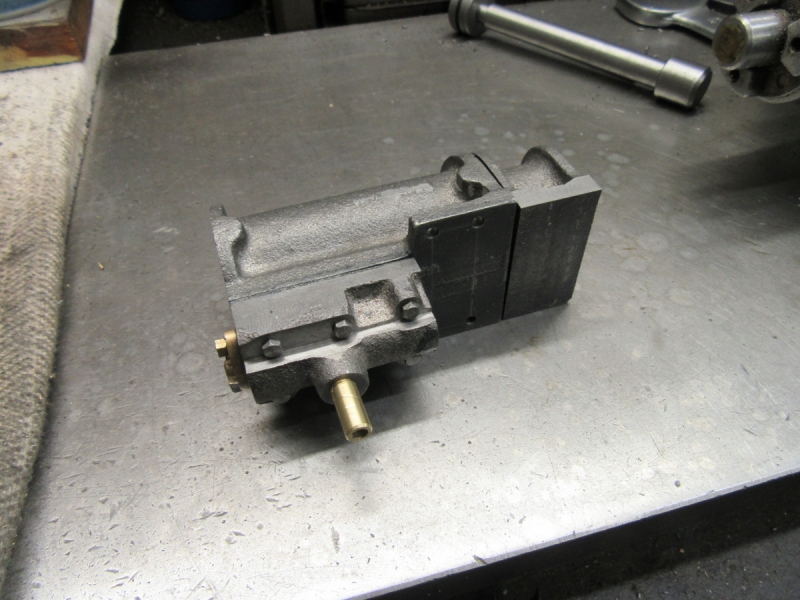

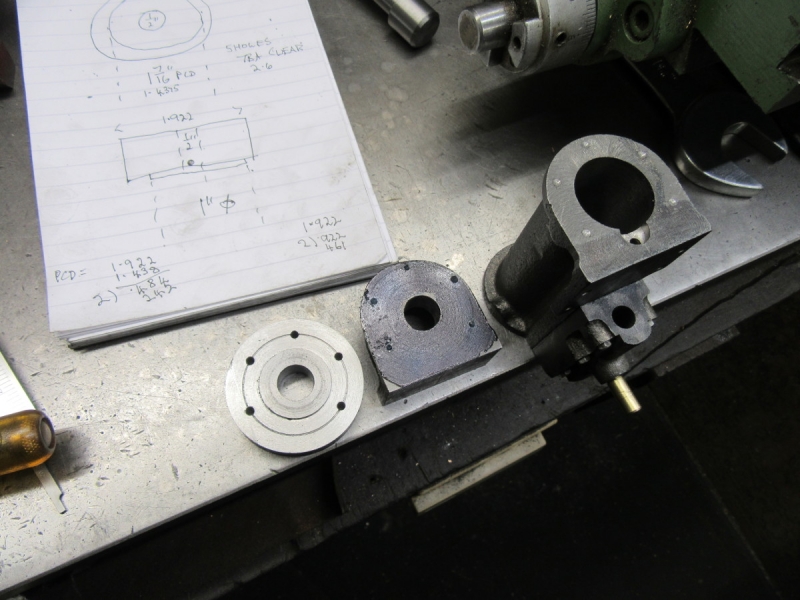

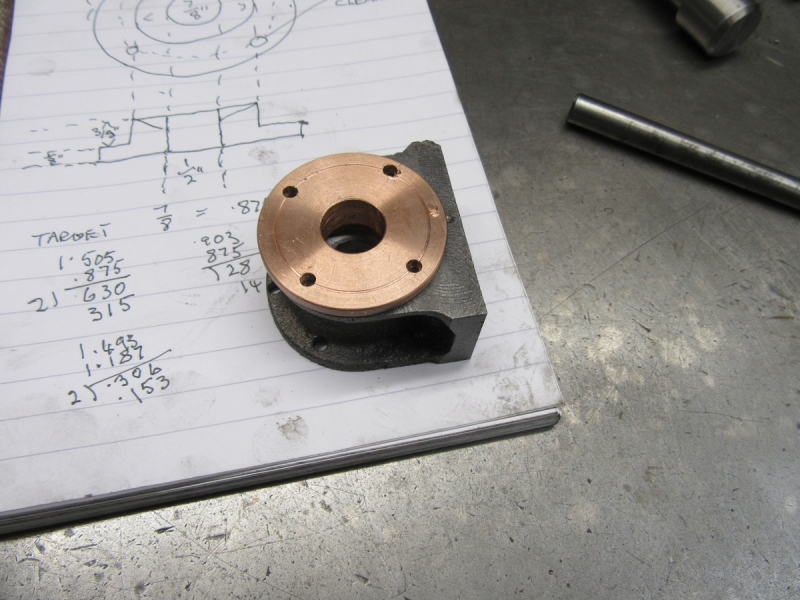

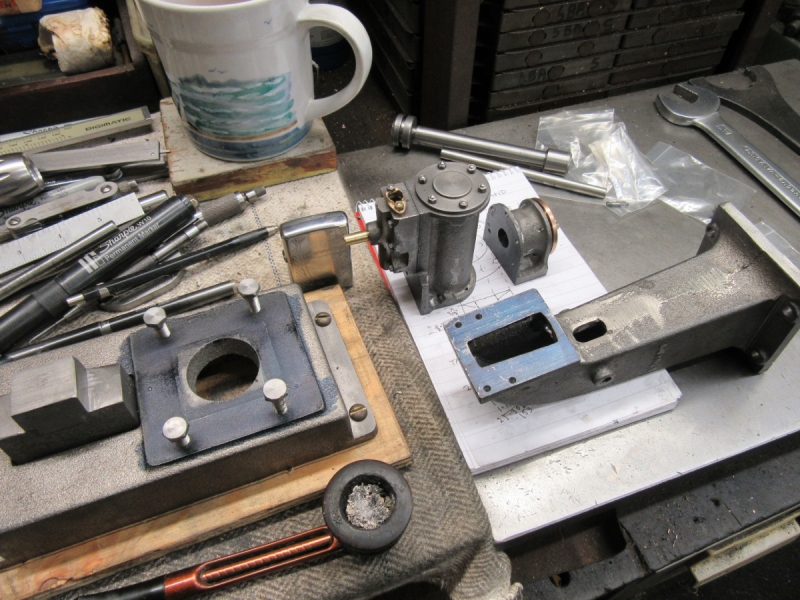

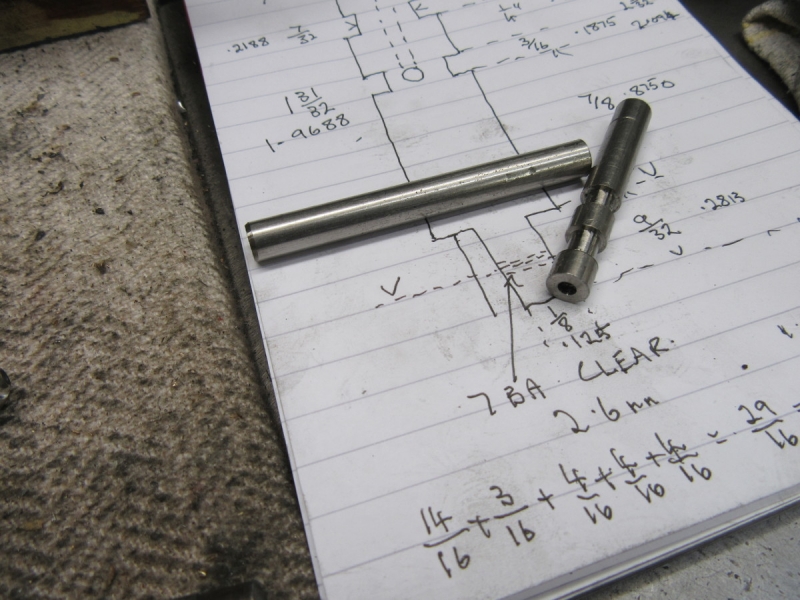

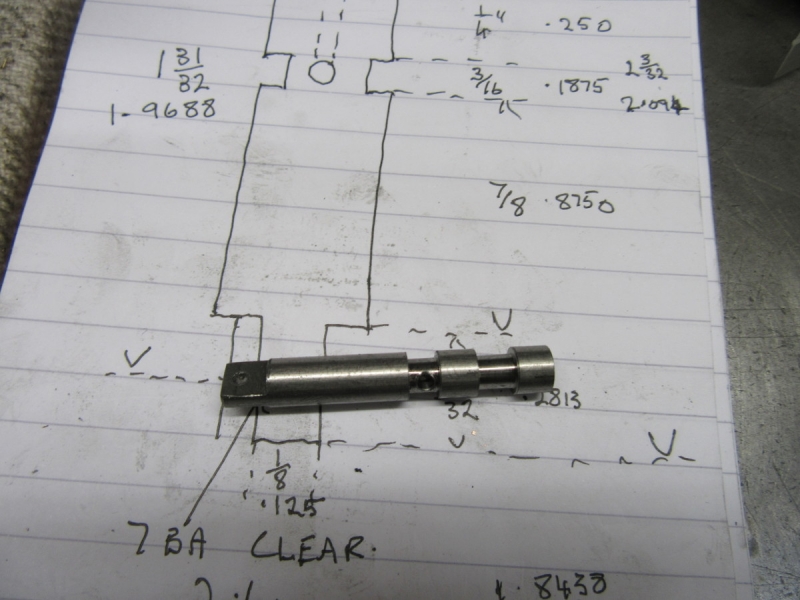

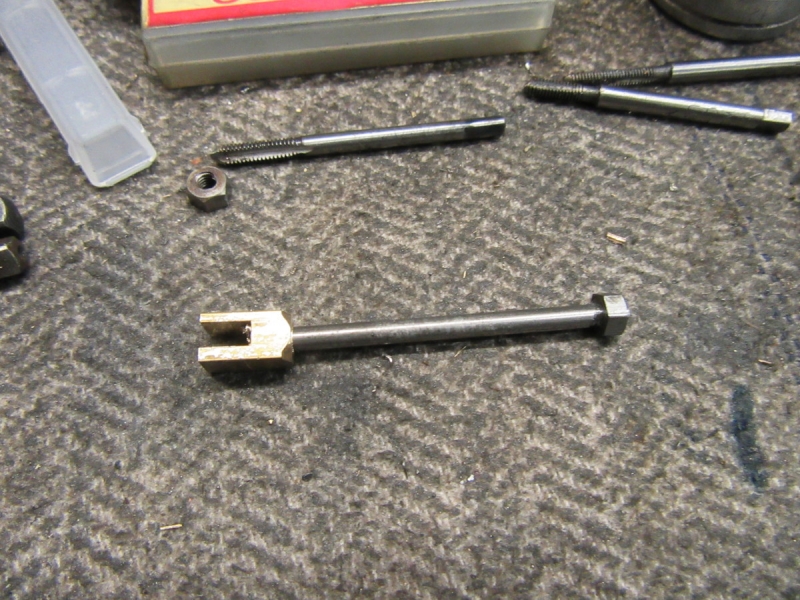

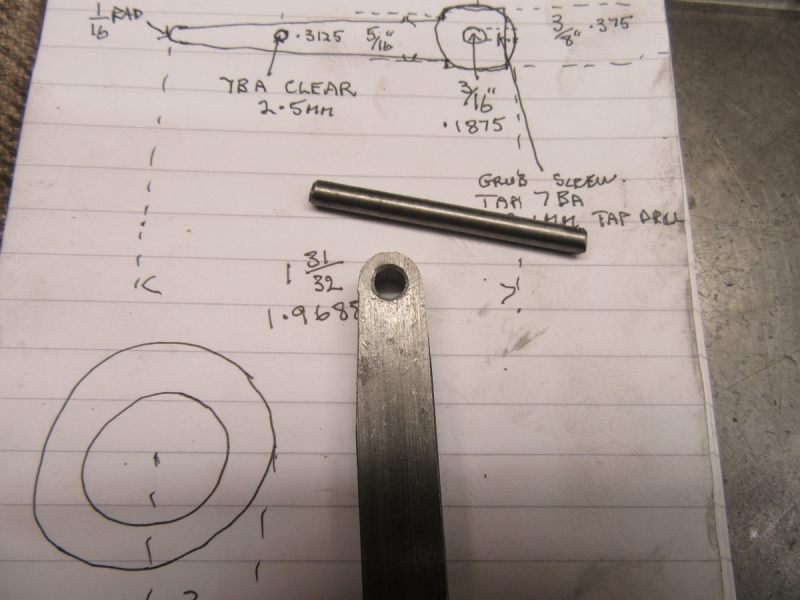

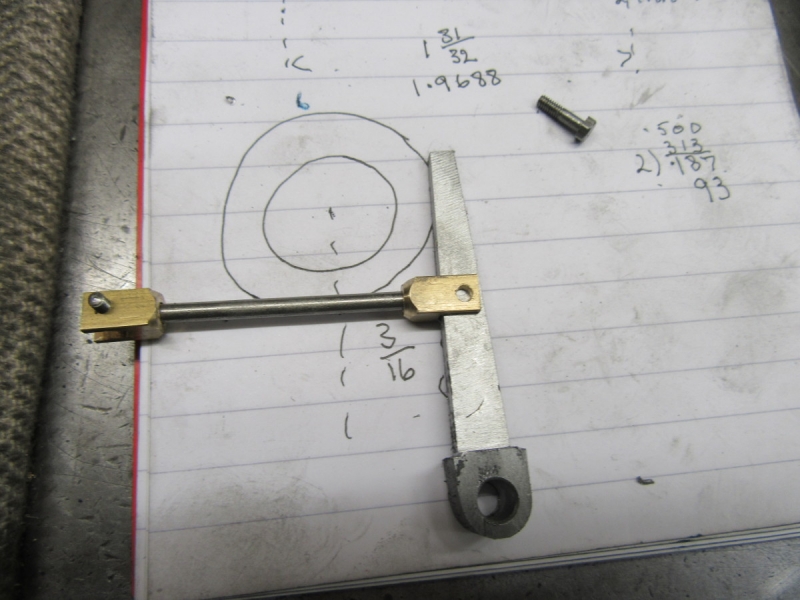

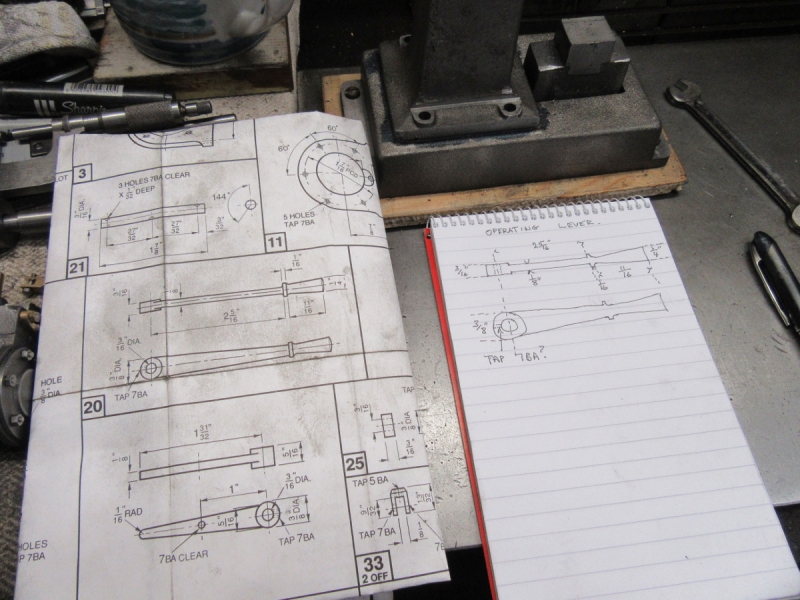

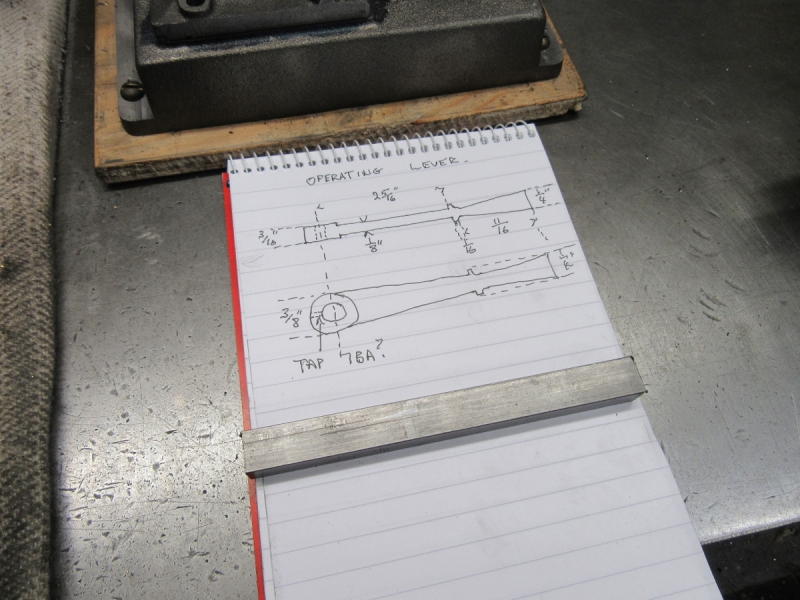

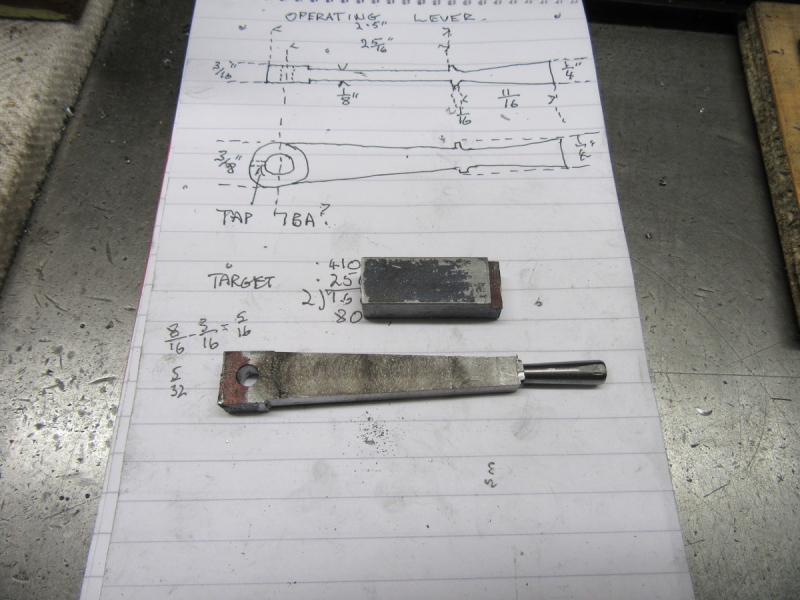

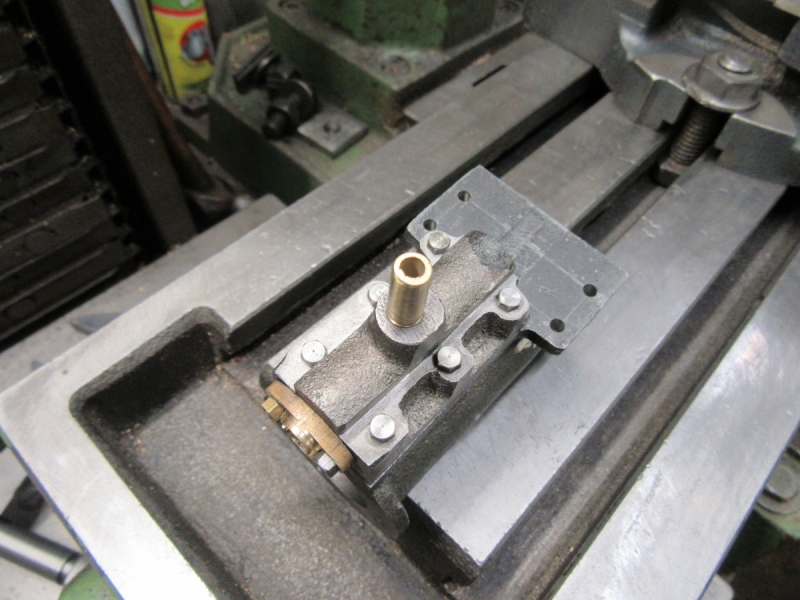

Here's my cheat, a 7BA bolt cut off and Loctited into the valve block. Sometimes we have to cut our losses.

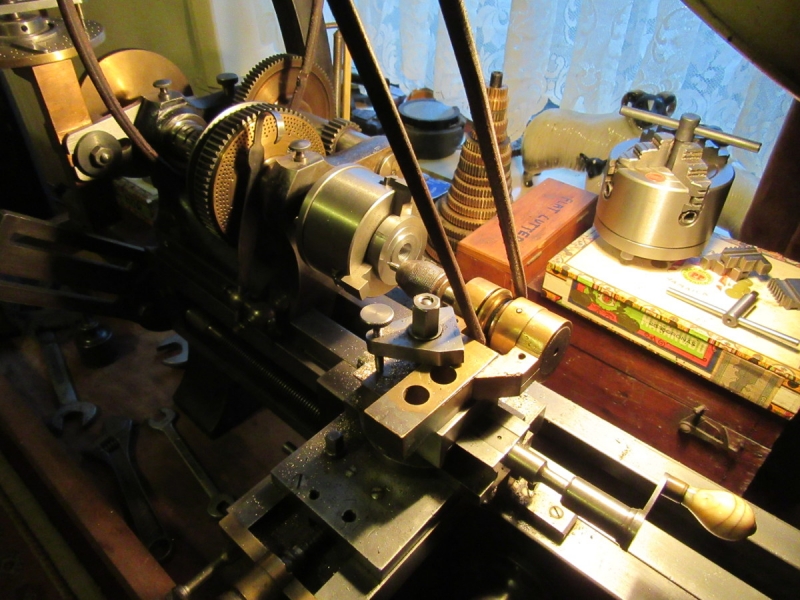

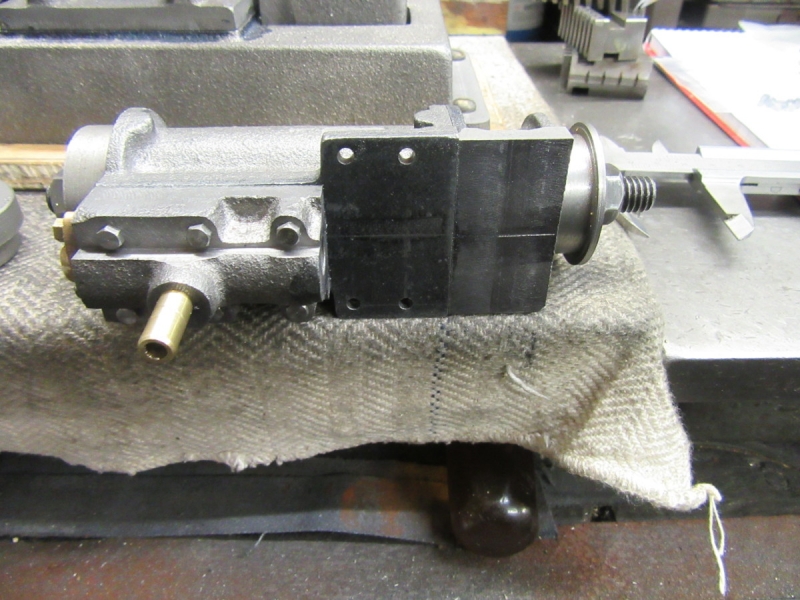

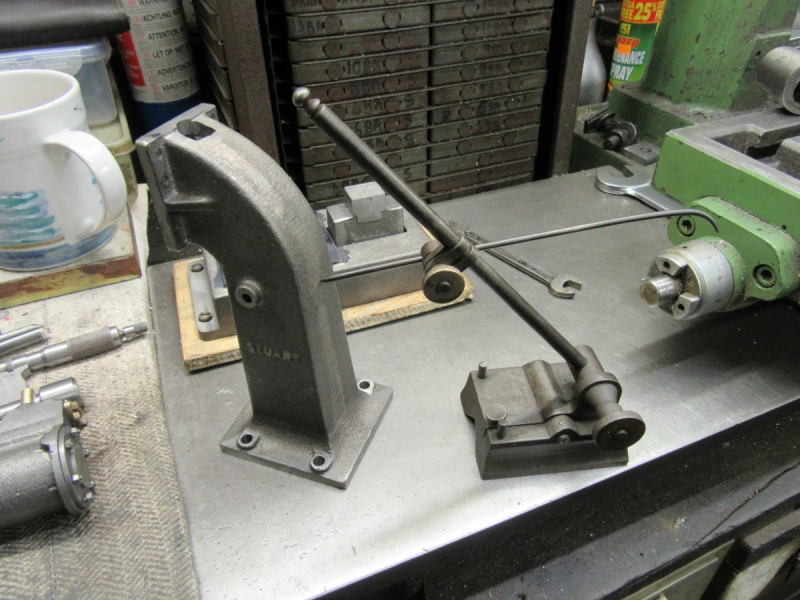

Time I fastened the hammer down onto the temporary base. First the anvil. 3/4" Brass round head Number 10 3/4" woodscrews. The colour is because they are old stock.

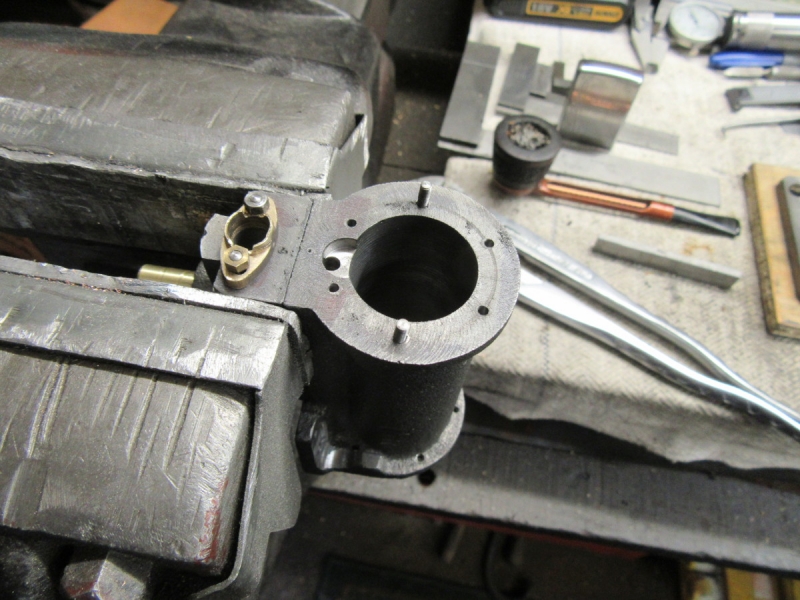

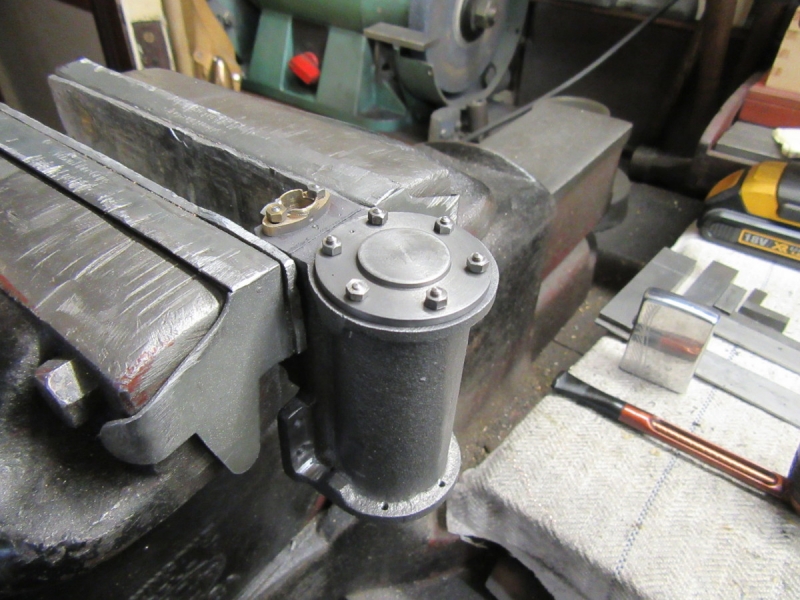

Then the standard on its base, same screws.

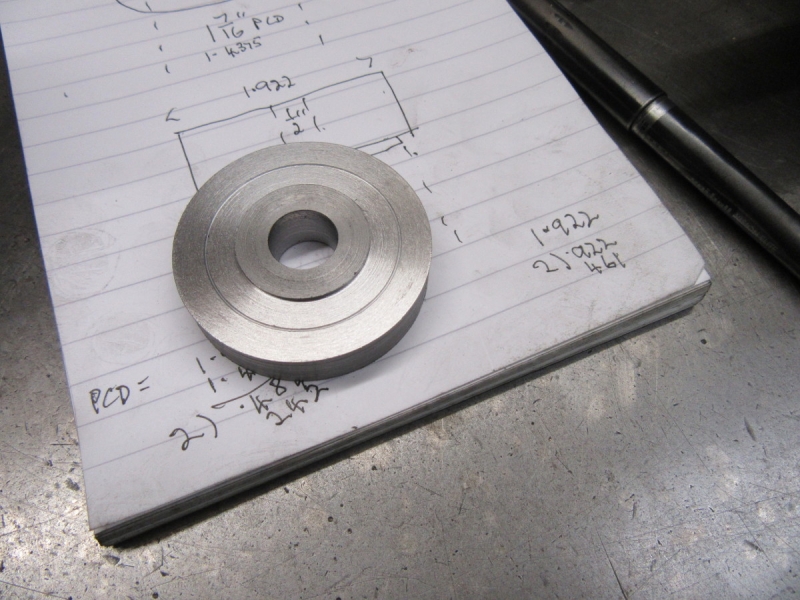

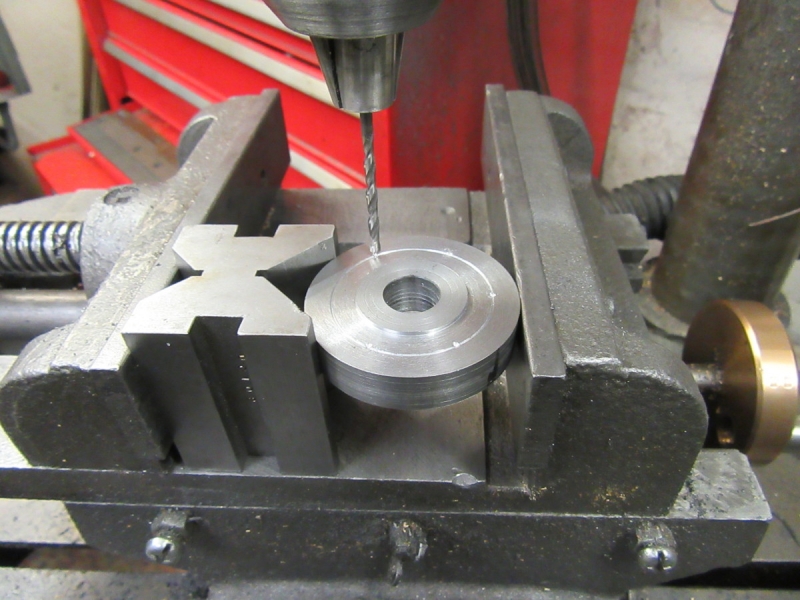

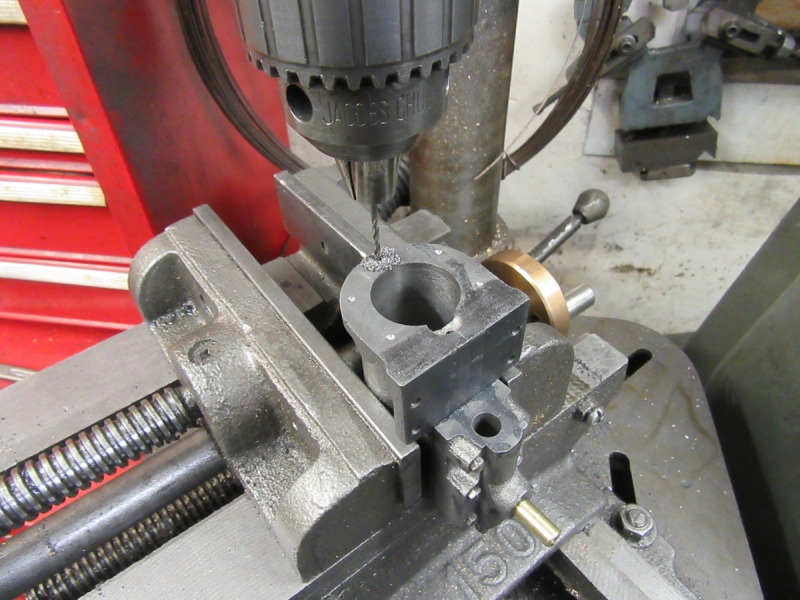

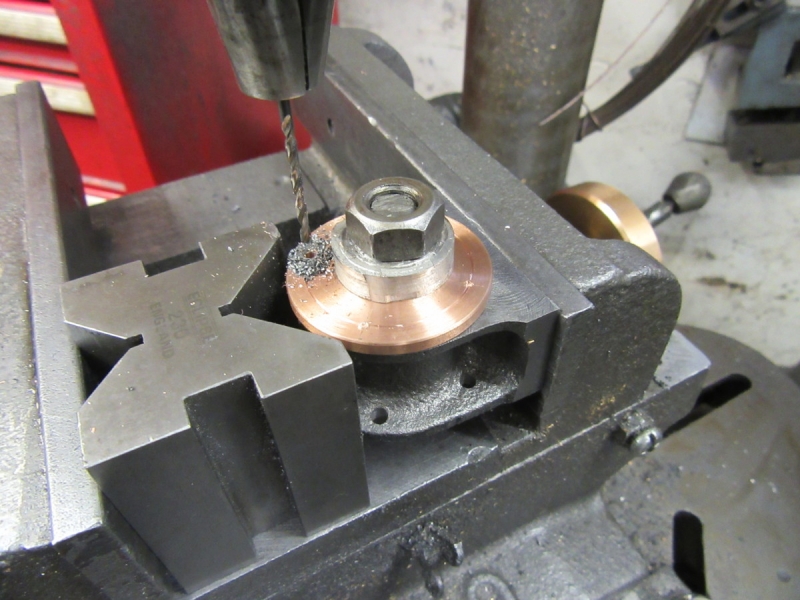

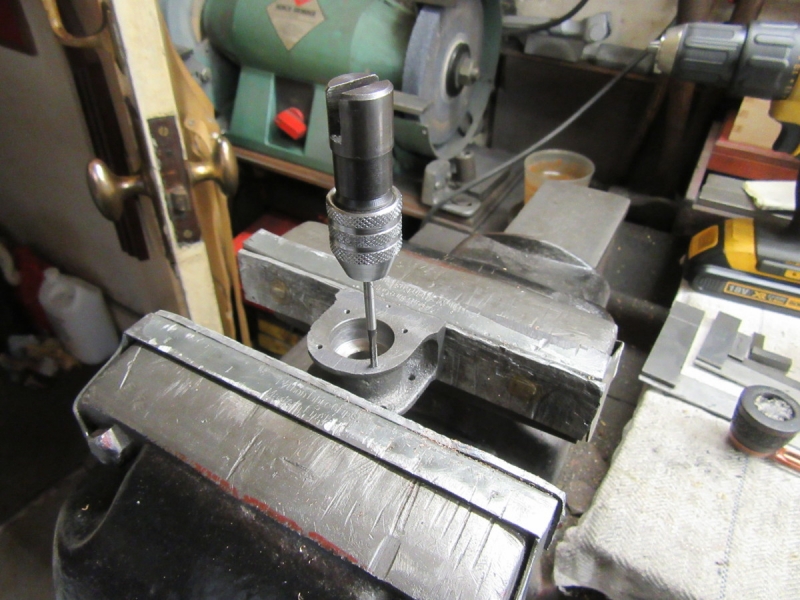

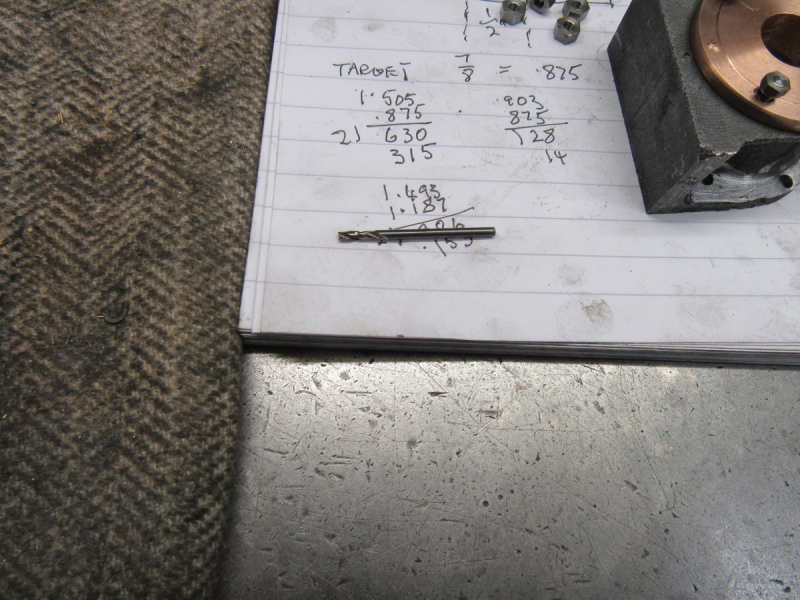

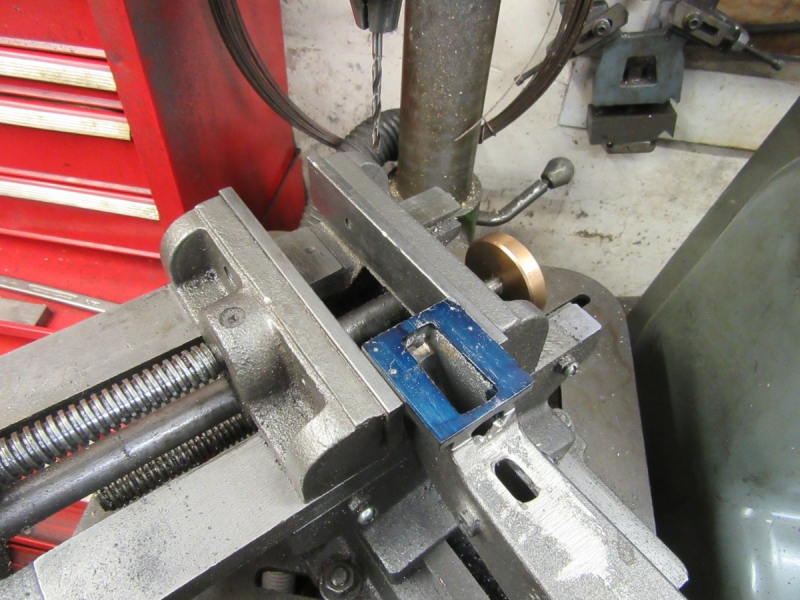

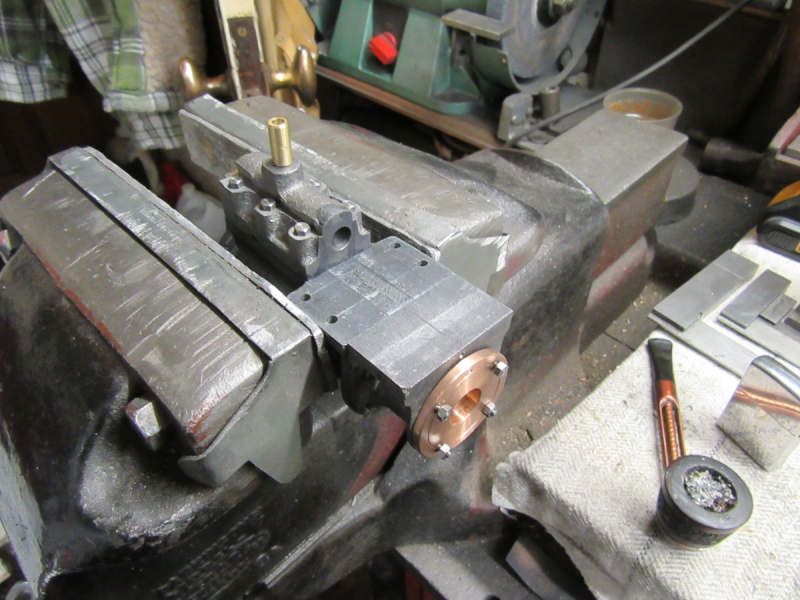

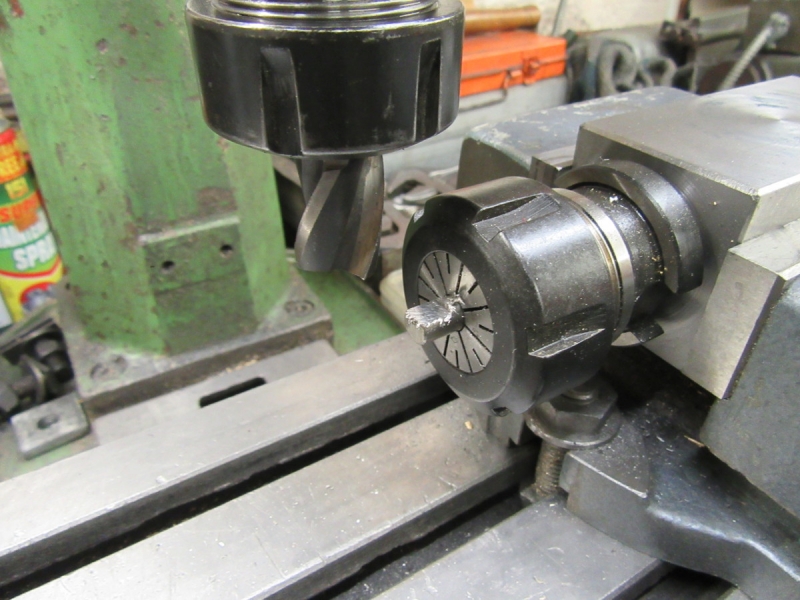

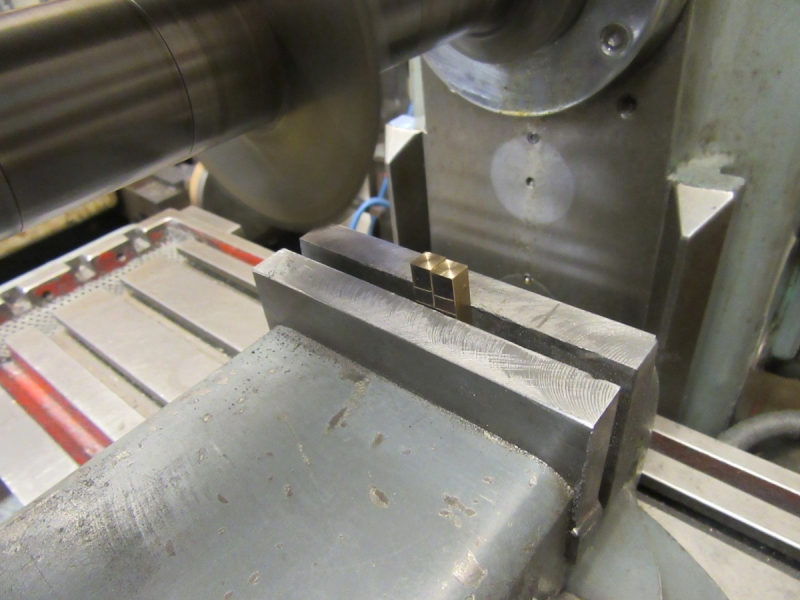

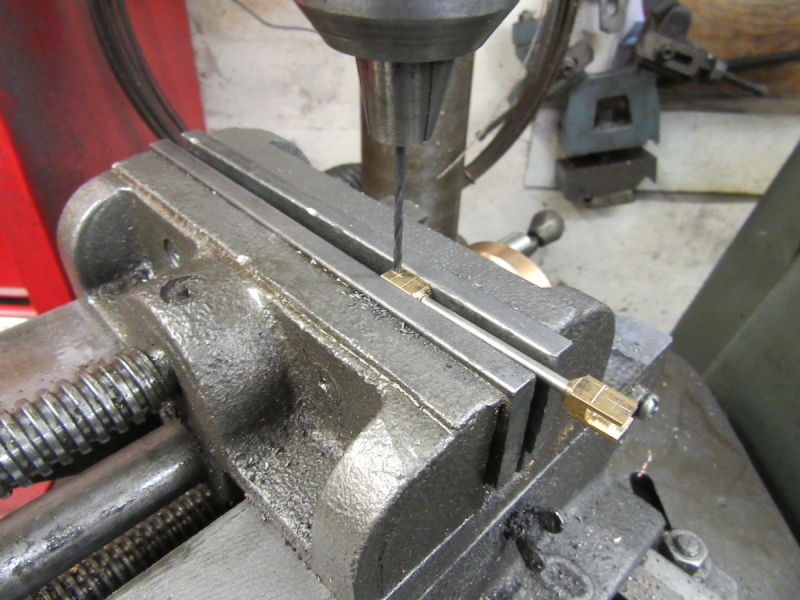

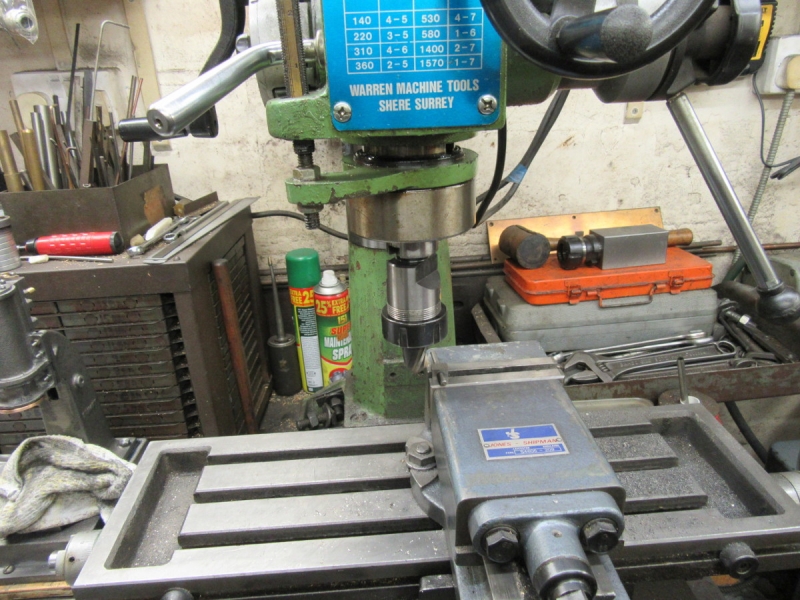

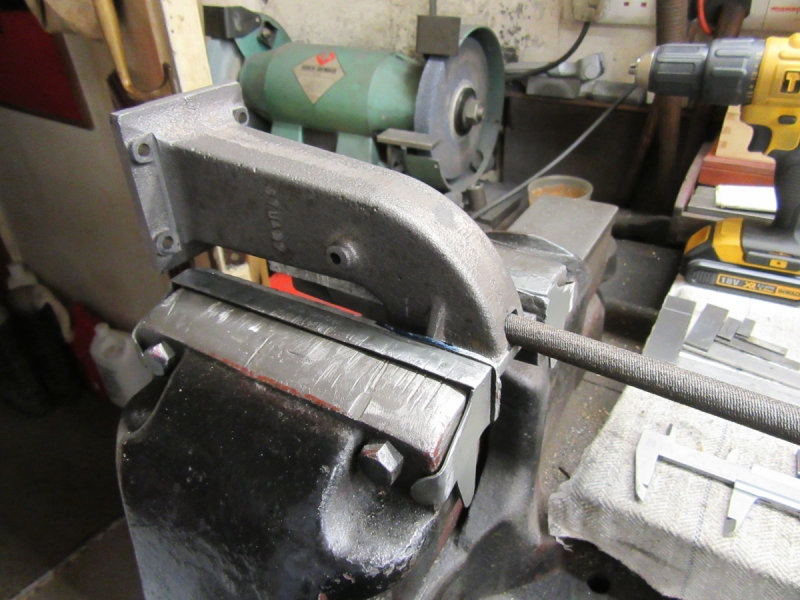

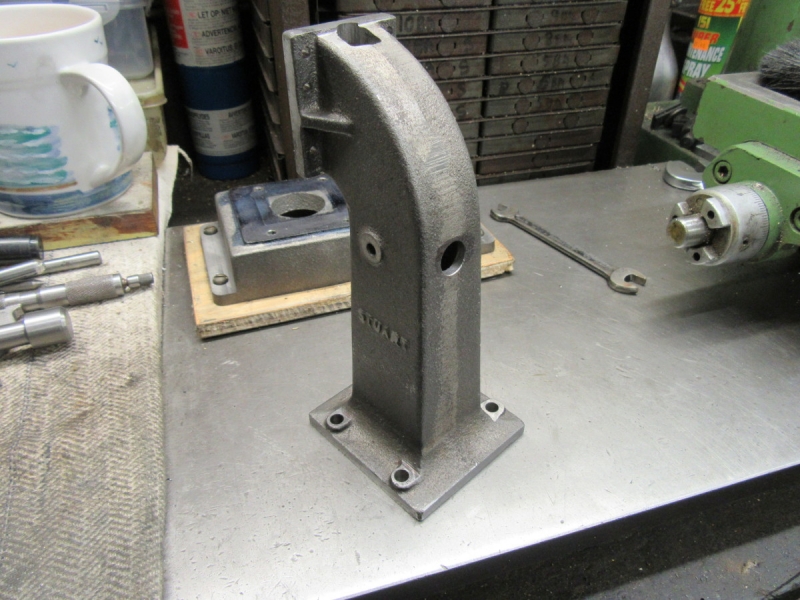

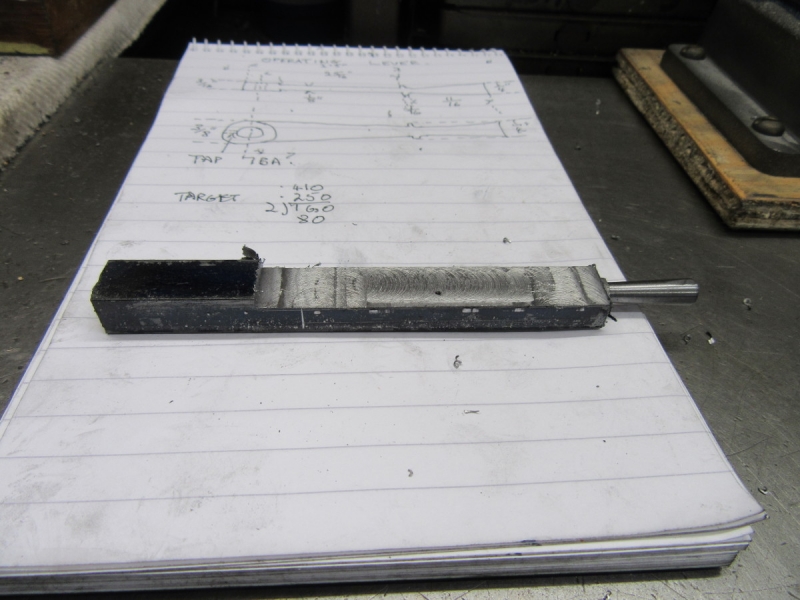

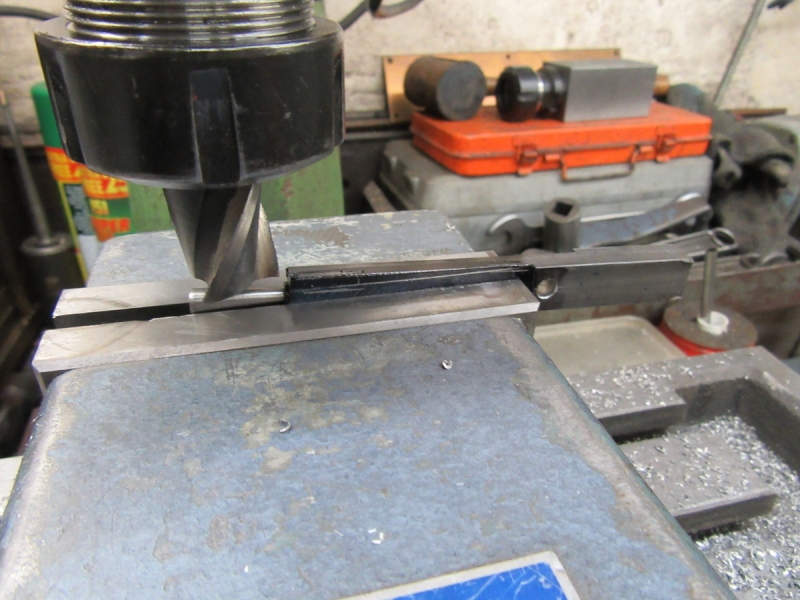

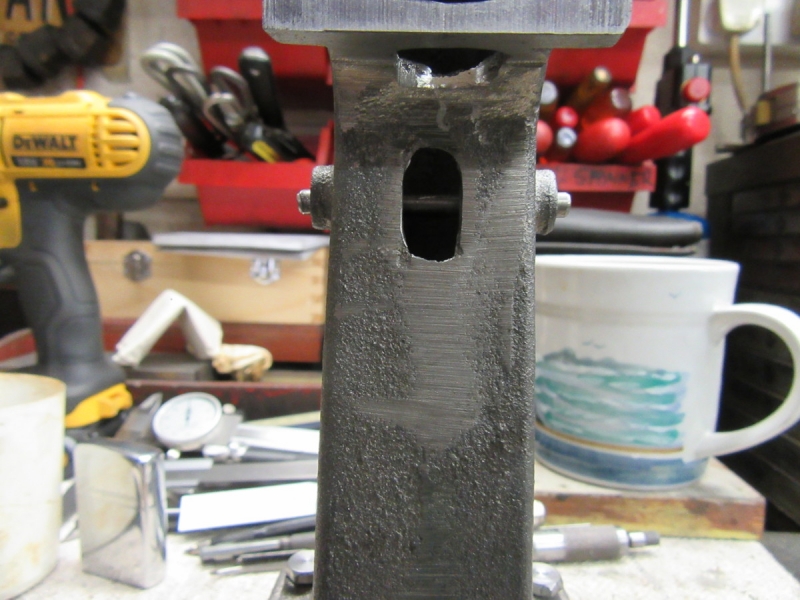

I need to drill the hole through the standard for the cross shaft that carries the operating handle and the link and yoke connecting it to the valve. Lots of sophisticated measures can be used. I opted for punching a mark in the centre of the boss on each side, and poking a 1/8" drill through as a pilot for the 3/16" hole I need for the shaft using the DeWalt drill.

I drilled each side separately and then poked the drill straight through to check the holes line up. It was OK.

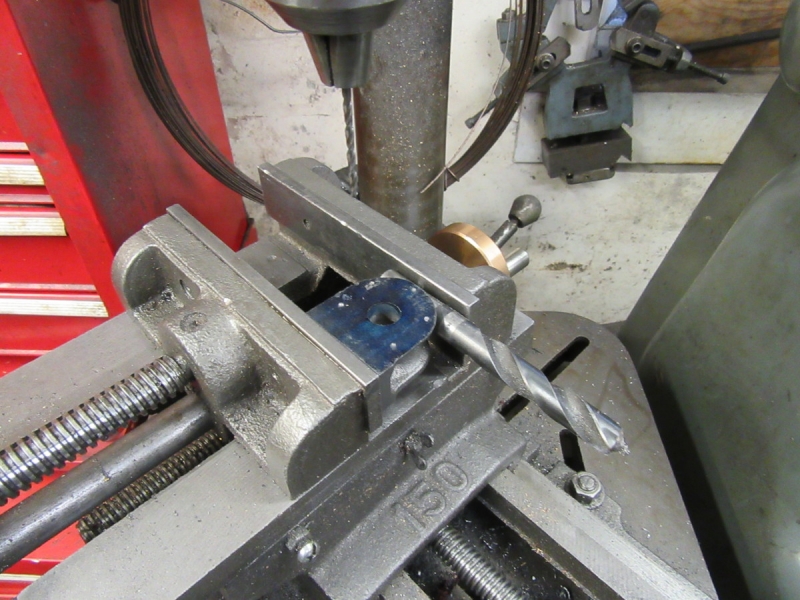

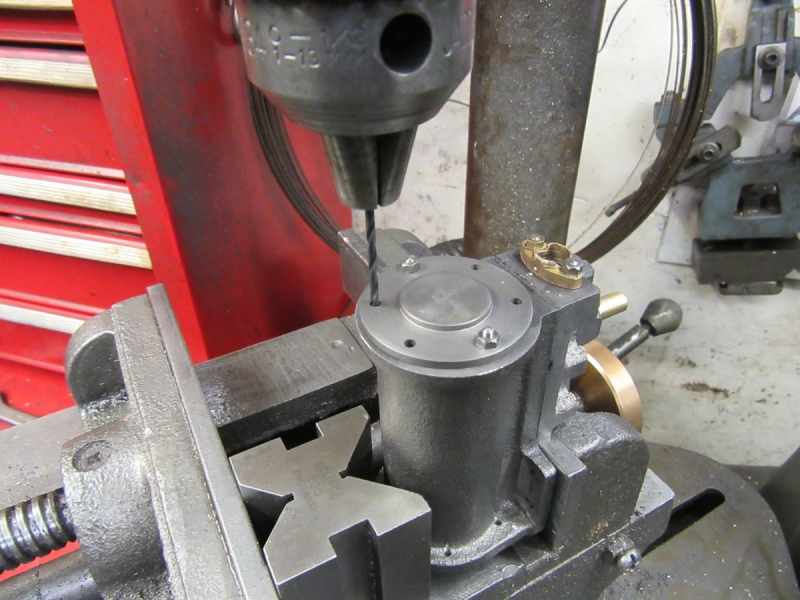

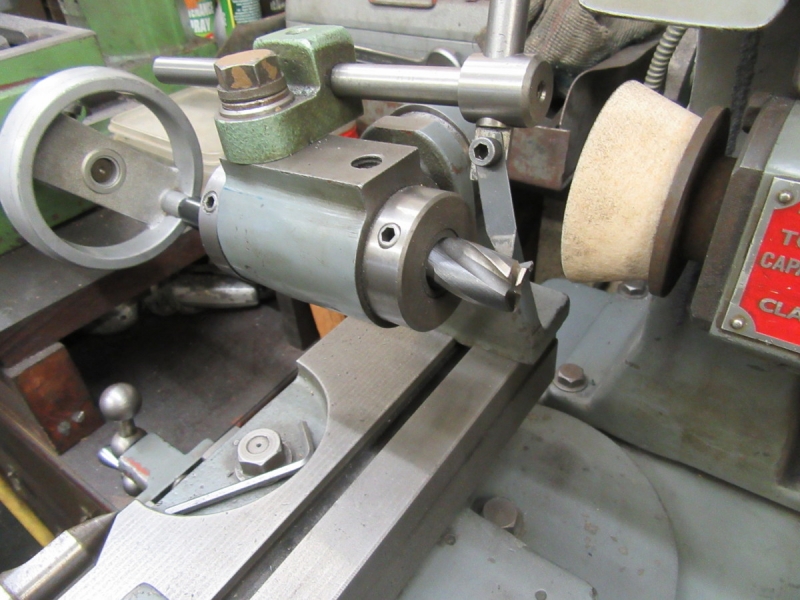

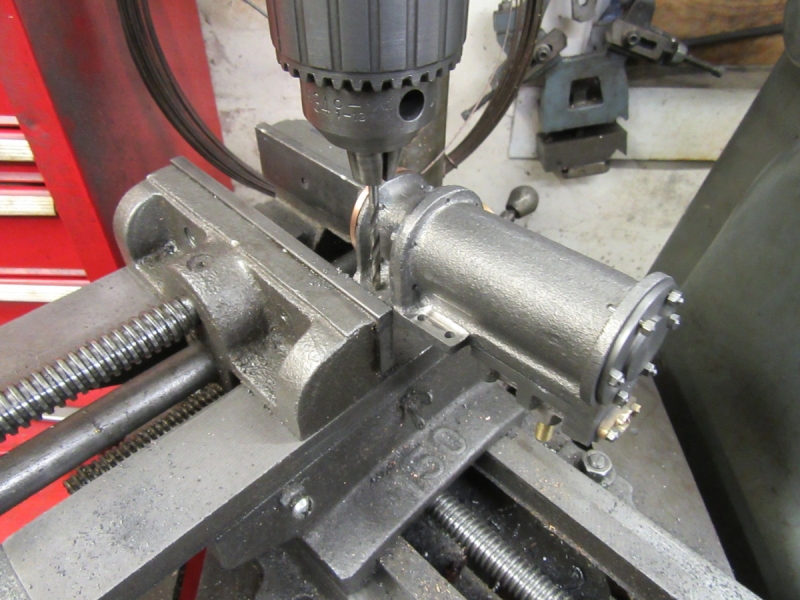

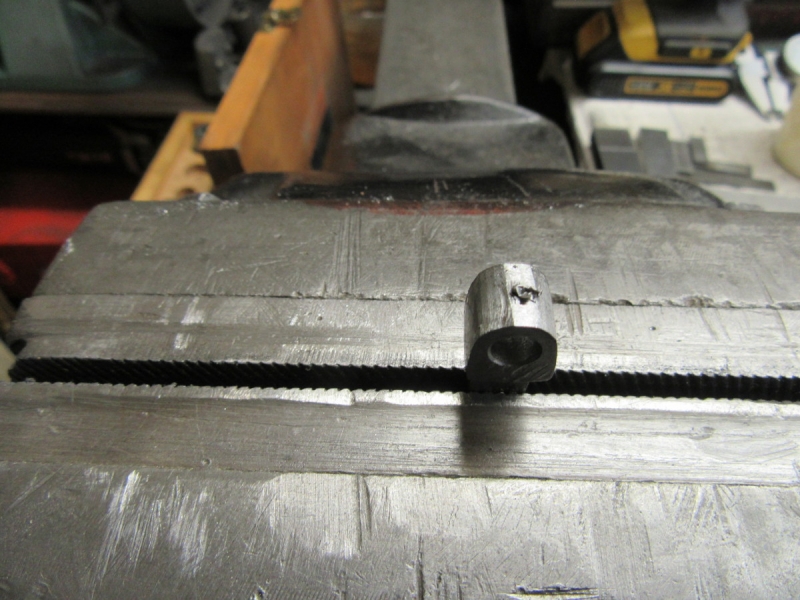

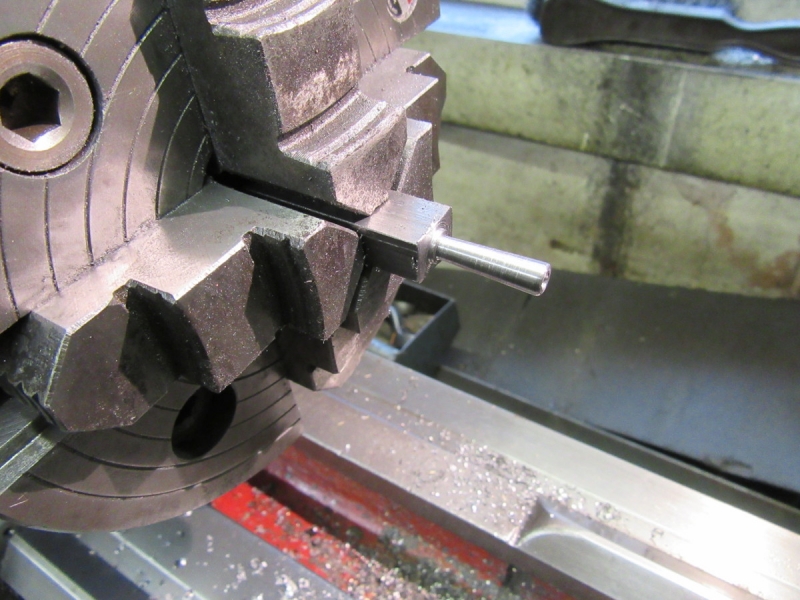

Then I drilled it 3/16" for the shaft following the two pilot holes. Notice the piston ring on the drill. Handy tip, if you do that and adjust the orientation so that the piston rod wanders from one end to the other and doesn't head for one end or the other you can be sure that the drill is level.

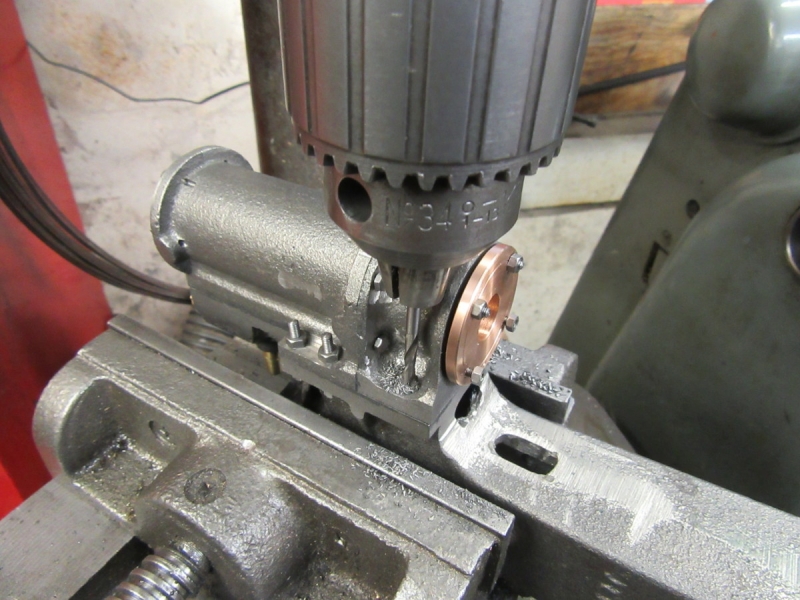

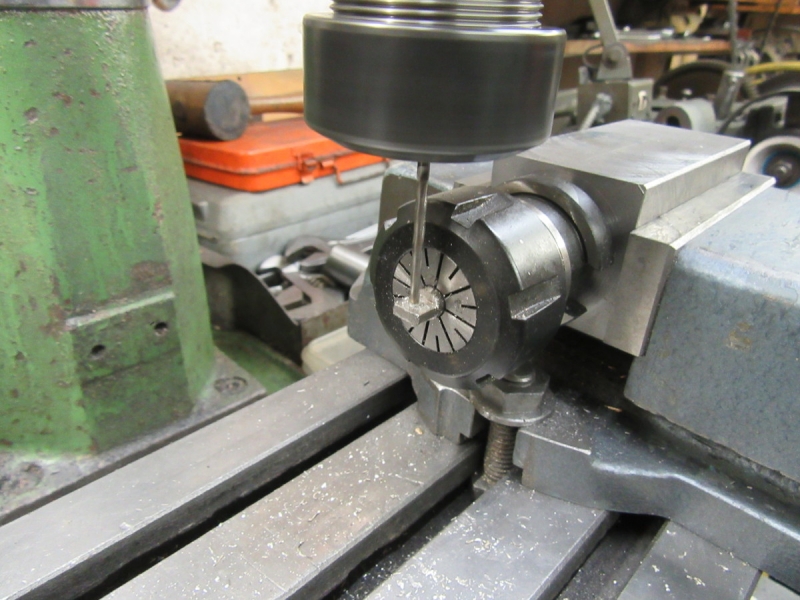

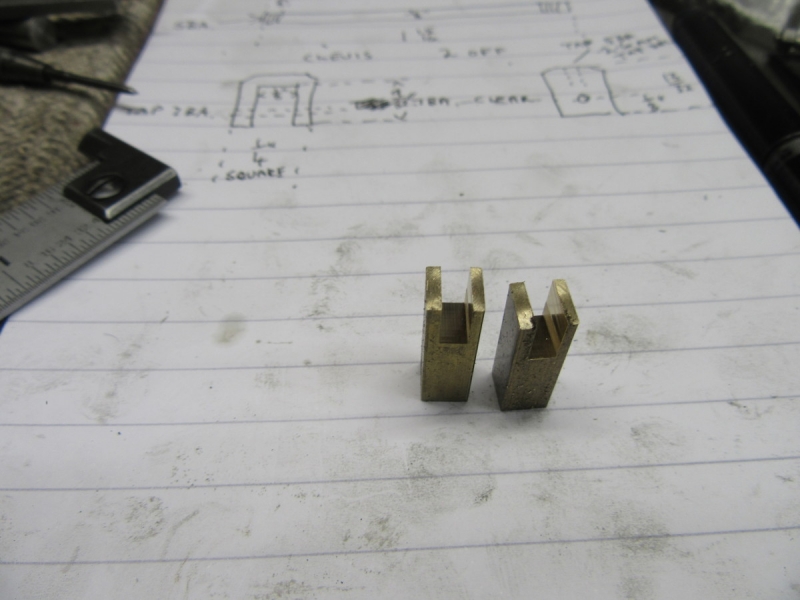

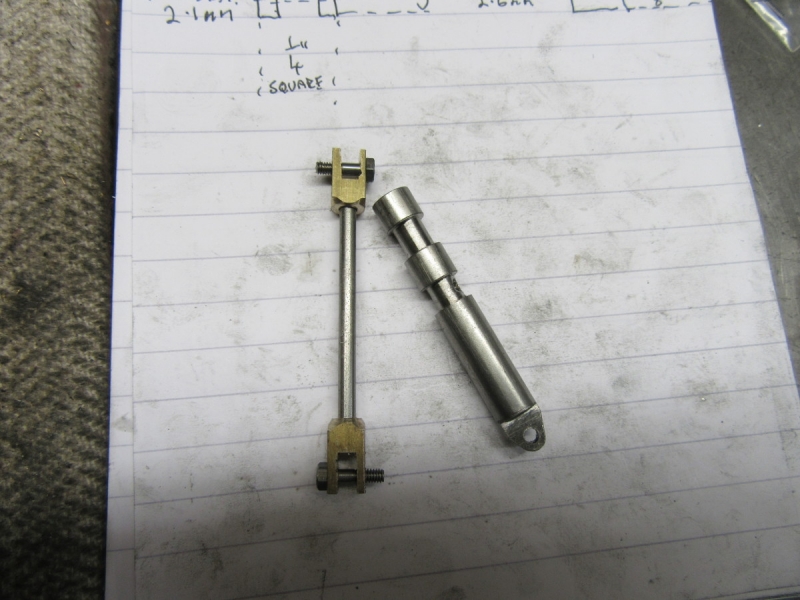

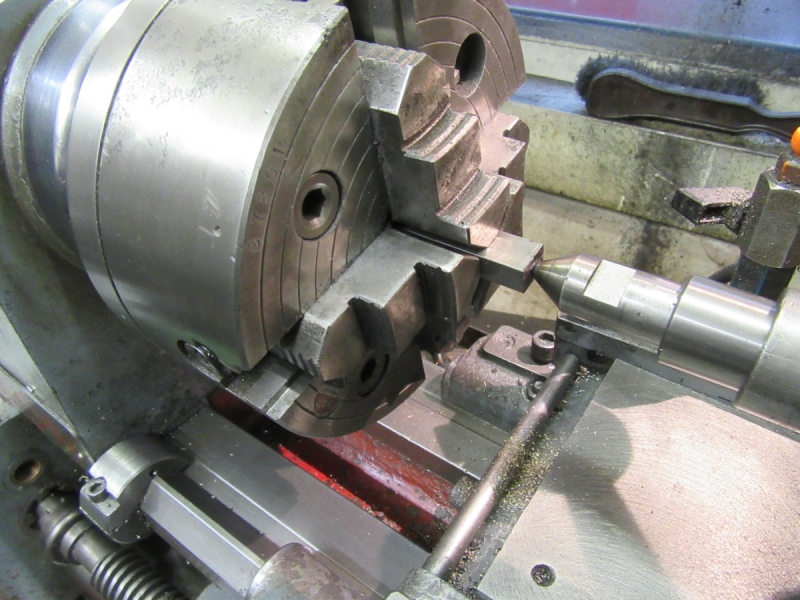

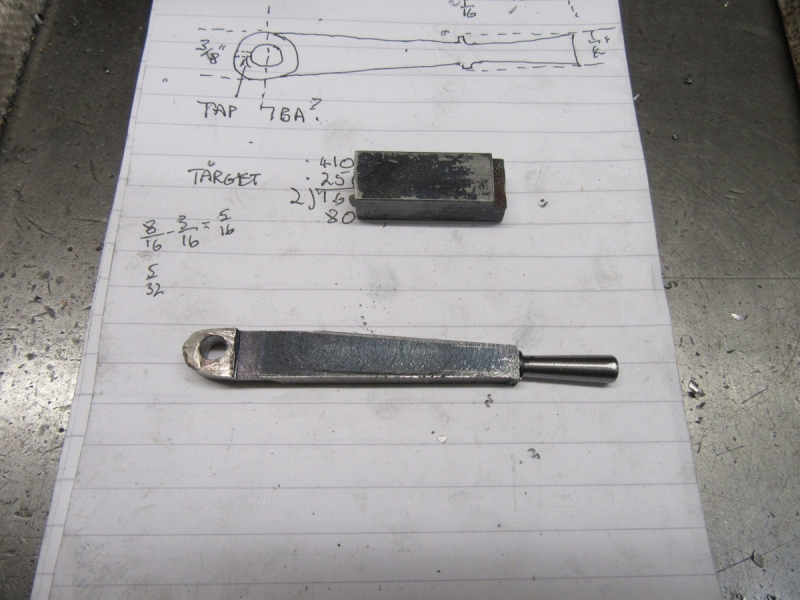

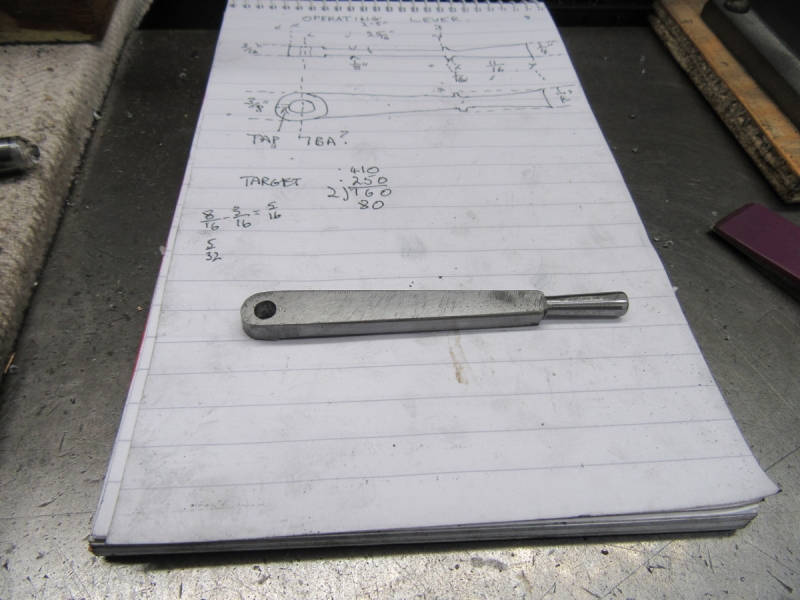

Here's the result, the shaft fits and is level but a bit tight, there is obviously a tiny amount of aberration in the coincidence of the two holes.

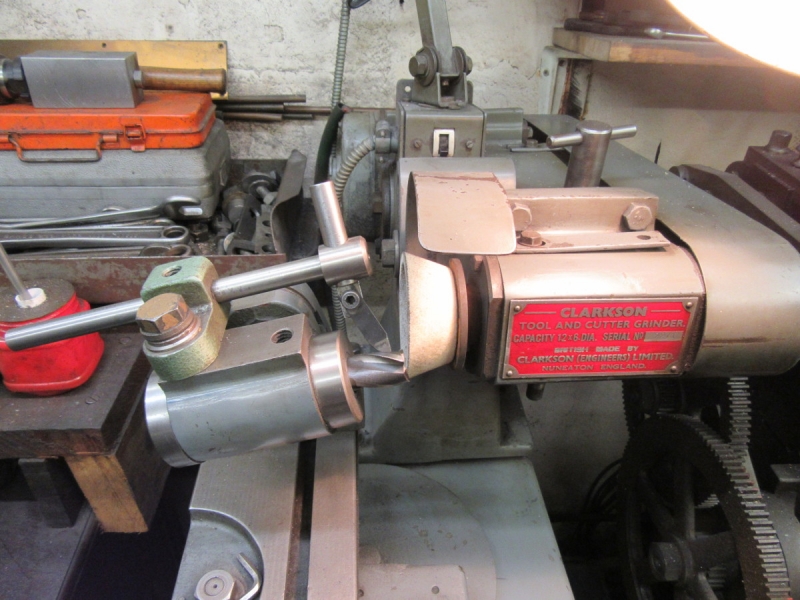

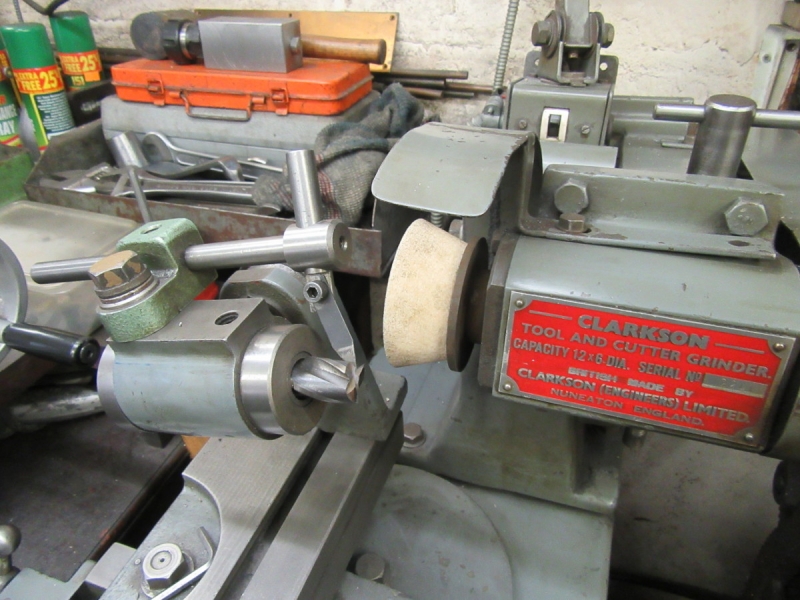

So I popped a 3/16" reamer through and cleaned the holes up. The shaft now fits and is a nice running fit, it's turning freely. That is quite enough for this morning, I didn't get in the shed until after 8AM. Nice result.... we have moved forwards.