SHED MATTERS. MARINE ENGINES.

Re: SHED MATTERS. MARINE ENGINES.

Hi Stanley,

As I said in our recent contact, I have a few general questions about mill engines, mills and the textile industry. You advised me to put the questions somewhere on OGFB and as I have been following this forum since the beginning, where better to put them!

In no particular order, here are my questions:-

1)

It seems by observation when travelling around that mills in Lancashire were often much larger than the mills over here in the Woollen District. Is there a reason for that? In my limited experience of mills in Dewsbury and Ossett, they seemed to go in for start-to-finish manufacturing at one site. It looks like some of the Lancashire mills specialised in one part of the process (spinning or weaving). Is this why they were larger?

==========================

2)

Does the above account for why the lists in OGFB show more large engines over that side?

==========================

3)

What was the most powerful engine installed in a mill, where was it and who made it?

==========================

4)

On most of the engines I've seen in action, the "push" stroke from the cylinders towards the crank seems normally to be above the centre-line and the "pull" (obviously) below the centre-line. I imagine that is so the deflecting force on the piston rod is downwards via the slipper onto the slide in the bed. Am I right?

I am aware of one engine personally that, I seem to remember, ran "backwards", but as I saw it when I was less than 7, I can't remember what arrangements they made to handle this deflecting force. I suppose it must have had a normal slipper that acted on an inverted slideway or some other kind of slidebars like on a loco.

Was I imagining things or did engines run that way? If so, were they in the minority? Why would they need to run "backwards" (discounting pit winding engines or other types that needed to run either way)?

==========================

5)

I think you said once that cross-compound engines usually "lead" with the LP cylinder. Is there a reason for that? Is there a standard layout (LP on the left/HP on the right)? What's the standard (if any) for which side leads on engines configured like Ellenroad with two identical compound halves?

==========================

6)

On all the engines I've seen that are tandem compounds, the LP is nearer to the crankshaft and the HP at the back. Is there a reason or need for this?

==========================

7)

In your LTP files and other places, I see mention of machines called "tapes" and having to run them on a donkey engine when the mill engine was standing. I don't recognise this term and don't know what the machines did and why they'd need to run when the rest of the mill was stood. Is this a cotton industry specific machine? My knowledge is limited to woollen mills.

==========================

A bit long and rambling, but all are things I've wondered about for a while. I think this is the right place to scratch that itch!

Thanks a lot

Mick

As I said in our recent contact, I have a few general questions about mill engines, mills and the textile industry. You advised me to put the questions somewhere on OGFB and as I have been following this forum since the beginning, where better to put them!

In no particular order, here are my questions:-

1)

It seems by observation when travelling around that mills in Lancashire were often much larger than the mills over here in the Woollen District. Is there a reason for that? In my limited experience of mills in Dewsbury and Ossett, they seemed to go in for start-to-finish manufacturing at one site. It looks like some of the Lancashire mills specialised in one part of the process (spinning or weaving). Is this why they were larger?

==========================

2)

Does the above account for why the lists in OGFB show more large engines over that side?

==========================

3)

What was the most powerful engine installed in a mill, where was it and who made it?

==========================

4)

On most of the engines I've seen in action, the "push" stroke from the cylinders towards the crank seems normally to be above the centre-line and the "pull" (obviously) below the centre-line. I imagine that is so the deflecting force on the piston rod is downwards via the slipper onto the slide in the bed. Am I right?

I am aware of one engine personally that, I seem to remember, ran "backwards", but as I saw it when I was less than 7, I can't remember what arrangements they made to handle this deflecting force. I suppose it must have had a normal slipper that acted on an inverted slideway or some other kind of slidebars like on a loco.

Was I imagining things or did engines run that way? If so, were they in the minority? Why would they need to run "backwards" (discounting pit winding engines or other types that needed to run either way)?

==========================

5)

I think you said once that cross-compound engines usually "lead" with the LP cylinder. Is there a reason for that? Is there a standard layout (LP on the left/HP on the right)? What's the standard (if any) for which side leads on engines configured like Ellenroad with two identical compound halves?

==========================

6)

On all the engines I've seen that are tandem compounds, the LP is nearer to the crankshaft and the HP at the back. Is there a reason or need for this?

==========================

7)

In your LTP files and other places, I see mention of machines called "tapes" and having to run them on a donkey engine when the mill engine was standing. I don't recognise this term and don't know what the machines did and why they'd need to run when the rest of the mill was stood. Is this a cotton industry specific machine? My knowledge is limited to woollen mills.

==========================

A bit long and rambling, but all are things I've wondered about for a while. I think this is the right place to scratch that itch!

Thanks a lot

Mick

- Stanley

- Global Moderator

- Posts: 104551

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

Mick, good questions. First thing to say is don't believe anything I say until you have done your own reading and confirmed it. I can oly give the benefit of my own experience and nobody knows everything!

Question 1.

In the early days of the steam cotton mills they were almost all 'combined' or 'vertical' mills. In other words they took in the raw cotton and did all the processes through to woven cloth under the same roof. Two things combined to change this, better transport links and the search for the most economic way of producing cloth. The latter was affected by two things that could lower costs, specialising in one process and aiming all resources at one process therefore gaining economies of scale under one roof. From about 1875 onwards mills in S Lancashire started specialising in spinning and the weaving mills in NE Lancs found that it was cheaper to import the yarn from the spinners than do it themselves. Concentrating on weaving meant the process in the NE mills was simpler, larger units and lower production costs. There was another factor, the advances in spinning machinery were far more extensive than those in looms and specialist spinners could use the latest machinery thus making the price differential greater. It's instructive to note that with almost no exceptions, the mills in the NE that stuck to the vertical model all got into financial difficulties after about 1885. This was what ruined the Bracewells in Barlick. They never adapted to the new conditions.

Question 2

Woollen Mills had big engines as well but because they stuck to the vertical model this was only in the new larger mills that were chasing economies of scale. From 1875 onwards the cotton industry in Lancashire boomed and bigger and bigger mills were built needing larger engines but this was mainly in the spinning side.

Question 3.

The biggest engine I know of was the Big Carels engine made in Belgium at Mons Mill at Todmorden. Lots of stuff on the web about it. Bit of a cheat actually as it was built for a double mill but they never built the second half so it ran underpowered all its life. The Ellenroad engine in its modified form was big, it was theoretically capable of 3,000hp. Both spinning mills. Weaving sheds seldom needed more than 2,000hp.

Question 4.

You are right, this is known as 'running over' and means that simple slipper guides could be used making them easier and cheaper to build. The mill engines were non-reversing so this was OK. You're right in that some engines ran 'under' or backwards. In order to do this they needed either trunk guides or slipper bars on top of the crosshead. The main reason why this was sometimes needed was when an older beam or smaller engine had to be replaced and there wasn't enough room to install the new bigger engine in the same location so it was built on the other side of the shaft. This meant it had to run under in order to avoid expensive alterations to the transmission.

Question 5.

Yes, they usually do and I've never been able to find a reason for it. Ellenroad was originally a triple expansion and the left side was the Intermediate pressure cylinder with two LPs one on either side. As the left side was the high pressure side the left was leading and it was left that way. I haven't enough experience with other tandems to say whether this was usual but I suspect it was. A long standing convention perhaps. In theory it doesn't matter which side leads when an engine is quartered. As for which side is the LP on a cross compound, it could vary and this was usually because the LP and air pump and condenser were placed on whichever side gave the shortest pipe run to the cooling water supply.

Question 6.

Some tandem engines had the LP at the back but this was usually when they had a surface mounted air pump which was cheaper and easier to install, also more accessible for maintenance. If the air pumps were in the cellar under the engine it made more sense to have the HP at the back so the steam flow went down the line of the engine with air pumps and condensers in the cellar beneath a bell crank drive from in front of the LP, Ellenroad is like this. Having the steam to exhaust flow in one direction made for more simple pipe layouts.

Question 7.

Tapes are tape sizing machines or slashers. They were essential to weaving because the yarn needed to be converted from the large spinner's beams to loom warps that fit individual looms. At the same time the tape coated the yarn with a mixture of tallow, gum and water that gave it a protective coating so the action of weaving didn't damage the yarn in the warp as it passed through the violent action of the healds and reeds. Without it there were too many yarn breakages which made weaving uneconomical. The reason why the tapes needed the donkey engine was that once a loom warp had been started it had to be made non-stop because if the tape was stopped the yarn in the machine stuck to the hot drying drum and the whole warp was ruined. The donkey was also used for running the tapes on overtime which was a common occurrence in a busy mill.

Question 1.

In the early days of the steam cotton mills they were almost all 'combined' or 'vertical' mills. In other words they took in the raw cotton and did all the processes through to woven cloth under the same roof. Two things combined to change this, better transport links and the search for the most economic way of producing cloth. The latter was affected by two things that could lower costs, specialising in one process and aiming all resources at one process therefore gaining economies of scale under one roof. From about 1875 onwards mills in S Lancashire started specialising in spinning and the weaving mills in NE Lancs found that it was cheaper to import the yarn from the spinners than do it themselves. Concentrating on weaving meant the process in the NE mills was simpler, larger units and lower production costs. There was another factor, the advances in spinning machinery were far more extensive than those in looms and specialist spinners could use the latest machinery thus making the price differential greater. It's instructive to note that with almost no exceptions, the mills in the NE that stuck to the vertical model all got into financial difficulties after about 1885. This was what ruined the Bracewells in Barlick. They never adapted to the new conditions.

Question 2

Woollen Mills had big engines as well but because they stuck to the vertical model this was only in the new larger mills that were chasing economies of scale. From 1875 onwards the cotton industry in Lancashire boomed and bigger and bigger mills were built needing larger engines but this was mainly in the spinning side.

Question 3.

The biggest engine I know of was the Big Carels engine made in Belgium at Mons Mill at Todmorden. Lots of stuff on the web about it. Bit of a cheat actually as it was built for a double mill but they never built the second half so it ran underpowered all its life. The Ellenroad engine in its modified form was big, it was theoretically capable of 3,000hp. Both spinning mills. Weaving sheds seldom needed more than 2,000hp.

Question 4.

You are right, this is known as 'running over' and means that simple slipper guides could be used making them easier and cheaper to build. The mill engines were non-reversing so this was OK. You're right in that some engines ran 'under' or backwards. In order to do this they needed either trunk guides or slipper bars on top of the crosshead. The main reason why this was sometimes needed was when an older beam or smaller engine had to be replaced and there wasn't enough room to install the new bigger engine in the same location so it was built on the other side of the shaft. This meant it had to run under in order to avoid expensive alterations to the transmission.

Question 5.

Yes, they usually do and I've never been able to find a reason for it. Ellenroad was originally a triple expansion and the left side was the Intermediate pressure cylinder with two LPs one on either side. As the left side was the high pressure side the left was leading and it was left that way. I haven't enough experience with other tandems to say whether this was usual but I suspect it was. A long standing convention perhaps. In theory it doesn't matter which side leads when an engine is quartered. As for which side is the LP on a cross compound, it could vary and this was usually because the LP and air pump and condenser were placed on whichever side gave the shortest pipe run to the cooling water supply.

Question 6.

Some tandem engines had the LP at the back but this was usually when they had a surface mounted air pump which was cheaper and easier to install, also more accessible for maintenance. If the air pumps were in the cellar under the engine it made more sense to have the HP at the back so the steam flow went down the line of the engine with air pumps and condensers in the cellar beneath a bell crank drive from in front of the LP, Ellenroad is like this. Having the steam to exhaust flow in one direction made for more simple pipe layouts.

Question 7.

Tapes are tape sizing machines or slashers. They were essential to weaving because the yarn needed to be converted from the large spinner's beams to loom warps that fit individual looms. At the same time the tape coated the yarn with a mixture of tallow, gum and water that gave it a protective coating so the action of weaving didn't damage the yarn in the warp as it passed through the violent action of the healds and reeds. Without it there were too many yarn breakages which made weaving uneconomical. The reason why the tapes needed the donkey engine was that once a loom warp had been started it had to be made non-stop because if the tape was stopped the yarn in the machine stuck to the hot drying drum and the whole warp was ruined. The donkey was also used for running the tapes on overtime which was a common occurrence in a busy mill.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104551

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

Bugger you Mick! You caused a disaster! I got so wrapped up in replying to you that I forgot I had Jack's mince cooking on the stove in the front room and it's burned to a crisp! I'd relit it and left the damper opened so it got far too hot. You see how I suffer for you lot!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: SHED MATTERS. MARINE ENGINES.

Hi Stanley,

Not the first time I've been blamed for a disaster and I'm sure it'll not be the last.

Thanks for the prompt and very full response. I still haven't given up on scanning those photos, so I'll be in touch again when I have them available.

BR

Mick

Not the first time I've been blamed for a disaster and I'm sure it'll not be the last.

Thanks for the prompt and very full response. I still haven't given up on scanning those photos, so I'll be in touch again when I have them available.

BR

Mick

- Stanley

- Global Moderator

- Posts: 104551

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

Yes Mick, sorry about that, I was mad with myself of course. You'll be pleased to know there was mince in the freezer, Jack has been fed!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: SHED MATTERS. MARINE ENGINES.

Hi Stanley,

As promised, I got the photos of Syke Ing Mill engine re-scanned. The quality is not the best, but maybe I can get a better copy later. Can you tell me how to attach them to this topic?

BR

Mick

As promised, I got the photos of Syke Ing Mill engine re-scanned. The quality is not the best, but maybe I can get a better copy later. Can you tell me how to attach them to this topic?

BR

Mick

- PanBiker

- Site Administrator

- Posts: 18104

- Joined: 23 Jan 2012, 13:07

- Location: Barnoldswick - In the West Riding of Yorkshire, always was, always will be.

Re: SHED MATTERS. MARINE ENGINES.

Best way is to add them to the Gallery. Take a look at this thread (click the link) for instructions on how to upload to the gallery and then how to insert in posts

Images Tips and Tricks

Images Tips and Tricks

Ian

Re: SHED MATTERS. MARINE ENGINES.

Hi Ian,

Thanks for the advice. Here we go....

BR

Mick

Thanks for the advice. Here we go....

BR

Mick

- Stanley

- Global Moderator

- Posts: 104551

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

Nice pics and a very clean house and engine.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: SHED MATTERS. MARINE ENGINES.

Hi Ian,

I notice that if I just open OGFB as a vistor, the images are blocked and only become visible when I log on. Is there something I could do to make them universally visible?

BR

Mick

I notice that if I just open OGFB as a vistor, the images are blocked and only become visible when I log on. Is there something I could do to make them universally visible?

BR

Mick

- PanBiker

- Site Administrator

- Posts: 18104

- Joined: 23 Jan 2012, 13:07

- Location: Barnoldswick - In the West Riding of Yorkshire, always was, always will be.

Re: SHED MATTERS. MARINE ENGINES.

I noticed that you have uploaded them into your personal gallery rather than one of the public galleries. This will be the reason that they are not visible to visitors. If you add any more, navigate to a suitable category within the gallery and upload to there before inserting in your posts. This should make all the images available to all visitors to the site, members or not.

Incidentally, I can see them OK in your post as I have Moderator privileges as does Stanley.

Incidentally, I can see them OK in your post as I have Moderator privileges as does Stanley.

Ian

- Stanley

- Global Moderator

- Posts: 104551

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

Thanks for that Ian, I hadn't realised we can see personal pics. I can understand why but it hadn't dawned on me. Slowing up in me old age!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: SHED MATTERS. MARINE ENGINES.

Hi Ian or Stanley,

Can you suggest a suitable public gallery to upload to? I don't want to mess about where I shouldn't...

BR

Mick

Can you suggest a suitable public gallery to upload to? I don't want to mess about where I shouldn't...

BR

Mick

- PanBiker

- Site Administrator

- Posts: 18104

- Joined: 23 Jan 2012, 13:07

- Location: Barnoldswick - In the West Riding of Yorkshire, always was, always will be.

Re: SHED MATTERS. MARINE ENGINES.

There are quite a few to choose from Mick. If they are mill engines you could put them in a relative category for the town they are located in. Or you could put them in the history category. From the sites point of view it does not really matter, if you add a reasonable description to your images it will make it easier for the site search facilities to find them or anyone browsing the gallery. Add a few keywords that you think would be relevant and that's all you need.

Don't worry too much about putting them in the wrong place, they can be linked into your posts wherever they are.

Don't worry too much about putting them in the wrong place, they can be linked into your posts wherever they are.

Ian

- Stanley

- Global Moderator

- Posts: 104551

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

Shed is warming up!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- PanBiker

- Site Administrator

- Posts: 18104

- Joined: 23 Jan 2012, 13:07

- Location: Barnoldswick - In the West Riding of Yorkshire, always was, always will be.

Re: SHED MATTERS. MARINE ENGINES.

You are nearly there Mick, Gallery bit is OK but If you copy the text from the URL box you will get a full size image in the post like this:

You must insert this in the post via the insert image icon (2nd row down at the top) the one with the little mountain when compiling your post in the editor. If you point your mouse at the icon it will say "Insert Image". Paste the copied text string into the "enter a link for image" box. The image will be inserted at the cursor position and aligned according to which radio button you have selected.

You have copied the Image BB code form the box below and pasted directly into the edit box which gives the small representation of the image like this :

You must insert this in the post via the insert image icon (2nd row down at the top) the one with the little mountain when compiling your post in the editor. If you point your mouse at the icon it will say "Insert Image". Paste the copied text string into the "enter a link for image" box. The image will be inserted at the cursor position and aligned according to which radio button you have selected.

You have copied the Image BB code form the box below and pasted directly into the edit box which gives the small representation of the image like this :

Ian

Re: SHED MATTERS. MARINE ENGINES.

Hi Ian,

I realised my mistake immediately after posting my last reply, but wasn't sure of the correction. Doh! I managed the first time round from my private gallery but didn't remember the right sequence the second time.

Let's try again.

BR

Mick

I realised my mistake immediately after posting my last reply, but wasn't sure of the correction. Doh! I managed the first time round from my private gallery but didn't remember the right sequence the second time.

Let's try again.

BR

Mick

- Stanley

- Global Moderator

- Posts: 104551

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

Sarah and Mick called in for a cup of tea. Nice visit, I think Sarah has Mick well in hand, an impressive woman! They delivered the big machine vice that Mick has refurbished for me. I shall put it together today and see how it sits on the HM. It's a big lump! He brought me a plaster cast of one of his roses as well.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104551

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

No messing about here. The new vise set up square on the HM and ready for action. Mick made a good job of the refurb. Apart from a few scars where a cutter has gone where it shouldn't, its in good nick. I can see it coming in handy mainly because the jaw aperture is bigger than my existing vises. A good addition to the shed! Thanks Mick.

By the way, he's painted it in Harrison grey so it matches the miller!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: SHED MATTERS. MARINE ENGINES.

Hi Stanley , glad the vice is ok for your mill and the colour is fitting too. Nice to see you and Jack yesterday and cheers for the Cuppa. Sarah enjoyed the visit too and was especially impressed with your wood burner as well as your spacial awareness

I know the vice has gone to a good home , I am sure you will find some work for it ............. plus its got you back into the shed

Cheers Mick.

I know the vice has gone to a good home , I am sure you will find some work for it ............. plus its got you back into the shed

Cheers Mick.

- Stanley

- Global Moderator

- Posts: 104551

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

That's true. Mind you Sarah wasn't impressed by the lathe in the front room, don't try it! It may be a bridge too far. Hearing her accent reminded me that I used to live with a woman from Newbiggin and she told me what my lisk was.... Ask Sarah, she'll clue you up if you don't know.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104551

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: SHED MATTERS. MARINE ENGINES.

I keep going in the shed and admiring the new vise sat there looking serious on the HM bed! I have a feeling I'd like to have a good cleaning up session and who knows, something might strike me! Definitely on my mind which is good, Spring must be here in the shed!

One thing I have a yen to do is solve a small problem on the big compound in the front room. There's a tight spot developed on one segment of the revolution and I don't know what it is.....

One thing I have a yen to do is solve a small problem on the big compound in the front room. There's a tight spot developed on one segment of the revolution and I don't know what it is.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: SHED MATTERS. MARINE ENGINES.

Yet another project has kept me away from rebuilding my Harrison L5 lathe , this time it was to make a safety rail and gate in alloy to match an existing bit of rail that goes around some floating jetty type walkway in a marina. I am no expert at alloy welding but my friend was stuck for getting it done so I said I would give it a go.

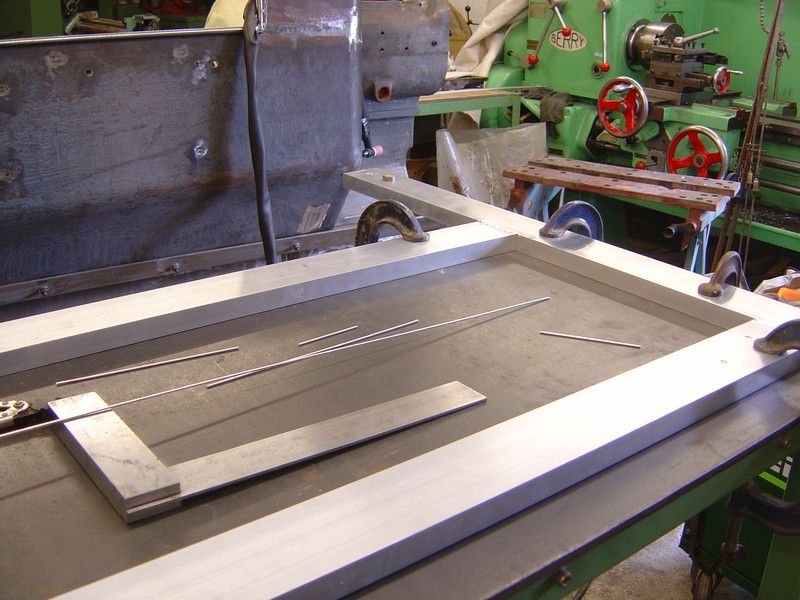

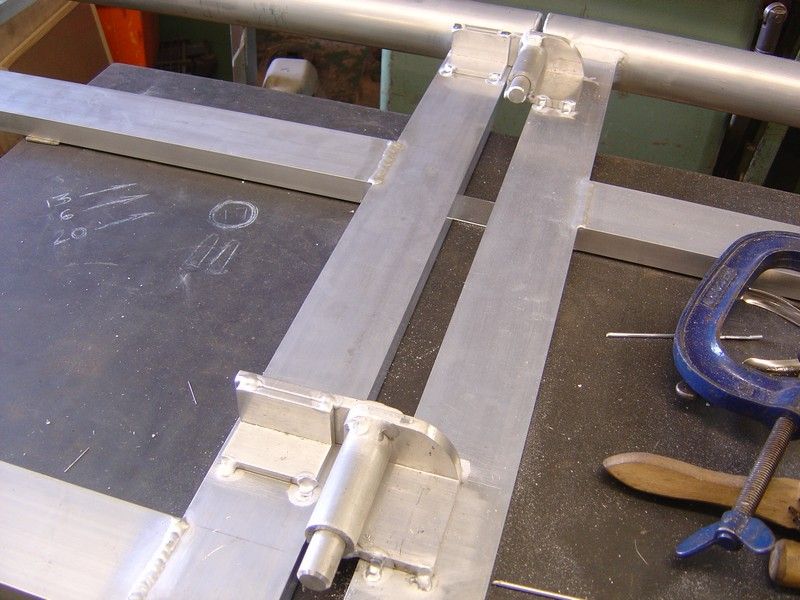

This is the basic job laid out after being cut to size, the closest bit of frame is the old original part , no matching handrail could be found so the round tube had to be used to do the new section with, of course everything had be measured from the bottom of the old handrail so all had to be laid out to get thing to line up to look as matching as they could.

I had to dig the welding table out , which involved moving allsorts of stuff into my way for the next job lol. I clamped everything down square and welded one side , the frame was bigger than the table so was more hassle than it looks here.

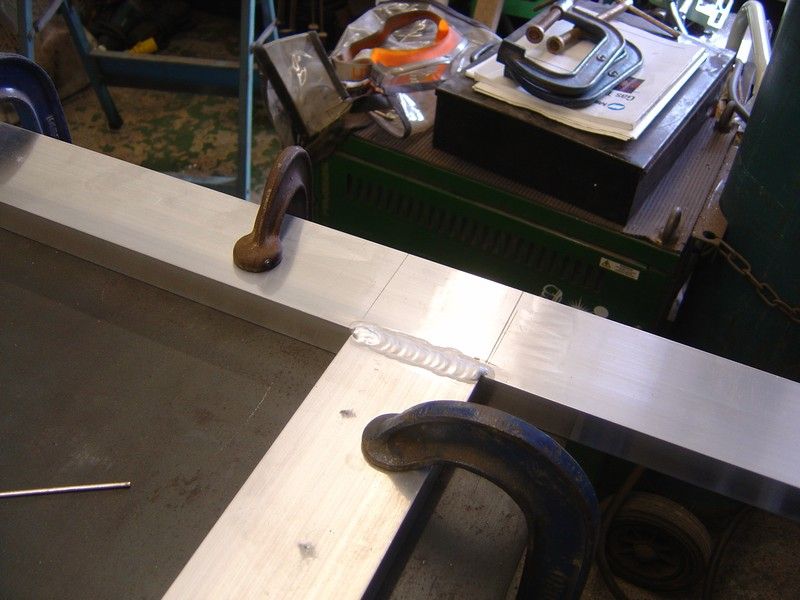

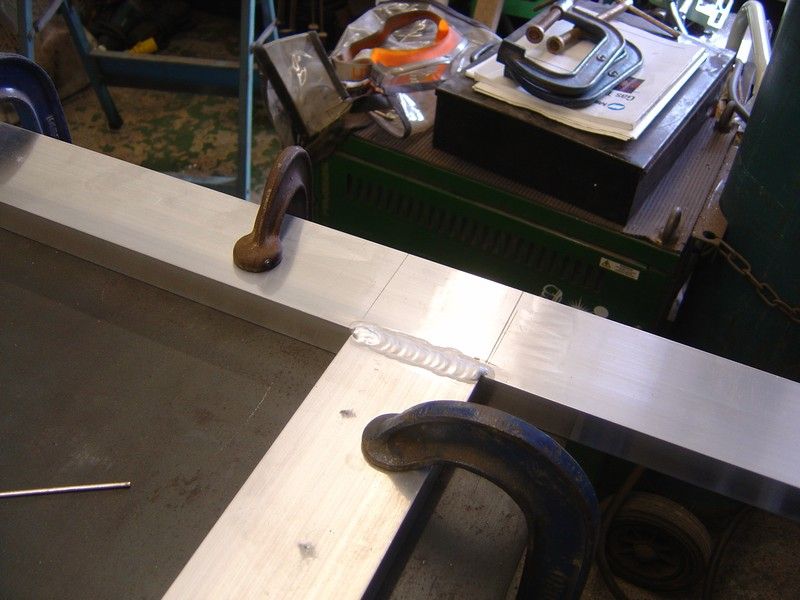

It was welding ok, Could be better mind! The material is about 3mm (1/8th inch) thick I am using 3.2mm rods and about 130 amps AC .

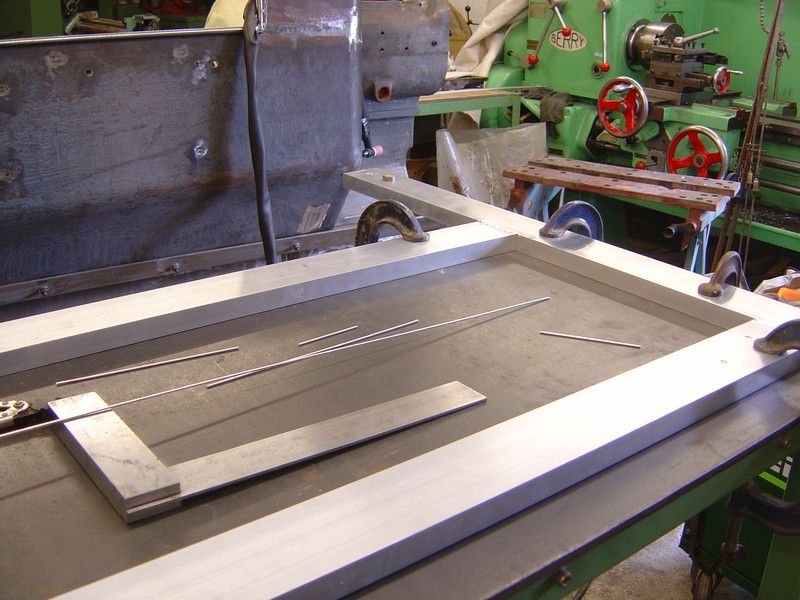

This is the frame welded up after much hassle , swearing and moving almost all the stuff in the way several times as well as the welder tripping the breaker a good few times, I made round discs that were a tight fit into the handrail and welded around to blank them off. I now had to figure out how to hinge the gate part , not as easy as you would think with the handrail being wider than the uprights etc.

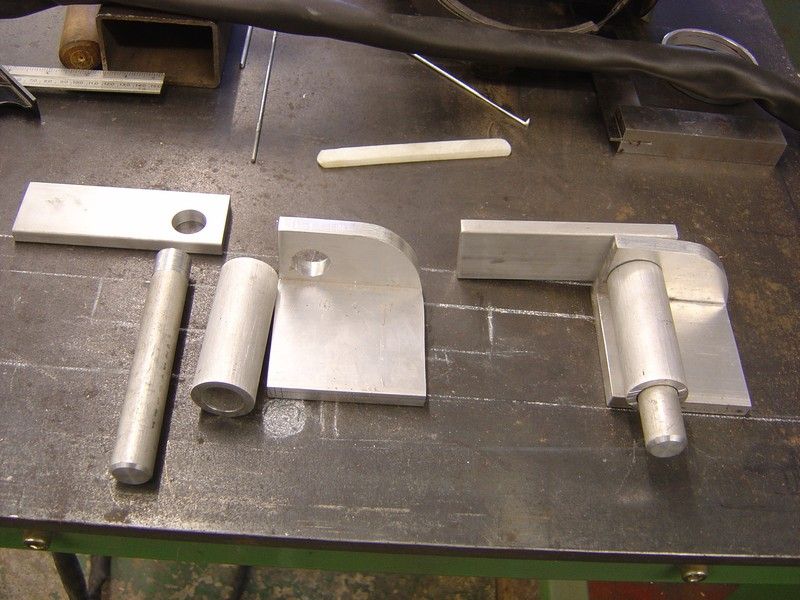

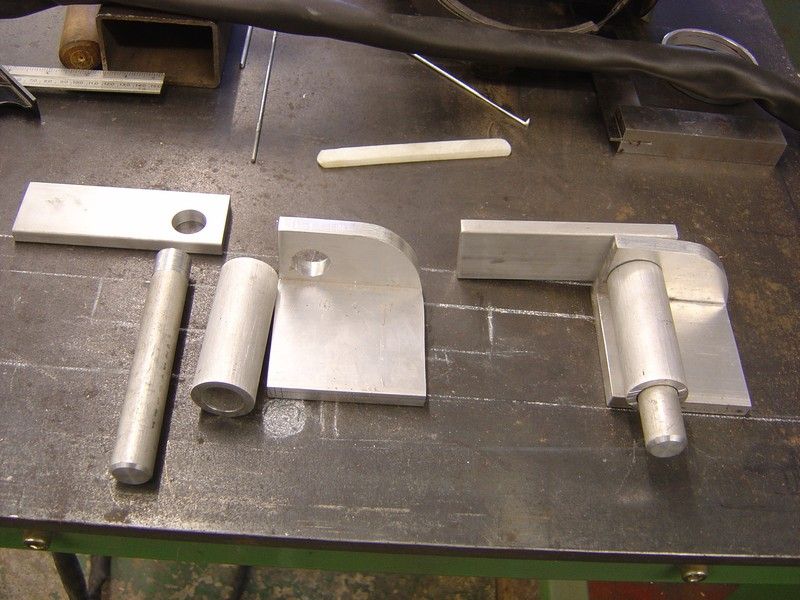

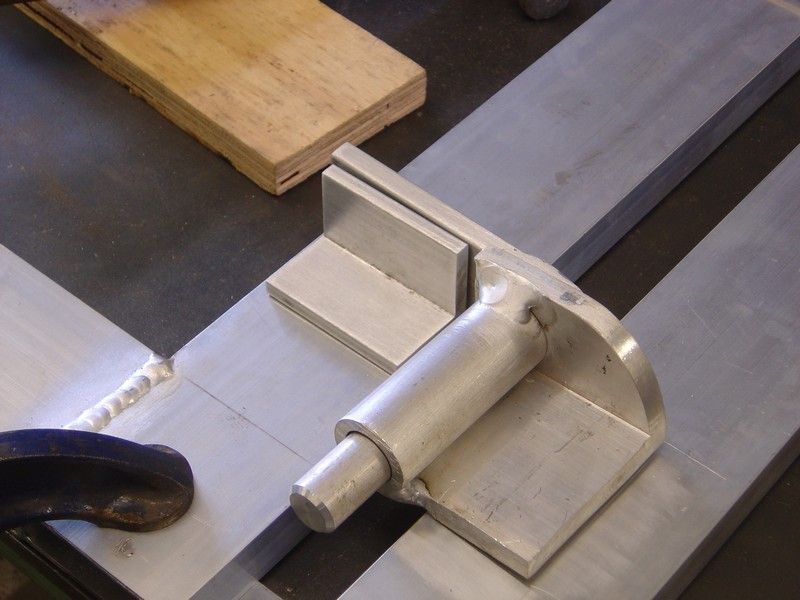

This is what I came up with for the hinges , it was Apollo 13 style , they had to made out of what was lying about so this was my best option, nice big chunky jobs , that even a fat bloke can lean on and not bend while shirking work

To make things easier to line up while welding I decided to add the bits of angle under the pin sides of the hinges

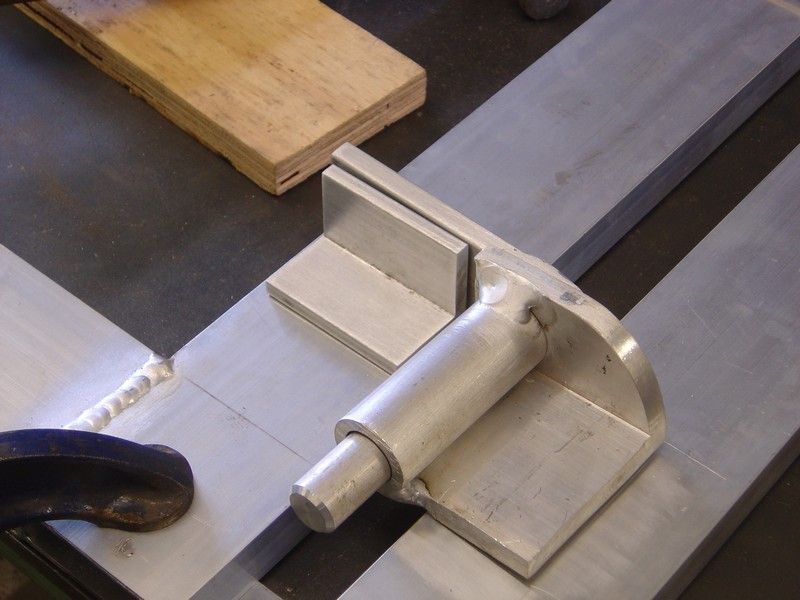

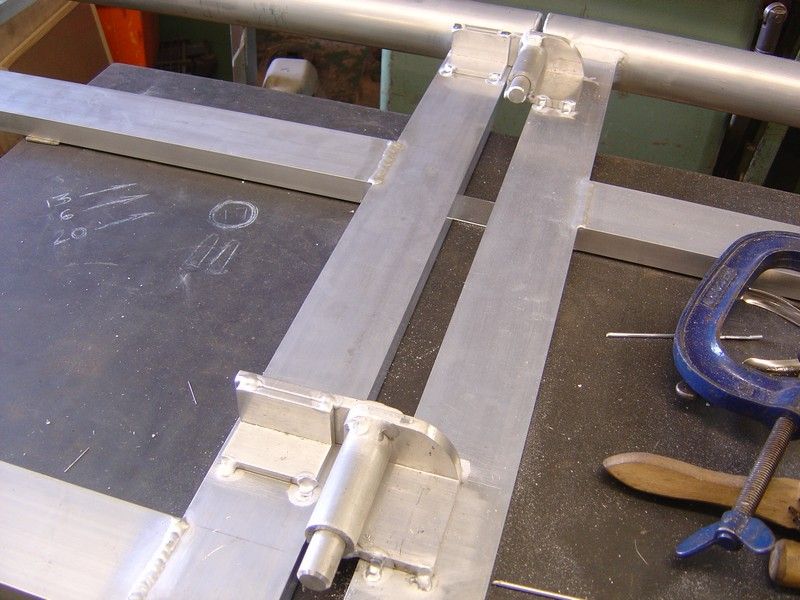

After much clamping and checking , hinges tacked up and tested to double check that nothing catching at either end of the gate.

This shot shows the general shambles I am working in , no room to get around with ease and welding at the wrong angles and stretching across etc buts thats just how it is when every project is nothing like the last lol. Also half the mess is what has been mover to make room for the welding table and the frame to then clamp to it.

The finished job , its still quite light to carry , the gate has had the top hinge welded at a height that it will foul the handrail so can not be lifted off , as metal things have a habit of walking these days

The welds look ok when you look at the overall thing , I know they could be better, I ended up starting with a 2.6mm tungsten, then wanted to go to 3.2mm but I had a faulty gas lense so had to go up to I think 5mm but could not crank the amps up more as tripping the house breaker so not idea really but did do the job.

This is the hinge set up welded, no way these babies are falling off thats for sure !

The gate swung open, I double checked that there was no crossed wires to which way it had to swing and what side it pivoted on before welding anything ........ its happened before lol

Right as usual I will end with saying , it really is the lathe now lol.

Cheers Mick.

This is the basic job laid out after being cut to size, the closest bit of frame is the old original part , no matching handrail could be found so the round tube had to be used to do the new section with, of course everything had be measured from the bottom of the old handrail so all had to be laid out to get thing to line up to look as matching as they could.

I had to dig the welding table out , which involved moving allsorts of stuff into my way for the next job lol. I clamped everything down square and welded one side , the frame was bigger than the table so was more hassle than it looks here.

It was welding ok, Could be better mind! The material is about 3mm (1/8th inch) thick I am using 3.2mm rods and about 130 amps AC .

This is the frame welded up after much hassle , swearing and moving almost all the stuff in the way several times as well as the welder tripping the breaker a good few times, I made round discs that were a tight fit into the handrail and welded around to blank them off. I now had to figure out how to hinge the gate part , not as easy as you would think with the handrail being wider than the uprights etc.

This is what I came up with for the hinges , it was Apollo 13 style , they had to made out of what was lying about so this was my best option, nice big chunky jobs , that even a fat bloke can lean on and not bend while shirking work

To make things easier to line up while welding I decided to add the bits of angle under the pin sides of the hinges

After much clamping and checking , hinges tacked up and tested to double check that nothing catching at either end of the gate.

This shot shows the general shambles I am working in , no room to get around with ease and welding at the wrong angles and stretching across etc buts thats just how it is when every project is nothing like the last lol. Also half the mess is what has been mover to make room for the welding table and the frame to then clamp to it.

The finished job , its still quite light to carry , the gate has had the top hinge welded at a height that it will foul the handrail so can not be lifted off , as metal things have a habit of walking these days

The welds look ok when you look at the overall thing , I know they could be better, I ended up starting with a 2.6mm tungsten, then wanted to go to 3.2mm but I had a faulty gas lense so had to go up to I think 5mm but could not crank the amps up more as tripping the house breaker so not idea really but did do the job.

This is the hinge set up welded, no way these babies are falling off thats for sure !

The gate swung open, I double checked that there was no crossed wires to which way it had to swing and what side it pivoted on before welding anything ........ its happened before lol

Right as usual I will end with saying , it really is the lathe now lol.

Cheers Mick.