Shed Matters 3

Re: Shed Matters 3

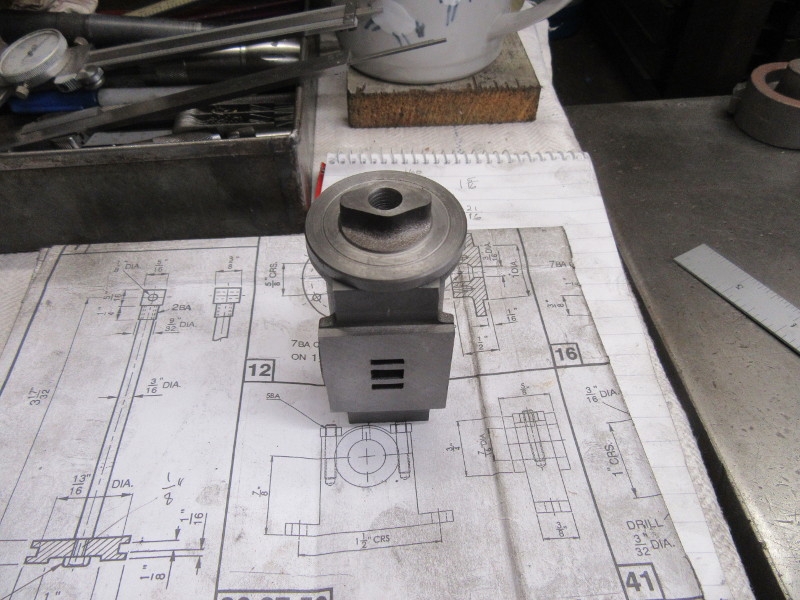

Not a lot done here recently. I drilled the bearing housing and tapped the matching face in the main housing. I used a couple of drills to pin the two pieces together whilst drilling the holes through. It was then that I realised I had not skimmed the face of the casting for the screw heads to seat. Thus I turned up a mandrel to mount the housing in the lathe. As usual it took longer to make the mandrel than it took to complete the job. Well worth the effort and the mandrel will join the others for later reuse.

You do not have the required permissions to view the files attached to this post.

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

That is so true Bob. Little jobs spawn bigger ones and so often you find yourself forced into making stuff you had never envisaged. That's where patience kicks in..... (You have the same auto punch as mine Bob.)

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: Shed Matters 3

Stanley, I must have had that auto punch for 45 years. It was part of our tool kits at CEGB.

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I had one of the model that they made before that. When it failed in the end I tried to repair it but it defeated me! I keep thinking I'd like one that is a bit less chunky, I might be more accurate with it.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: Shed Matters 3

I find that a magnifier helps my accuracy but this punch certainly is a bit chunky. I have another model that is a bit finer but does not have as strong a spring so is ok on soft materials but not steel. I must admit that I do like the the tools that I use regularly, you get used to them so it helps your accuracy as you make fewer slips.

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

And I don't know about you but I sometimes do a trial mark and punch on a piece of scrap, note where the aberration has taken me and then apply that to the serious piece. Aim off if you will. That can work.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

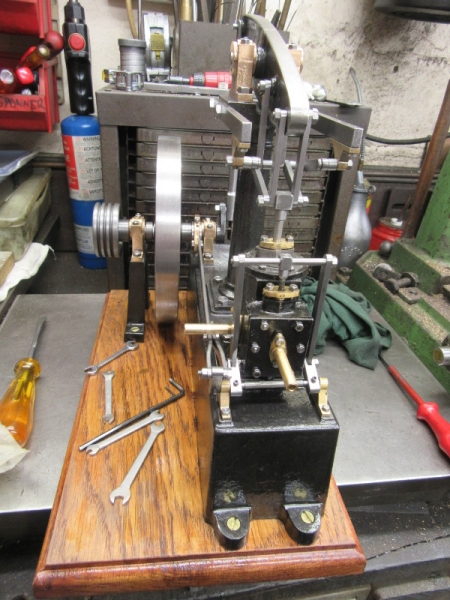

The first job this morning was to check that everything was free running and all the nuts and connections are tight. Then oil all the joints and finish fitting the axis pin in the crank connected directly to the valve rod. Then slacken both the glands on the piston and valve rods a touch and lubricate the rods. Then flood the valve and the cylinder with oil injecting it directly though the steam pipe. Then rotate the flywheel to get the surplus oil out of the system. That's why we have oil all over the bed.

Then a last check on all clearances and linkage joints. I set the valves and cranks to what I think is the right position, this includes the relationship of the connecting rod crank, I want it at right angles to give the maximum travel on the valve.

The gloves are off now quite literally, I am at the stage where we have to have the lid off the steam chest so I can actually see where the valve is in relation to the piston.

Now I can see the valve I can get closer to a viable setting. Now is the time to set the cranks in the valve gear and lock them in position on the cross shaft. I think I have it somewhere near but before I go any further I want to have a good think and make a final adjustment of the valve by altering the stroke of the valve rod itself. I decided to knock off early to give thinking time as the next job once I have made the decision about the valve rod is to replace the steam chest lid without packing and put some steam on it. (Air actually) That's the moment of truth and until I get there I can't be sure about my settings. Exciting times and so no rush, months of work is coming to fruition. I love this stage but am always nervous about it!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Today is valve setting. I got so engrossed that this is the first pic I did. By this stage I have adjusted the valve to make sure it's running central by taking the linkage down and adjusting the length of the valve rod. Then I put the lid back on with its paper gasket and moved on to adjusting the eccentric so steam admission was at the correct point.

This was where I ran into trouble. The Unbrako set screw on the valve rod crank hadn't enough hold and stripped. This is a fault with this design and was made worse by the fact my hole for it wasn't quite central. However, if you remember I'd drilled right through for the tapping of the set screw so I took it off and refitted it using the other side of the crank. This involved re-setting the valve event and so the lid had to come off the steam chest again. No rush, we are not on bonus!

I put 20psi on it and here's what happened. As you can see it's a runner! If I was running 300 looms I would have refined the adjustment of the events but as it will probably never get run again I left it how it is. I had got it near enough by eye.

So there you have it. A nice conclusion and it's ready for Susan to take away. Not perfect of course, they never are and I know all the things that could be better! But it's a successful conclusion, it is no longer a collection of bits of metal. it lives and it was me that did it! That's good enough for me.

Now I have to think what comes next. Not sure if I don't fancy a different design.

I have put all the tackle away and can now take a breather.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Thanks Ian. Neither did I really but I do tend to get a bit nervous when I get to this stage.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: Shed Matters 3

Well done, it really looks good. I wish you could put up a video of it running, I bet it goes like the clappers! Isn't it traditional to name engines? You should attach a name plate to it.

Re: Shed Matters 3

Well done on completing the project. Look forward to Shed Matters 4.

The phone does video, and an upload to Youtube isn't too hard. I've even done it.

PS too many smiles I think.

He could if he tried.

The phone does video, and an upload to Youtube isn't too hard. I've even done it.

PS too many smiles I think.

Born to be mild

Sapere Aude

Ego Lego

Preferred pronouns - Thou, Thee, Thy, Thine

My non-working days are Monday - Sunday

Sapere Aude

Ego Lego

Preferred pronouns - Thou, Thee, Thy, Thine

My non-working days are Monday - Sunday

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I'm considering this one next David, 12" long. I've asked Margaret if she fancies it. I fancy a change....

As for video, I don't want to complicate my life China. As for speed, it was doing about 150rpm on 20psi, if I gave it more it would be frightening with no load. No rush to decide.... (Besides, castings would be North of £500)

BTW I note that Stuarts sell a fully machined beam engine for about £1500 inc VAT. I could have saved all that trouble...

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: Shed Matters 3

Another excellent job Stanley. You might know all the bits that could be improved but it is a good runner and that is all we need to know. The was an old one of these on the ebay auction site last week at a starting bid of over £800. Of course it is not about money, it’s about the love of a job well done and a working machine.

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Thanks Bob, exactly, I love making lumps of metal come alive, exactly the same with your locos.

The money is only important when your buying the castings! The governor and steam valve are extra!

I know I'm not good on finish but technically it's good, very very little play anywhere, no knocks, taps or tight shops, runs very smoothly. In that respect I get better as I get older. I think that's something to do with having bad eyesight, you have to be ultra careful with your machining!

The money is only important when your buying the castings! The governor and steam valve are extra!

I know I'm not good on finish but technically it's good, very very little play anywhere, no knocks, taps or tight shops, runs very smoothly. In that respect I get better as I get older. I think that's something to do with having bad eyesight, you have to be ultra careful with your machining!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Finishing Susan's engine is a natural straight edge and you all know how I like them so this morning I started by having a good clean-up of the bench, Mrs Harrison and the floor. Things started to look quite tidy.

Only one thing to do in a clean shed. Make some muck! I happen to have about my person a beam engine cylinder casting. I think I may be making another one and so I chucked it in the mill and started doing the basic starting operations on it.

At closing time I have it ready for boring. It's not dimensionally correct, that comes once I have had it in the lathe and bored it as everything has to relate to the valve face and the bore. That's enough for this morning.....

In case you were wondering, the beam engine is cluttering my kitchen table up as eye candy!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I started this morning with one of my least favourite occupations, wood turning, it's so bloody messy! But this wasn't too bad and I looked on the bright side, the sawdust dries the oil off the lathe and that's a good thing when you are about to move on to Cast iron. What I'm doing of course is making a plug I can drive into the end of the bore of the cylinder so I can mark a centre which is to be used to set the cylinder up for boring.

I think that getting a cylinder set up for boring is perhaps one of the hardest thing about making a steam engine. It starts when you have driven the plug in and you are looking for a centre. The problem being of course that the cylinder is not round and is an irregular shape. The cast bore is only approximate so it probably took four goes before I was satisfied it was central. Next job is get the 4 jaw independent chuck on and grab hold of the casting the best way you can. My way includes aluminium pads so as not to mark the casting. Then you have to adjust the casting for centre but also for being square and perpendicular to the axis of the lathe mandrel. I don't mind telling you that this took over an hour. I think, but am not sure, that I have got it somewhere near right. All I can do now is face and bore it, take it out of the chuck and look at the back end! That's when you know for certain just how far out you were because believe me, with a casting like this if you get it right it's pure good luck!

This is why I say it is probably the most difficult thing. So that's for tomorrow, I am ready to bore.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

I started the morning by poking a 7/8" drill through the bore to get rid of the plug and skim of any flash round the ports. It squealed a bit but was OK.

Then I started boring to get to 1" bore. Light cuts and each one reversed and in effect doing a spring cut on the way back through. Measuring with expanding 'T' measures and micrometer after each cut. It took 3 cuts and I hit one thou under 1", that'll do me, I have to make the piston to fit. Once I had the bore done I faced the end so it is perfectly square to the bore.

As I said yesterday, these set ups are a bit of a lottery and the only reassurance comes when you take them out of the chuck and look at the other end! I wasn't wasting my time setting up yesterday and continually adjusting the hold I had on the casting. I got it about right. Remember that the casting isn't circular so it appears out of centre but measurement and comparison of wall thickness at each end shows it is only .003" out. Three thou will do me!

This is the other end. Not bad, a very good finish on a perfectly sized bore and it's central in the casting (allowing for the variations in the casting.) This will do for today. I knocked off and did my Co-op shop. Not a bad morning! This and better will do.

Then I started boring to get to 1" bore. Light cuts and each one reversed and in effect doing a spring cut on the way back through. Measuring with expanding 'T' measures and micrometer after each cut. It took 3 cuts and I hit one thou under 1", that'll do me, I have to make the piston to fit. Once I had the bore done I faced the end so it is perfectly square to the bore.

As I said yesterday, these set ups are a bit of a lottery and the only reassurance comes when you take them out of the chuck and look at the other end! I wasn't wasting my time setting up yesterday and continually adjusting the hold I had on the casting. I got it about right. Remember that the casting isn't circular so it appears out of centre but measurement and comparison of wall thickness at each end shows it is only .003" out. Three thou will do me!

This is the other end. Not bad, a very good finish on a perfectly sized bore and it's central in the casting (allowing for the variations in the casting.) This will do for today. I knocked off and did my Co-op shop. Not a bad morning! This and better will do.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Some mistake surely? An uneven shaped casting in the 3 jaw SC chuck? Not so, it's in there so I can butt the accurate end of the casting on the face of the chuck and face this end to match. Eccentricity doesn't affect facing of course.

A few careful cuts and the job's done.

Next job was to finish the valve face to the right depth. I used a fly cutter because they give a far better finish than an end mill.

Before I put the end mill back in the VM I dressed the wheel and touched the cutter up. I gulleted it as well and really ought to have backed it off as well but didn't. Then I put it back in the mill.

Next job was to drill the 3/16" exhaust port.

Closing time. We have a cylinder that is dimensionally correct and ready for the next operations. I shall decide what they are when I see if the castings arrive today. Two hours satisfying work, all done slowly and carefully and I like the result. By the way, as usual, the quality of the iron and the castings is superb, no blow holes or hard shops, that's why the bore is so good.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

The castings are here. As always, Stuart really do pack things securely! It took 20 minutes on the exterior packing to get to the top stage and another half hour with a Stanley knife operating on the tough vacuum packing but now it is all free. All I have to do now is put it all away in the shed.

Well, we're committed now aren't we. I can't die for at least six months!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- PanBiker

- Site Administrator

- Posts: 18116

- Joined: 23 Jan 2012, 13:07

- Location: Barnoldswick - In the West Riding of Yorkshire, always was, always will be.

Re: Shed Matters 3

As this is the third one Stanley you shouldn't complain about the 6 and 7BA screws, this punishment is of your own making.

Ian

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Nonsense, I shall still complain! I hate 7BA taps! (Don't be surprised if I substitute 6BA for some of them)

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

The landscape in the shed has changed! It now includes the castings and stock for Margaret's engine. Just come at the right time. Today's job is to make the top lid as that is needed as a template for drilling the stud holes, top and bottom, in the cylinder.

The first thing was to chuck it (very precariously!) for all the operations on this face, true the spigot, face the surfaces and leave the register an exact fit in the cylinder. Expect some very gentle cuts!

You can measure as much as you like but this is the real test of the fit!

Then reverse the lid and turn all the other faces and the periphery, drill for the valve rod and the packing gland and last of all mark the pitch circle diameter of the stud holes.

Knocking off time. Some very careful turning and a good result. We have a lid that's ready for drilling for stud holes and then it can be used as a template for all the other drillings and of course the base. Yes I am slow but I am accurate, this lid is good! Nice morning.

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Re: Shed Matters 3

Slow but sure is good here as well Stanley. I have had a fun time trying to work out way of holding the turbine casing cover so that I can face the mating surface and adjust the casting thickness. The exhaust port cast into the other side prevents and holding in a lathe chuck. I eventually found that with a few packing pieces underneth and some aluminium pads that I could mount it on the mill. Adjusting level was a good test of my new inclinometer. I finished off by turning it over and skimming the pads for the screw heads and the drain cock.

You do not have the required permissions to view the files attached to this post.

- Stanley

- Global Moderator

- Posts: 104654

- Joined: 23 Jan 2012, 12:01

- Location: Barnoldswick. Nearer to Heaven than Gloria.

Re: Shed Matters 3

Impressive Bob. I haven't got beyond a spirit level yet!

Stanley Challenger Graham

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!

Stanley's View

scg1936 at talktalk.net

"Beware of certitude" (Jimmy Reid)

The floggings will continue until morale improves!

Old age isn't for cissies!