Page 101 of 123

Re: Shed Matters 3

Posted: 20 Jul 2024, 06:05

by Stanley

I made an error of judgement this morning, I decided to put some taper in the connecting rod and this meant turning it down from full stock thickness by hand using the top slide set at one degree. I got fed up with winding that bloody handle but once I had started I had to keep going. All I will say is that I am very close and will make it p[retty tomorrow. This morning though I'm stopping and having my breakfast!

Re: Shed Matters 3

Posted: 21 Jul 2024, 05:54

by Stanley

After yesterday's dispiriting experience I carried on making a tapered rod by hand but using a better cutter. All went well and I polished the rod and presented it to the bearing. It is ready for finishing and attaching. Then I moved on to clean and oil Mrs Harrison and make a new everyday HSS cutter. I tested it for centre by turning a face as usual, by far the best way of finding out if you have it right! Now for breakfast.

Re: Shed Matters 3

Posted: 22 Jul 2024, 06:22

by Stanley

This morning was first fitting the rod to the crank bearing then cutting the foot back to the bearing thickness and after that drilling the hole for the hinge pin in the small end. Some very peculiar measurements meant I had to use my head. I shall fit the rod tomorrow and find out if I got it right..... Now for breakfast.

Re: Shed Matters 3

Posted: 23 Jul 2024, 05:52

by Stanley

This morning I started by fitting the con rod and crank bearing and testing the stroke of the piston. It is fine. The crank bearing is snug, which is how it should be of course. I oiled it and using my drill I drove the crankshaft to run the bearing in and ease it slightly. It is an easy but close fit now. Just right as it will not get any tighter over rime. It is a very good fit. Then I fitted the back lid with gasket and tightened that down. I have taken the nuts off the piston rod gland and am ready for installing the packing but as it was nearing knocking off time I thought I'd done enough and have come away for my breakfast.

Re: Shed Matters 3

Posted: 24 Jul 2024, 05:56

by Stanley

You might well think this is exactly the same as yesterday but if you look carefully there is a small difference, the Piston rod and valve rod glands have been packed to prevent leakage. This was a fiddle and it took me an hour. Not made any easier by the fact i had 4BA nuts on the valve rod studs when they should have been 5BA. Don't laugh until you have tried it..... Main thing is I realised and the gland is tight now. Now for breakfast.

Re: Shed Matters 3

Posted: 25 Jul 2024, 06:16

by Stanley

I started on the valve train and the first element for shaving was the valve rod support which is one of my least favourite parts because there is nothing you can measure, it is all rack of the eye and guess work. I pressed on and reached the stage where I had the support the right shape and drilled the top to accept the valve rod and the base 5BA clear for the two bolts that will hold it on. Then I offered it up and marked for the first bolt. I have drilled and tapped that and fitted the support with one bolt tightened up. I shall now mark, drill and tap the second hole while it is in situ, that way I know it will fit. But that's for tomorrow. I have done my hour and am going to have breakfast.

Re: Shed Matters 3

Posted: 26 Jul 2024, 05:16

by Stanley

I went in the shed early and I'm out early as I want a sleep before I have to be up for boiler maintenance at 09:00. Only one object in mind. finish mounting the valve rod support on the bed and make sure it is allowing the valve rod free movement. That's done so I am having an early breakfast.

Re: Shed Matters 3

Posted: 27 Jul 2024, 06:06

by Stanley

This morning I started on making the clevis that will connect the Valve rod to the eccentric arm. Careful measuring and marking and then cutting the slot with a slitting say before drilling and tapping for the 7BA bolt that will make the connection with the arm. Slow careful work because I can't see this small but at closing time I had the bolt fitted and ready for more fitting in the valve train. But that's for tomorrow, now the job is breakfast!

Re: Shed Matters 3

Posted: 28 Jul 2024, 06:06

by Stanley

The job this morning was to finish the clevis that joins the valve rod to the valve train and prepare and fit the end of the eccentric rod to fit it.

Re: Shed Matters 3

Posted: 29 Jul 2024, 05:50

by Stanley

I concentrated on the eccentric strap. I used a small slitting saw to cut the strap in two and then I refitted the strap together and set it up in the VM for boring. I have sharpened the everyday HSS cutter in the Clarkson T&C grinder.

Tomorrow I shall start the day by boring and fitting the strap. Right now it's breakfast time!

Re: Shed Matters 3

Posted: 30 Jul 2024, 06:03

by Stanley

Today was all about the eccentric strap and rod. The first job was to bore the strap out to the size of the eccentric. Then reduce the width and length of the rod to the necessary size and adjust the rounding of each end. The 5BA clearance hole at the eccentric end was drilled and countersunk for the fixing screw. Tomorrow I shall mill out the socket in the strap for the rod. At the moment I am more interested in breakfast.

Re: Shed Matters 3

Posted: 01 Aug 2024, 05:54

by Stanley

Just one job. Mill out the socket for the eccentric rod into the strap, drill and tap the necessary hole and fit the rod using the countersunk screw. Then replace the normal cutter on the VM. That's quite enough for a warm morning in the shed.

Re: Shed Matters 3

Posted: 02 Aug 2024, 06:10

by Stanley

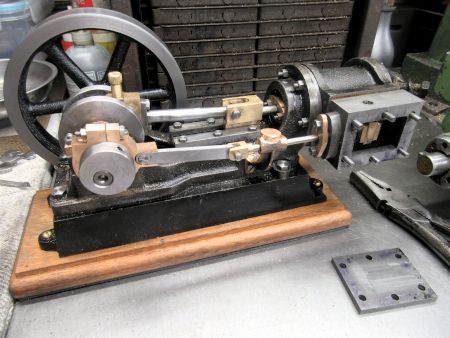

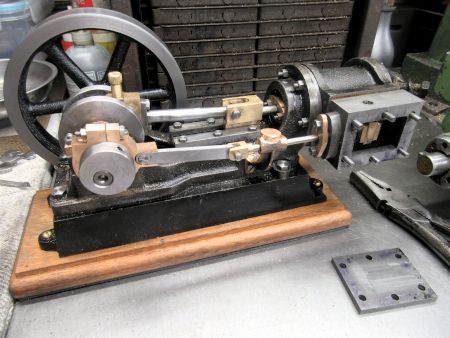

Only one pic this morning. I have spent an hour installing the eccentric strap on the eccentric and Setting the valve to somewhere near running position. I say somewhere near because that's all I am going to do. Truth to tell the engine is too closely fitted and really needs a lot of easing before it's ready to run. It can be turned over by hand and is accurately made but the valve train is very tight. I shall finish rebuilding it tomorrow and then it can go on the kitchen table. I have ordered another set of castings this morning. From experience they will be with me Sunday or Monday so I shall have plenty to do! Now I want my breakfast....

Re: Shed Matters 3

Posted: 03 Aug 2024, 05:32

by Stanley

Only one image, an addition to the engine family on the kitchen table..... This morning I finished lacing the engine up, lubricated it and cut the excess off the studs at each end of the cylinder. Notice I have two crankshafts waiting for an engine and there is a set of castings on order for the next one.

Is it a good engine? Yes, OK for a bloke my age. I haven't tried to run it because I think it's too closely fitted. If at some time in the future someone wants to rework it they'll find everything is there and in the proper place!

Now for breakfast....

Re: Shed Matters 3

Posted: 04 Aug 2024, 05:30

by Stanley

Only one image and on ly a half an hour in the shed spent cleaning up. I started with a chip chase, then I cleaned and oiled both of the CI surface plates and put a clean tablecloth on. Next was a good vacuum of the floor and of course clean the vacuum and put it away. Now I shall have breakfast!

Re: Shed Matters 3

Posted: 05 Aug 2024, 05:38

by Stanley

No shed this morning. Nothing pulling me in there.....

Re: Shed Matters 3

Posted: 06 Aug 2024, 04:48

by Stanley

Nothing to report again. I expect the castings this morning.....

Re: Shed Matters 3

Posted: 06 Aug 2024, 12:59

by Stanley

Five hours waiting for the courier but here we have the parcel. I have unpacked everything and put all the waste in the grey bin. Now we can get back to normal.

Re: Shed Matters 3

Posted: 07 Aug 2024, 05:49

by Stanley

Re: Shed Matters 3

Posted: 08 Aug 2024, 06:13

by Stanley

First job was to turn down a wooden plug for the cylinder bore and then clean up the mess! Then drive the plug in and mark the centre of the bore on each end. Once that was done I could mount the cylinder in the vise on the VM and machine the face flat and true. While I had it mounted in the vise I changed over to a 1/4" slot drill and cut the exhaust port in the valve face. That was enough honest endeavour for this morning. Now the job is breakfast.

Re: Shed Matters 3

Posted: 09 Aug 2024, 06:08

by Stanley

This morning's task was to face each end of the cylinder square with the valve face and exactly the right length. I measured and marked and then set up in the mill and cut both faces. When I had finished that I checked everything and then measured and marked the centres of the bore. I am ready to bore the cylinder now but will probably do that later. Last job was to clear all my CI chips up. Now for breakfast.

Re: Shed Matters 3

Posted: 10 Aug 2024, 06:09

by Stanley

As you can see I decided to bore the cylinder. Not a lot to rep;ort. I bored the plug out and then took the bore to 10 thousandths over 1.5" checked it for parallelism and put the witness mark on the valve face for all the other parts. Then a clean up and put the mill back into normal mode. The bore is as near perfect as makes no matter. Now I can enjoy my breakfast.

Re: Shed Matters 3

Posted: 11 Aug 2024, 06:21

by Stanley

Re: Shed Matters 3

Posted: 13 Aug 2024, 06:11

by Stanley

Re: Shed Matters 3

Posted: 14 Aug 2024, 06:12

by Stanley