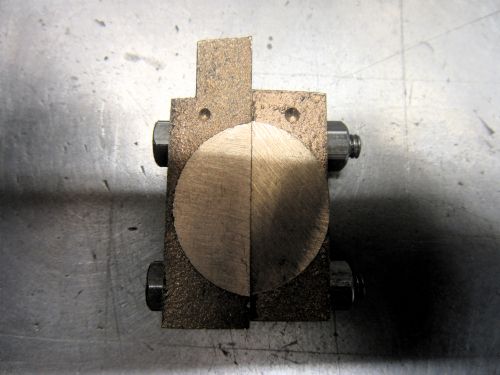

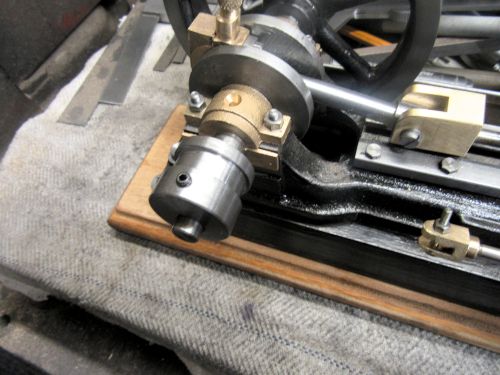

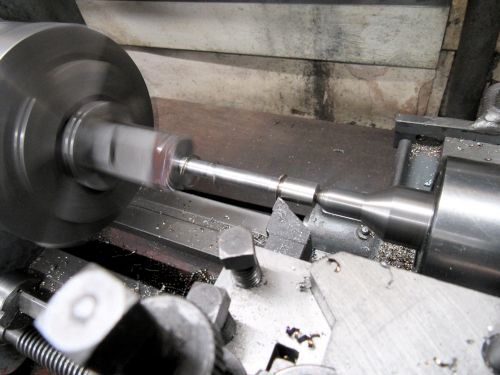

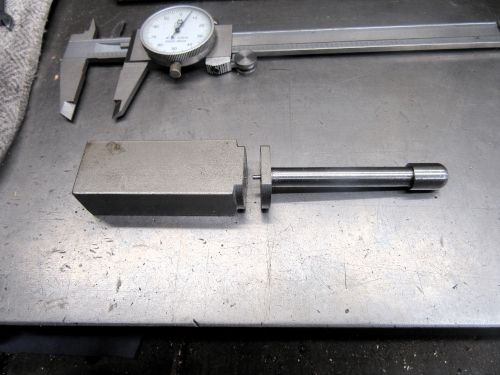

This morning O carried on with making the connecting rod. I cut the stock back to what I needed m put the shape in it, polished it and then parted it off. The image is of the rod ready for fitting accompanied by the remainder of the stock. That took an hour and a quarter but I think I have it right with no mistakes so now I deserve my breakfast!