When John gave me a can of brake cleaner last time he visited he opened my eyes, I didn't know it existed and up to then I had been using the cleaner that comes in a dye penetration test kit and I had run out. So I went looking and found this, 3 litres and a sprayer. It's been a while coming from Germany and I had to tweak their tail but it arrived yesterday.

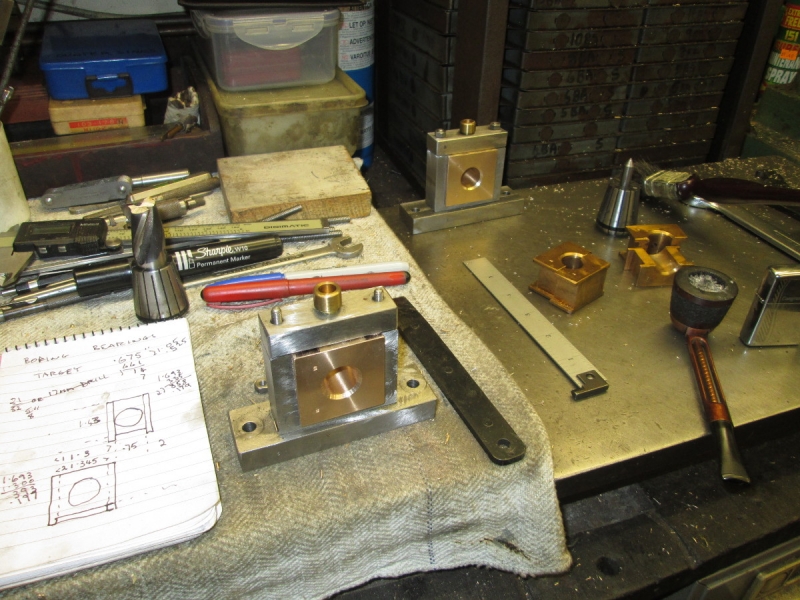

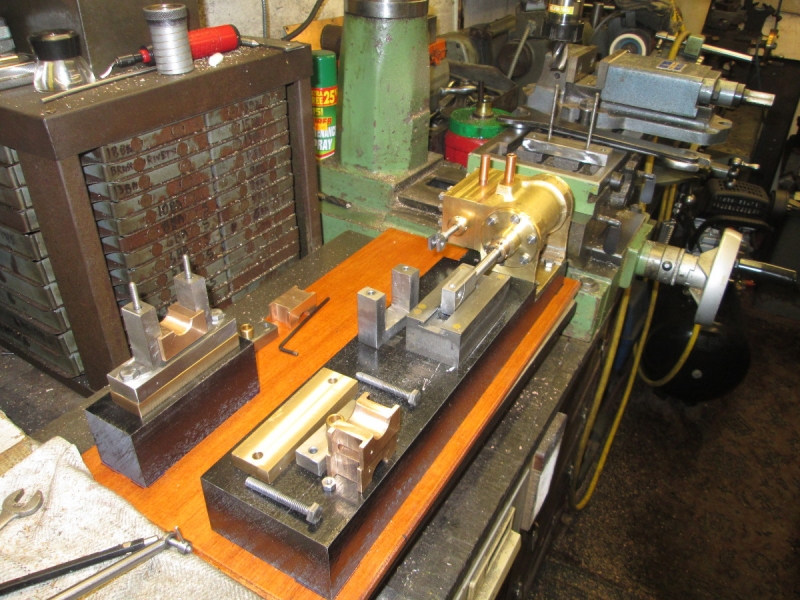

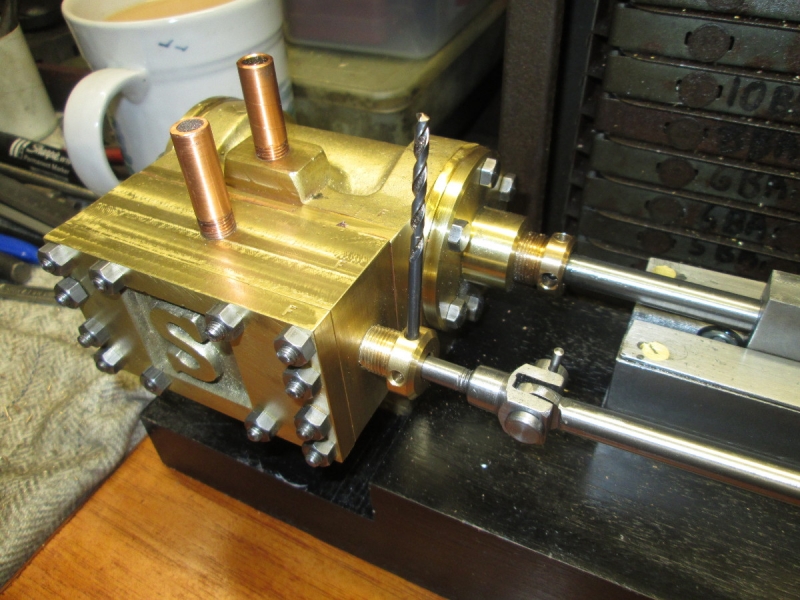

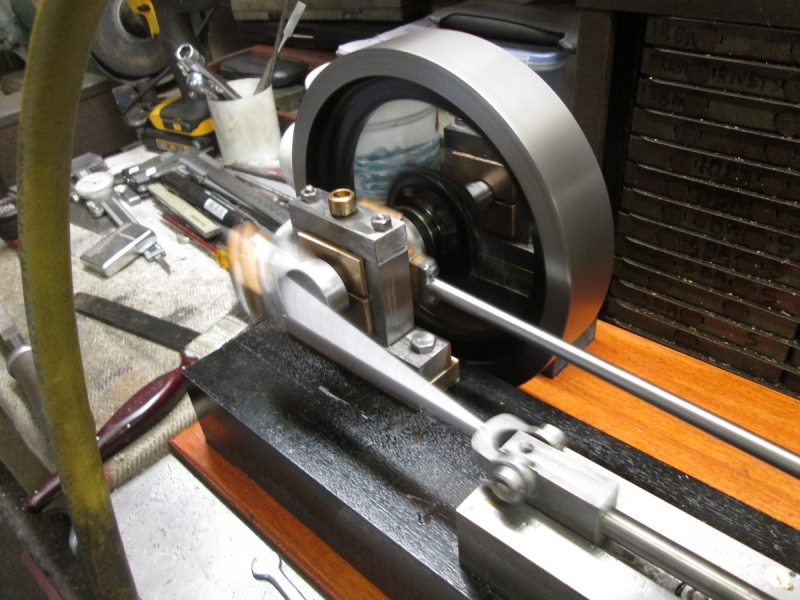

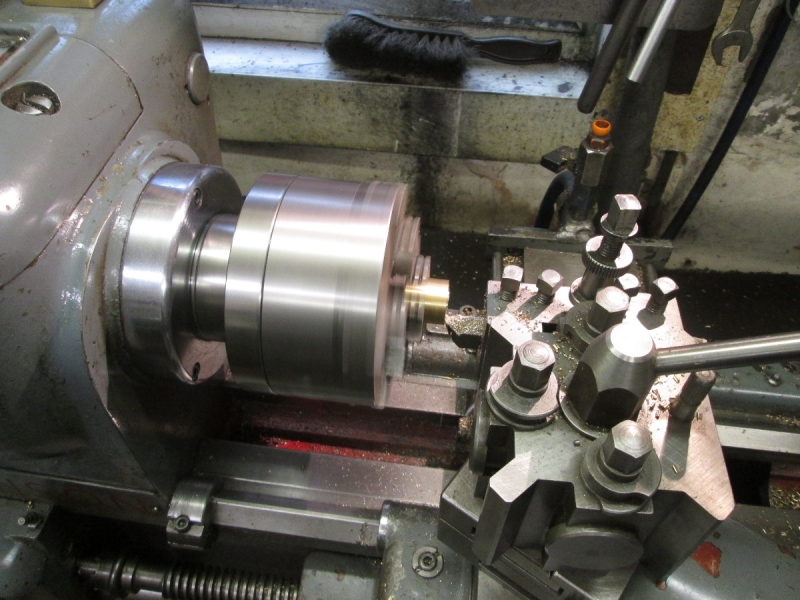

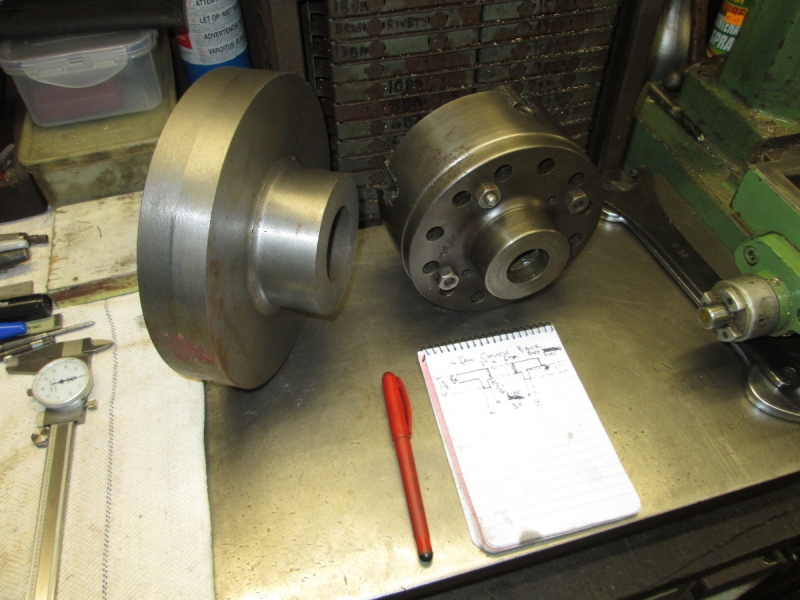

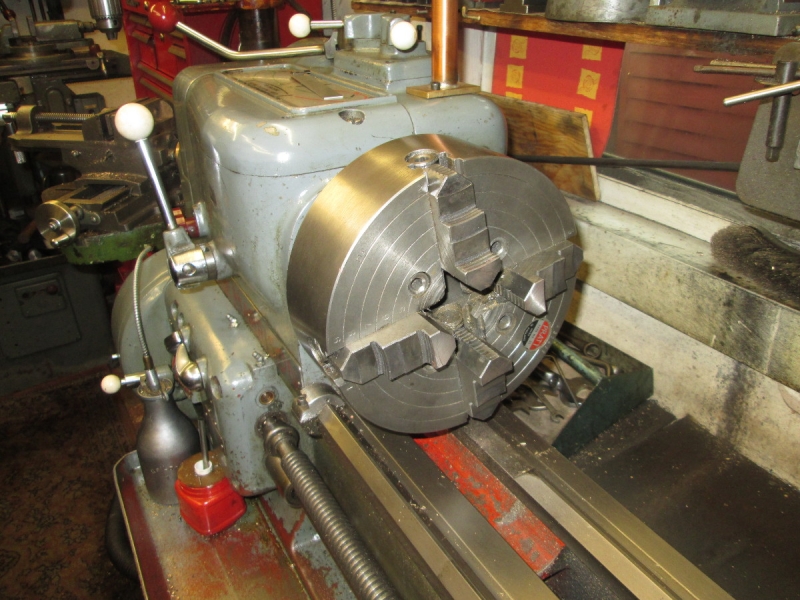

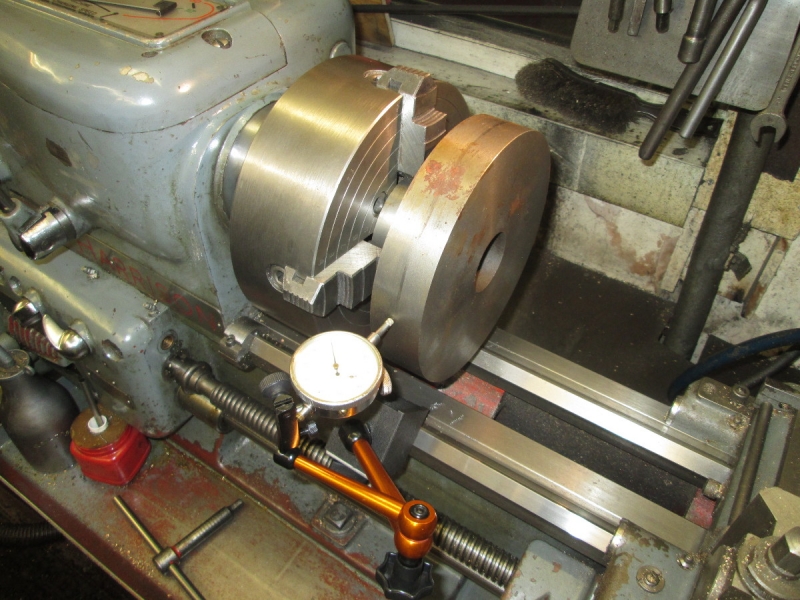

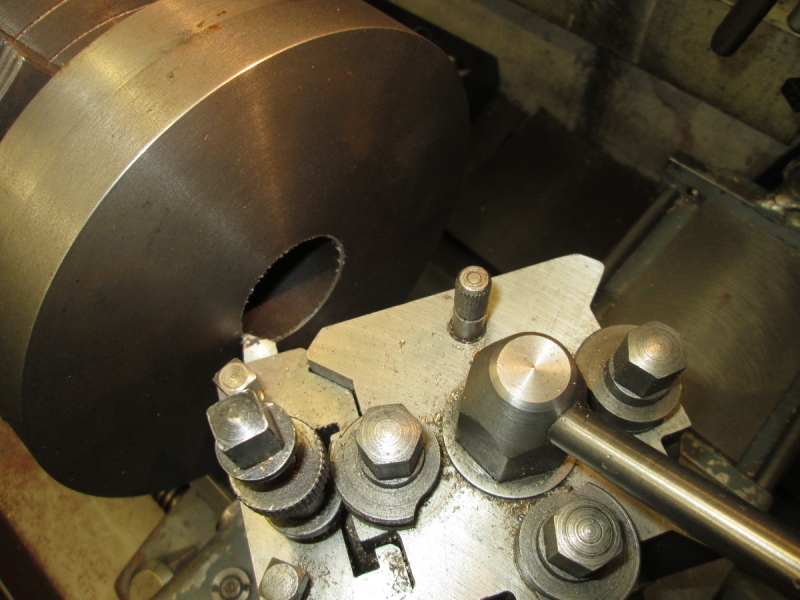

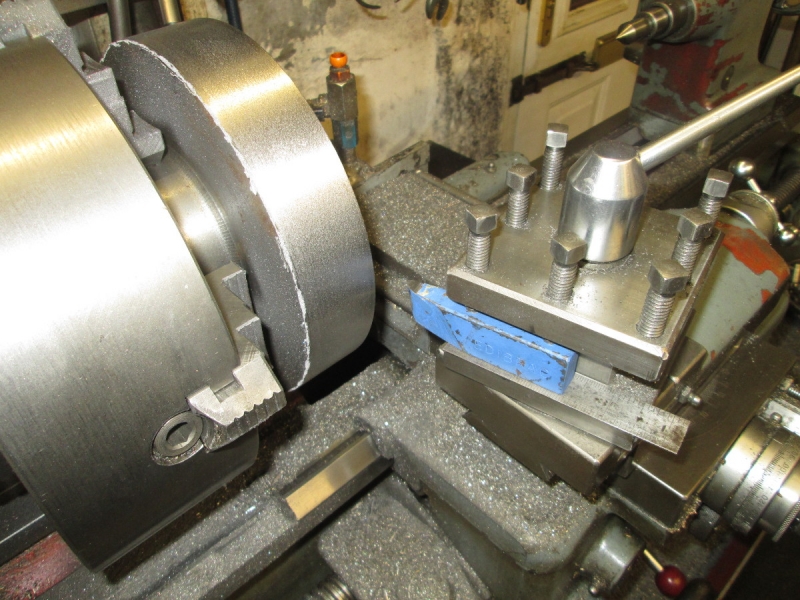

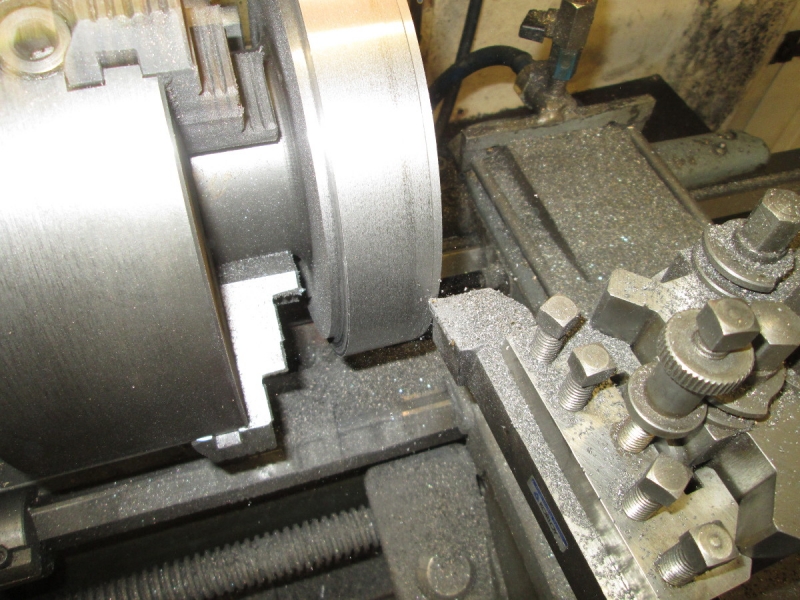

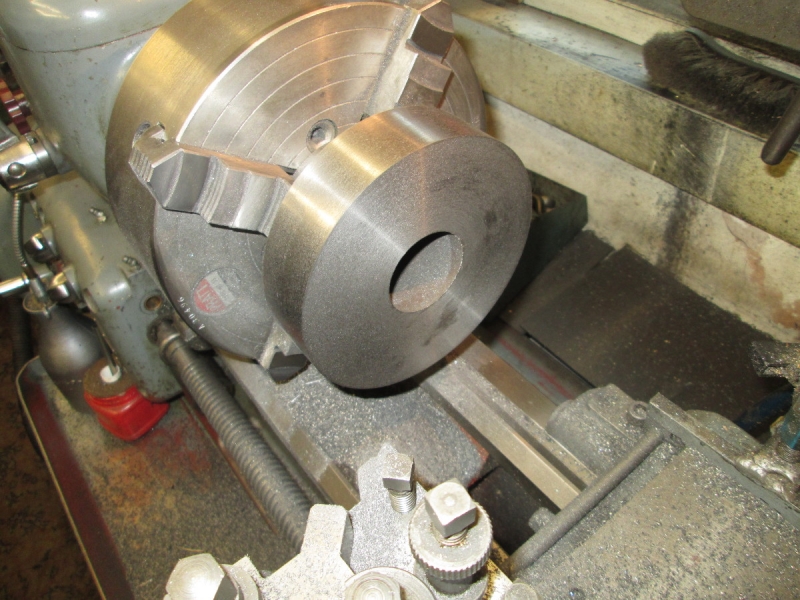

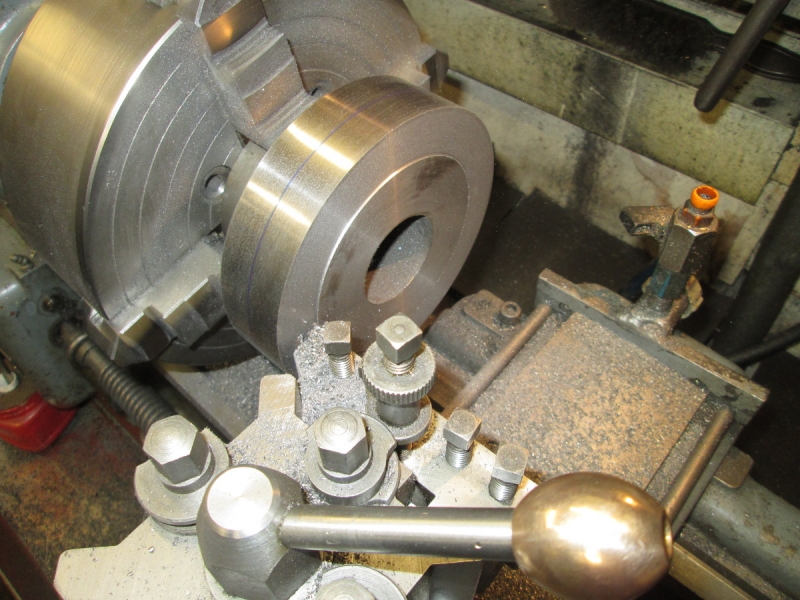

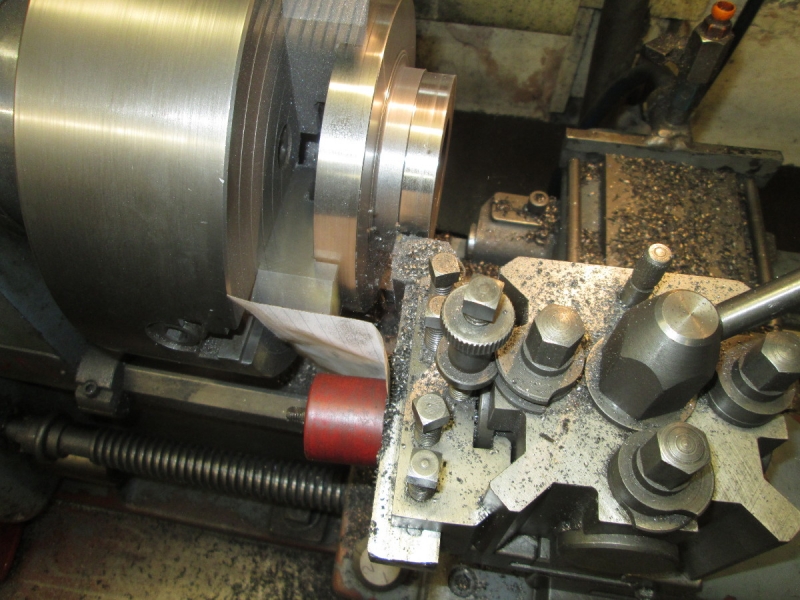

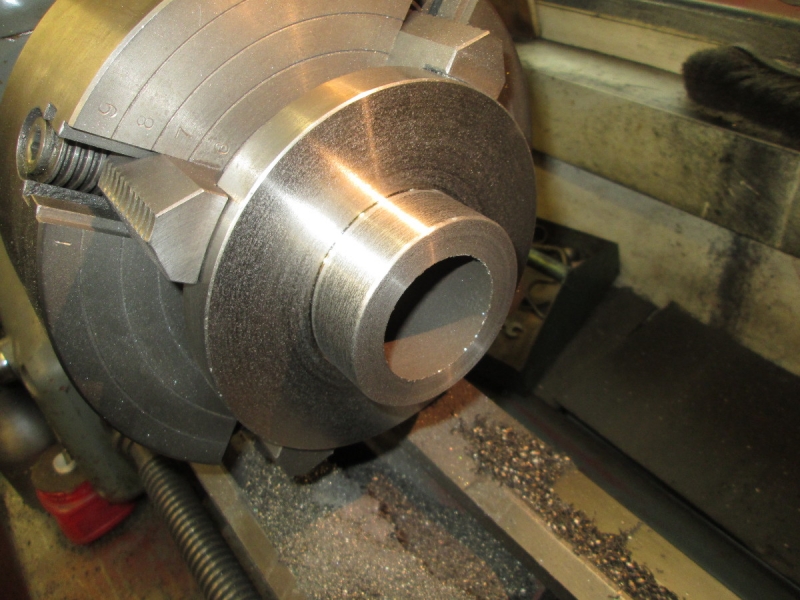

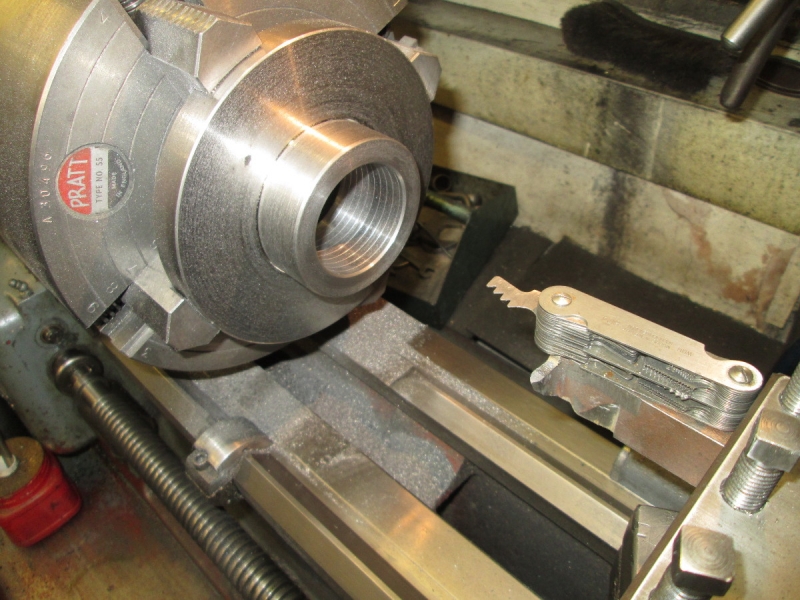

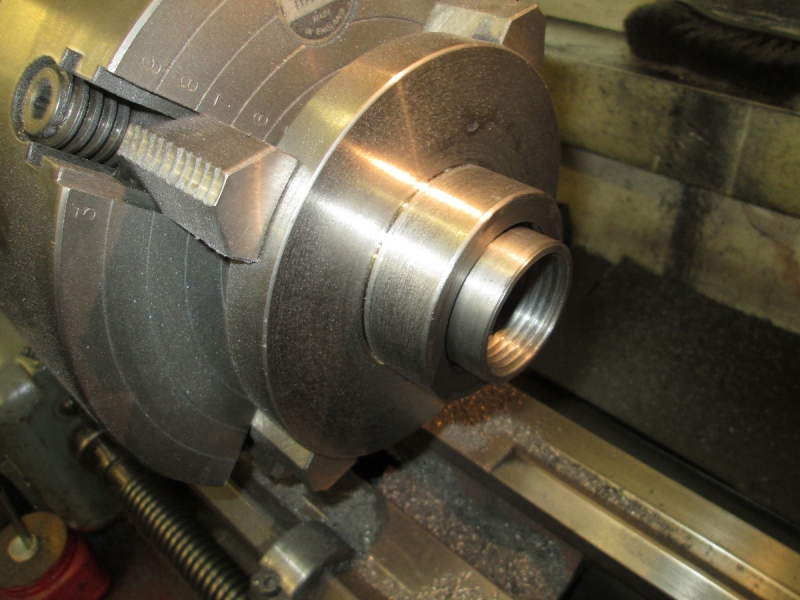

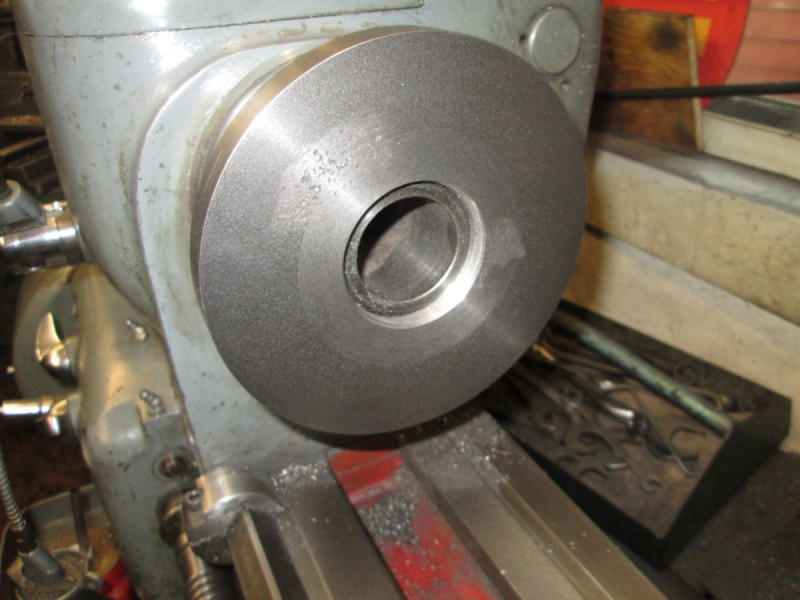

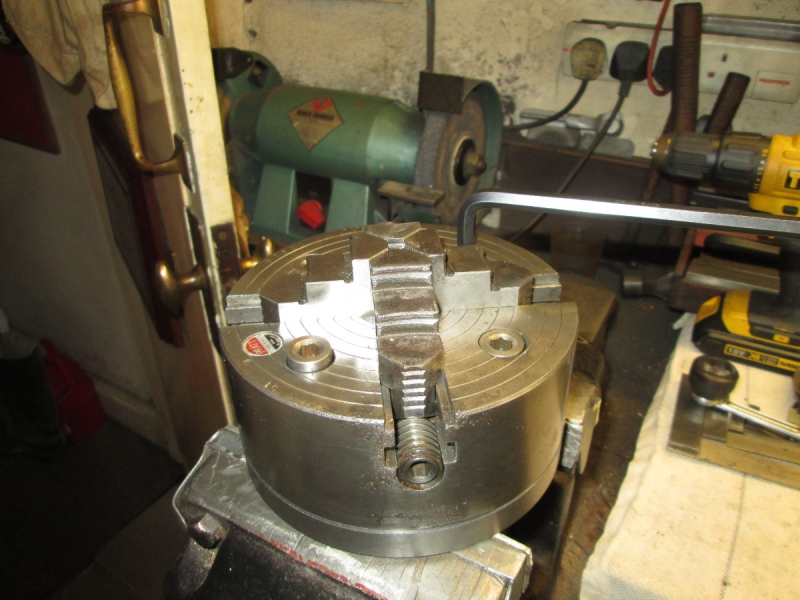

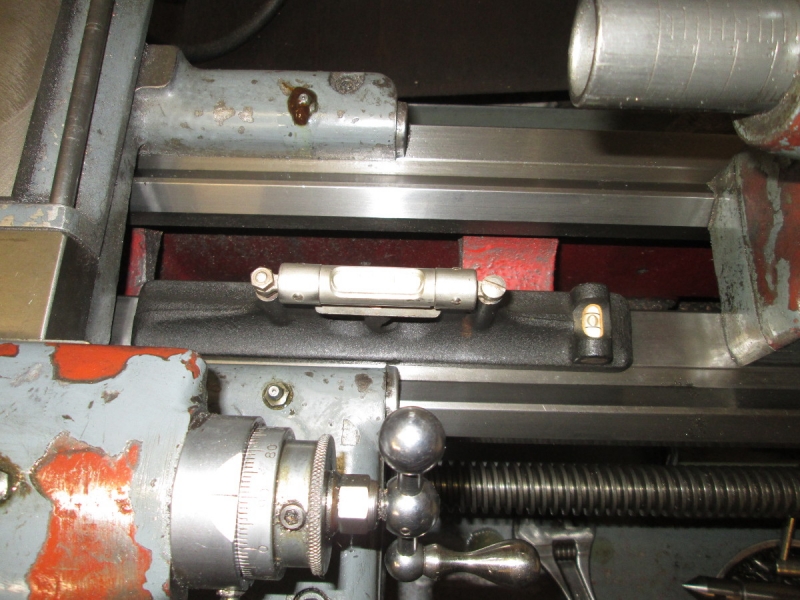

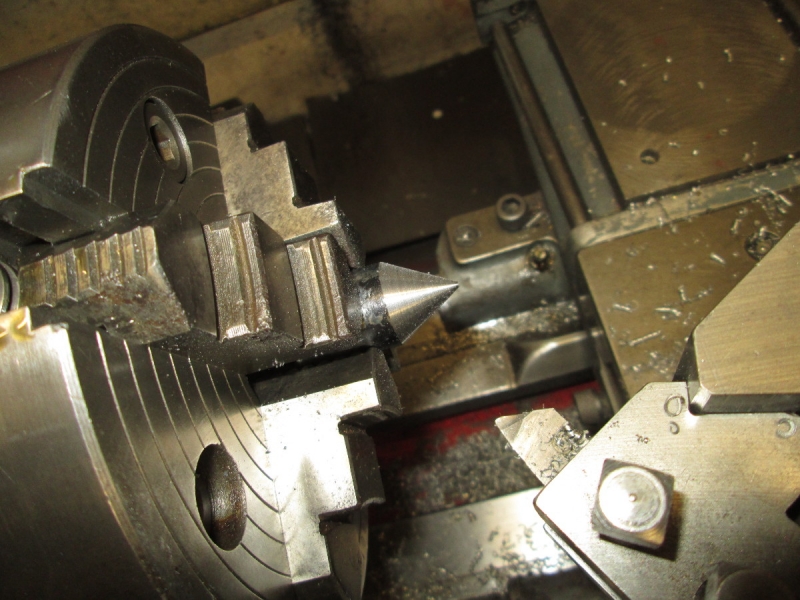

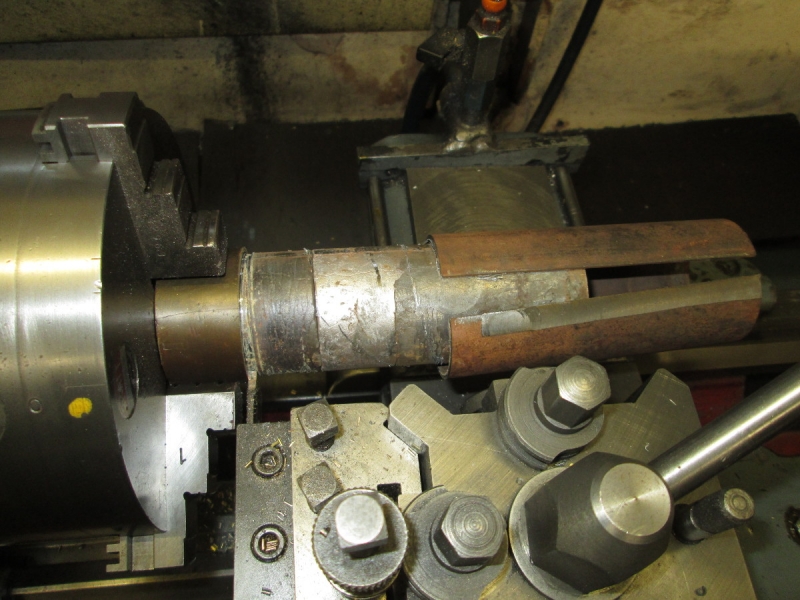

The morning has as usual been busy but I have got all my jobs done. Then on with my bearings. I made sure I had a clean face and countersunk the end of the bore.

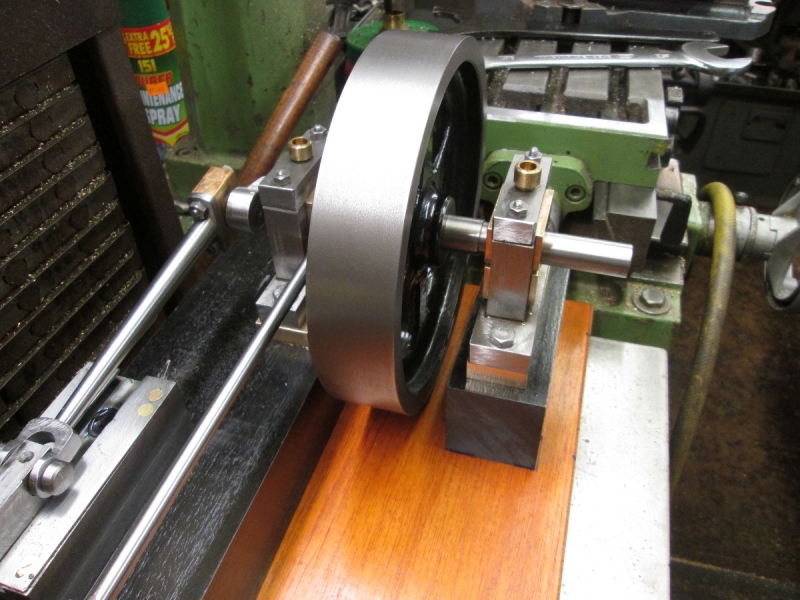

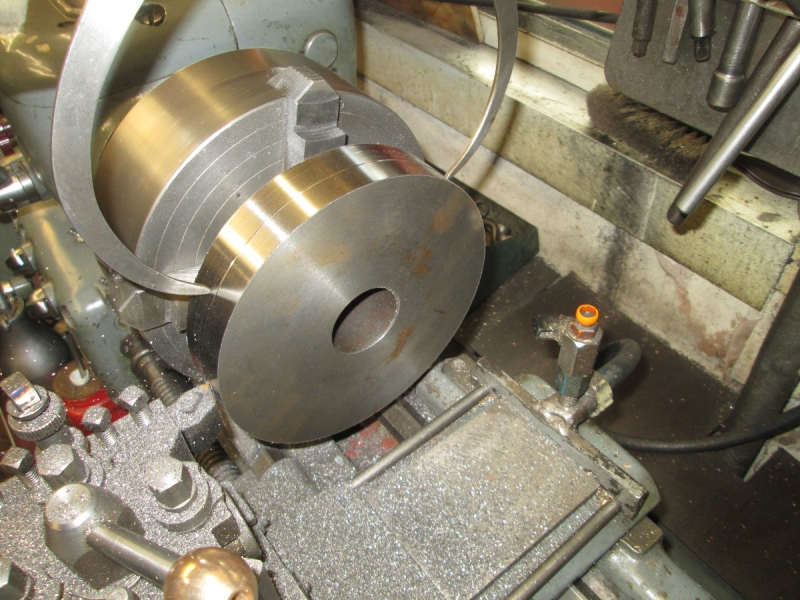

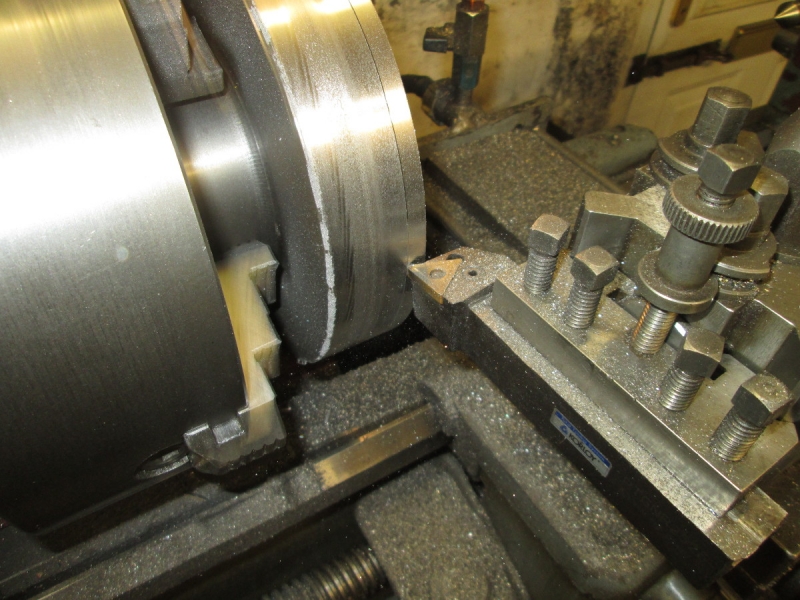

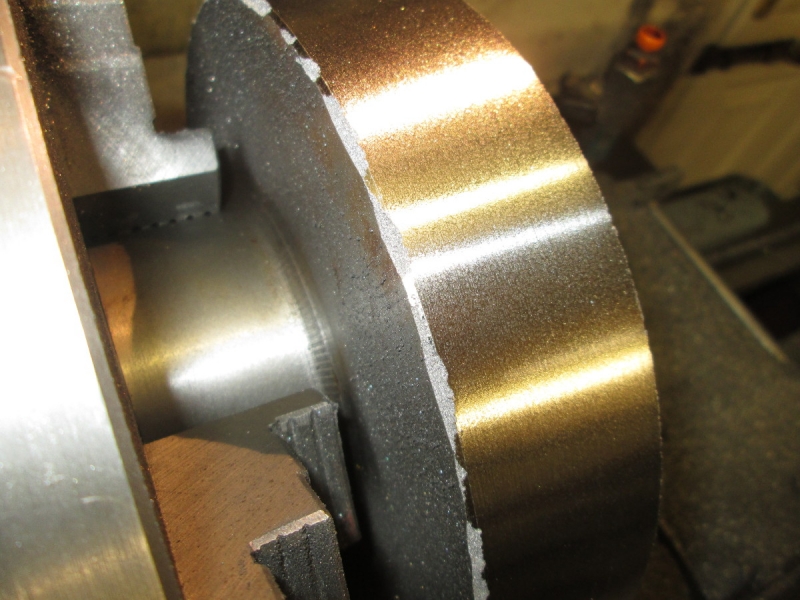

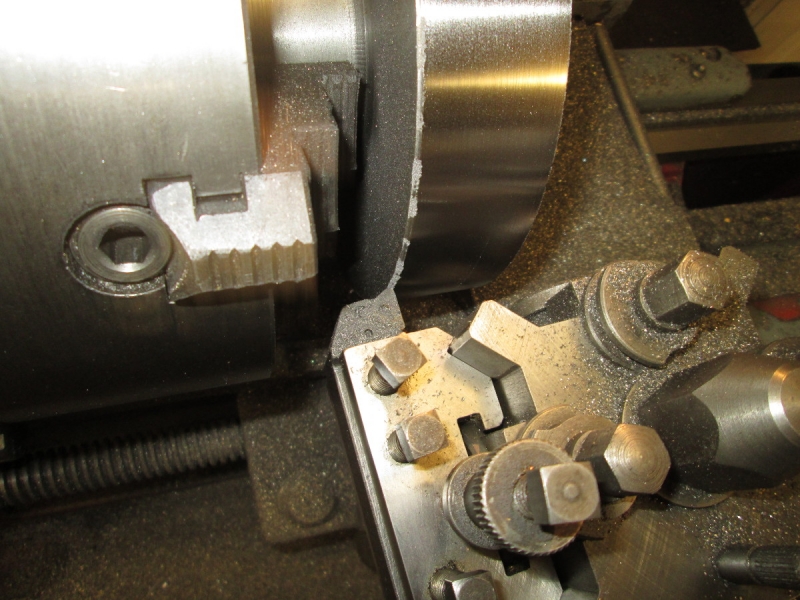

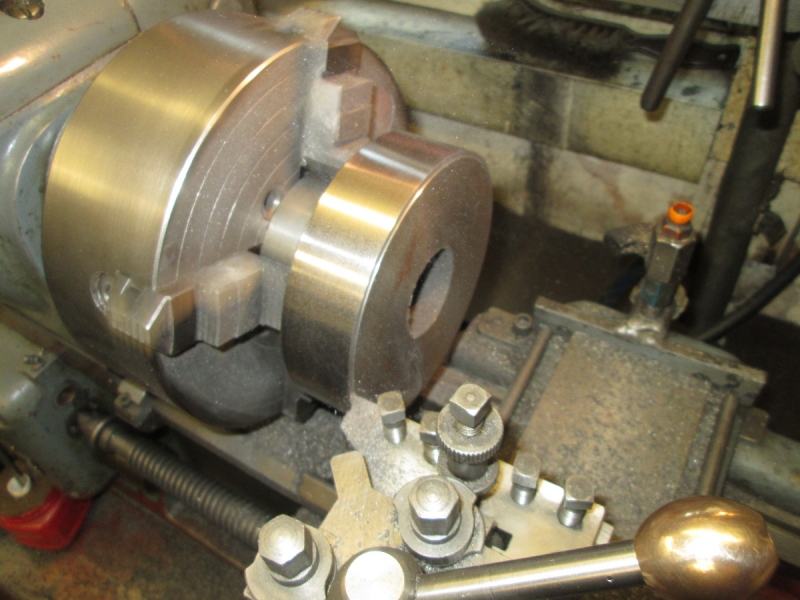

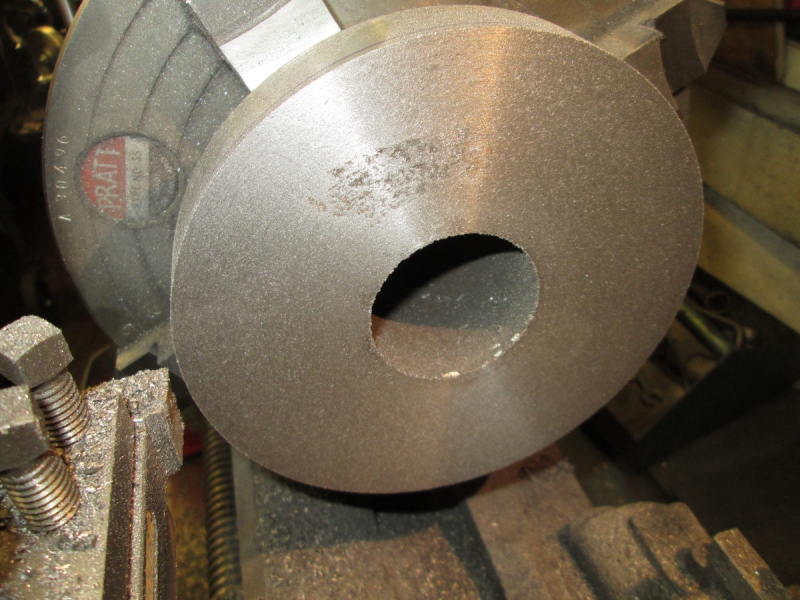

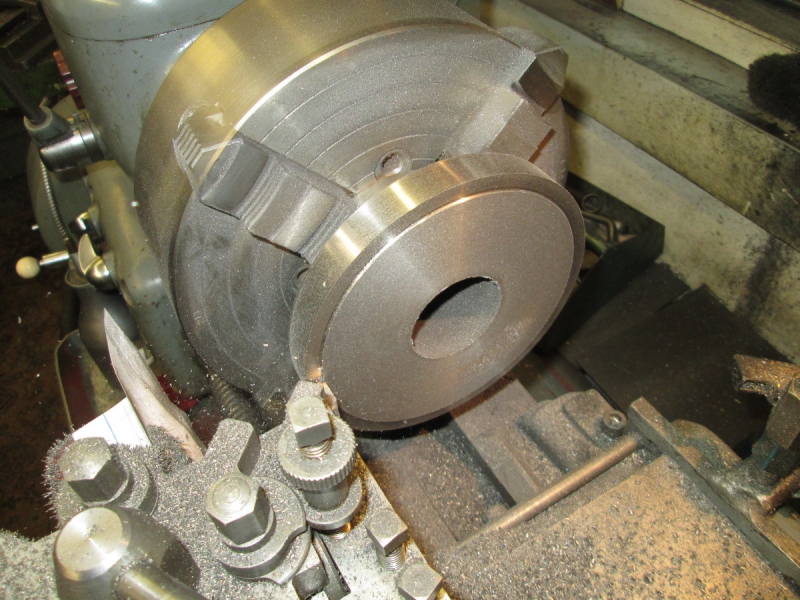

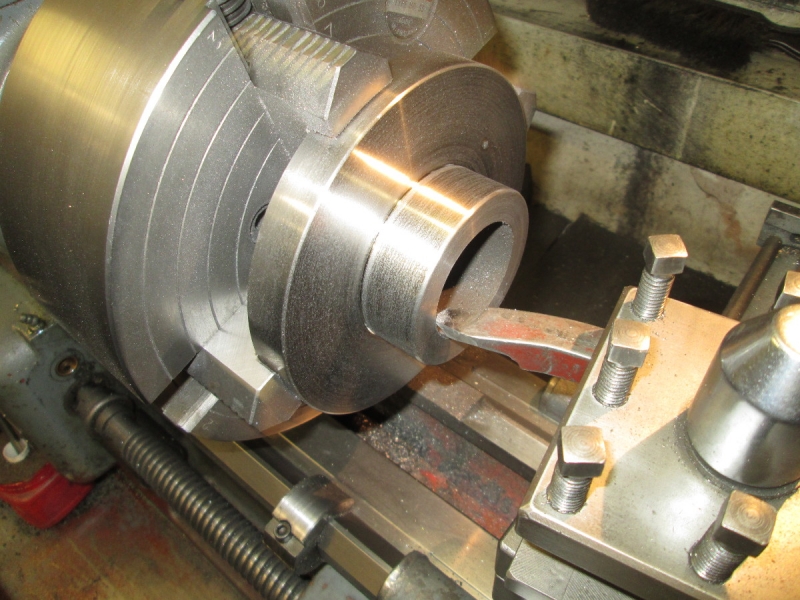

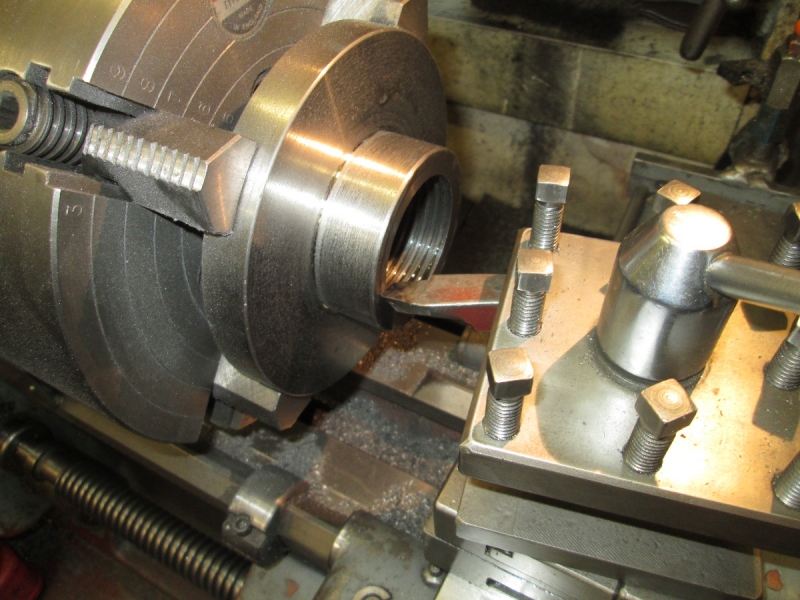

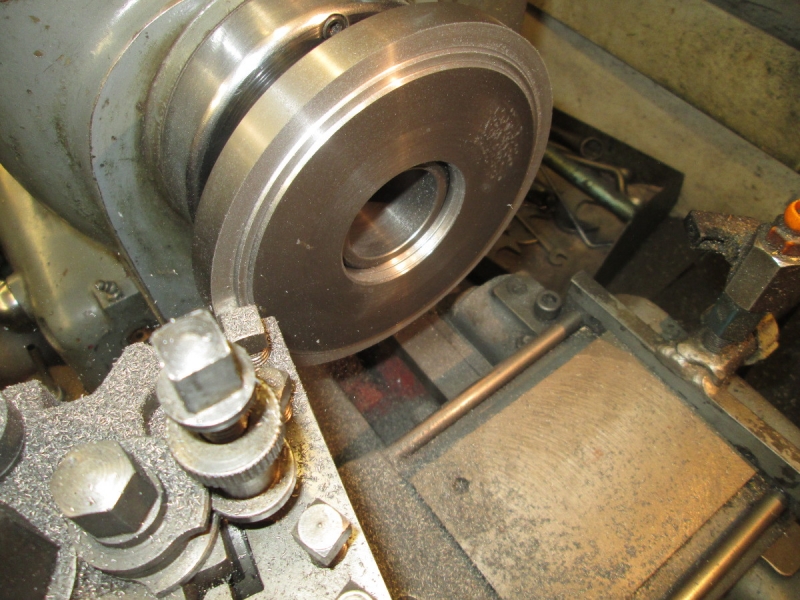

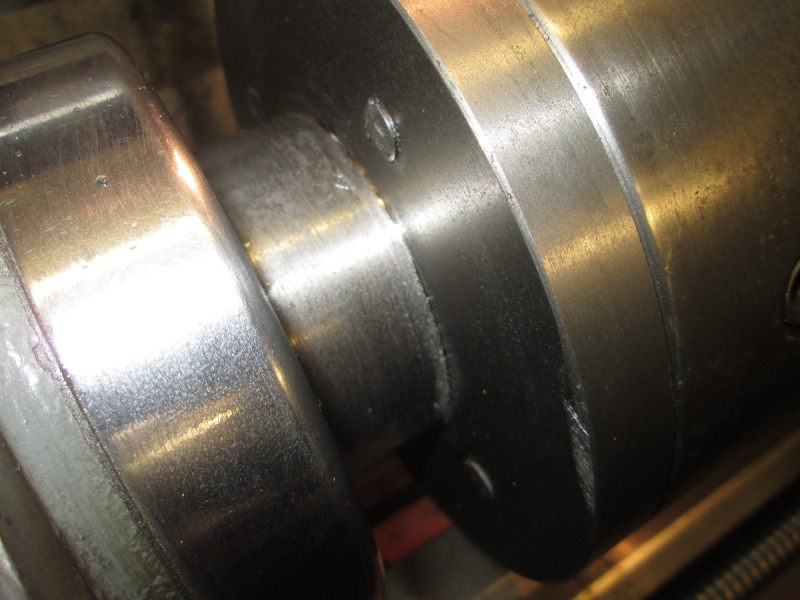

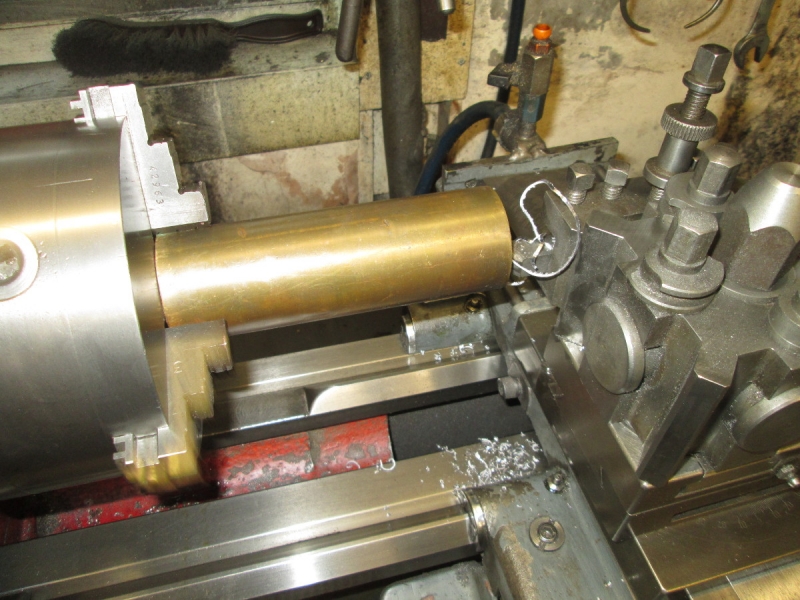

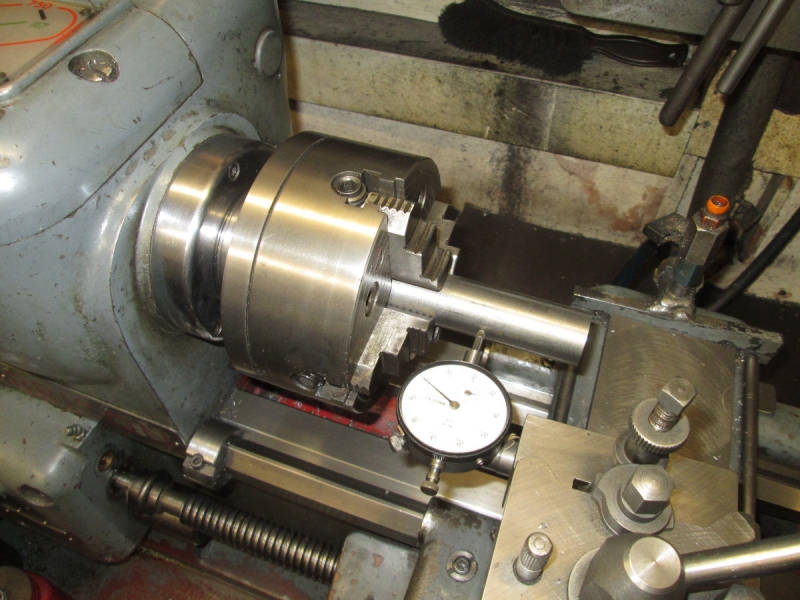

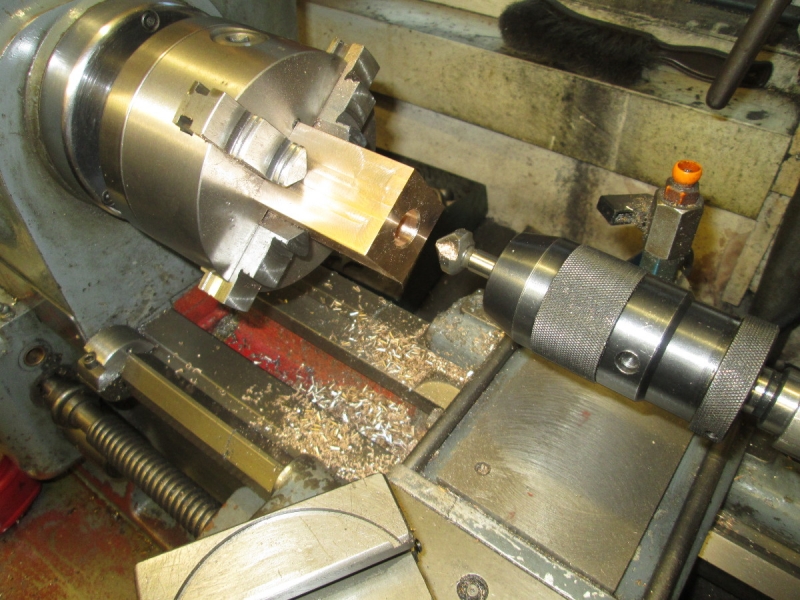

Then I parted the first bearing off at slightly more than the 1" I need. Then I faced the end left in the chuck and countersunk that as well before reversing it and parting the spare metal off, and then facing that one and countersinking it. Then I put the first one back in the chuck, faced the end that had been parted off and countersunk that as well.

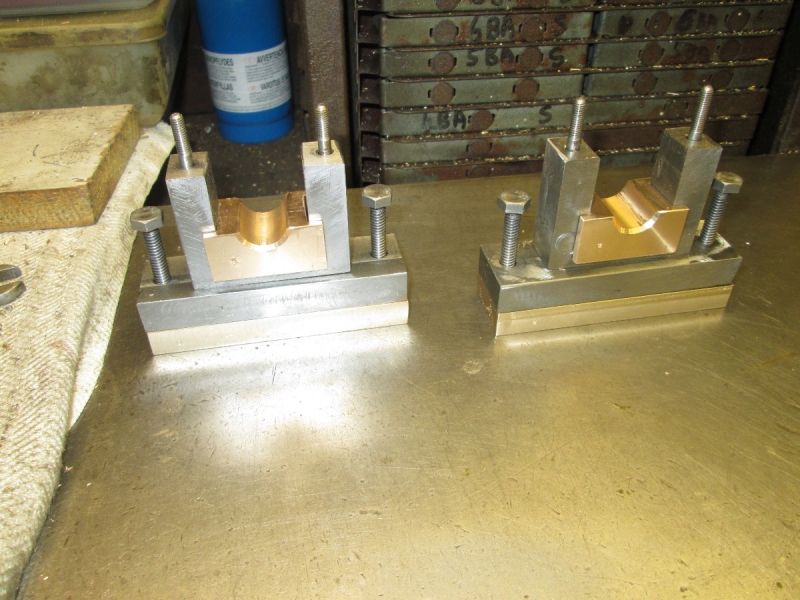

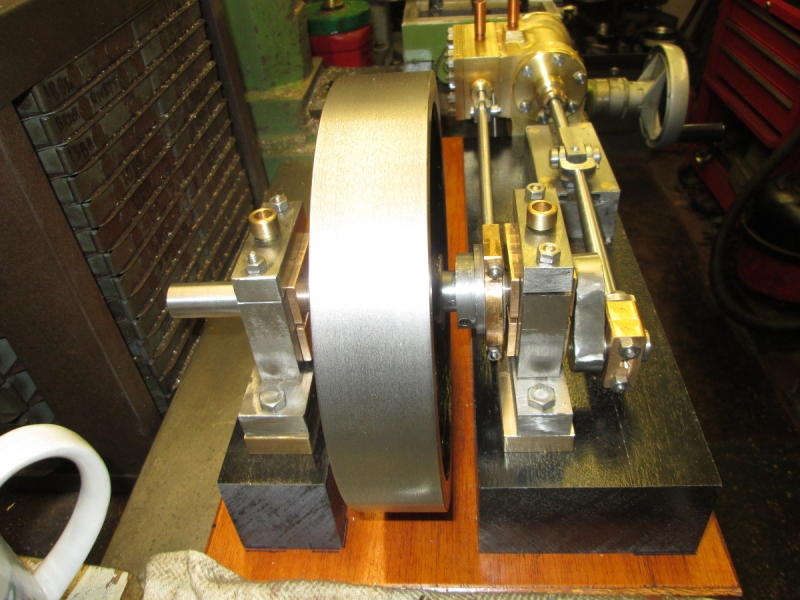

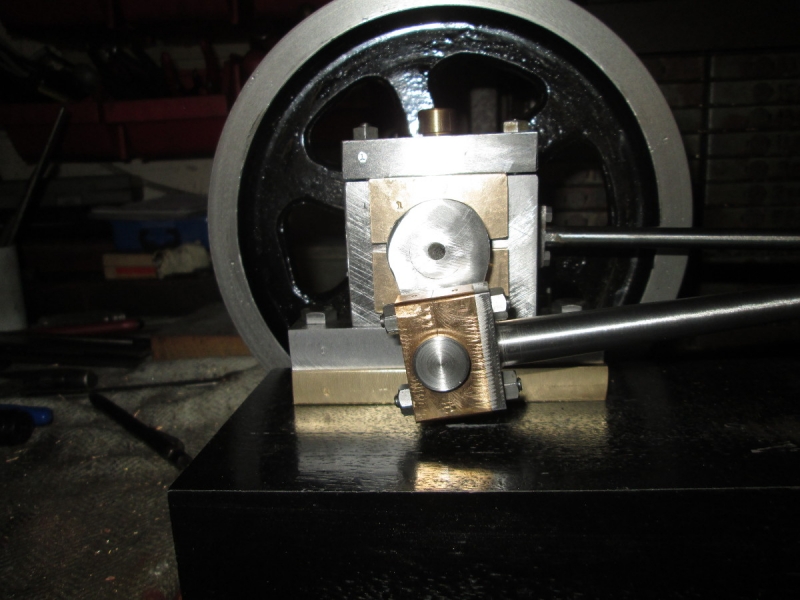

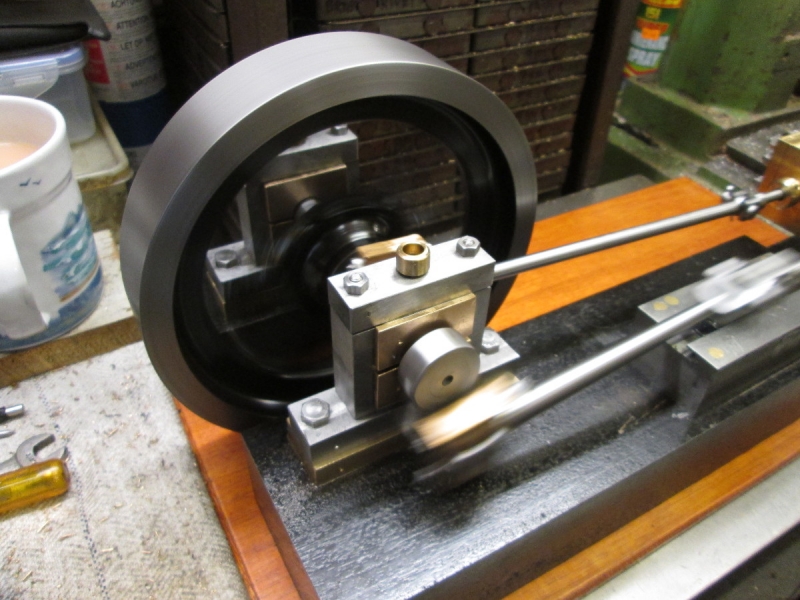

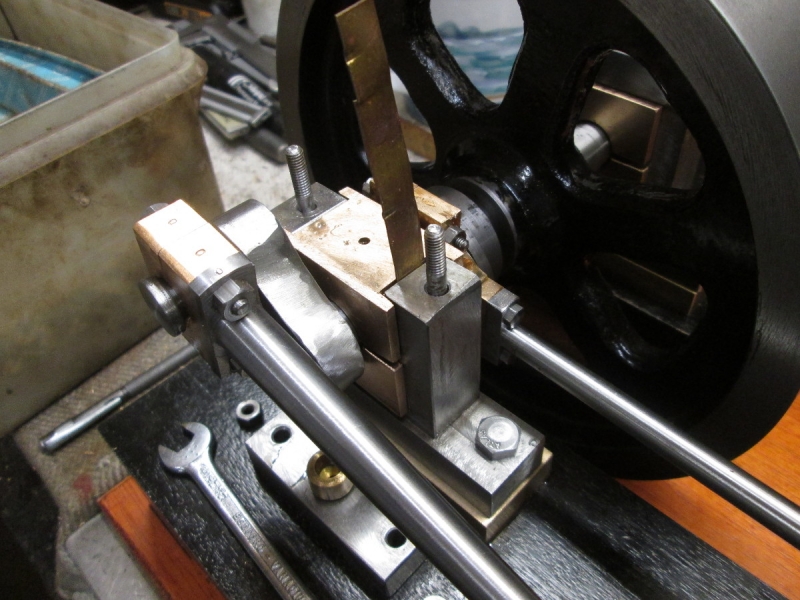

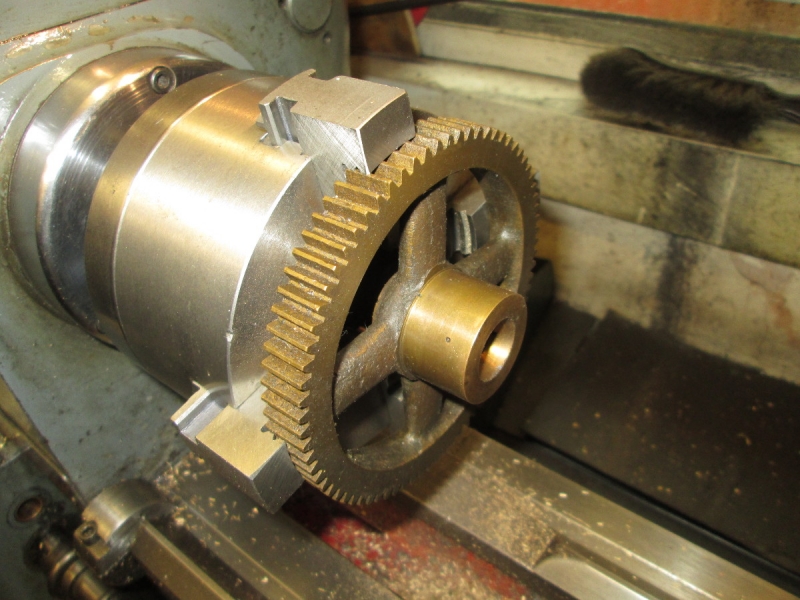

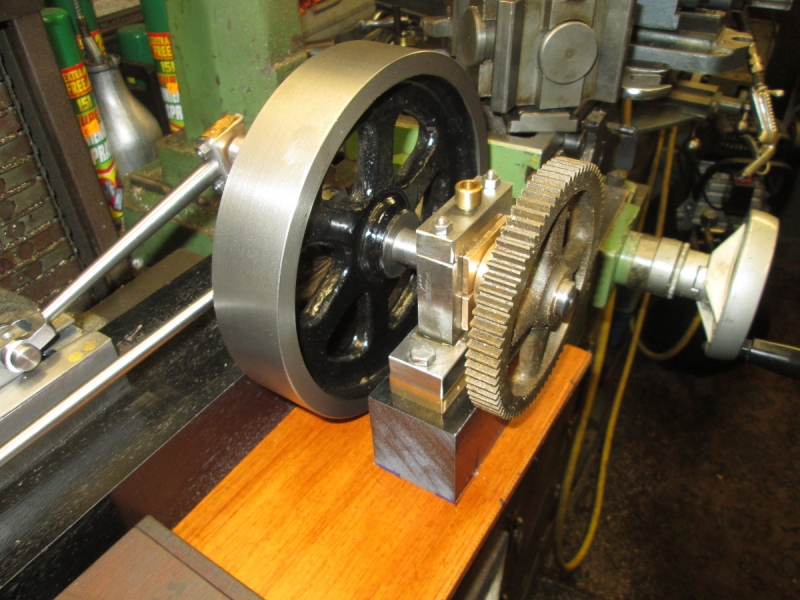

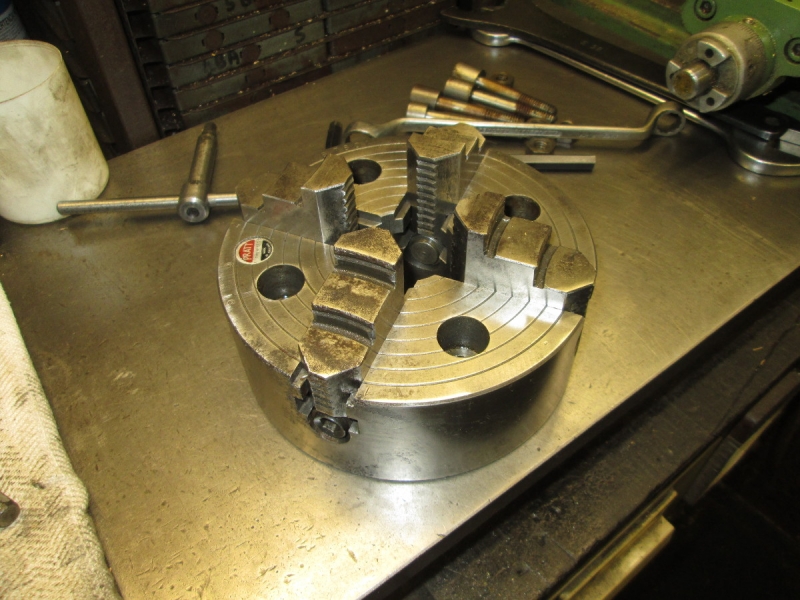

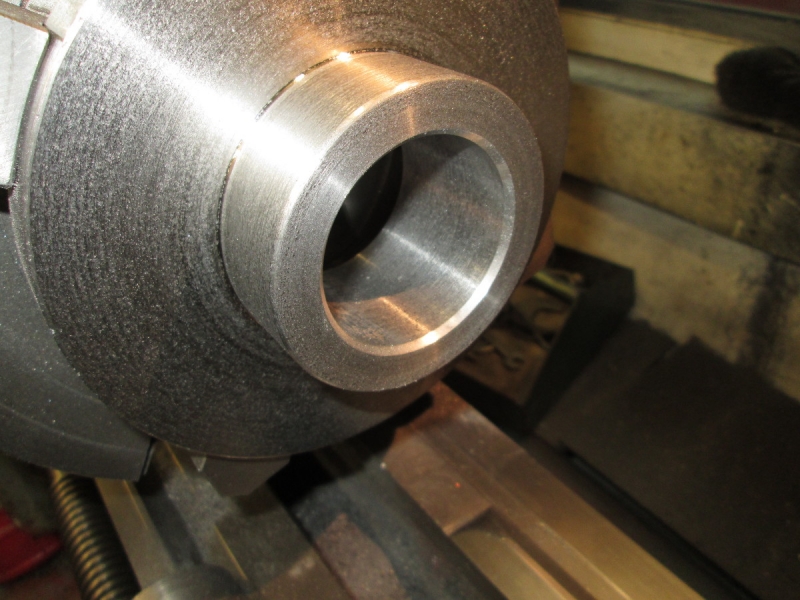

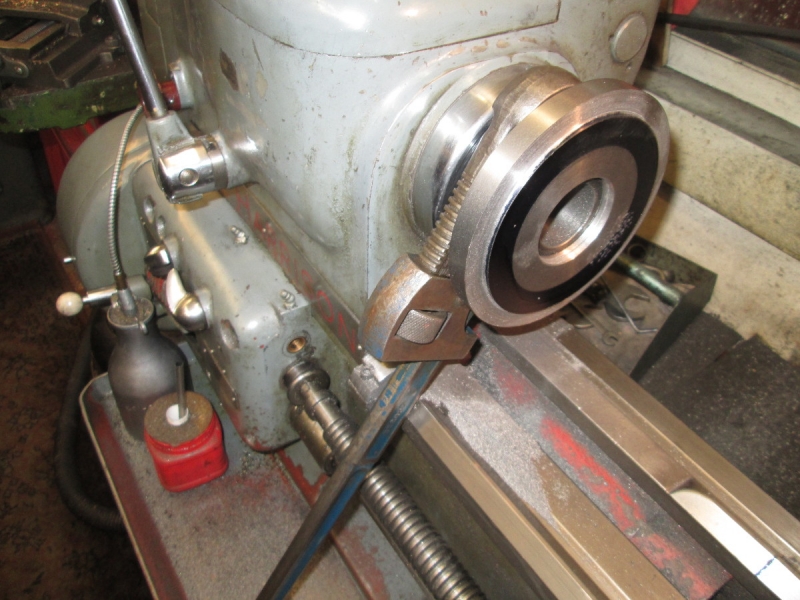

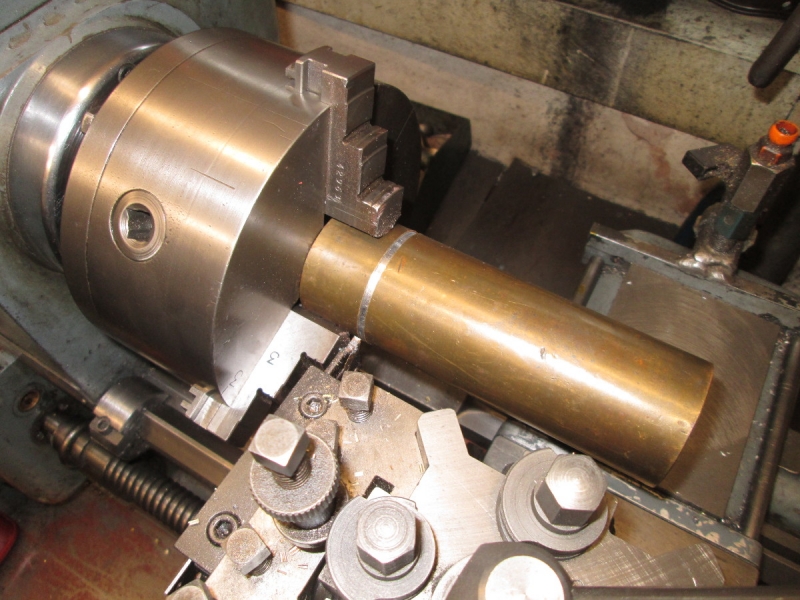

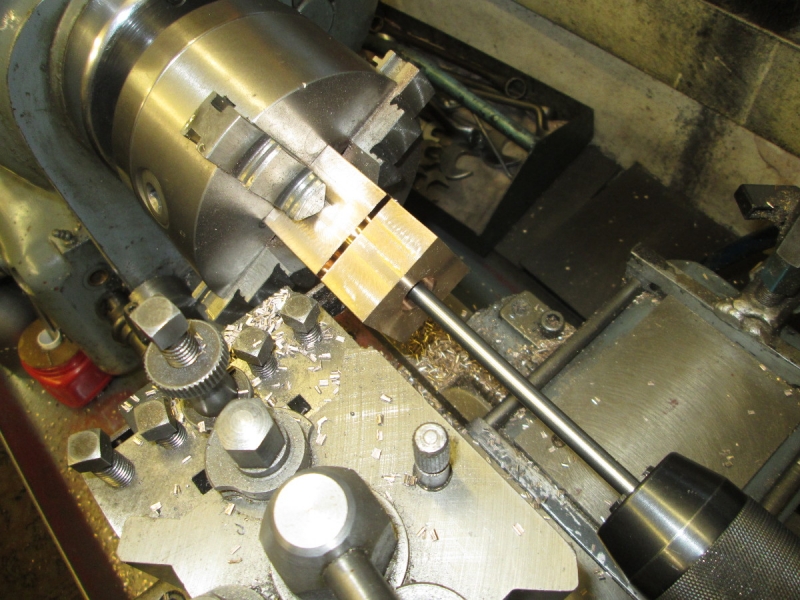

I broke all the edges and stamped each bearing with witness marks. In case you've been wondering, I haven't split the bearings and sweated them back together, I am just going to split them and accept the gap between the two halves which doesn't matter as the two will be stabilised by the housing. In fact the gap with edges chamfered will let oil circulate better in the bearing.

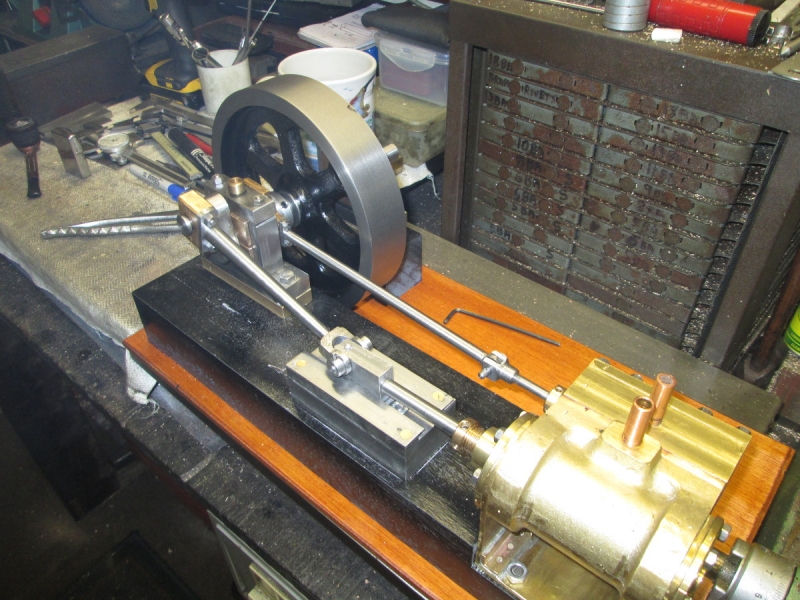

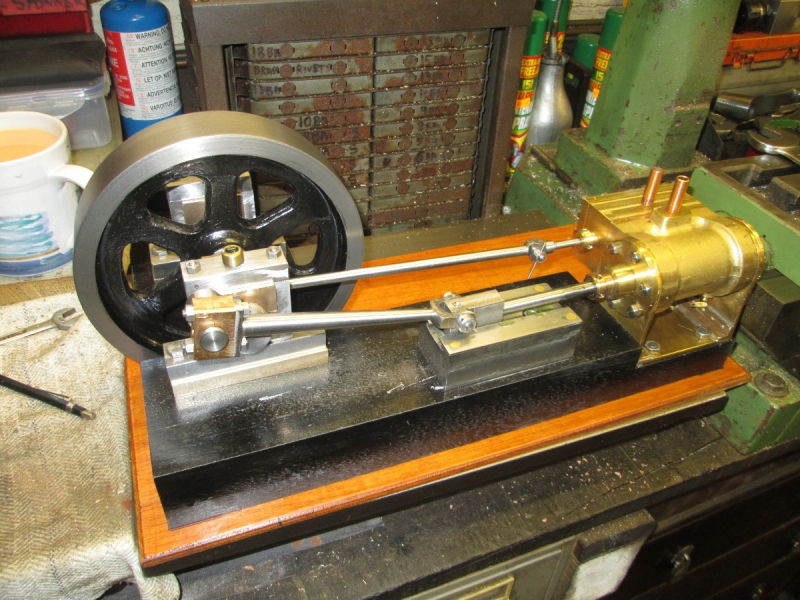

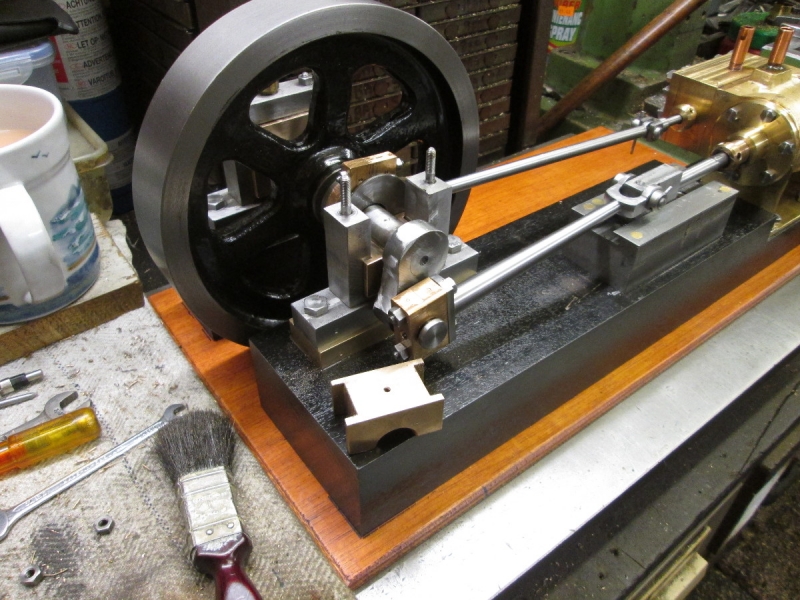

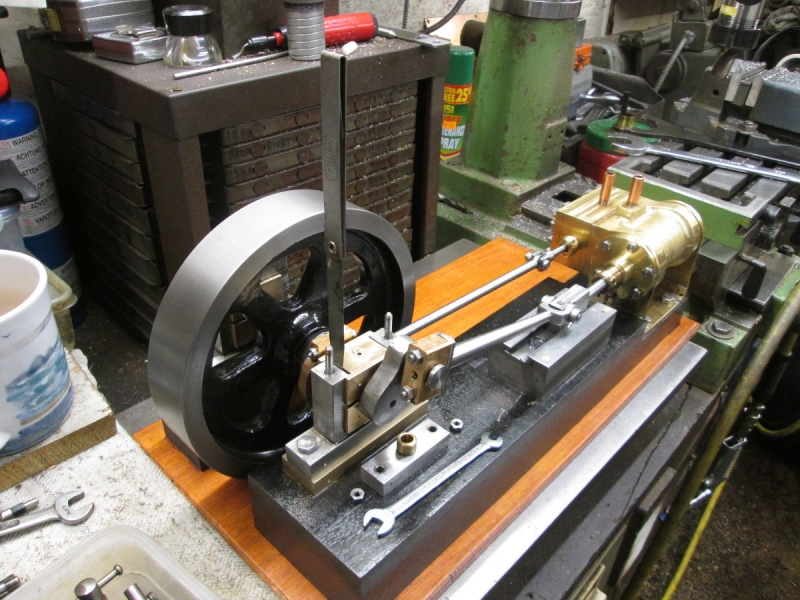

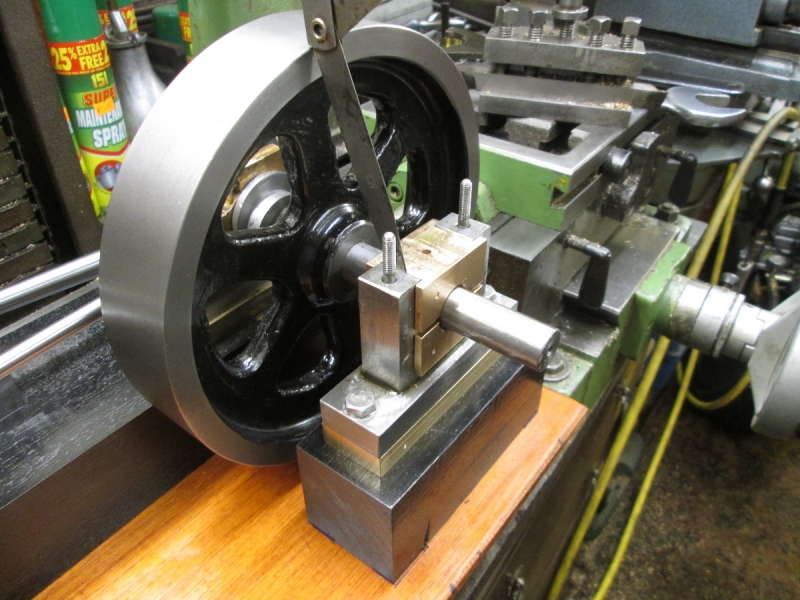

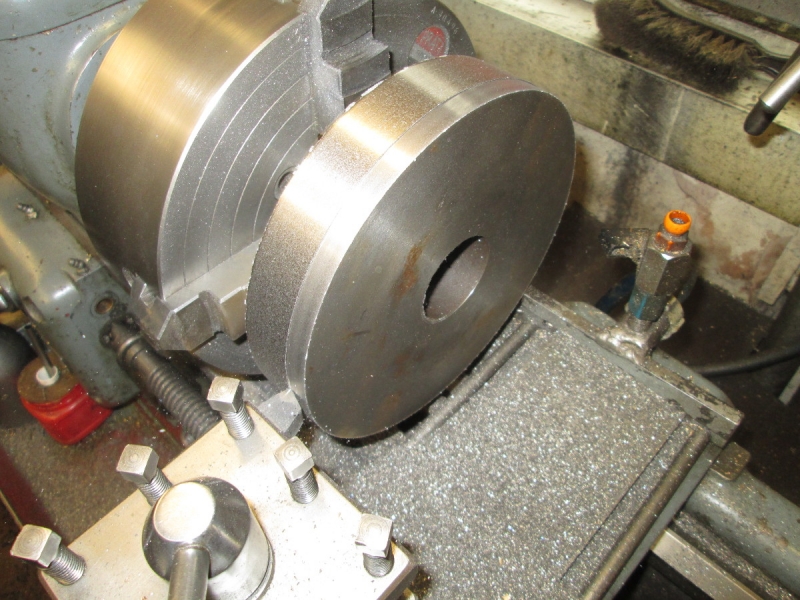

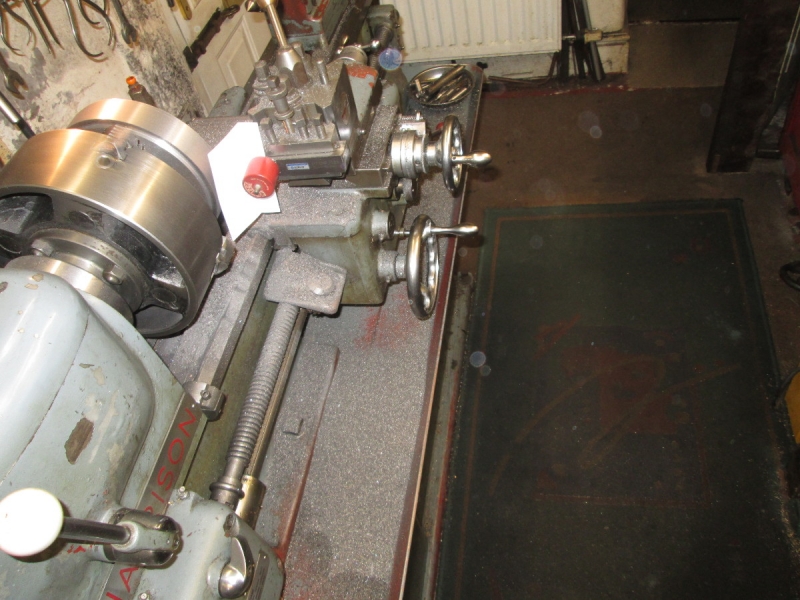

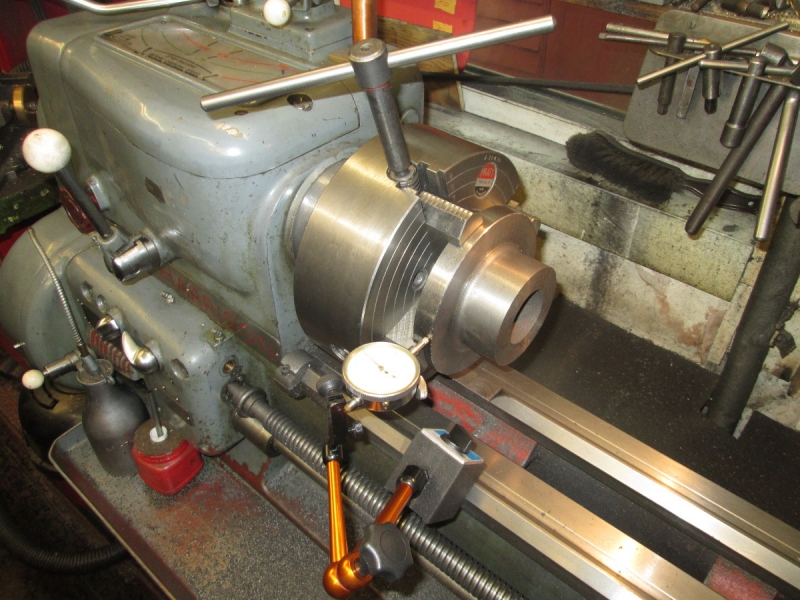

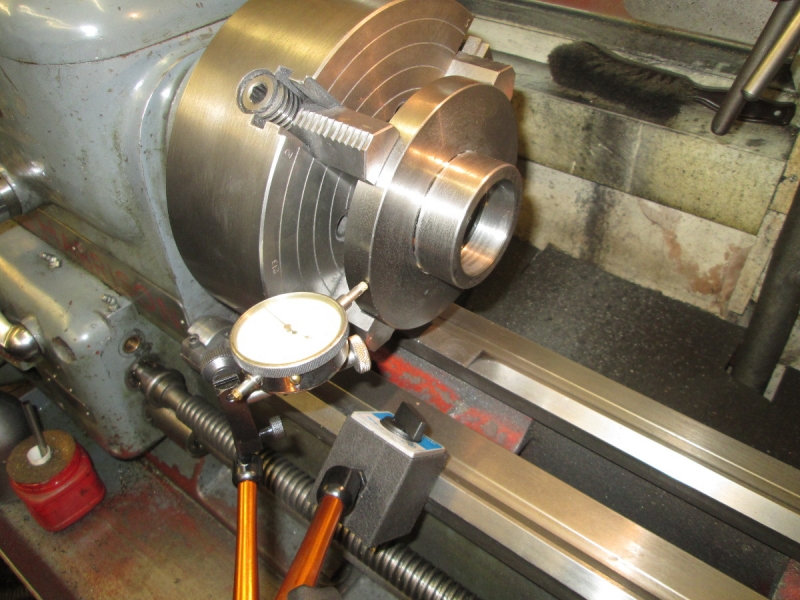

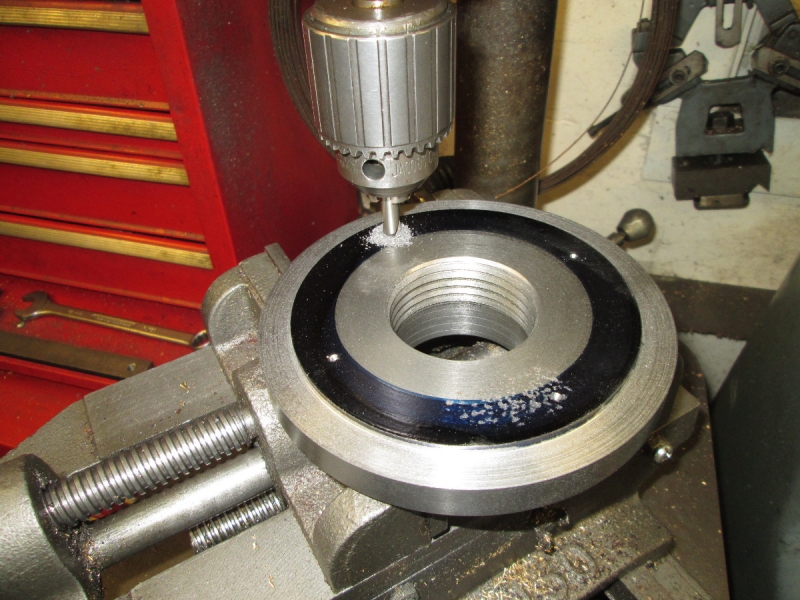

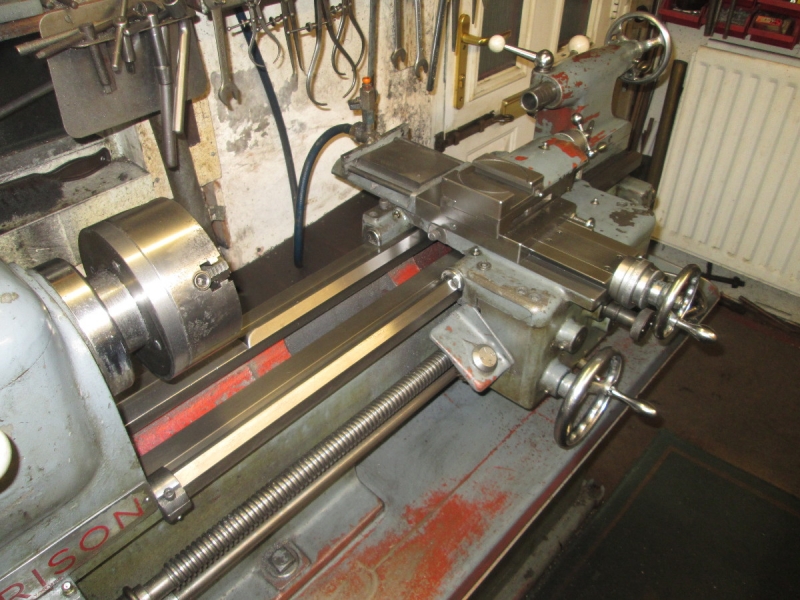

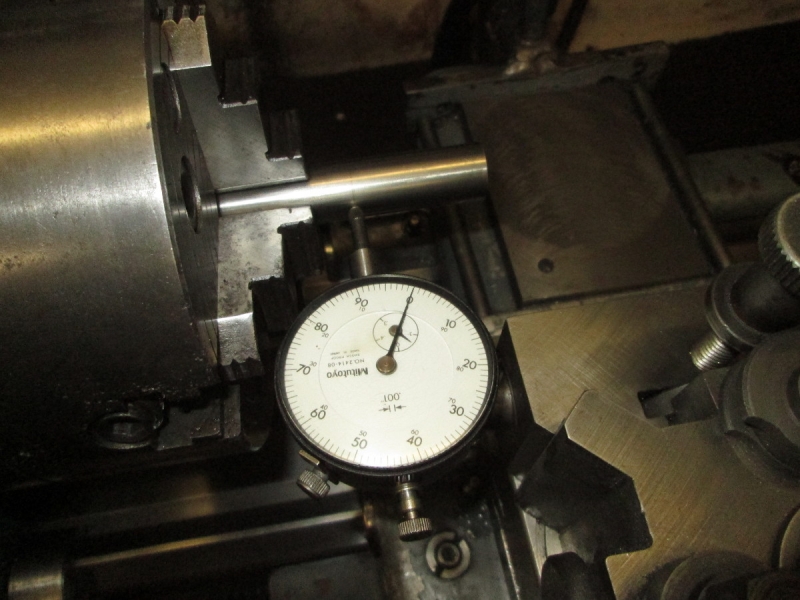

Here we are at knocking off time. Now I have some measuring and marking to do before I mill out the channels in the bearing brasses. But that's for tomorrow. I've made a better job of these I think, I've tried them on the shaft and they are a good fit. They are both identical and will be easy to fit. Re-making them was the right choice, far better than making do with the old ones. A nice hour in the shed!