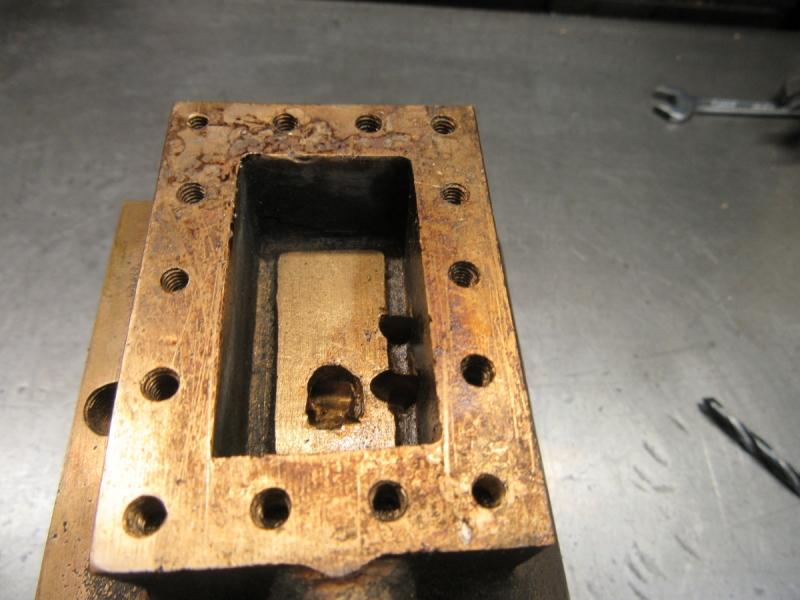

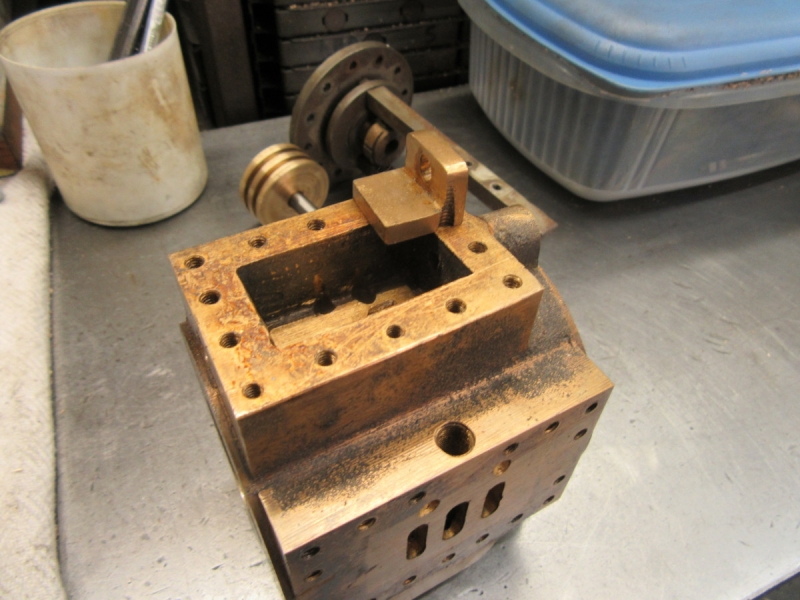

Some of you may recognise the traction engine cylinder that my mate Newton Pickles started on in the 1930s when he was a young lad and when he showed it to Johnny, his dad, he got a shock because he pointed out all the mistakes he had made. These included too many studs and some in the wrong place. This disheartened him so much he chucked it under the bench and never did anything with it. Eventually I was there when he decided to scrap it and I grabbed it.

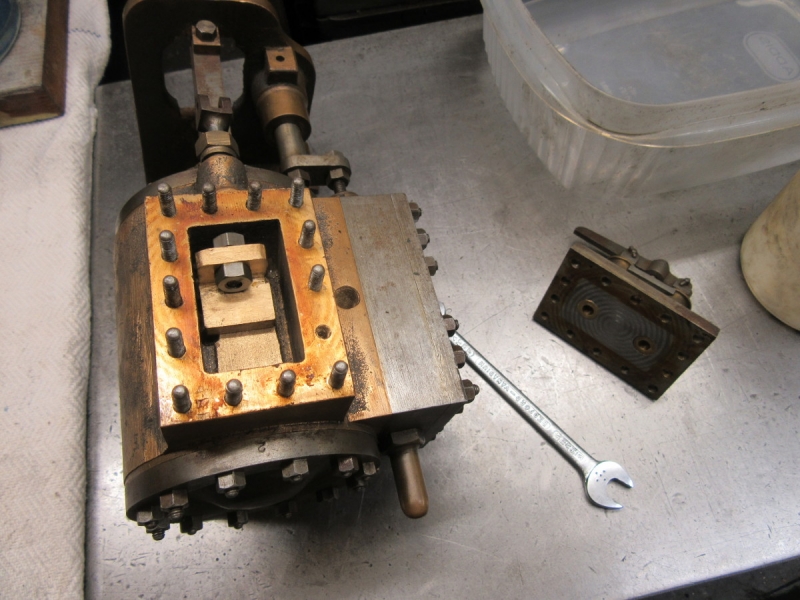

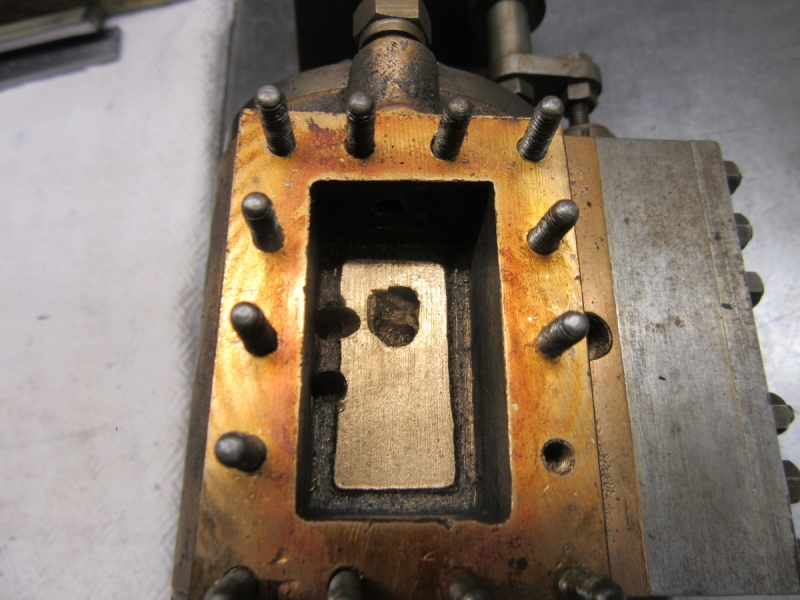

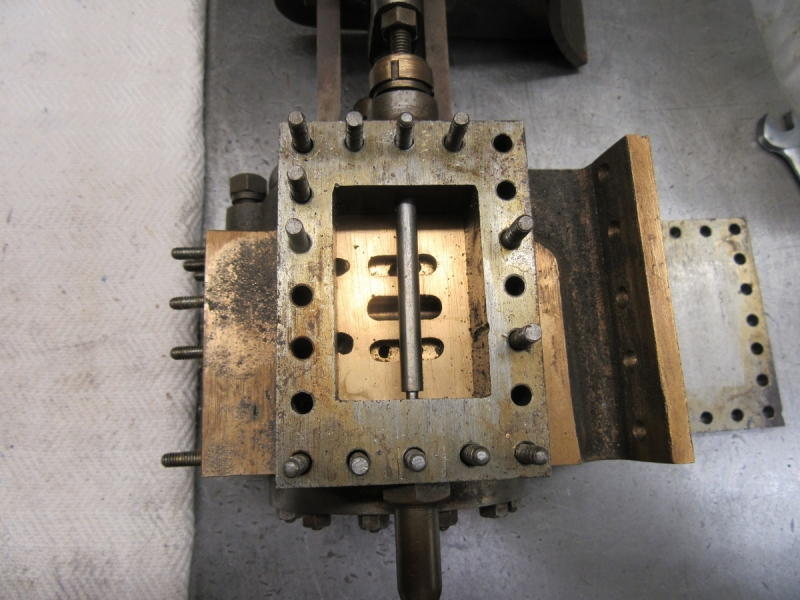

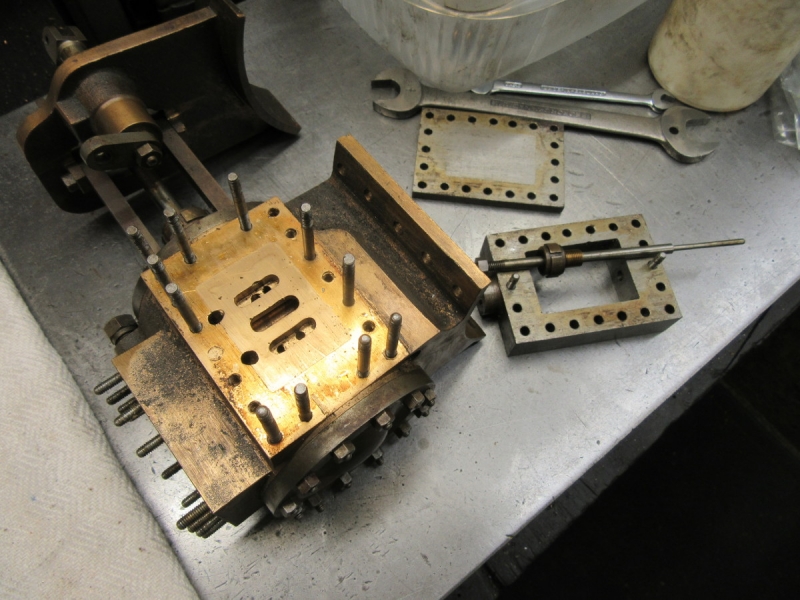

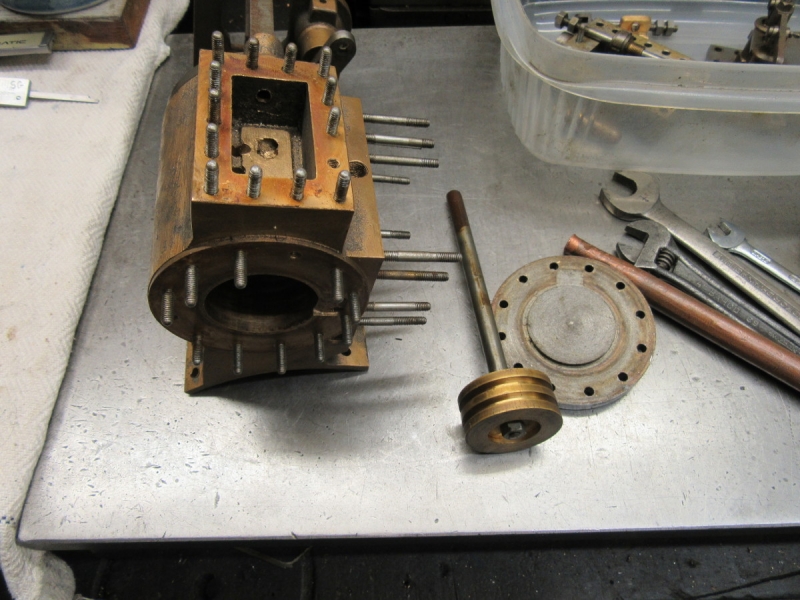

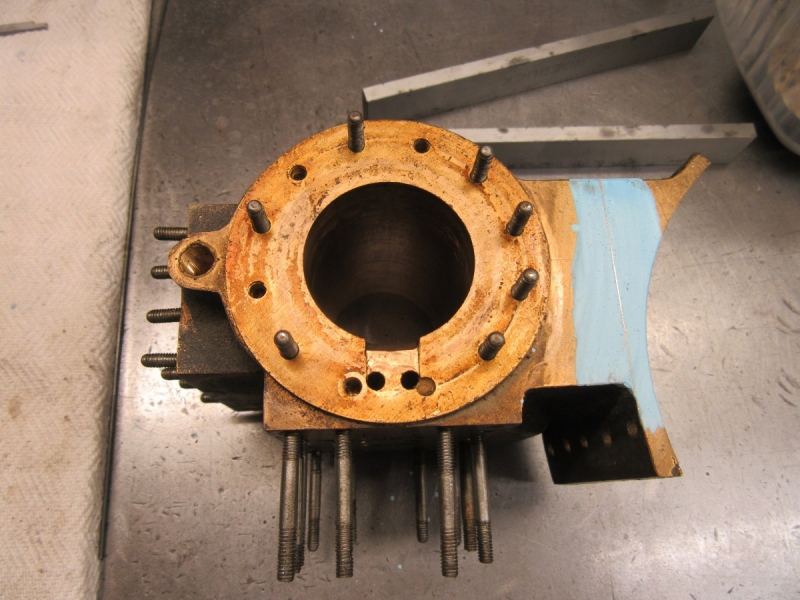

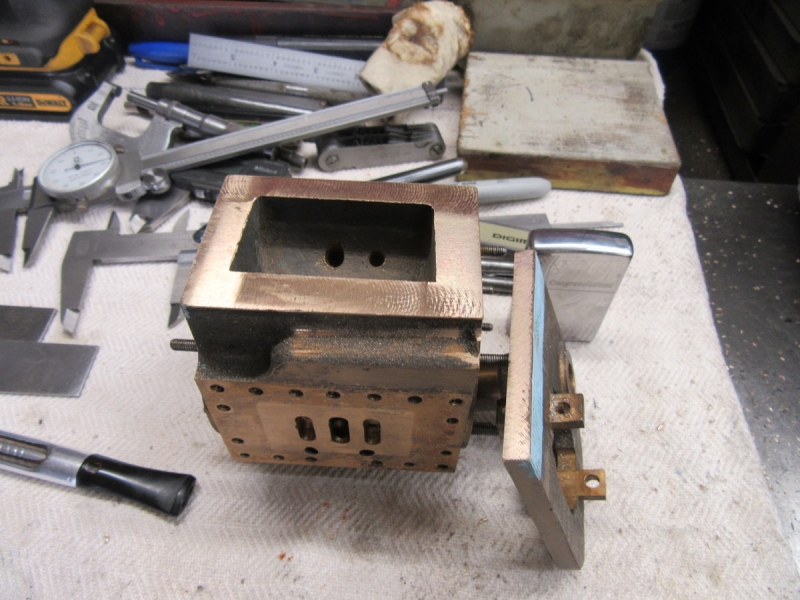

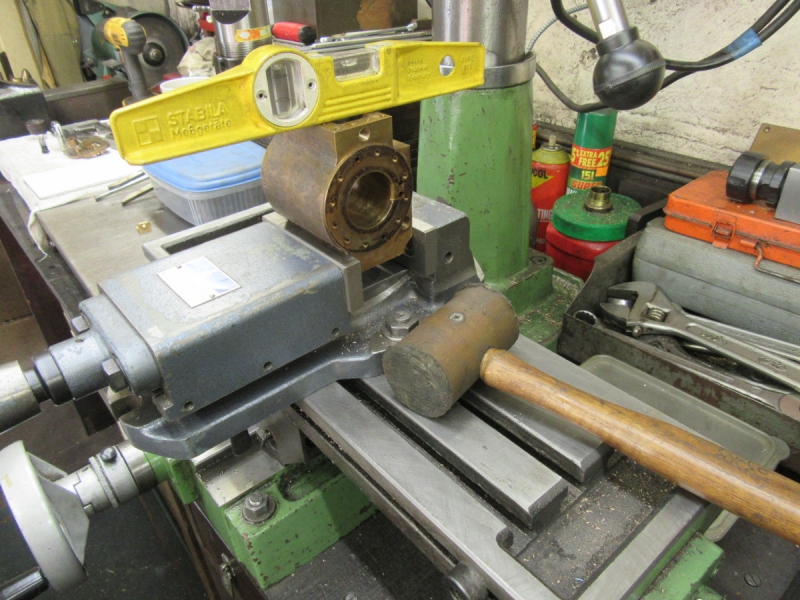

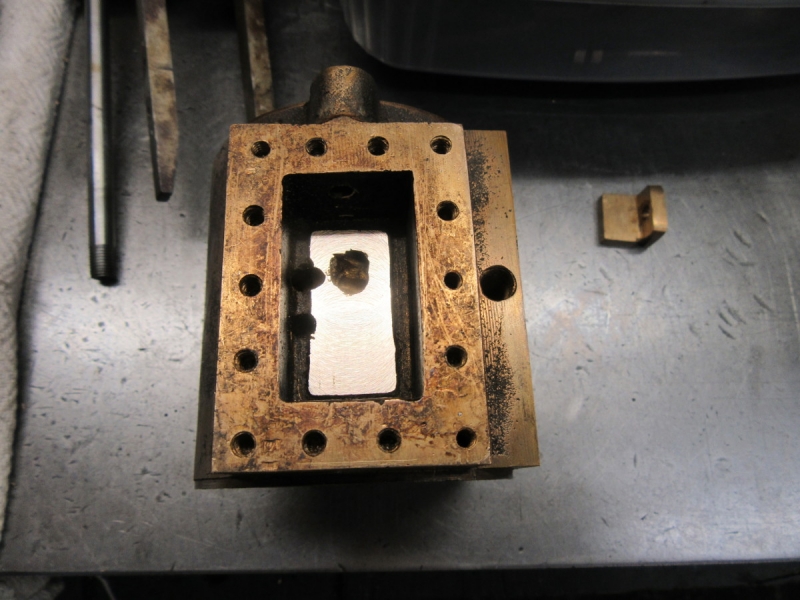

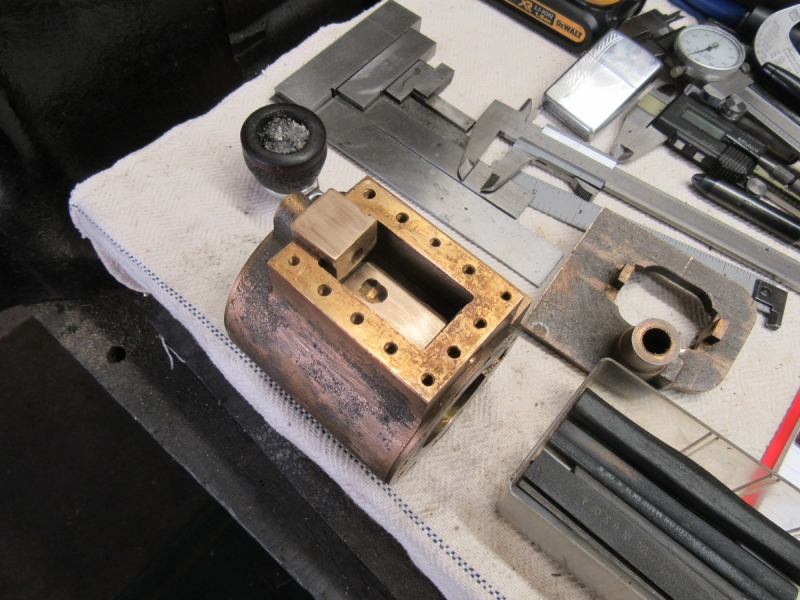

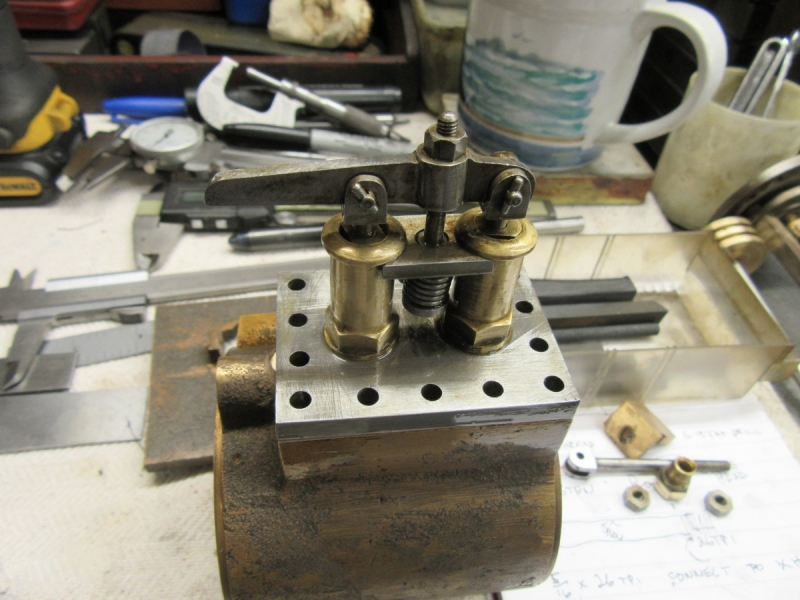

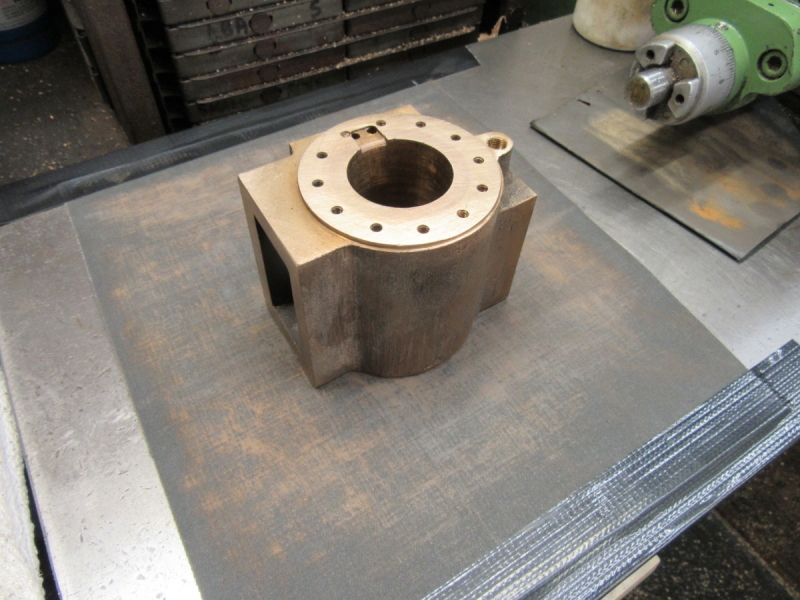

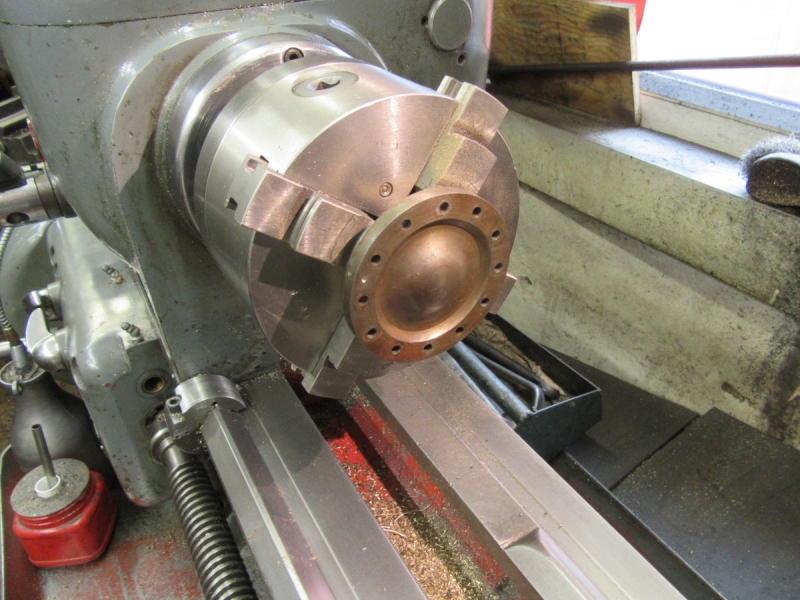

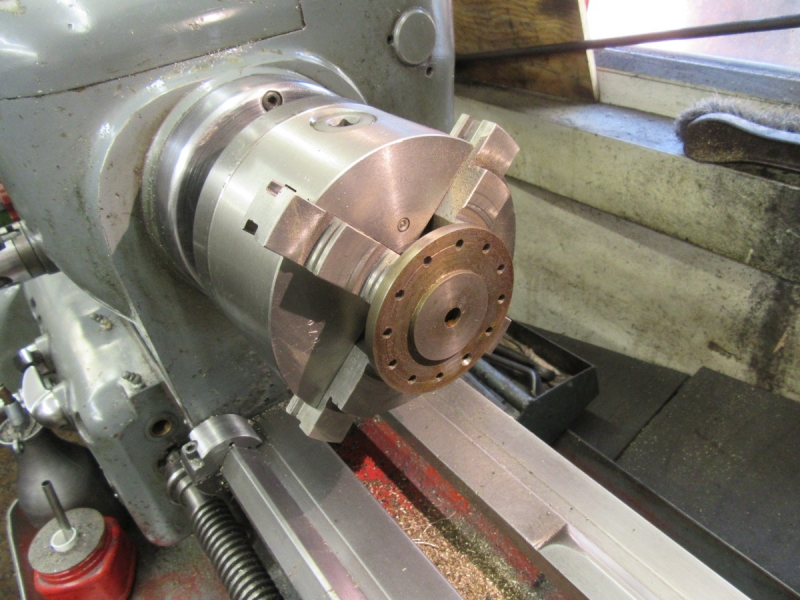

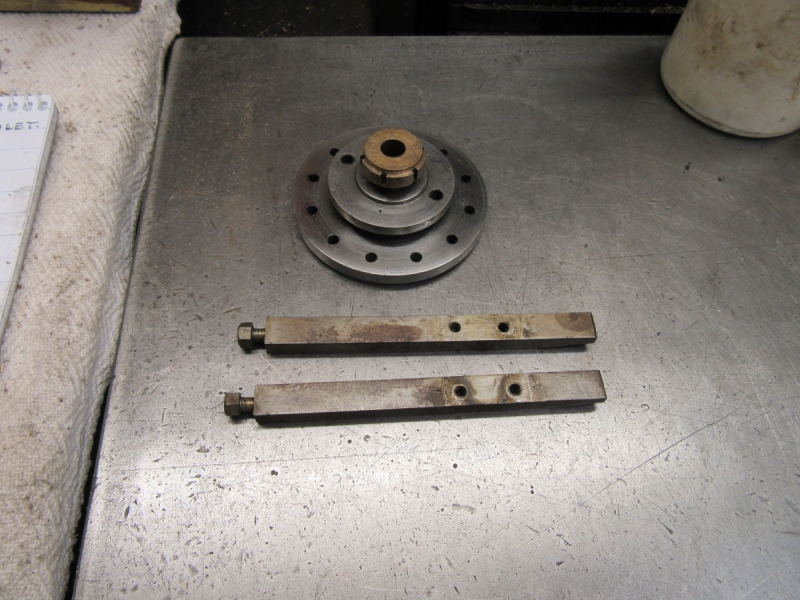

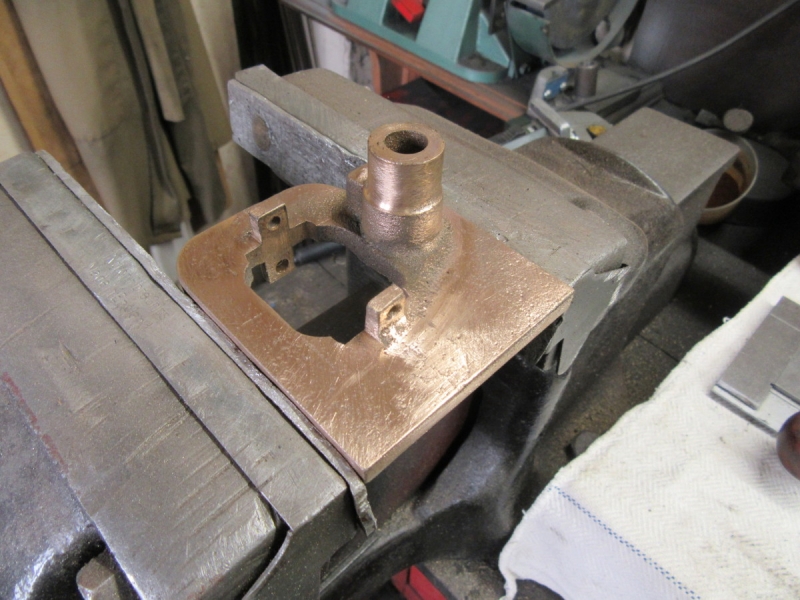

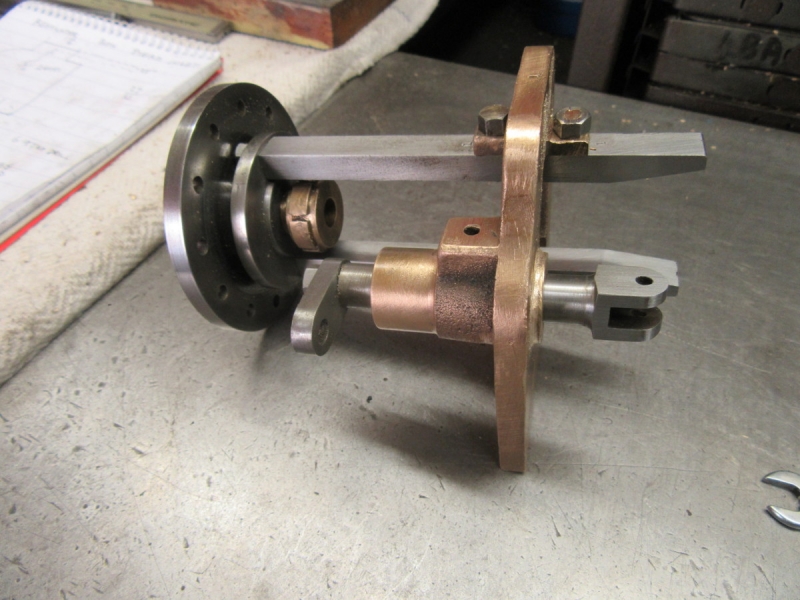

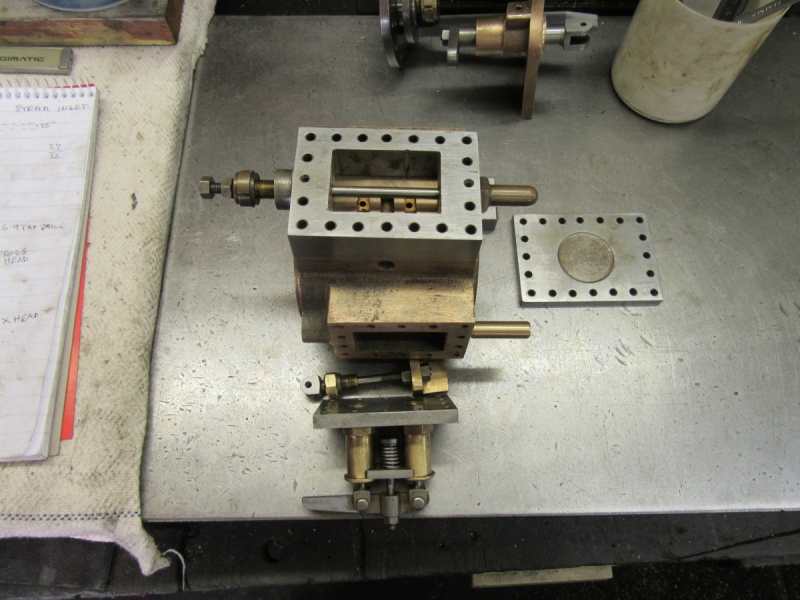

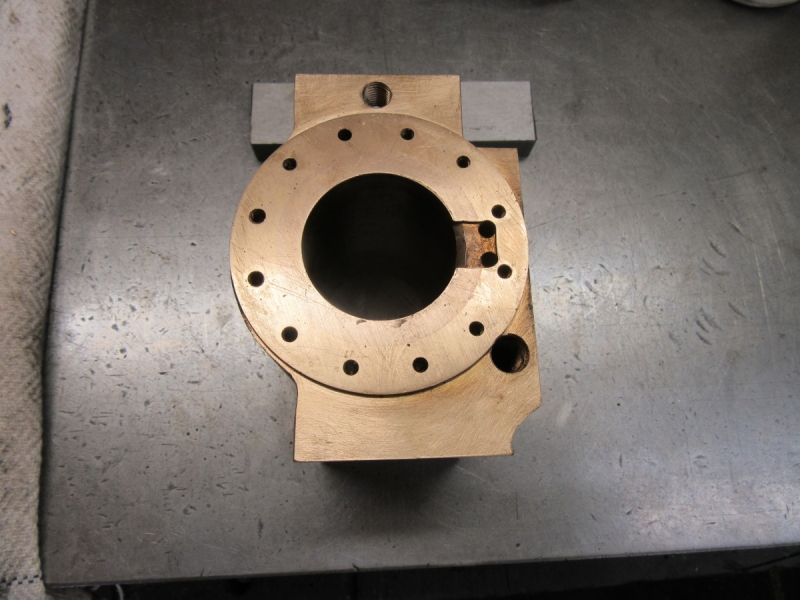

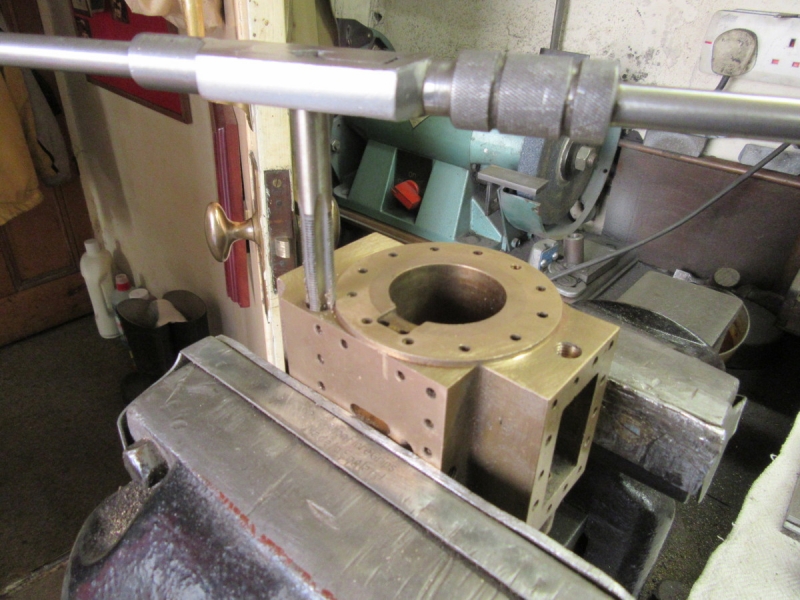

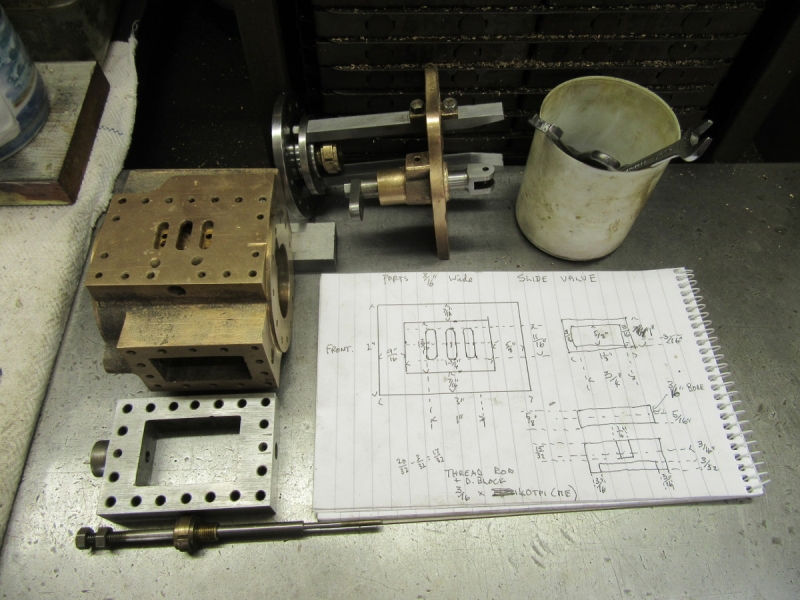

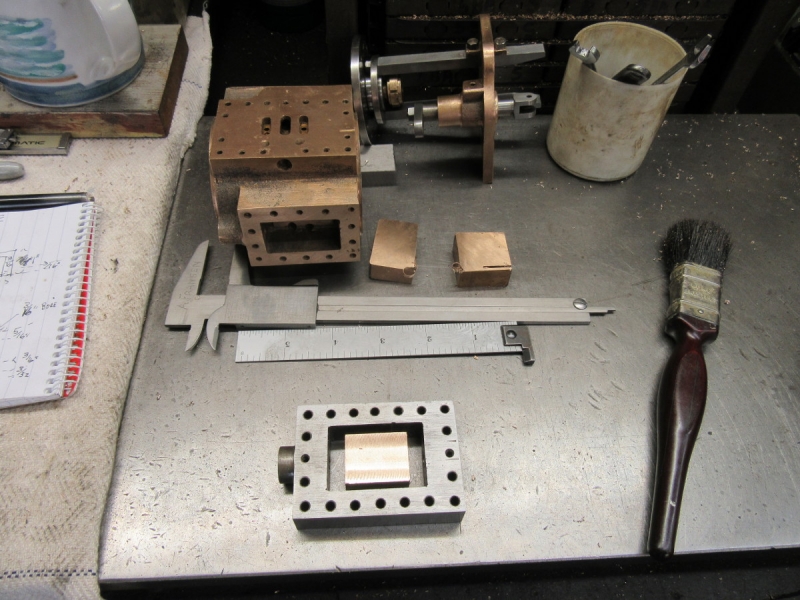

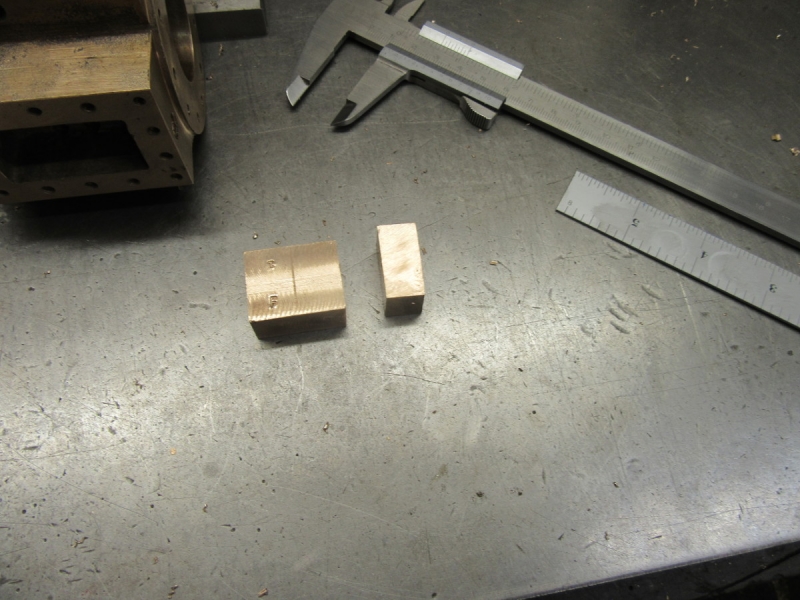

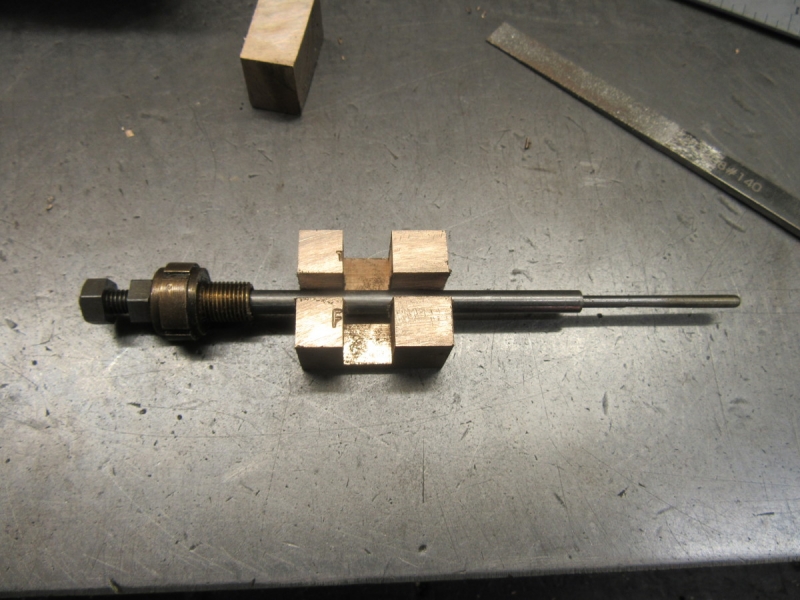

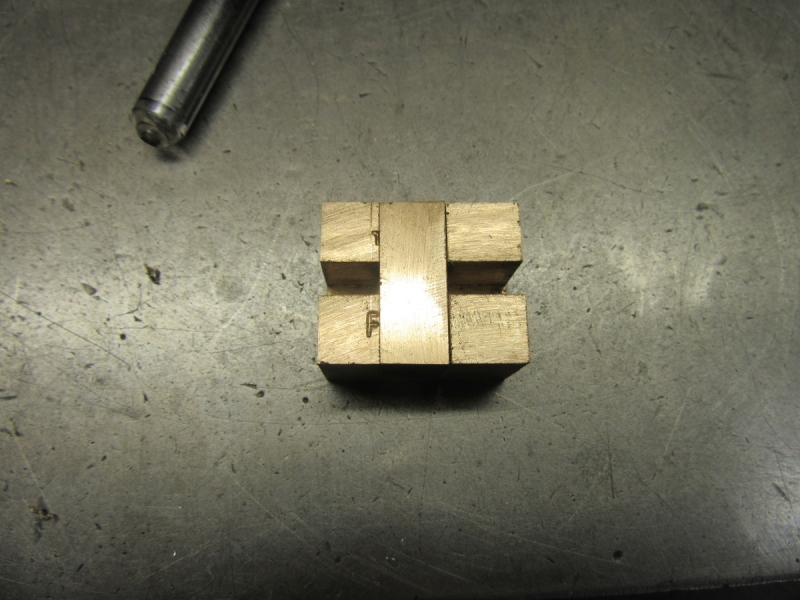

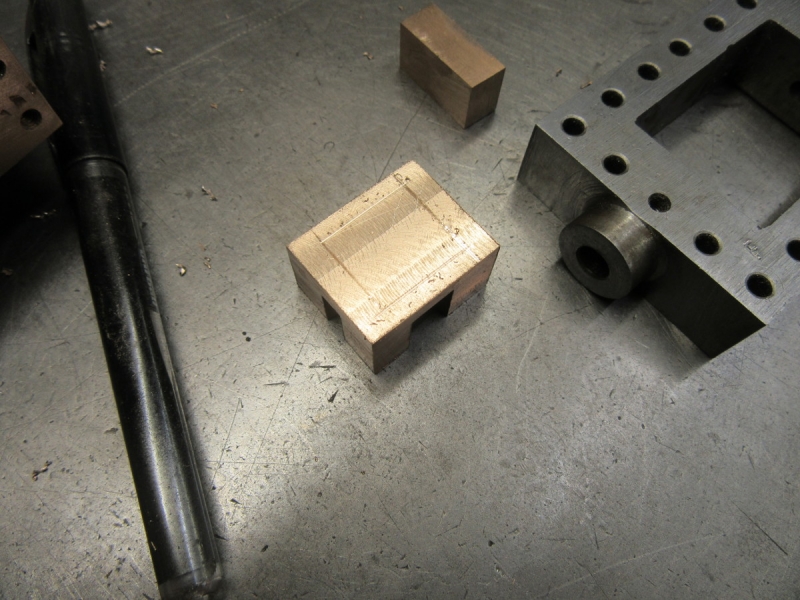

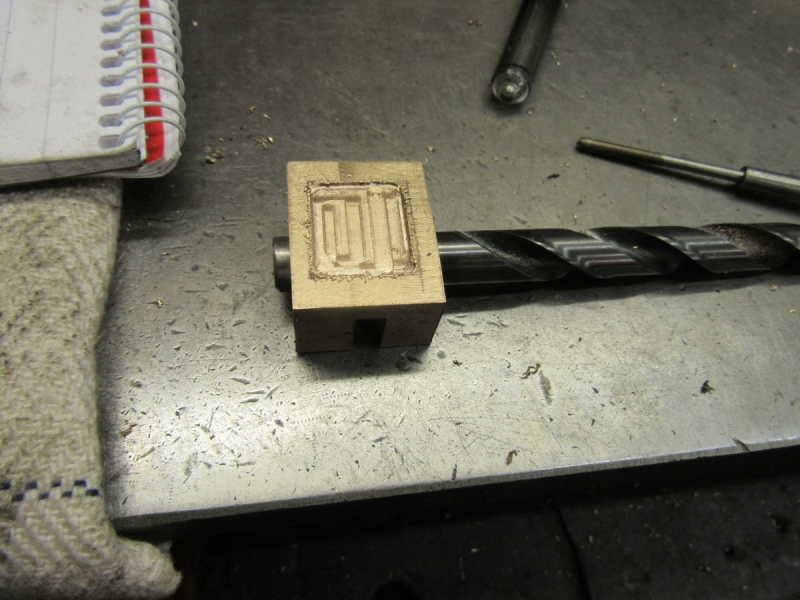

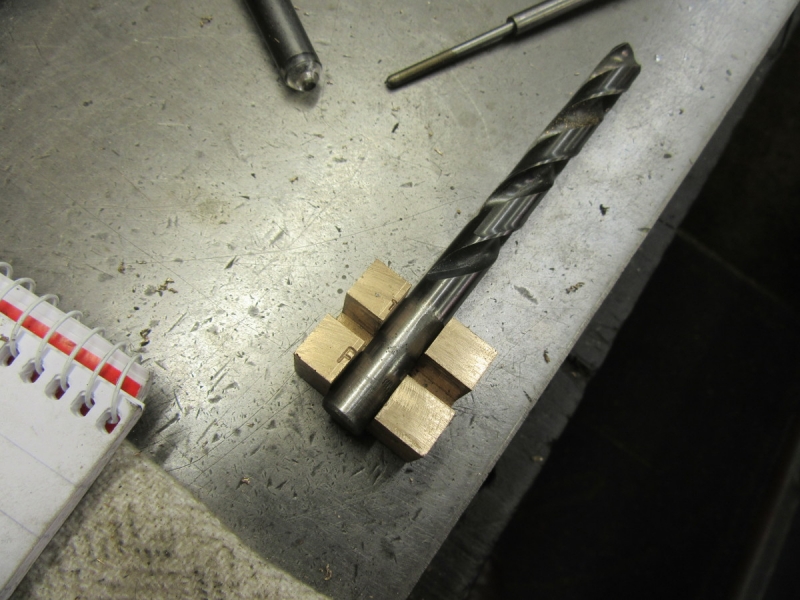

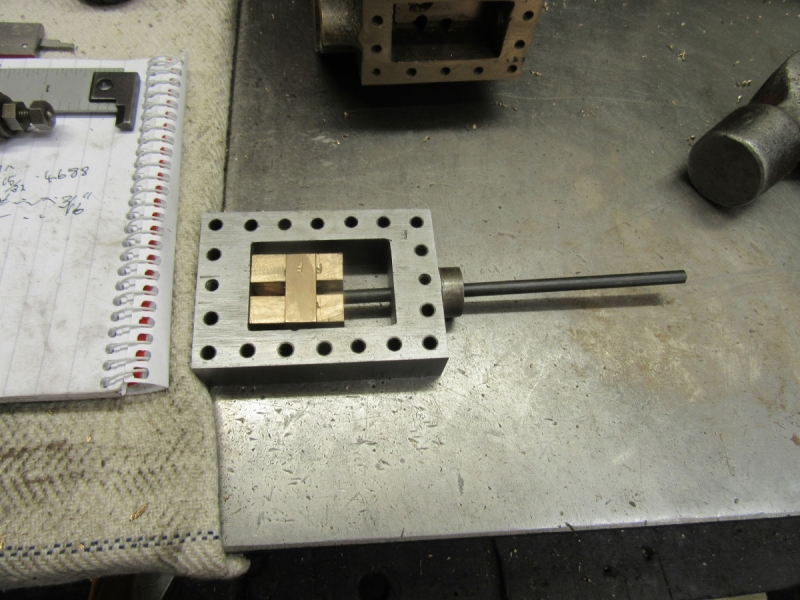

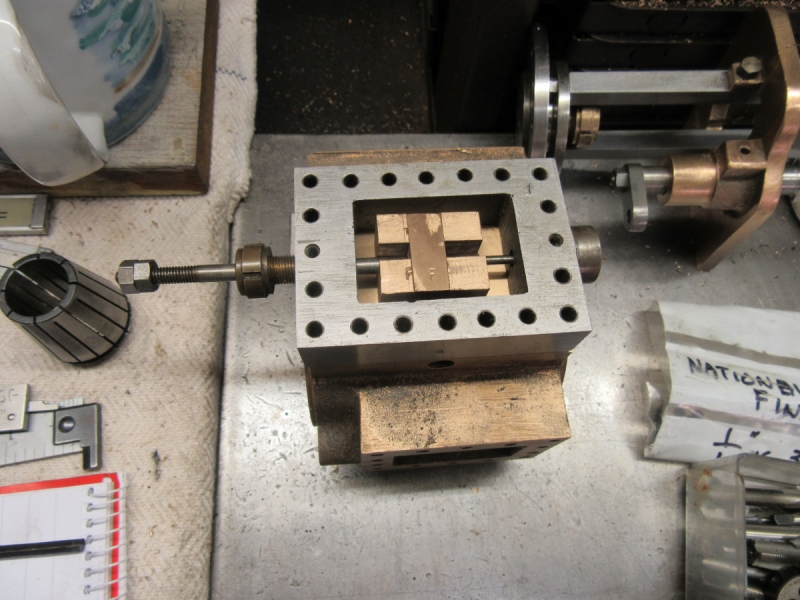

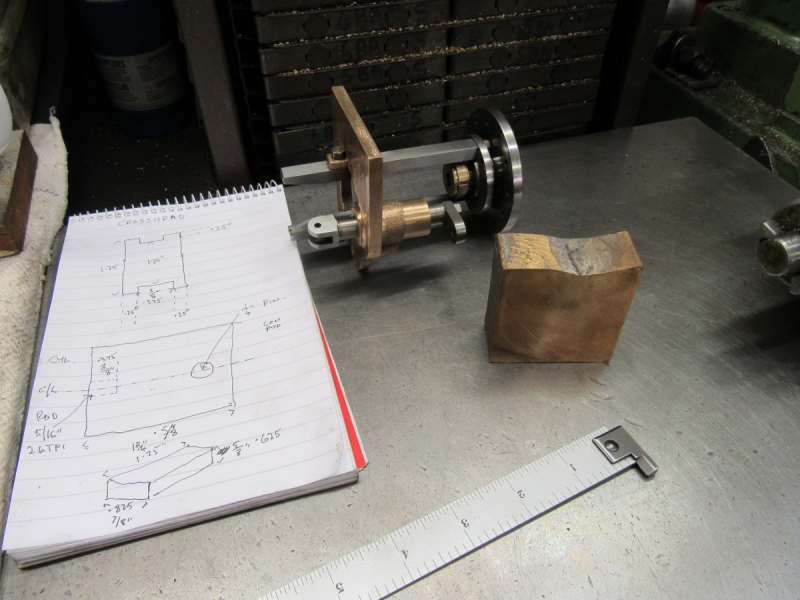

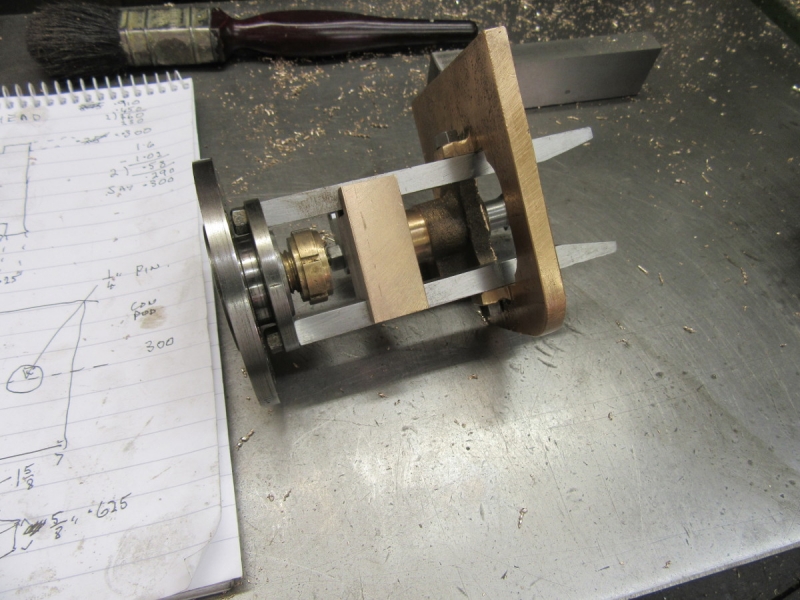

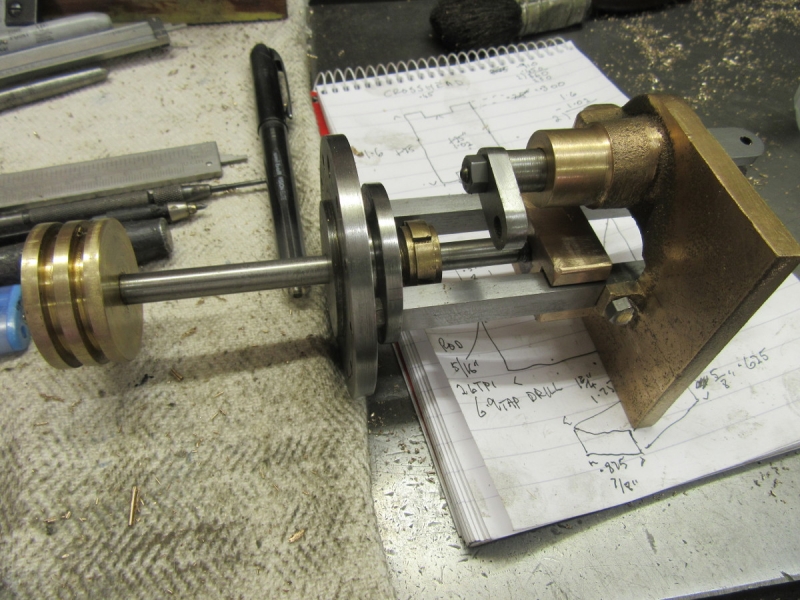

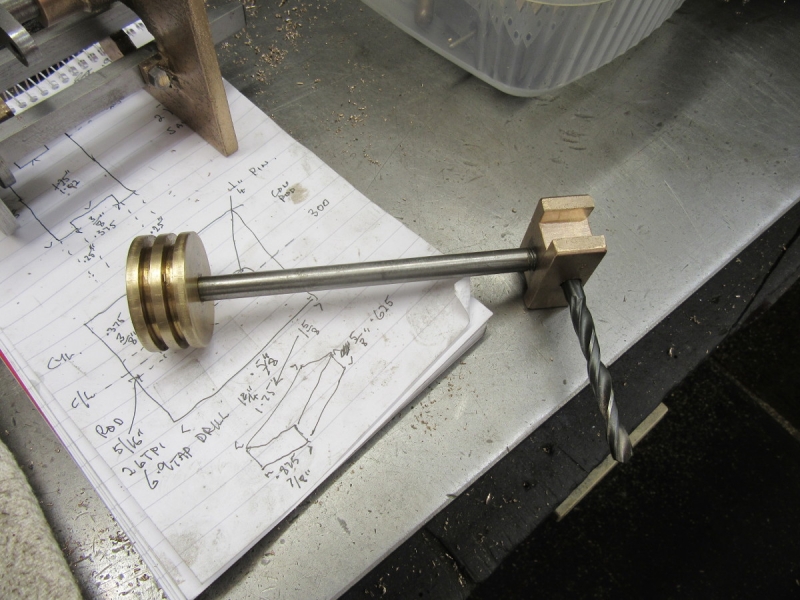

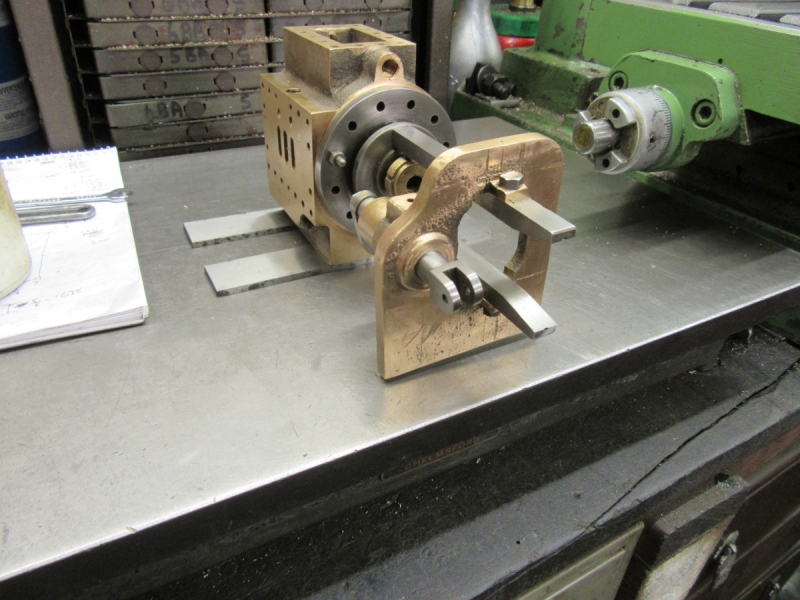

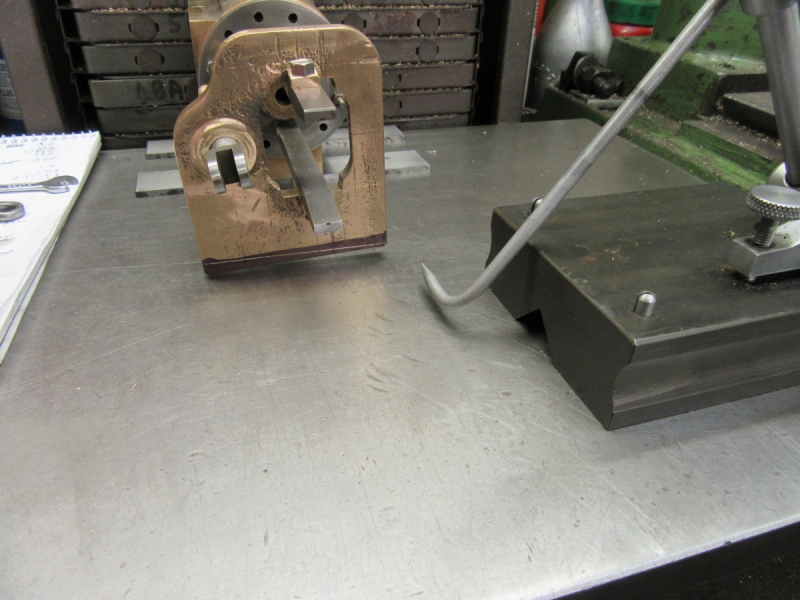

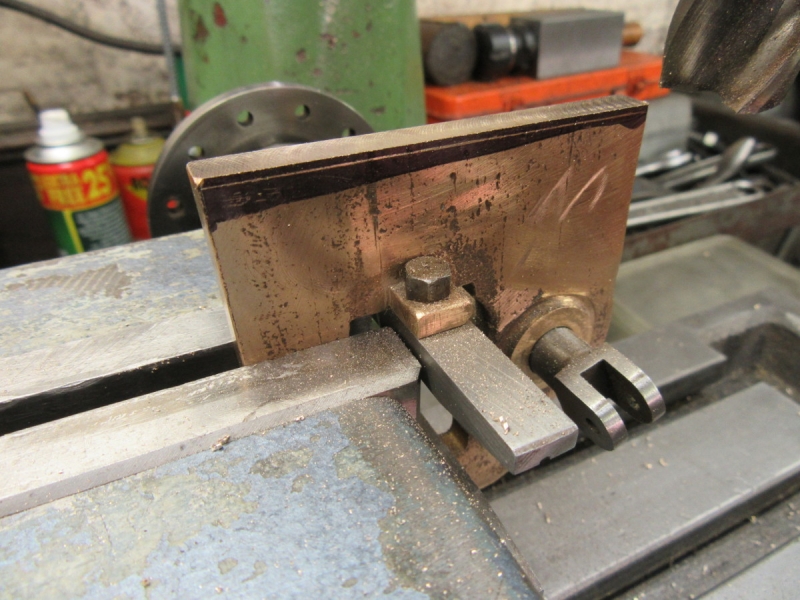

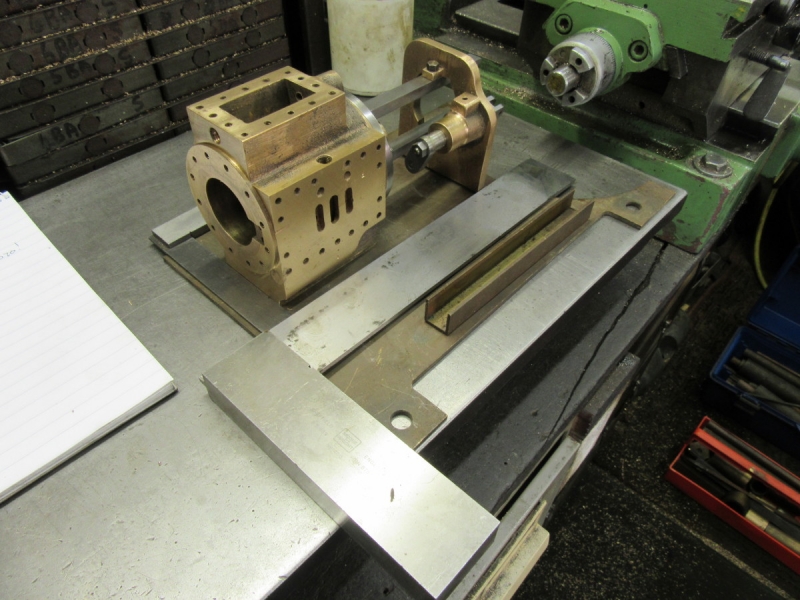

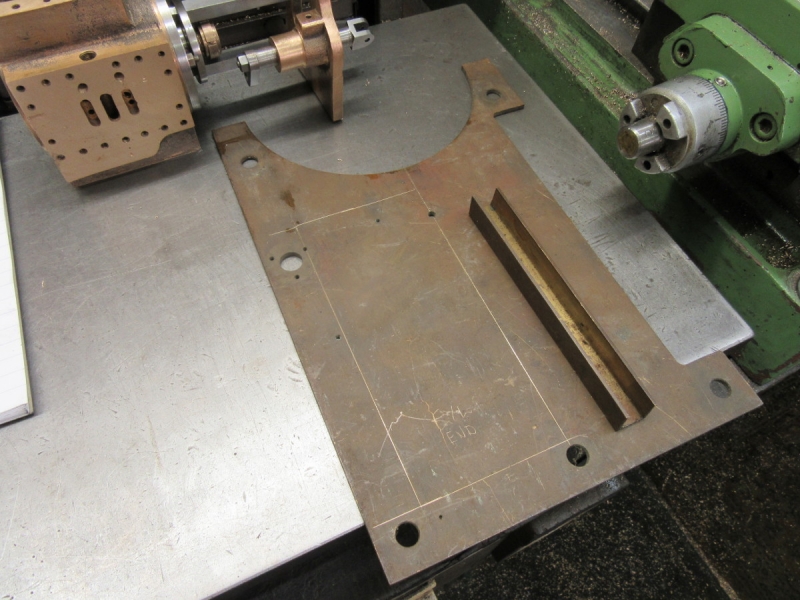

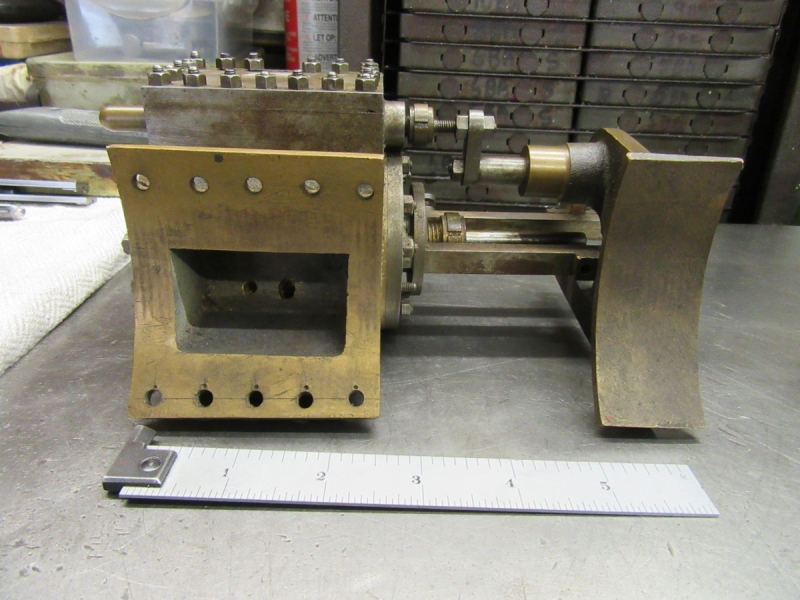

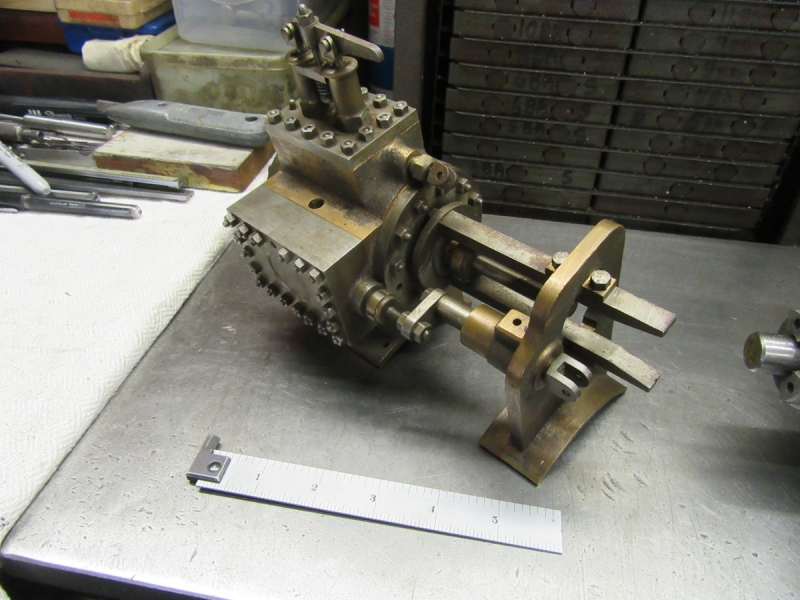

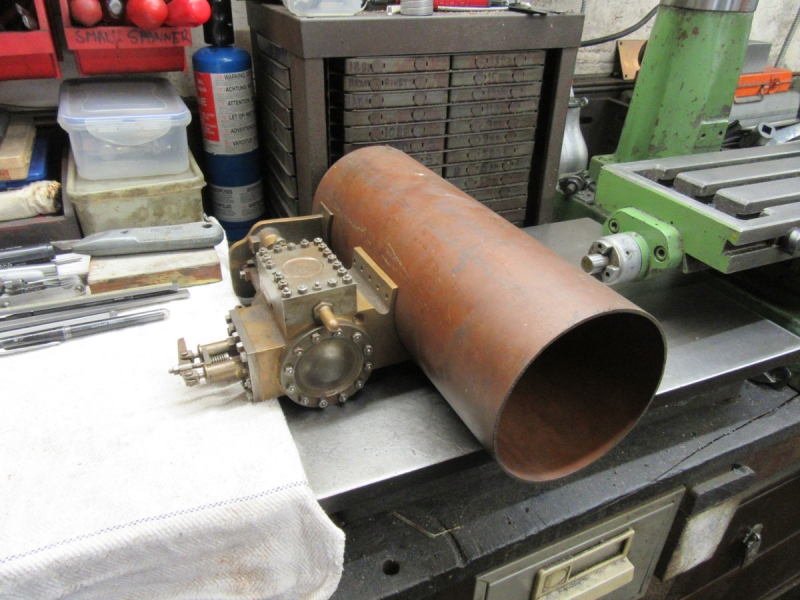

As you can see from the 6" ruler it's a fair lump and is more complicated than a normal steam engine cylinder. Notice that it has two steam chests, the one at the side is a normal slide valve but the other on top carries the safety valve for the boiler and includes the steam regulator, that's the small rod at the front with the clevis on. Also in the other view you can see that it's made to mount directly onto the boiler and the steam enters the casting through the holes in the recess in the bottom. I'm not sure why there are two, I'll find that out as I go forward. Then there is the piece of solid drawn copper pipe, roughly 11SWG which is an exact fit in the curve of the mounting and I think must have been intended to be his boiler.

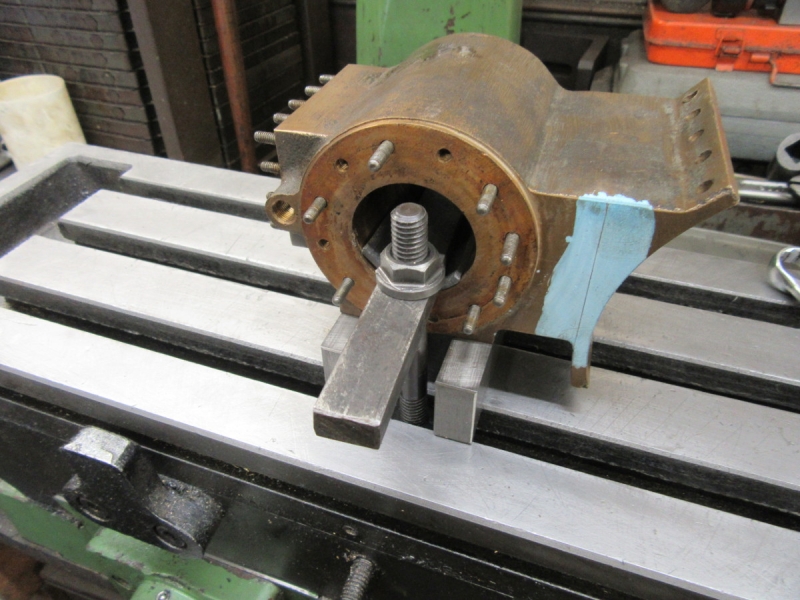

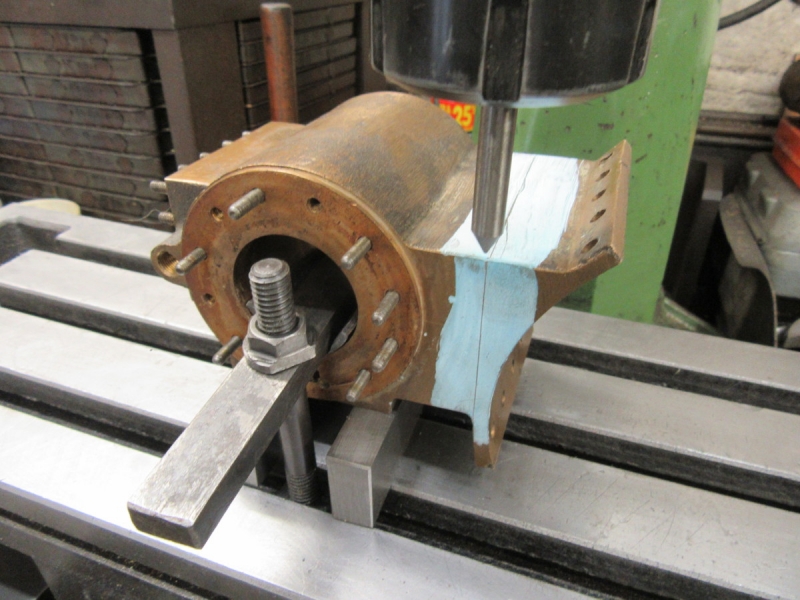

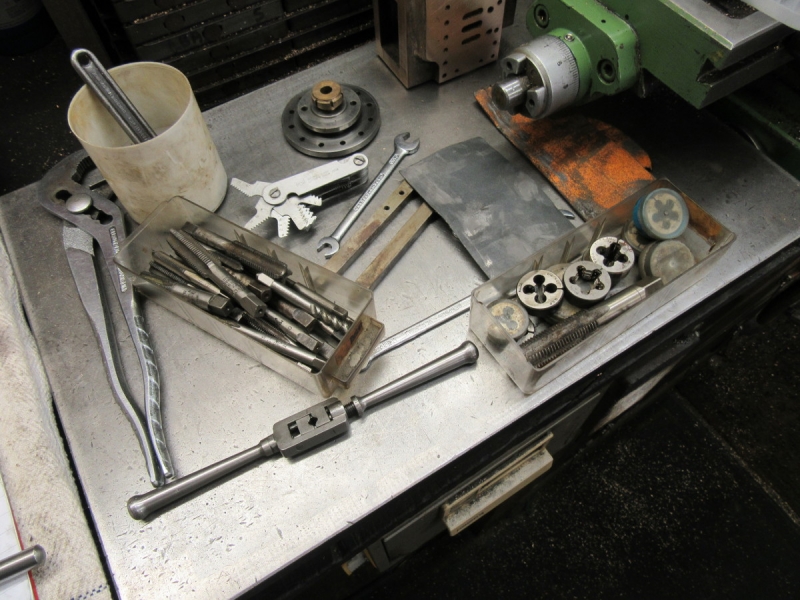

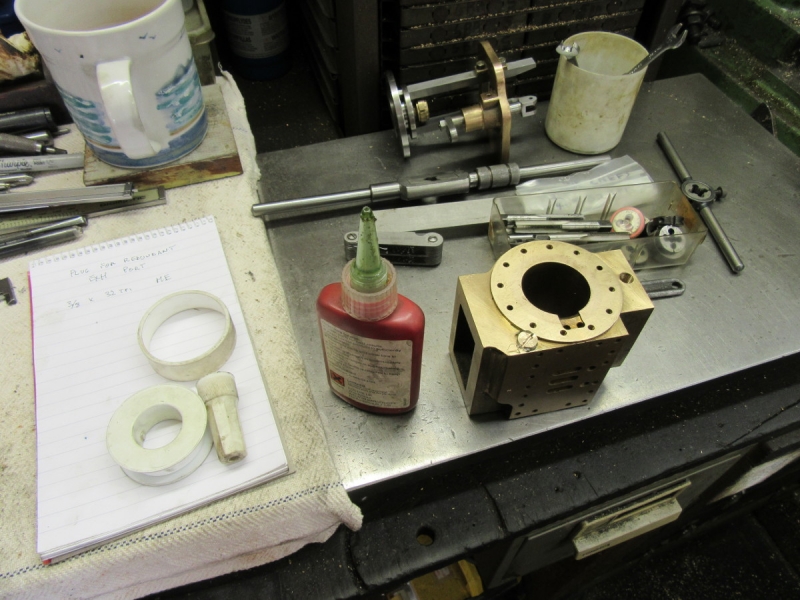

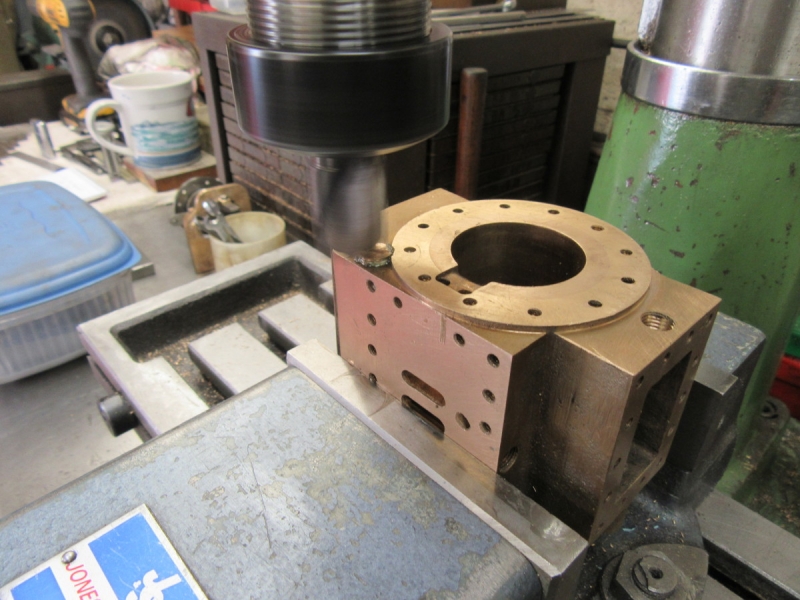

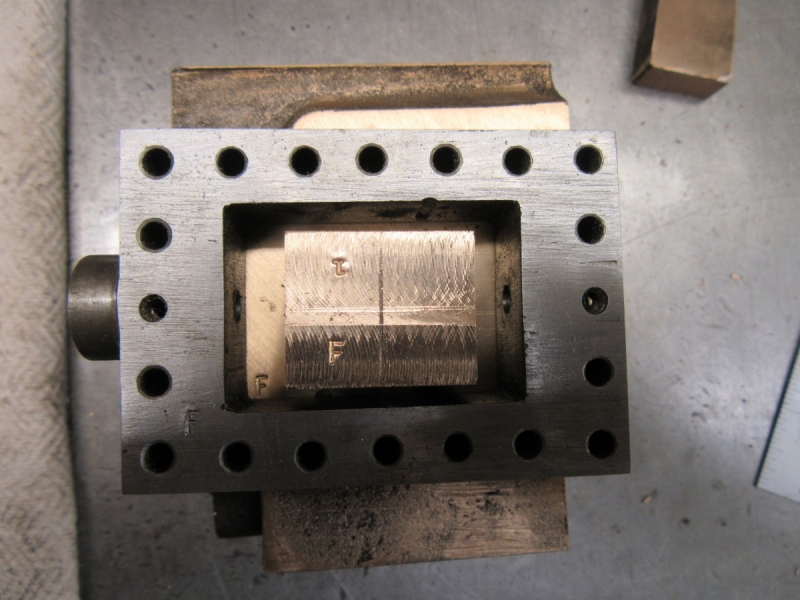

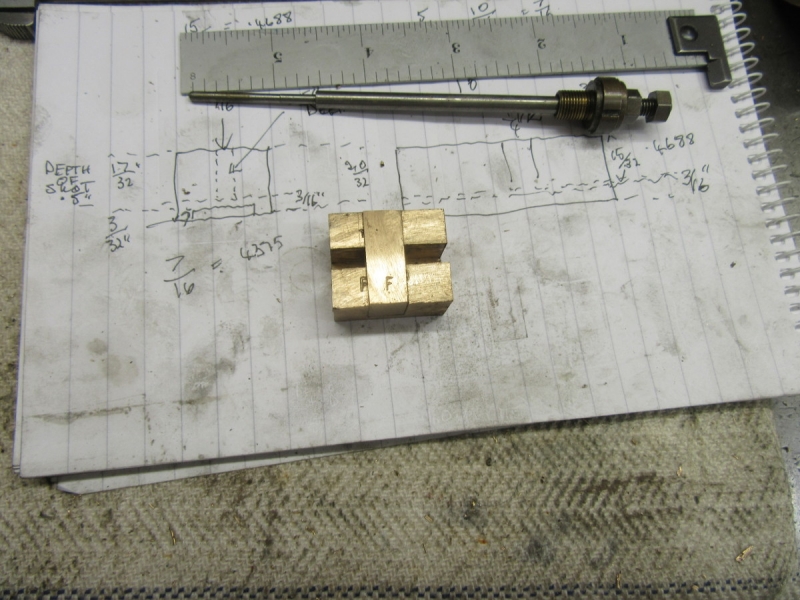

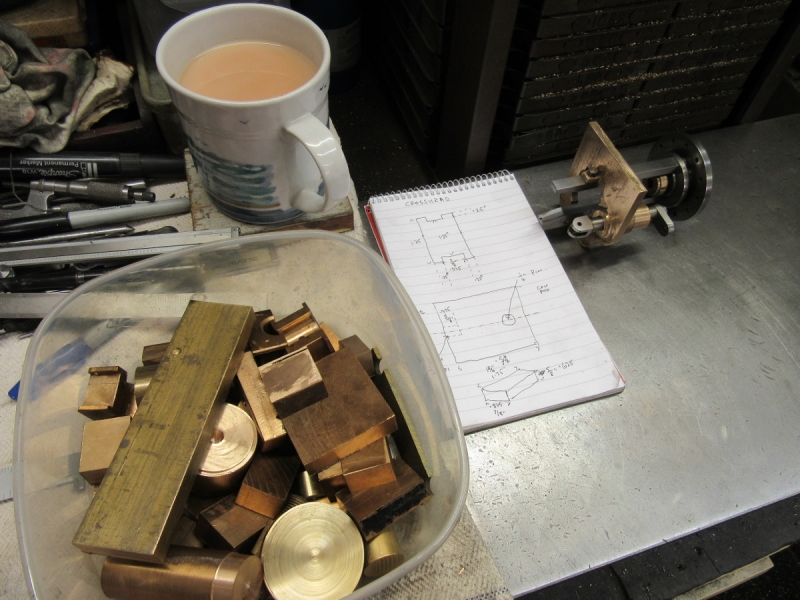

So, quite a lot to think about! At the moment all that is clear is that I am not going to venture into boiler making at my age! I'm not quite sure what I shall do. My first feeling is that I'd like to make a 'normal' steam cylinder out of it but there are certain hurdles I will have to jump if I do that. It's an interesting problem and I have plenty to think about. I have no doubt the Design Committee has already started on the project and who knows I might wake up tomorrow morning with some sort of an idea. I have an idea that the first job will be a strip down so I know exactly what the route of the steam passages is and also just what's inside that top steam chest.... I have an idea of course but it will be as well to be perfectly sure.

So, the least thing that has come out of the morning is plenty of brain fodder.......