Well at last some more progress on the lathe.

Its been slow as every small part needs a good go over now as everything looks rough compared to the lathe now so has to be fettled before it can go back on. I have got a print for the workshop wall too. Its of a Dame Laura Knight painting dipicting a lady operating a lathe in World War 2 called Ruby Loftus screwing a breech ring , real good detail on the lathe.

Right back to the lathe, its been electrics, lights , suds pump , Norton gear box , saddle , apron and lots of fiddly bits and bobs. A massive thanks to Bob KRV3000 for sorting out the Norton box and apron for me , Bob made new or fixed by sleeving most of the bronze bushes in box and apron as well as various other repairs that were needed after 60 years of use, as usual a superb job and they are sopt on now, so thanks again Bob.

I had already cleaned up the castings for the apron , and gearbox in prep for painting, this is them after Bob had run his magic touch over them.

The Norton box was primed and then test run to check all was well before painting, all correct and working much slicker and more quiet.

Time for more paint, primer first over the etch primer which is seen here.

Then grey topcoat, I was glad to see this lot grey at last I can tell you

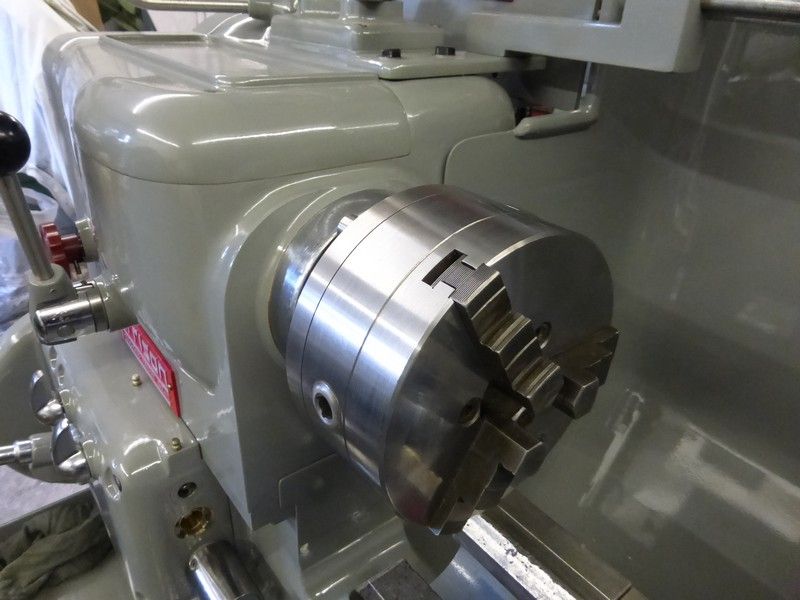

Box back on

Chuck guard and LED lamps fitted

Then another big thanks to my mate Dave who managed to set the inverter up so I could use the switch gear as I wanted, the inverter works fine but is not easy to set up if you are not used to them.

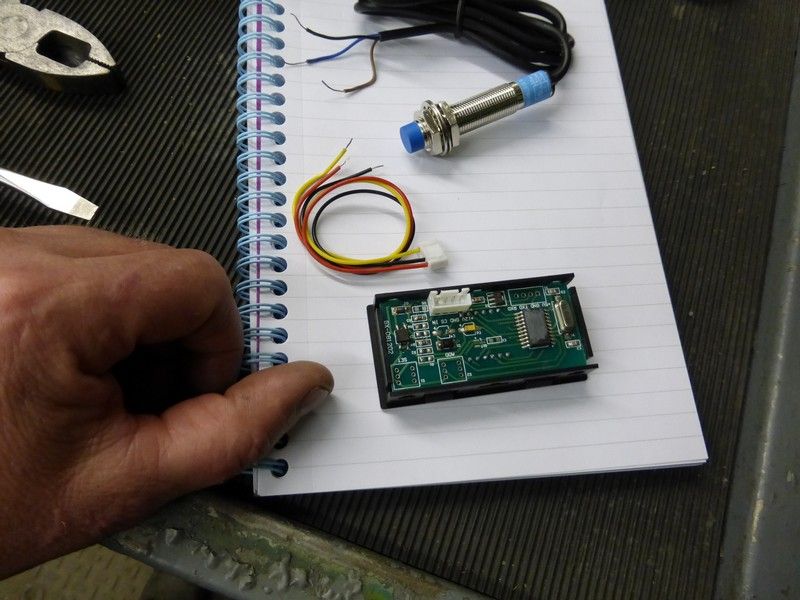

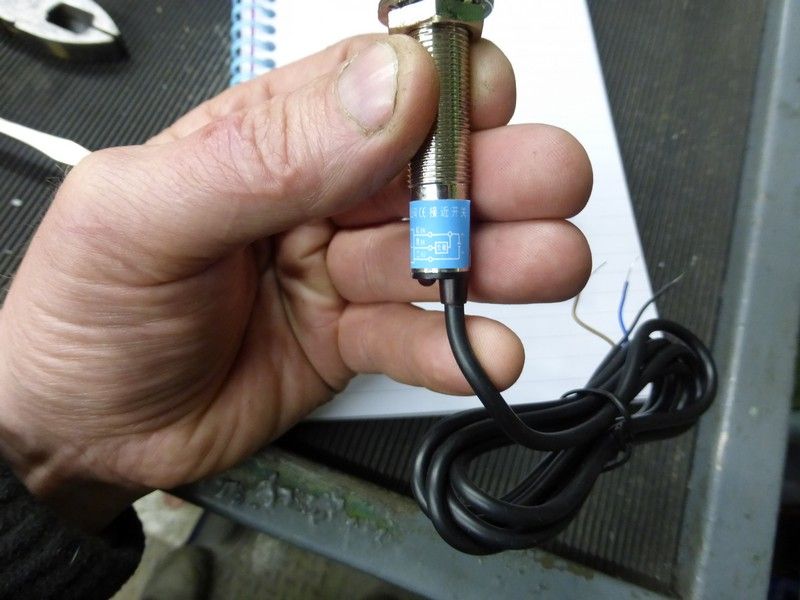

The front panel is all marked up with decals and the rev counter in place and wired up, this is 12volt unit meant for cars and has a pick up sensor that works off magnets on a collar around the spindle.

So thats about it up to now, the coolant tank and pump are fitted too and I am now sorting through all the little things that need fettled before they go back on but the light is at the end of the tunnel now I think .

The samll things are bit such as the hand wheel and shaft where the taper pin would not come out , then drilled off center so will have to be repaired before fitting again , all time consuming stuff.

Anyway Stanley , its about time you were back in that shed doing a project is it not

Cheers Mick