I sorted out the dies and then got round to the first of the interesting jobs I have lined up.... Newton's crankshaft was too long and needed reducing at each end. It looked a lot better when I popped it back in its bearings.

The next small task was to pop an eighth inch oilway in the pedestal bearings. Then clean the bore where it had broken through.

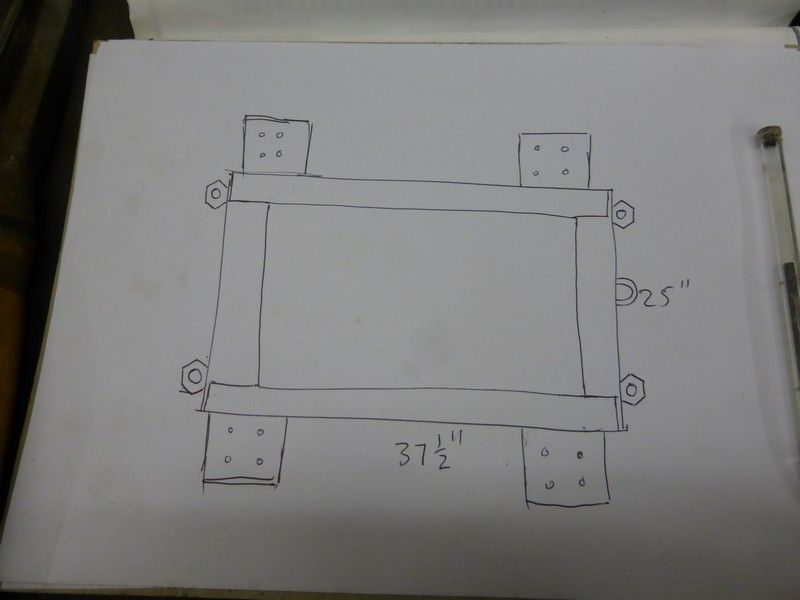

The next job was to drill the holes for the pedestal mounting bolts. I was going to make the two at the end where it is tight a smaller bolt but then decided it would look a lot better if they were all 1/4". I'm drilling tapping size here. On the flywheel bearing with the larger bore I broke through the wall of the bearing but I can deal with that later. Still plenty of bearing surface....

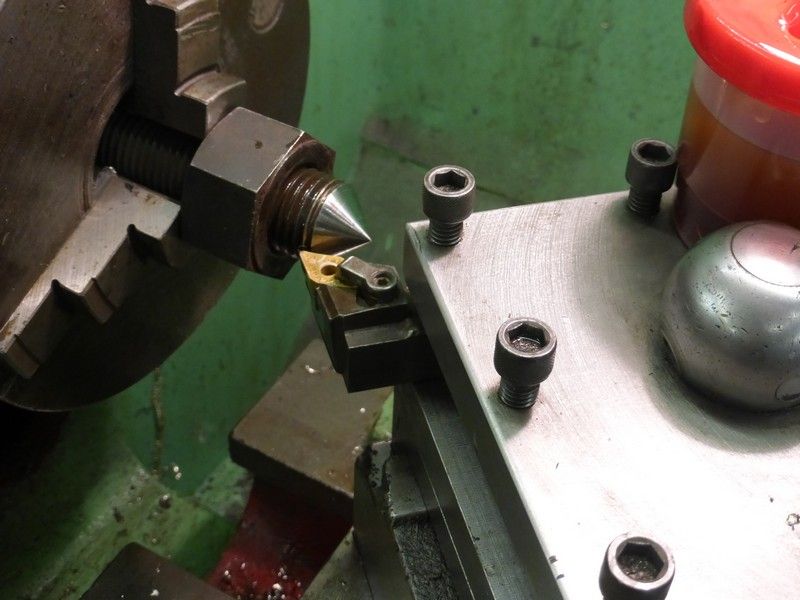

This was almost a big mistake. I had it in my head I wanted a gas engine type lubricator on the crank brass. I pop marked the location and was just going to drill it tapping size or the lubricator when I realised that if I did I'd cut the clamp bolt! So I had a rethink, popped it in the pillar drill and made twin lubricating holes down each side of the bolt.

Then it started to get exciting! I installed the con rod and took the back lid off so I could see where the piston was when the crank was on the back centre. If I get this right I know the front is OK because it has slightly more clearance.

Then a good clean up. Clear the bed of the VM and clamp the engine down tight on its wooden packing. I shall make the final checks on position and poke the drill through the holes I have already made in the pedestals to get an accurate mark for tapping the holding down bolt holes.

Close of play. I shall leave the final adjustment of the pedestals till tomorrow. I did this pic of the bench, you can tell we are getting towards a conclusion, it isn't cluttered up with parts!

A good morning......