Shed Matters 3

Re: Shed Matters 3

There is something almost artistic about that Stanley.

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I agree with you. In 1927 he had just got married and was setting a workshop up. He wanted a Birch Ornamental Turning Lathe to make the gears for his clock-making but couldn't afford one so he built a copy of the one he wanted but with a few additions. He was a pretty good engineer!

I started the day working for you Bob. Here's the tube, I got it down to do proper measurements so that you can plot if you want to. Length is 13 and 1/8". OD is 5". ID is 4 and 13/16". Wall thickness is one tenth of an inch.

Then I started working my way down my list of valve motion parts. Dead easy but one less!

Then a couple of links. I measured one and clamped both together to drill them. That ensures they are identical. I am not shaping them and I haven't rounded the ends, I'll do that when I get to fitting.

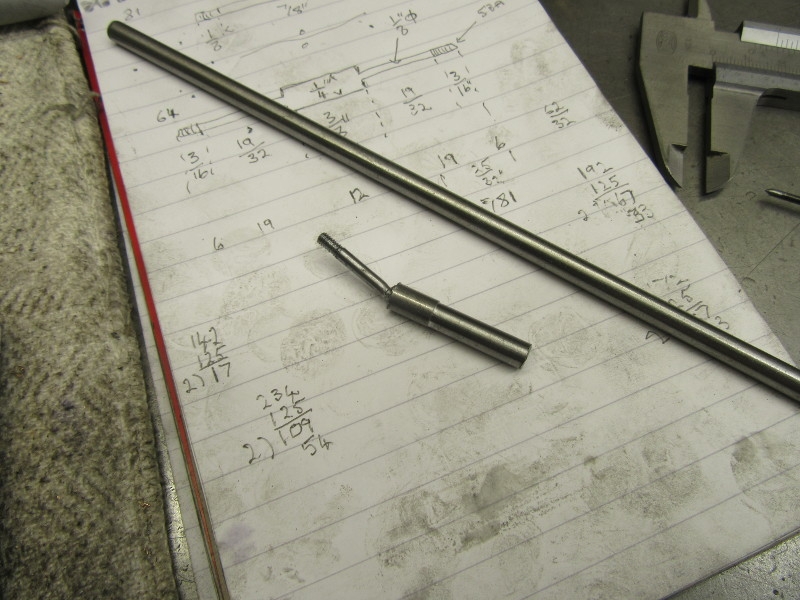

I pressed on into the next shaft, another dead simple one but due to bad eyesight I measured it wrong. None of the original stock left so into the treasure chest. This is a bundle of silver steel I bought from K Steels when it was on offer. £10 for the lot and I've used quite a bit of it since. Never walk past a bargain! The first piece I pulled out was the right one, 5/32" diameter.

Out of focus but I measured it right this time and here I've made the first cut, 7/16" turned down to 1/8". This was knocking off time, I'd done two hours. I'll cut the other end tomorrow. Never mind the mistake, good progress!

I started the day working for you Bob. Here's the tube, I got it down to do proper measurements so that you can plot if you want to. Length is 13 and 1/8". OD is 5". ID is 4 and 13/16". Wall thickness is one tenth of an inch.

Then I started working my way down my list of valve motion parts. Dead easy but one less!

Then a couple of links. I measured one and clamped both together to drill them. That ensures they are identical. I am not shaping them and I haven't rounded the ends, I'll do that when I get to fitting.

I pressed on into the next shaft, another dead simple one but due to bad eyesight I measured it wrong. None of the original stock left so into the treasure chest. This is a bundle of silver steel I bought from K Steels when it was on offer. £10 for the lot and I've used quite a bit of it since. Never walk past a bargain! The first piece I pulled out was the right one, 5/32" diameter.

Out of focus but I measured it right this time and here I've made the first cut, 7/16" turned down to 1/8". This was knocking off time, I'd done two hours. I'll cut the other end tomorrow. Never mind the mistake, good progress!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I started the day by finishing the cross shaft I cocked up yesterday. It's good now, better actually for the mistake because this one is made of high carbon silver steel, a cut above the mild steel provided.

For the next three items I need 1/4" square stock and for some reason the stock is short so I went into this treasure chest, a box of key steel. Over the years it has saved my bacon many times! Always be looking to build up boxes like this!

First job in making the first item, the crank that takes the input from the valve rod, was to square the end. Notice that even though it is square it can be held in the three jaw chuck, the centre doesn't matter.

First I drilled the two 1/8" holes in their proper locations and then marked for drilling for the set screw that locks the crank on the cross shaft I made earlier. As usual, I have rejected the 7BA MS set screw provided and will use an 1/8" Whitworth Unbrako socket head screw, they are better quality being made of high tensile steel.

I drilled and started tapping and broke the tap. Par for the course and as always my fault but that doesn't alter the fact. As usual, even though I knew it was useless I wasted twenty minutes trying to get the broken piece out before accepting my fate and starting again. (All right, you can occasionally get lucky but not this time!)

Knocking off time. I went for a different approach, I drilled for the tap first and went right through so the chips had somewhere to escape to. I used a slightly larger tapping drill as well because this is key steel and is tougher than normal mild steel. I shall drill the 1/8" holes next, that's relatively risk free!

An enjoyable morning because I surmounted the difficulties. No problem with breaking the tap, we've all been there with small taps like this. Onwards and upwards!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I started the day by remaking the crank I buggered up yesterday. I shall cut the Unbrako set screw back and round the ends when I am finishing the parts.

Next job is to make two identical cranks except that they need a 1/8" slot 1/4" deep in the end. First job was to cut a piece of stock long enough for both. They will be more easily dealt with if they stay together until I have done all my machining.

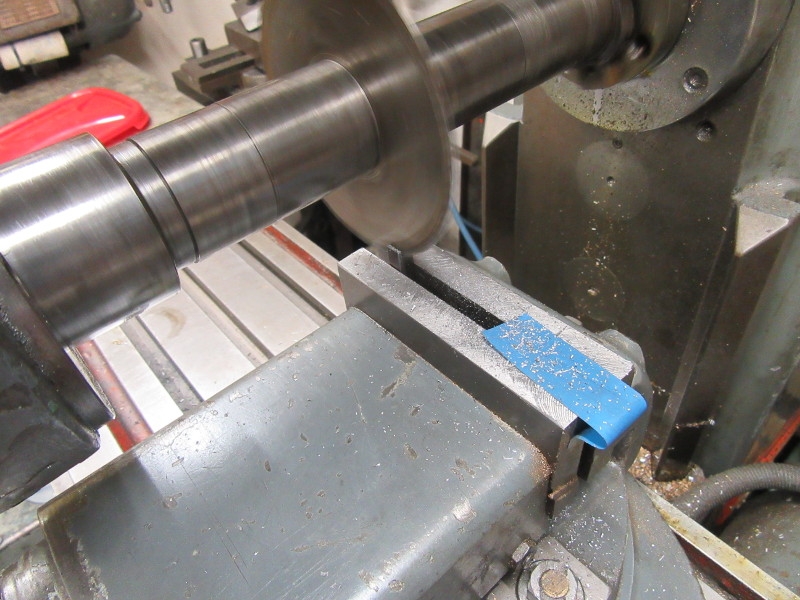

After a bit of setting up I was under the cutter in the horizontal mill cutting the first slot in one pass. The blue insulting tape is holding a piece of 1/4" stock in one end of the jaws of the vise to level out the pressures when I tighten down on the workpiece.

A bit later after some careful cutting. The eagle eyed will not that even after all my measuring and setting up I have cut the slots slightly off-centre. Par for the course I am afraid with my eyes but it will be OK. The horizontal mill is the ideal tool for jobs like this, clean accurate slots.

Knocking off time. I have measured and marked and am ready to drill and tap for the set screws. I want to come fresh to that so I have left that for tomorrow...

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: Shed Matters 3

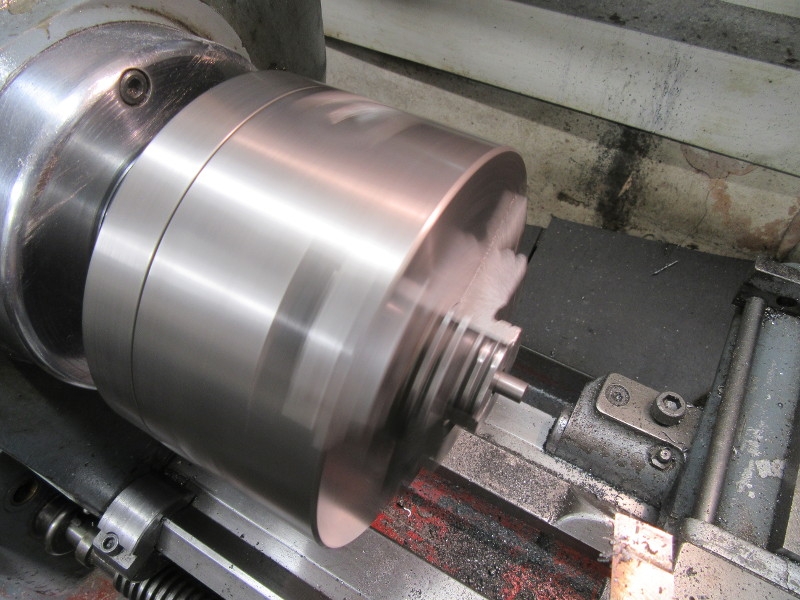

Shame about the tap Stanley, but we have all been there. I have the recess machined To depth in the adaptor head for the indexer. I now need to get the diameter right, that is the critical dimension. When that is right I can spot through for the fixing holes.

You do not have the required permissions to view the files attached to this post.

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Bob, Newton always said that when you put the mating part in and it didn't fall out you had got it right.....

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Still working on my cranks. Here I have drilled for tapping but before I got here I had a full investigation, checking tapping drill sizes, the condition of my taps and threading a couple of test holes to identify which was the best of my old taps, they could be getting on for 100 years old! The conclusion I came to was that I could go ahead with the best tap but I also went on the web and spent £20 at Chronos on a set of 3 1/8" Whitworth HSS taps, taper, second and plug. There is no doubt at all that I would benefit from new sharp taps, I am going to have this problem again with the next engine.

Then I went on to tap the holes but with one important change. I didn't start in the pillar drill on the same setting as the tapping drill. I went old fashioned and tapped the through holes by hand.

It worked and I have both set screws fitted.

Then on to the relatively easy job of drilling for the 1'8" shafts.

Knocking off time. I have all the parts of the motion made. I still have to decide about rounding the ends, shortening the Unbrako set screws and generally making them pretty. I'm glad to see those cranks out of the way! So it's a good morning!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

This pic sums up the morning's task. I have all the parts of the valve motion made but not finished. Now it's the turn of the parallel motion which has more parts. So the first job was to identify them all and draw up a list. The ones with the crosses next to them are lathe work, the one remaining is 8 off the same size link motion bars. So I decided to make them first, they are the most repetitious and frankly, boring. First job was to sam up the stock, 1/8" X 1/4" MS bar. Then a fag packet drawing and decisions about measurements. First job was to reduce the stock to 8 pieces 2" long exactly. (I say exactly, as near exact as makes no matter.) All that took time...

Here we are at closing time. I have got eight bars, all cut to length and marked for the 1/8" holes needed. The next job is to stand at the pillar drill and drill 16 of them. That's the first job tomorrow morning. I have done quite enough standing at the bench for one morning. I know my limitations.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: Shed Matters 3

Will you drill them individually Stanley or use one as a pattern for the others? Today I finished the adaptor plate for the dividing head though the morning started slowly as the bolts for my milling machine clamps had damaged threads and needed recutting before I could clamp the plate down to counterbore the fixing holes. It is finished now and I have done a trial fit of both the 4 jaw and 3 jaw chucks.

You do not have the required permissions to view the files attached to this post.

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

That looks like a clean tidy job Bob. You're better at finish than I am!

I shall drill the 8 bars individually, I seem to get them somewhere near right that way.

Have a look at what size your bolts are, if they're cap head Unbrako Imperial I almost certainly have them in stock.

I shall drill the 8 bars individually, I seem to get them somewhere near right that way.

Have a look at what size your bolts are, if they're cap head Unbrako Imperial I almost certainly have them in stock.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

First job today is drilling the holes in the links of the parallel motion.

16 holes later, all de-burred and polished. Next job!

Lathe work now for a change. I have to make 4 small collars that are part of the linkage.

Some time later, we have 4 tiny collars ready for fitting.

Knocking off time. The results of two hours work. We move slowly forwards!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Two extra matters today.

First, a set of BA spanners arrived from Chronos to fill the gaps in my small spanner arsenal.

Then Sue and Bob turned up to pick up their loot. Socially distanced of course. Sue has Wendy's book as they are going to the Anchor for lunch with her and Col, at last that gets delivered. I got Sue one of the Artisan Baker's wonderful malt loaves to try out.

So there is a little bit more room in the house!

First, a set of BA spanners arrived from Chronos to fill the gaps in my small spanner arsenal.

Then Sue and Bob turned up to pick up their loot. Socially distanced of course. Sue has Wendy's book as they are going to the Anchor for lunch with her and Col, at last that gets delivered. I got Sue one of the Artisan Baker's wonderful malt loaves to try out.

So there is a little bit more room in the house!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: Shed Matters 3

Good photo Stanley, nice to see you again and good lunch with Wendy and Col

If you keep searching you will find it

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Did the malt loaf hit the spot?

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: Shed Matters 3

It did, very nice. Perfect with a spread of butter and a cup of tea. Thank you. We enjoyed it and will do so again today.

If you keep searching you will find it

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I like my new spanners but I did a bit of final finishing on them. This should have been done at the manufacturers but is too expensive. We are not into Britool quality these days. I tried them all and they fit the nuts they are marked for. I have been feeling the need for these in the smaller sizes for years.

Then I started working my way through the list. This was an easy one and I soon knocked it out.

Then I started on a slightly trickier one, tiny turning!

A moment of inattention after half an hour produced this result. Ah well! The air was blue for a moment and then I went and found some silver steel stock. I shall remake it tomorrow and get it right!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I started the day by putting right yesterday's cock-up.

Then I got stuck in, identifying what was next, doing a fag packet drawing, finding the stock. It all went well, so well that when I got to my normal knocking off time and was almost there I carried on and did two and a half hours.

Here's where I am now. All the parts are made for the valve and parallel motions. Tomorrow I'll go though them and make them all pretty. Once that's done I can start fitting. We are getting very close to a finished engine!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I think I forgot to mention that the set of HSS 7BA taps has arrived from Chronos. I am ready for the next engine!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Here's today's job, I have the parts for the Valve gear on the left and the parallel motion on the right made, what they need now is a few finishing touches.

The job was actually the trickiest, cutting the Unbrako set screws down to a more reasonable size. I cut them with a junior hacksaw and dressed the threads on the big diamond hone. I only lost one during the process!

Then round the ends and polish the parts of the valve gear.

Then all the links in the parallel motion were rounded and polished. Here we are at knocking-off time, all the parts breathed on and ready for fitting!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: Shed Matters 3

I have been making the bearing housing for the little turbine. It has two ball bearings, one at each end of the housing. It would be very easy to take off too much material in the cast aluminium housing, it cuts so easily.

You do not have the required permissions to view the files attached to this post.

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Tidy job Bob. I agree about ali, like brass some grades can grab the tool as well.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Today we are into fitting! I'm starting with the parallel motion which is the most complicated. First job was to dress all the small holes with a rat tail file to get a good fit. There are a lot of Holes!

The first part of fitting is to get the motion laced up with all the bits in the right place. No nuts on them yet. This takes longer than you think!

Then a long slow fiddly process of putting the nuts on and coping with all the little adjustments that have to be made. There is very little clearance on some of the parts. Many points needed a bit more thread on them. In this pic I have them all sorted except for the cross shaft nearest the column which will be a bit fiddly. I stopped when I got to that one!

I did this pic of the bench, you can always tell when I have been busy, more and more tackle has to come down off the shelf. It's at times like these when you are glad you have been giving house-room to tools that only get used once every Preston Guild.

A demanding but enjoyable two hours in the shed. I'm looking forward to tomorrow when I'll finish the parallel motion and attack the valve gear.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I started the day well by finishing the parallel motion. The shaft nearest to the column needed finishing and adjusting. All went well and we now have an engine where the beam is coupled to the cylinder and turns over. It's tight but that's how it should be at this stage, that will all ease when it runs. The main thing is that the tightness is even, there are no pinch points. Now was the time to change focus, get the parts of the valve motion out of their box and start building the valve gear.

I ran immediately into trouble. The cross shaft that is the basis of the gear was the wrong length as I had read the drawing wrong. I popped it in the lathe to adjust the size and went too hard at it and broke it in two. Ah well, sort another piece of stock out and remake it. In order to fit it I had to loosen one of the bearings it runs in. If you remember I had a problem with the 7BA bolts in the kit, they were undersize so when I fitted them I put Loctite on the threads.

That slipped my mind and here's the result. The Loctite worked and I sheared the bolt as I undid it. Not exactly the result I was after!

No point getting angry. I re-drilled the hole and tapped it again. Finger driven only!

This was knocking off time. Not there yet, plenty of little problems yet to solve. Not the easiest morning but par for the course! Let's hope tomorrow goes a bit more smoothly!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104652

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Fitting is a succession of small problems needing solution and this morning has been no exception. My aim is to get all the parts to fit each other. This pic shows where I started this morning. The cross shaft has had to come out again for a small adjustment in the length of the 1/8" shaft on the eccentric side.

So into the lathe and carefully extend the smaller section. While I had the bearing off on the right hand side I re-tapped both the holes to clear out any lingering Loctite residue. I did the same for the 7BA bolt that I managed to get out intact.

Then it was a question of working away at every joint to get them to fit. The ends of the connecting links to the valve rod shaft had to have a lot of time spent on them to get a good tight but free running fit.

There was a lot of this, easing holes with a rat tail file. Not to get an easy fit but to leave them tight but moving easily.

When I got to closing time I was dealing with the bolt that is the axis for the connection with the valve rod. Notice how little clearance there is between some of the bolt heads and the parts of the engine. In some cases I had to grind the heads of the bolts down to get them to fit. This is the sort of small problem that fitting addresses, the fits of shafts and bolts in holes and the ability for the parts to run without fouling the engine.

A trying morning but that's par for the course. You have to make slow patient progress solving one problem at a time. Onward and upward.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!