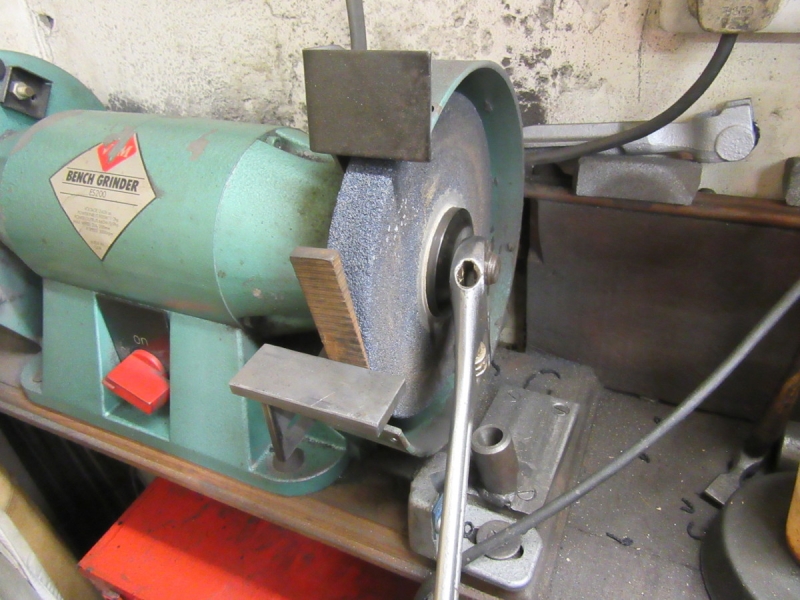

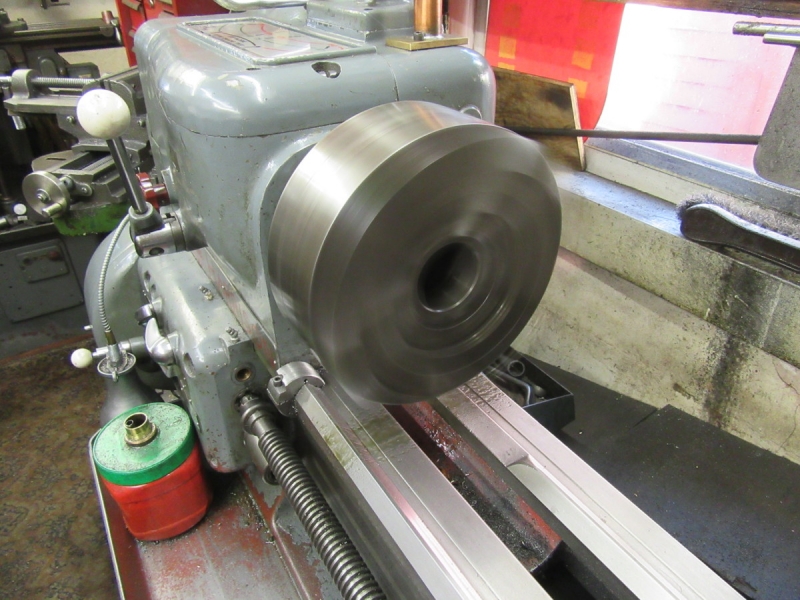

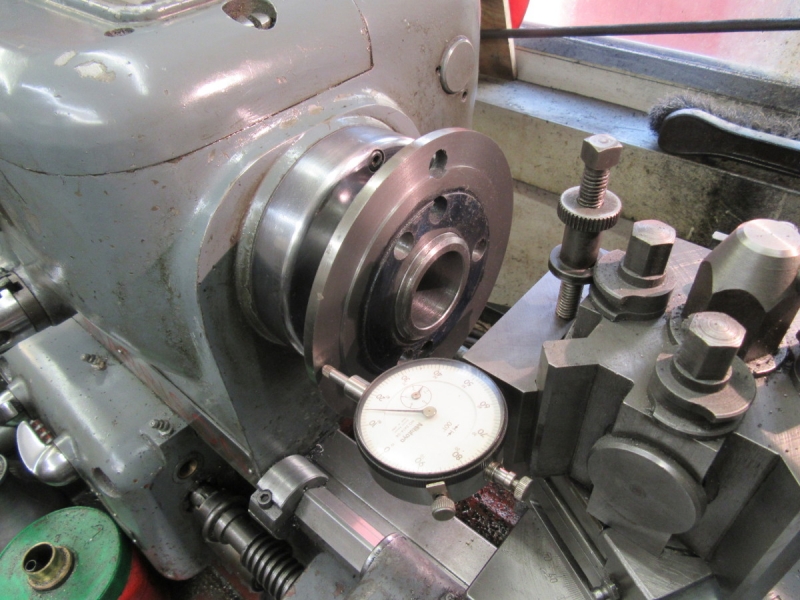

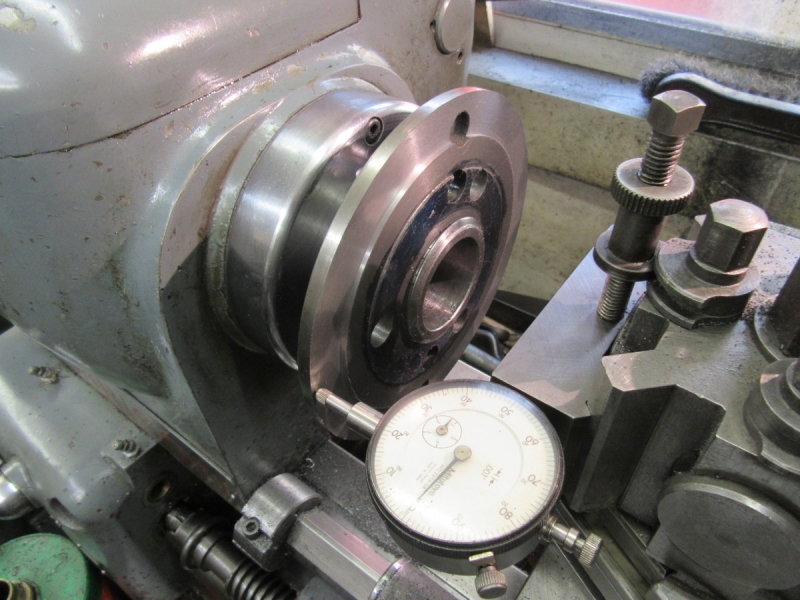

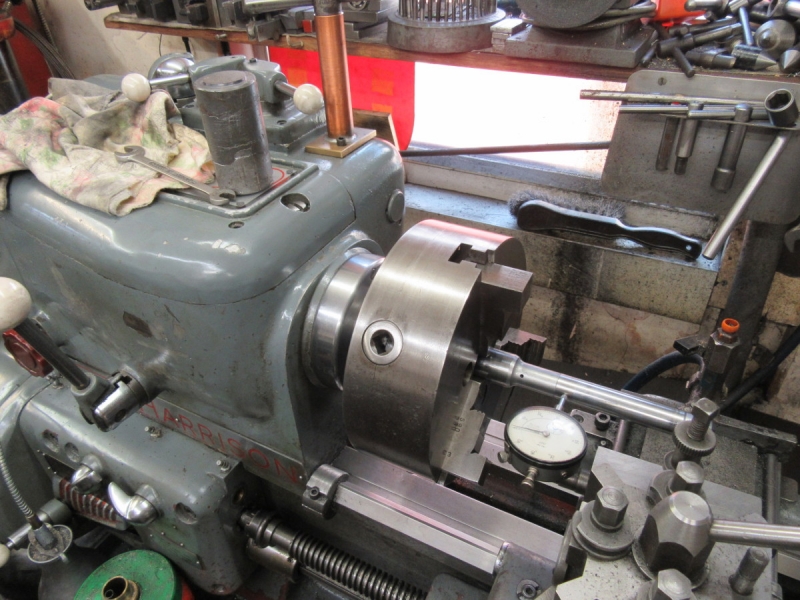

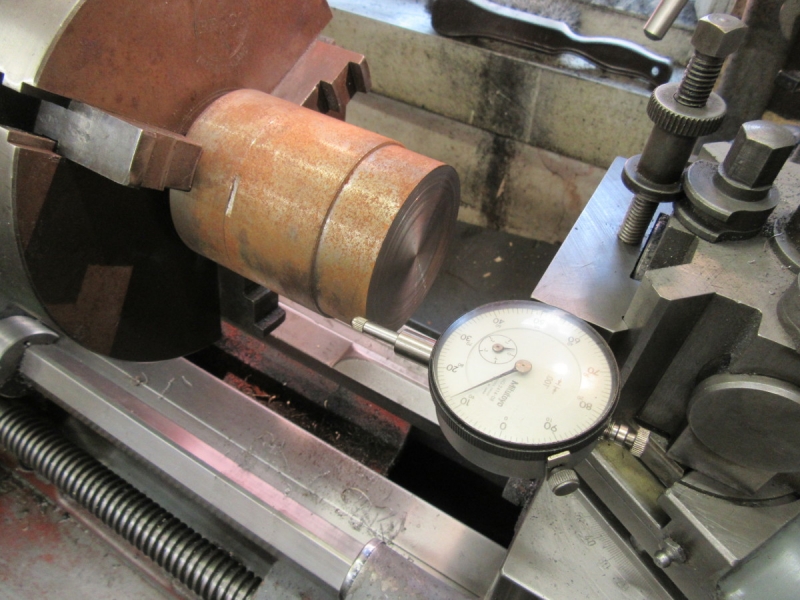

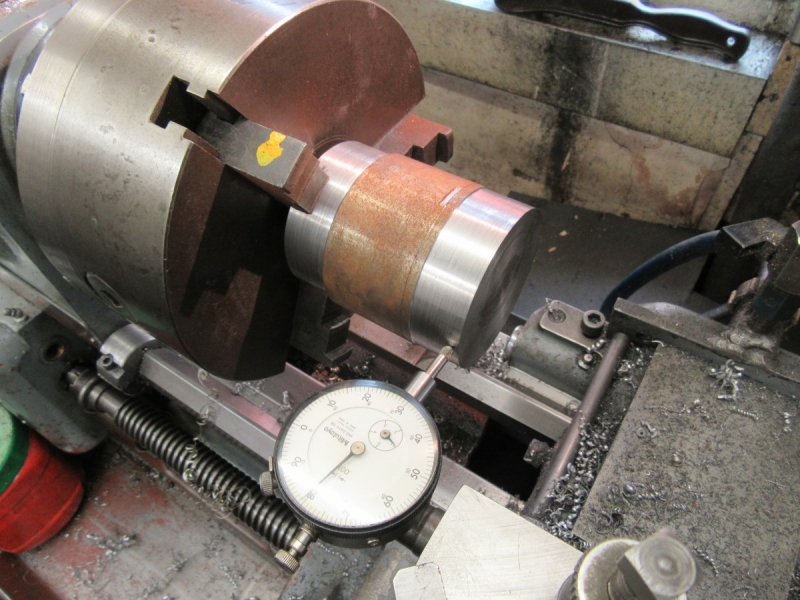

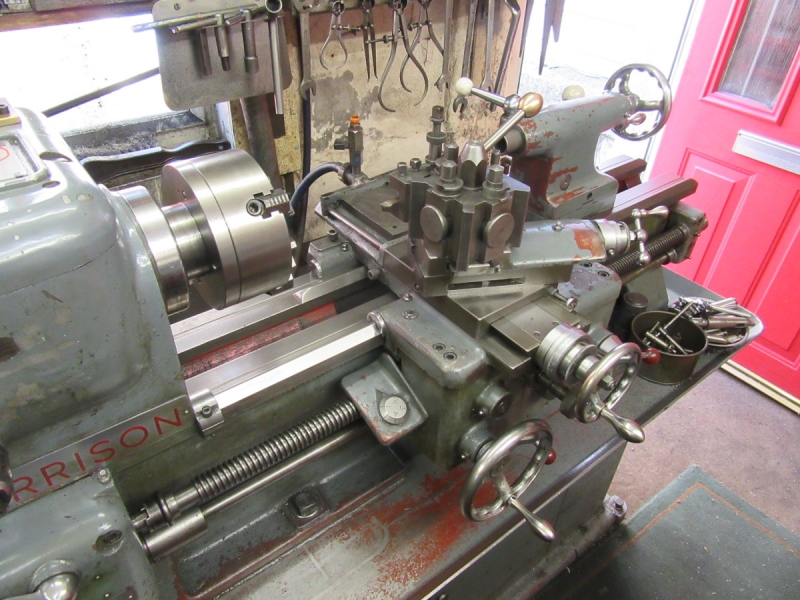

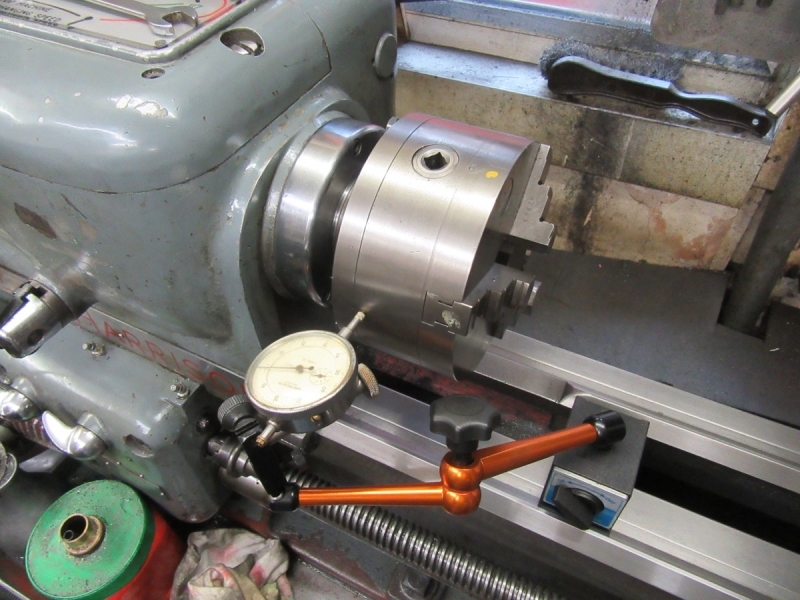

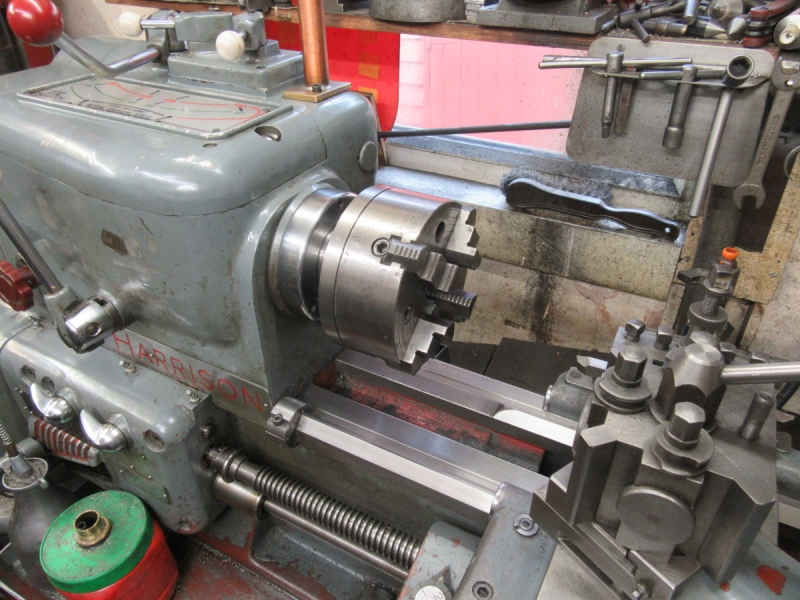

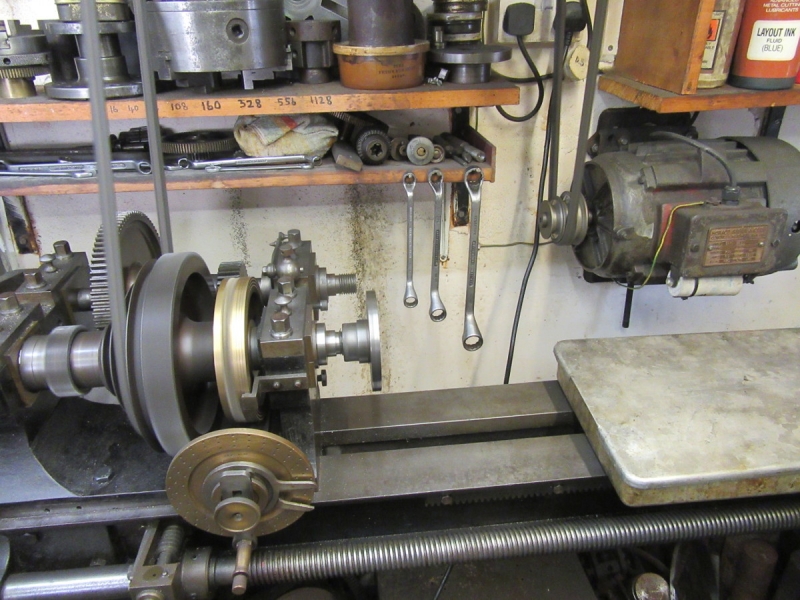

A rare event this morning, I fired up Johnny's big lathe because it was the easiest way to clean the original back plate to get an accurate measurement. It also gave me an excuse to oil the lineshaft and headstock. One thing that surprised me was that the backing plate doesn't run concentric on the spindle. Very surprising on anything to do with Johnny.... Then I repeated my measurements....

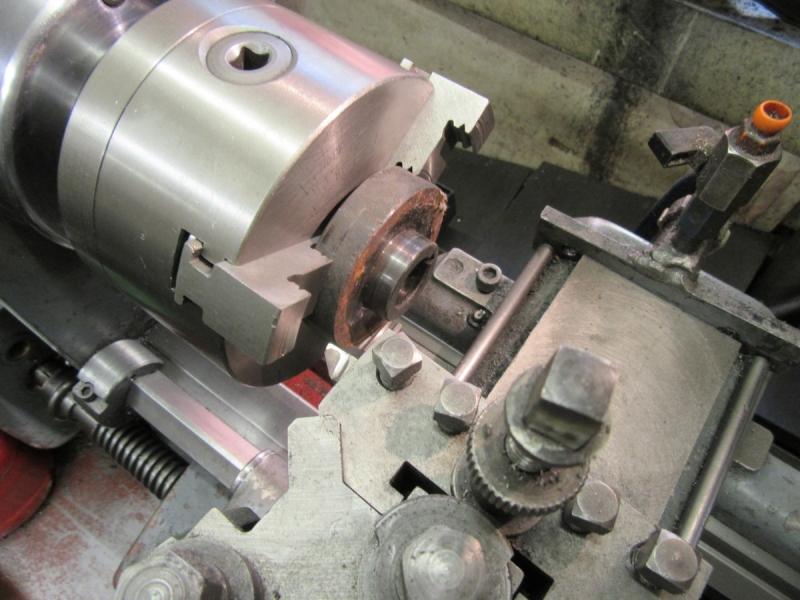

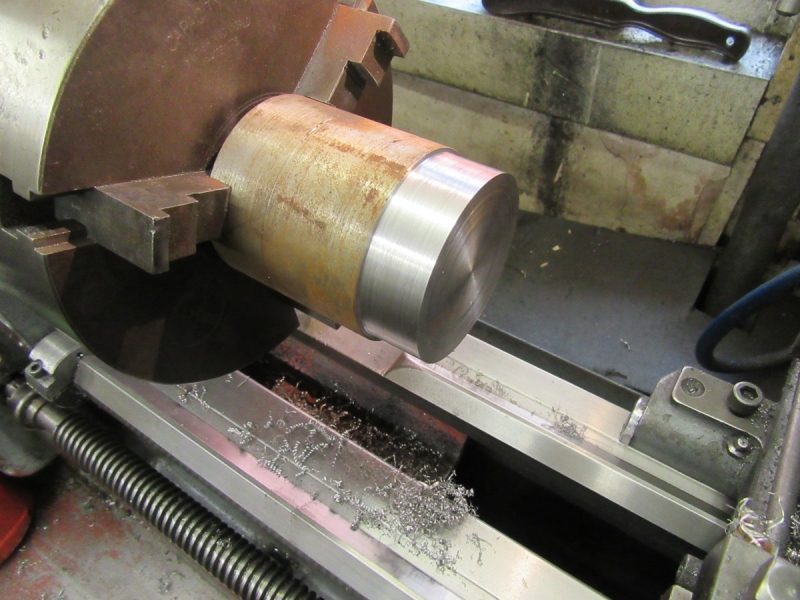

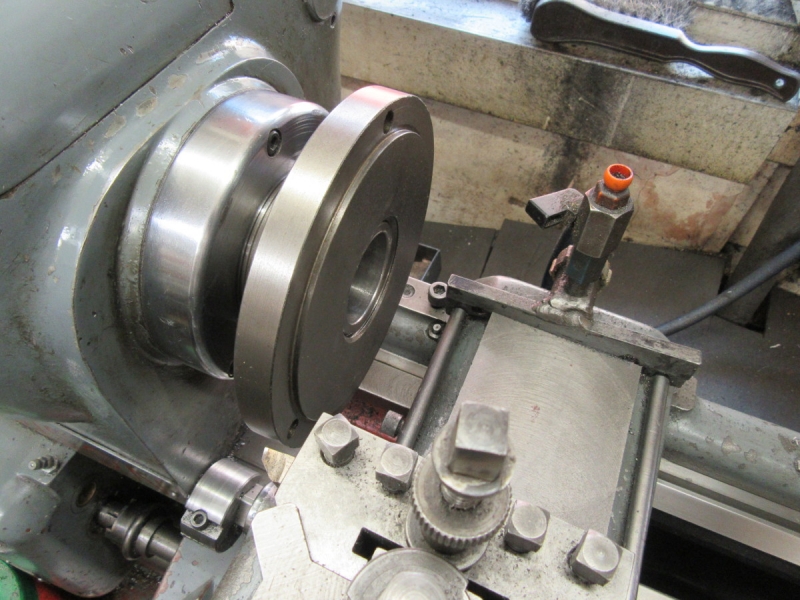

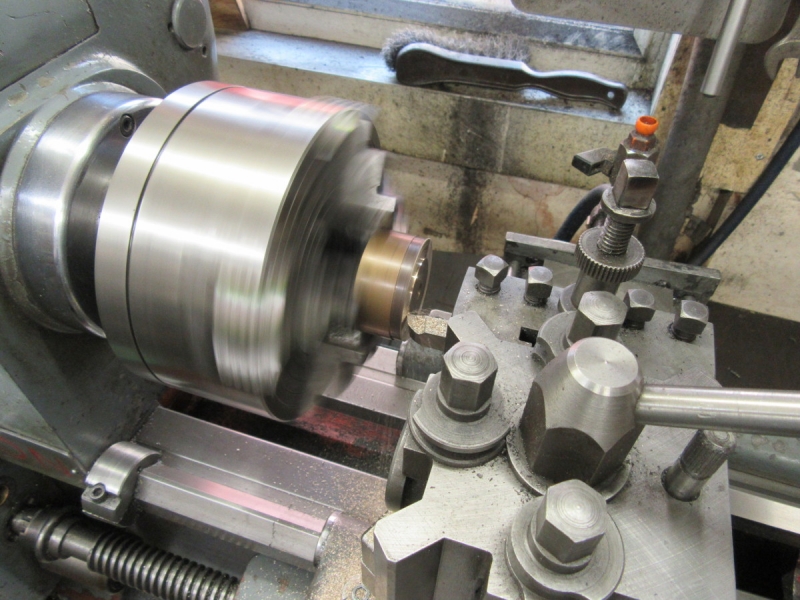

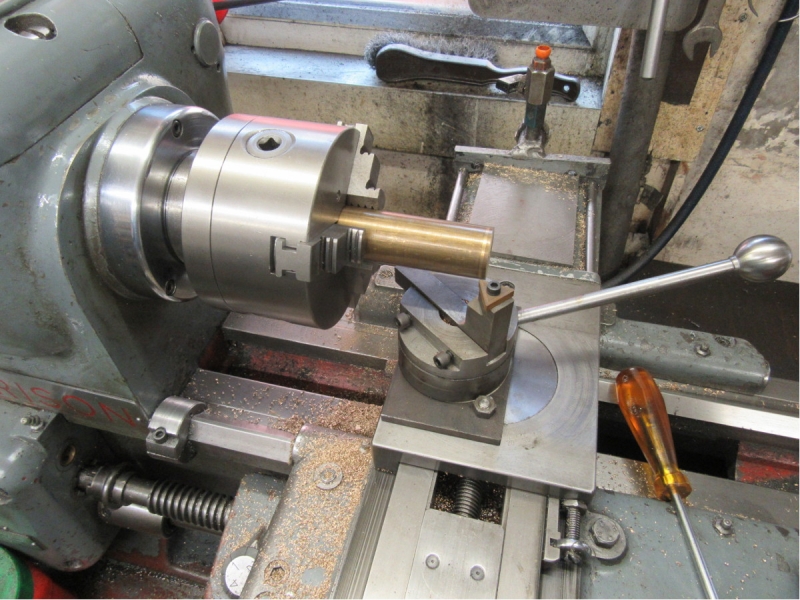

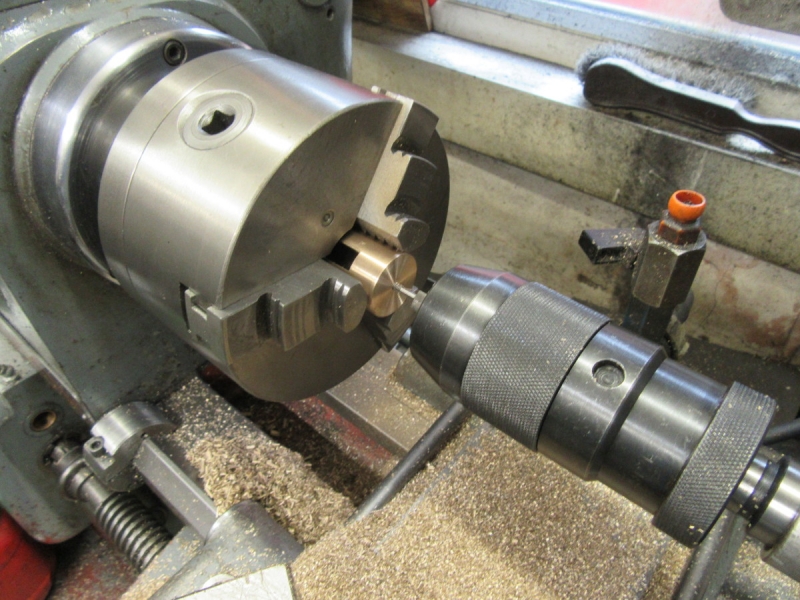

I made the first cut according to the calculations but before I took the last two thou off I checked it with the callipers, still the best way of checking. As it happened the original measurements were spot on.

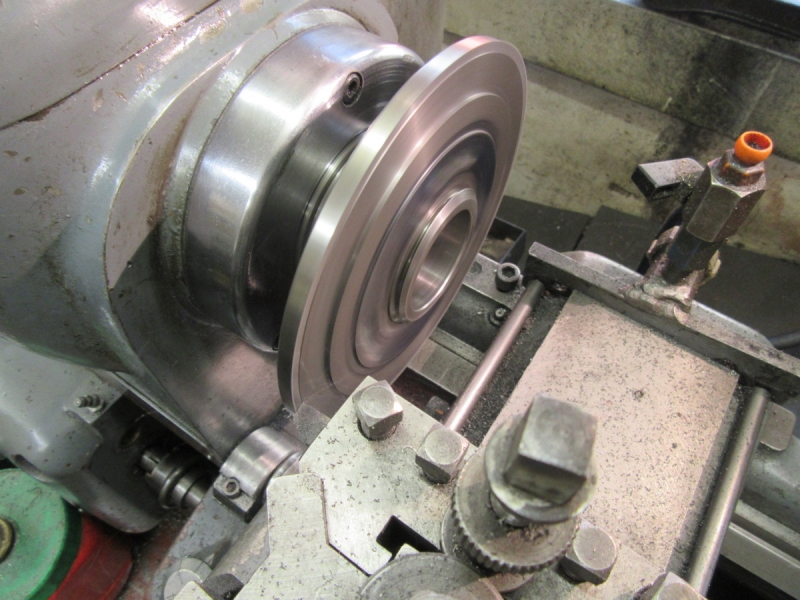

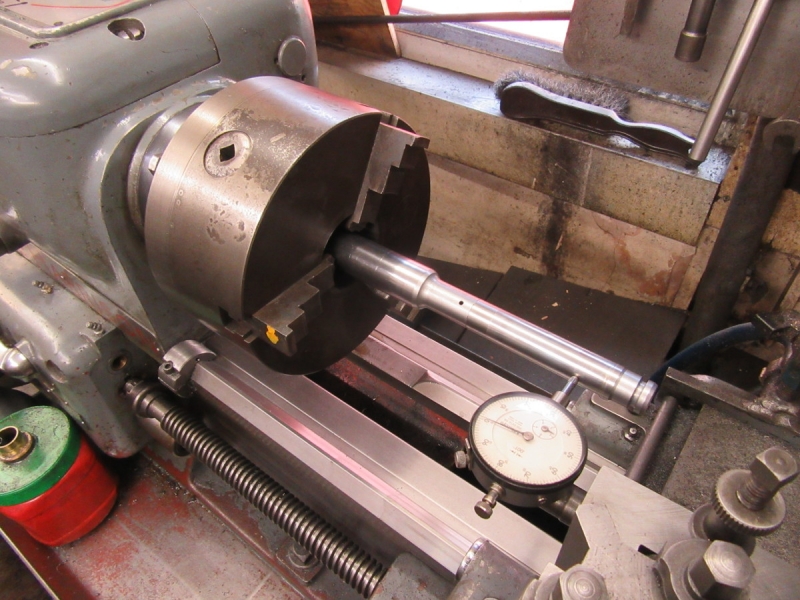

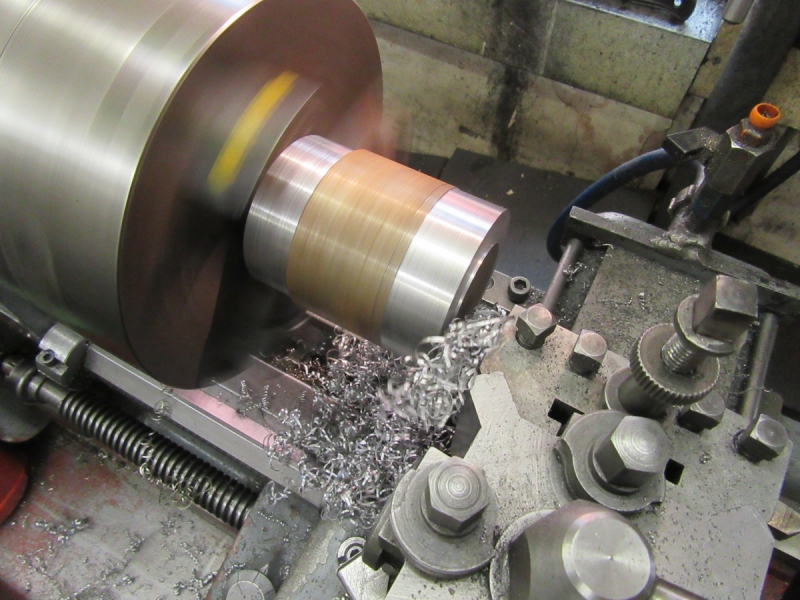

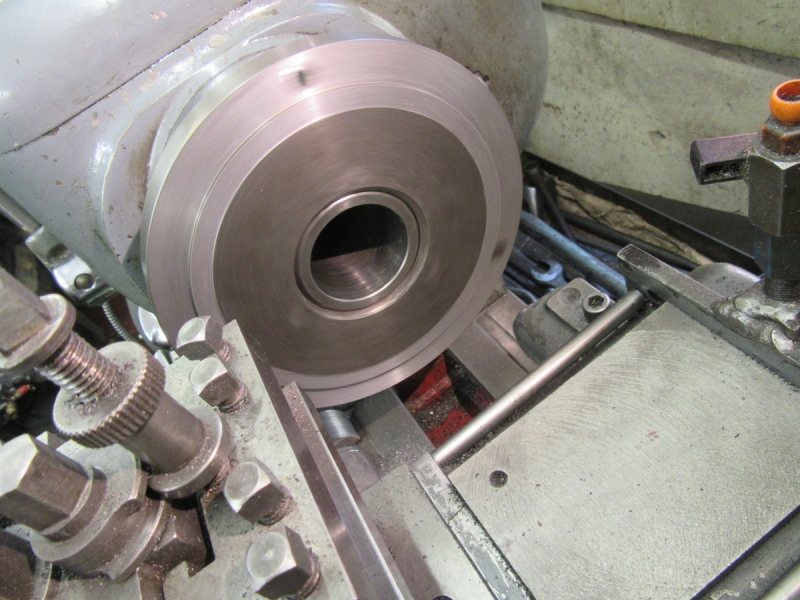

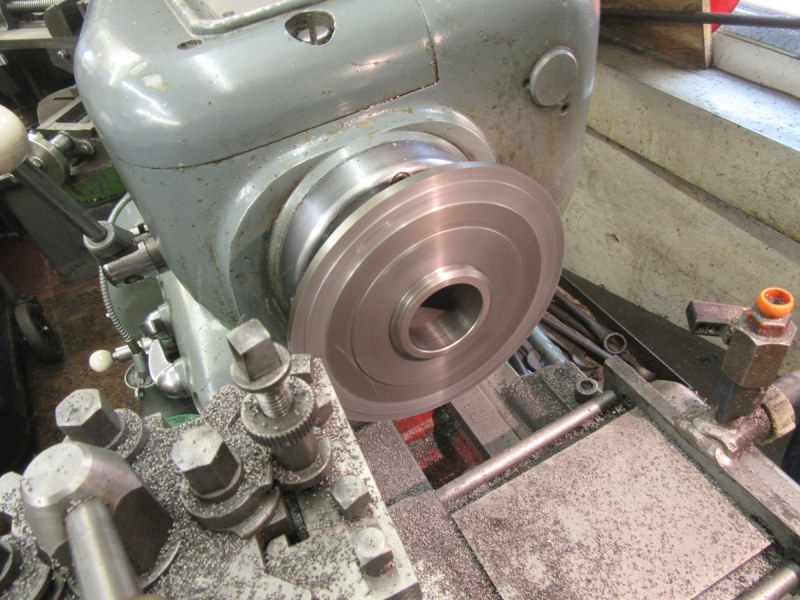

Taking the final cut to make sure we have the enough entry......

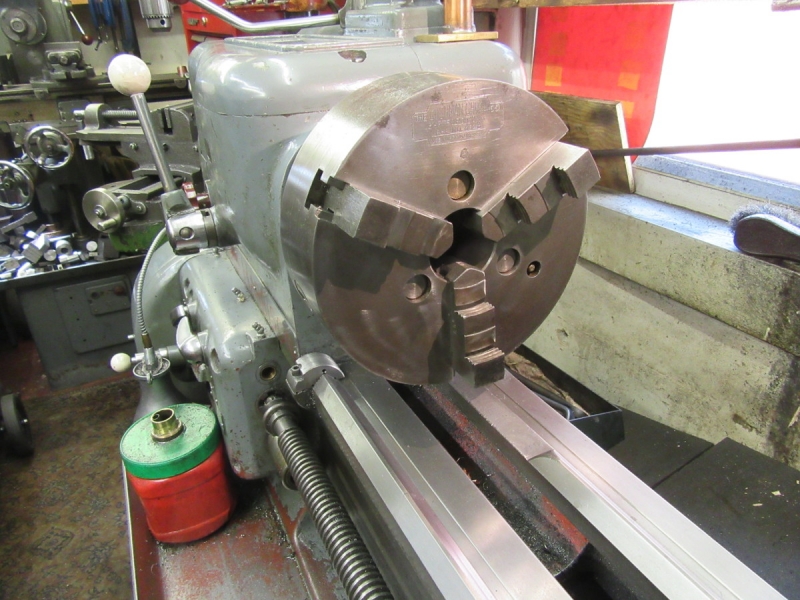

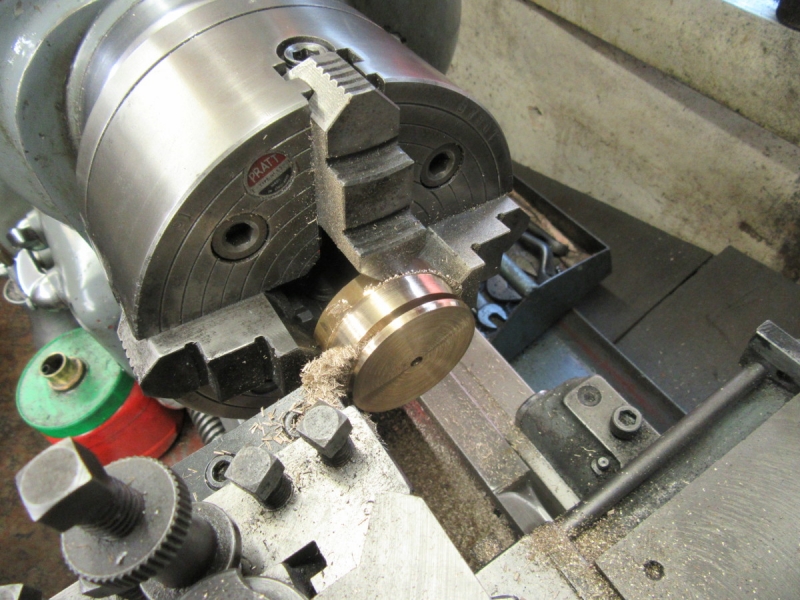

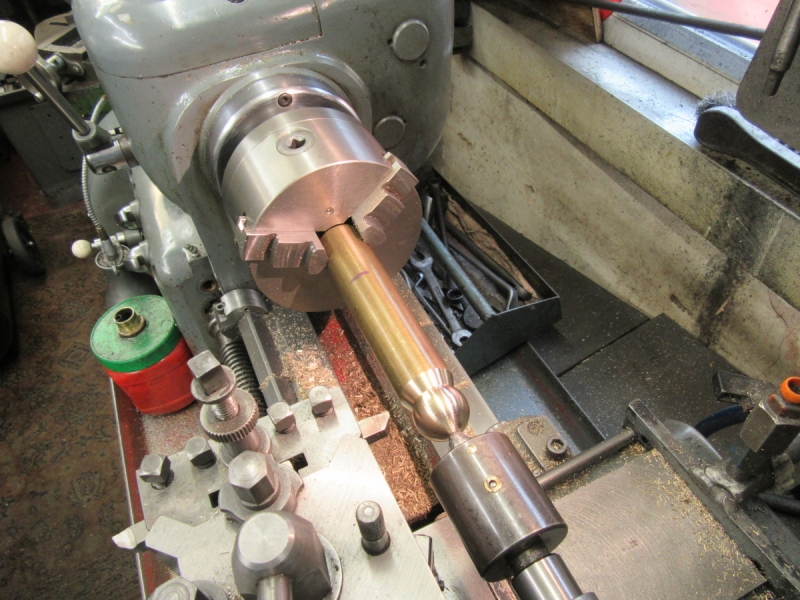

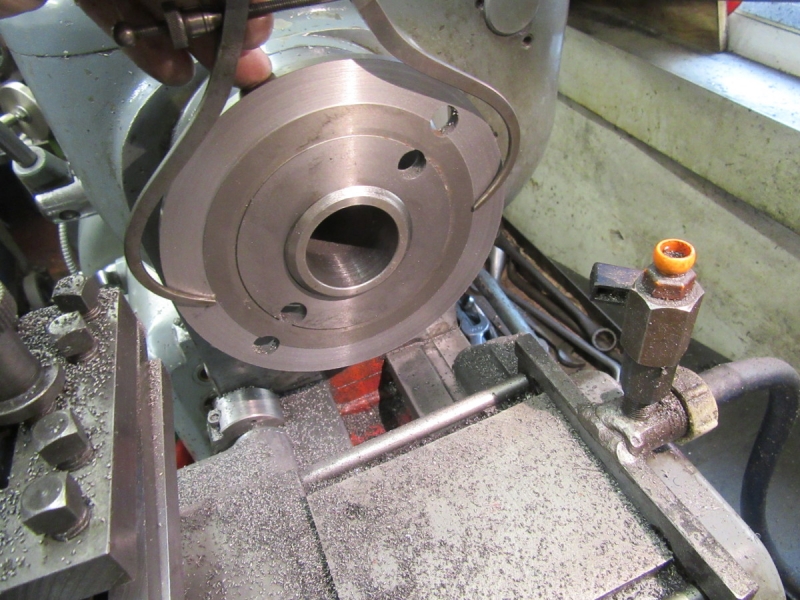

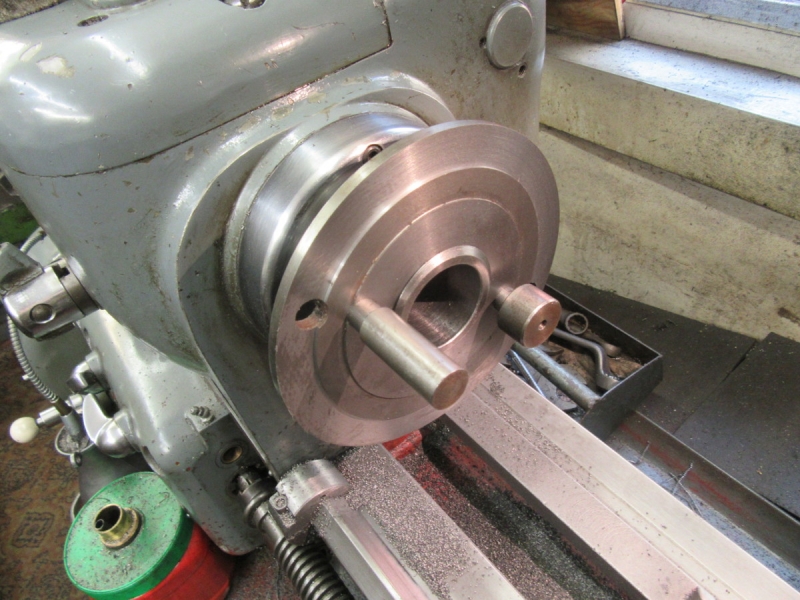

I had to temporarily put the catch pegs back in to give me grip to get the plate off the nose.

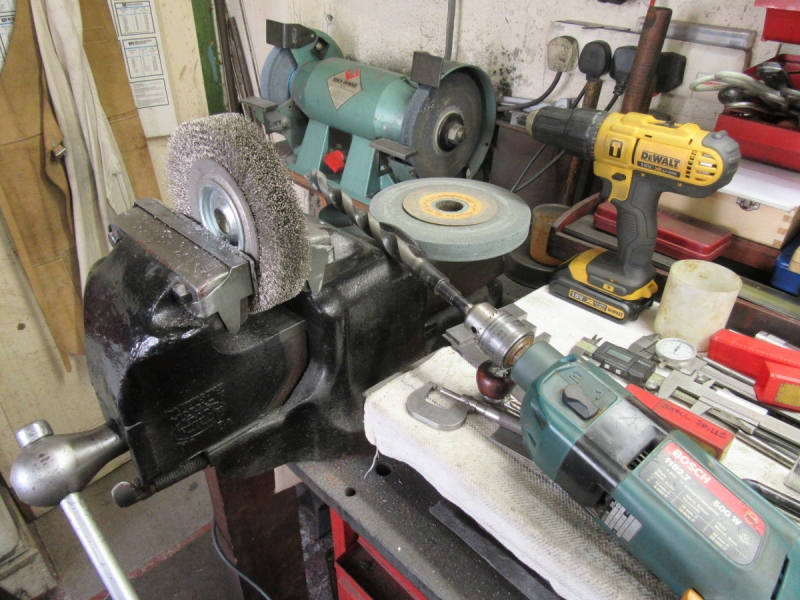

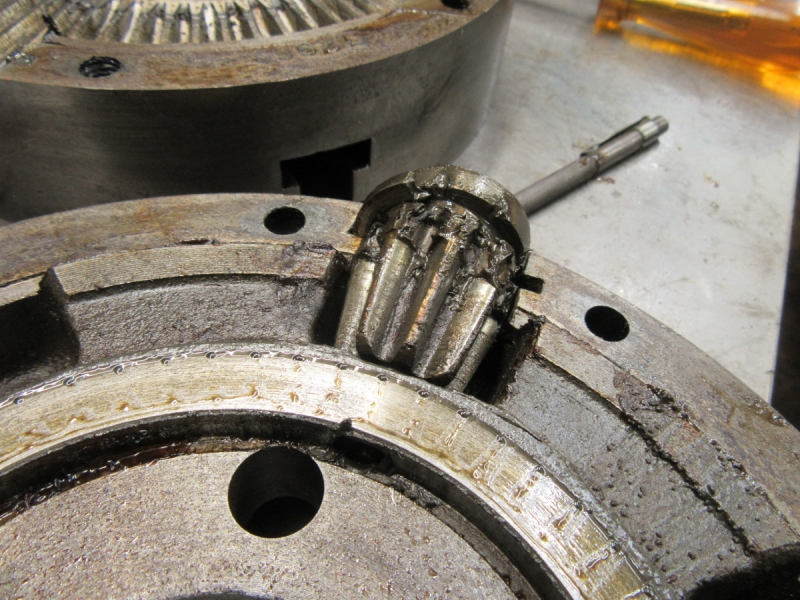

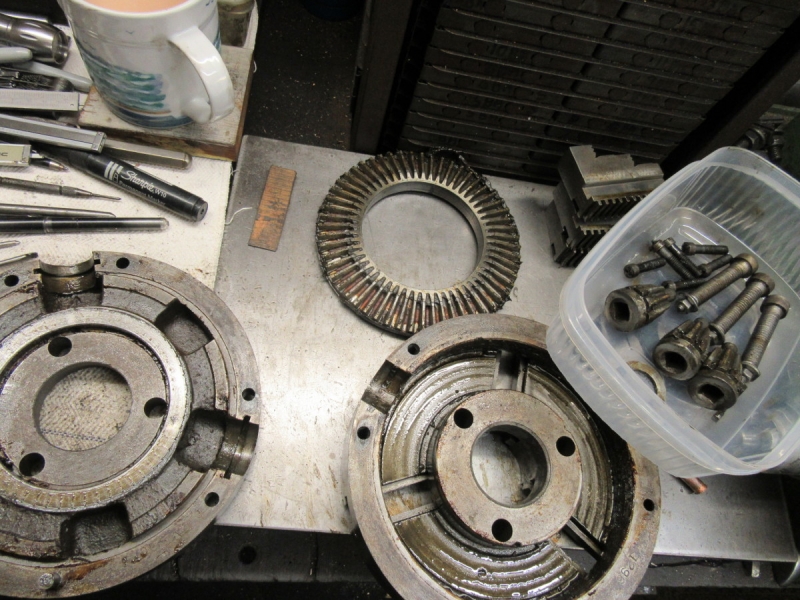

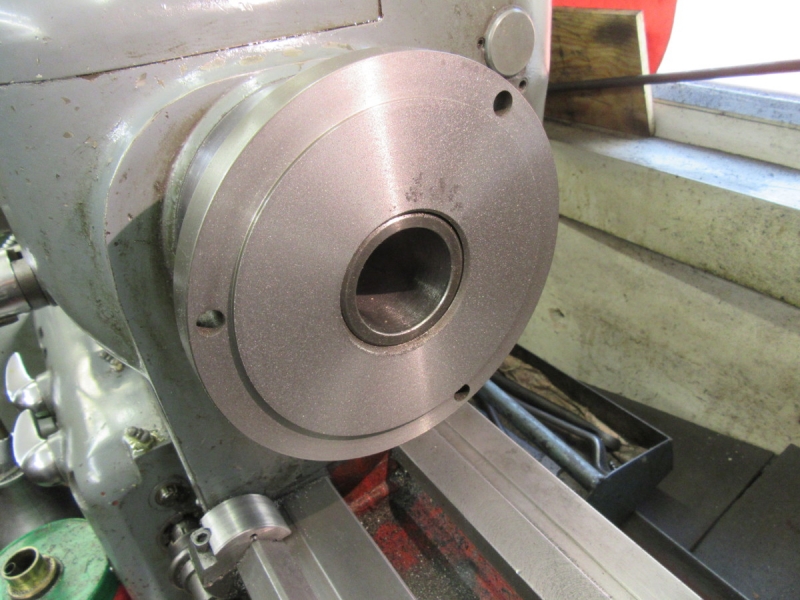

Then I had a trial fit, it's lovely, just right. By chance one of the holes coincides with one of the original bolts and I didn't see this one coming! I have been concentrating so much on getting a good fit it never entered my head. A bit of thought needed so I cleaned Mrs Harrison while I cogitated.

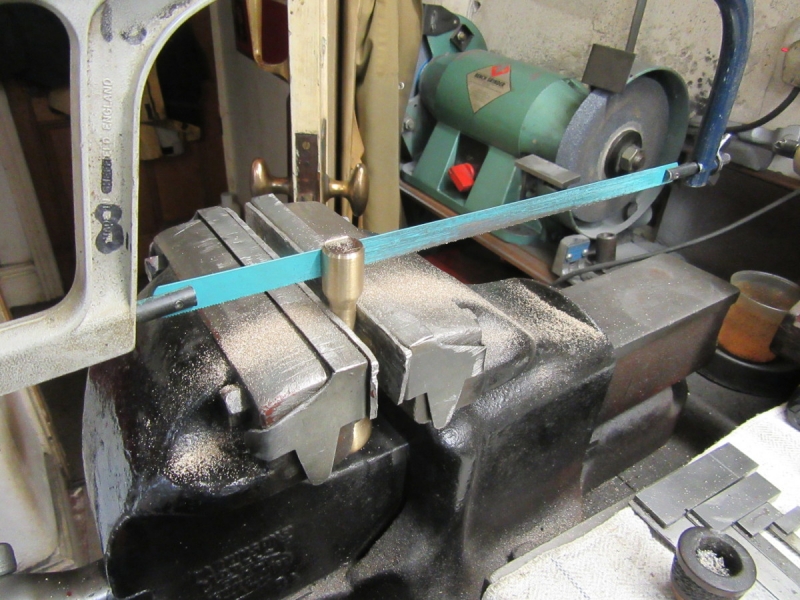

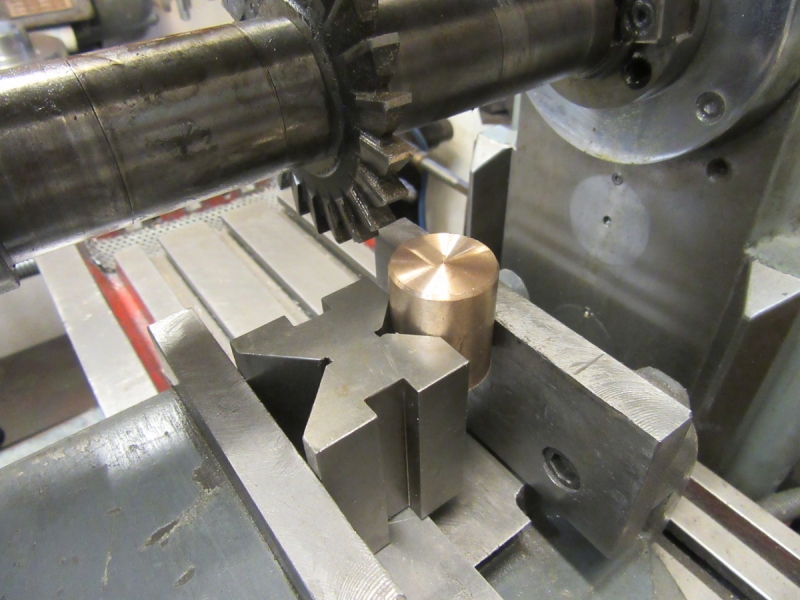

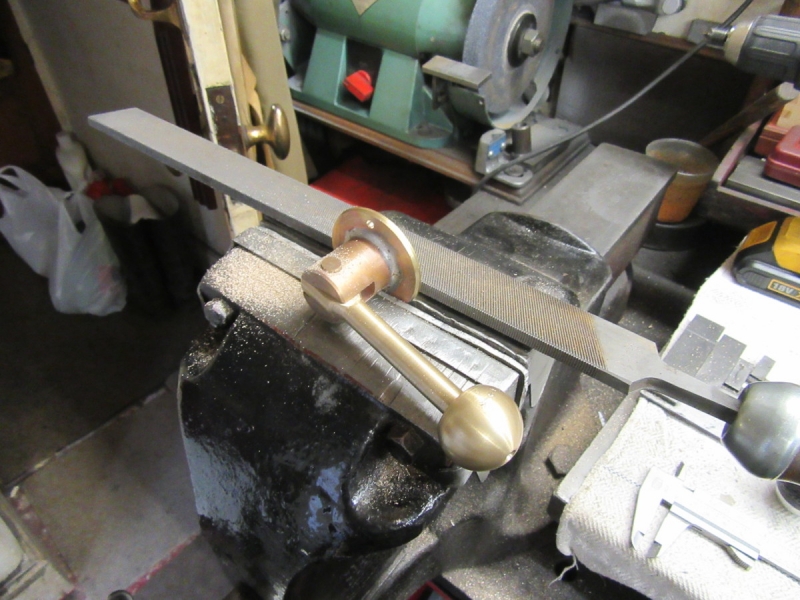

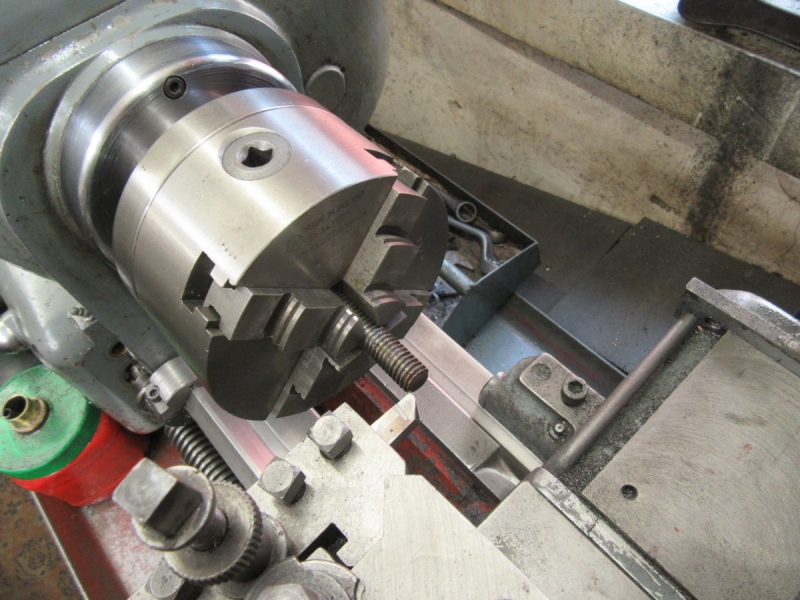

I have decided that this is the way out, turn the 1/2" bolts down to 1/4" and use a washer under each. 1/4" doesn't sound much but all they are doing is clamping the back plate in place. The good fit and the fact that the original bolt diameter is in the chuck and back plate is the main source of stability.

I got set up for tomorrow and took Jack out!