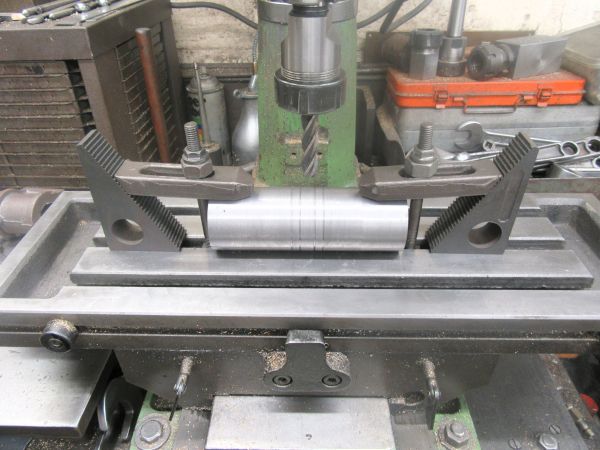

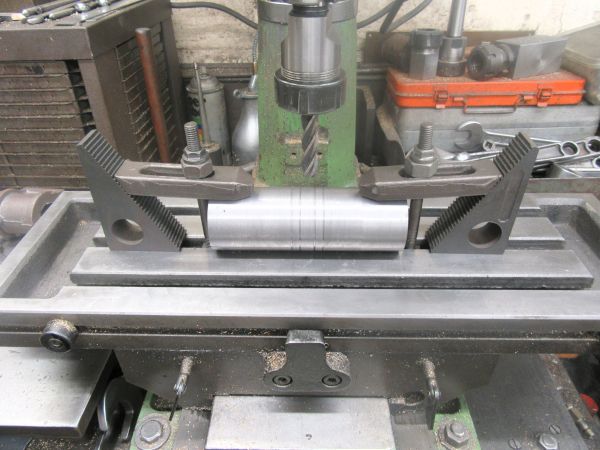

Sorry, images in wrong order. This morning has been spent measuring and marking and getting to this stage, ready to cut the slot. The time has been spent searching for, and failing to find, my only 7/16" cutter, so I have settled on one that is slightly larger and gave it a good sharpening on the Clarkson T&C grinder. It has two shafts to cut. As you can see I have ended up ready to actually start cutting.....

Re: Shed Matters 3

Posted: 02 Oct 2023, 10:00

by PanBiker

Stanley wrote: ↑02 Oct 2023, 06:40

I've already explained that Ian.

I must have missed that Stanley. Whatever keeps you going, wouldn't do for me though I still like a new challenge.

Re: Shed Matters 3

Posted: 03 Oct 2023, 06:00

by Stanley

Only one pic this morning. I started by speeding the mill up for the small cutter and started cutting with the 1/2" cutter I identified yesterday. Total disaster, the cutter wasn't working at all, must be my fault in that I've made a cock-up of sharpening it. Rather then start trying to rectify that I found a 1/2" slot drill and started cutting with it. It's shorter than the other but I console myself with the fact that even if it's a bit short of the mark it's still a lot of interrupted cutting and eccentric turning which I hate. I knocked off early as I want a sleep before Robin, my chiropodist, arrives to minister to my feet! As you can see it's a very clean cut....

Re: Shed Matters 3

Posted: 04 Oct 2023, 06:23

by Stanley

Only one pic needed today. I have completed the first and heaviest cut on both crankshaft blanks. The next job is to mark the depth of the four light cuts needed to cut out the flanks of the crank pins. A good morning, this is a lot of metal that doesn't need cutting as an interrupted cut. I am once more impressed by what is possible with my El Cheapo Chinese economy mill/drill. These are serious cuts no matter how expensive the mill that makes them. The only penalty is that lighter cuts mean slower work. I can live with that!

Re: Shed Matters 3

Posted: 05 Oct 2023, 06:32

by Stanley

Re: Shed Matters 3

Posted: 06 Oct 2023, 06:06

by Stanley

Re: Shed Matters 3

Posted: 07 Oct 2023, 06:05

by Stanley

Just one job this morning; setting up a crankshaft blank for eccentric turning in the lathe. This is one of the most difficult jobs I know and I spent an hour on it. However it is now very close to perfect. Probably about 2 thou out over the total length of the stock, that's near enough over 1/2"! I have shut down and am ready for turning the crank pins tomorrow....

Re: Shed Matters 3

Posted: 08 Oct 2023, 06:16

by Stanley

Only one image needed this morning. I was all ready and started into turning the crank pin. I had one problem, the carbide indexed cutter on my parting tool shattered and I had to fit a new one. Apart from that no dramas, just very thoughtful and careful cutting (with a lot of stick out!), 10 thou a time and keep going until I had a .375" crank pin (3/8") and at that point I polished it with emery strip and knocked off.

I have had worse mornings!

Just think of all that metal that I took out with the milling machine!

Re: Shed Matters 3

Posted: 08 Oct 2023, 09:28

by Stanley

I've had my second sleep and about to raid the Co-op. I went in the shed to feast my eyes on that little beauty.....

Re: Shed Matters 3

Posted: 09 Oct 2023, 06:00

by Stanley

The task this morning was the same as Saturday, set the stock up for eccentric turning the crank pin. Once again it took me almost an hour, it isn't easy! I got there and set my parting tool to cut the pin, 10thou at a time but it was too close to knocking off time to start what has to be a concentrated hour of turning! That's for tomorrow after BT have been.

Re: Shed Matters 3

Posted: 10 Oct 2023, 05:54

by Stanley

Only one pic needed this morning. I made sure I was in the shed in good time and got straight into repeated 10thou cuts across the crank pin. I finished up in time for early doors shopping with two crank pins formed in the two pieces of stock. I shall carry on with finishing them tomorrow.....