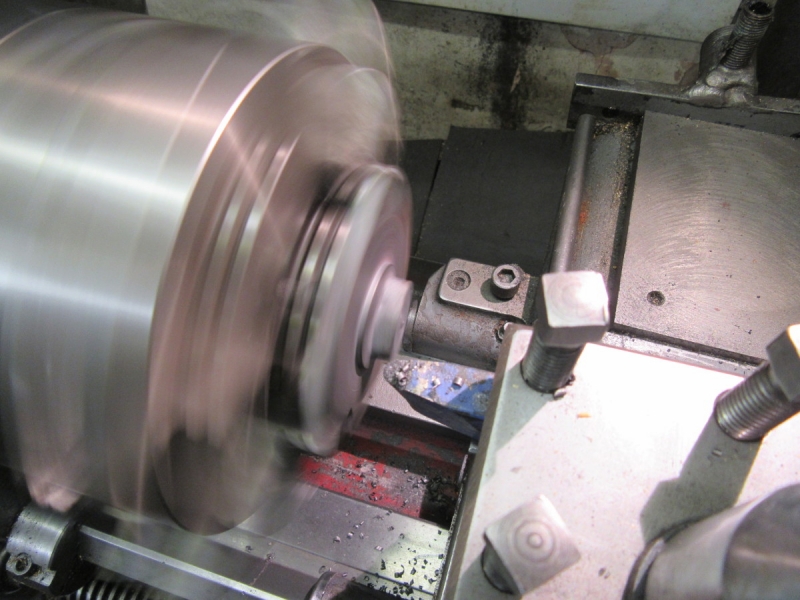

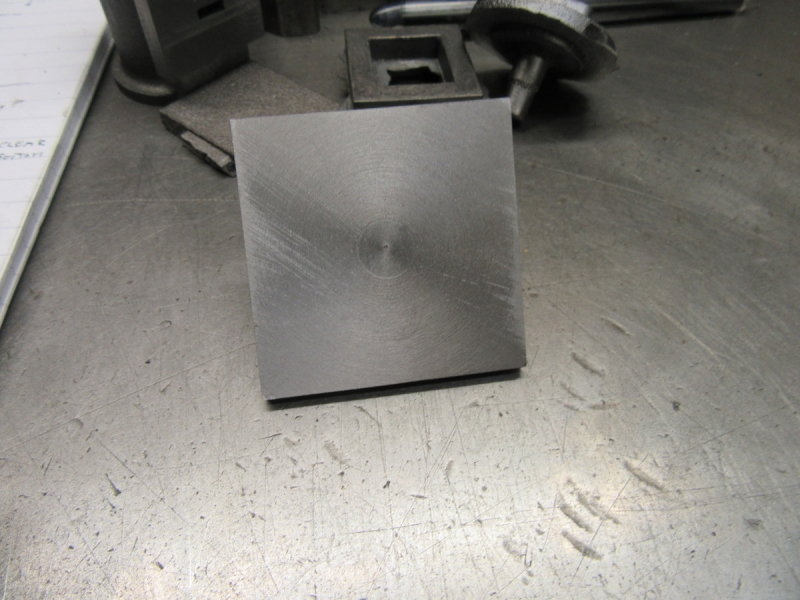

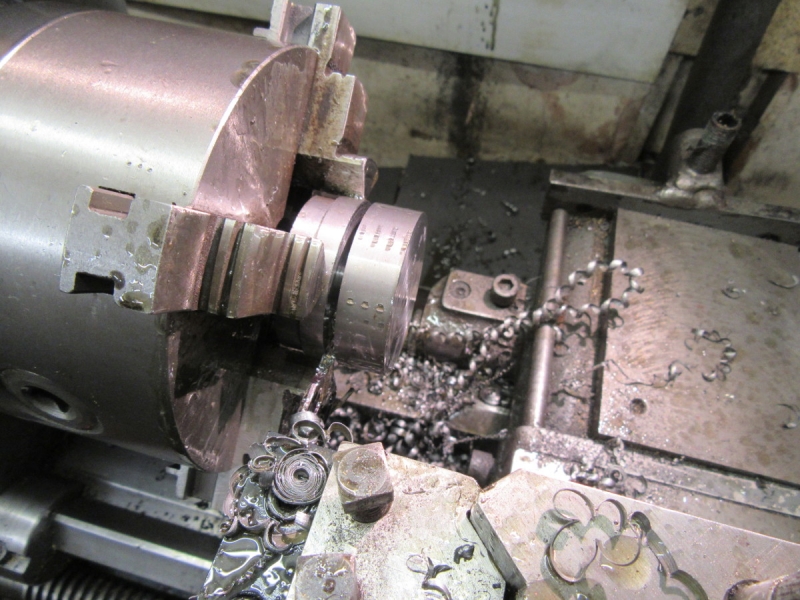

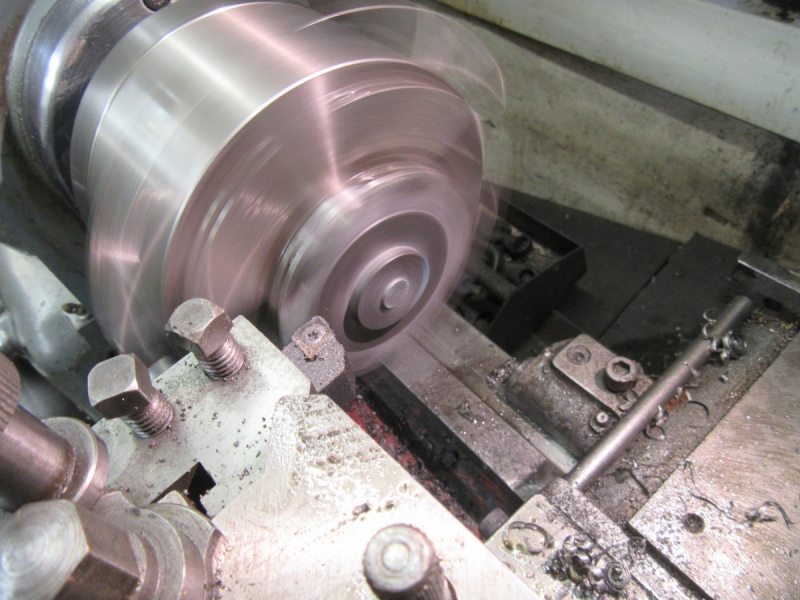

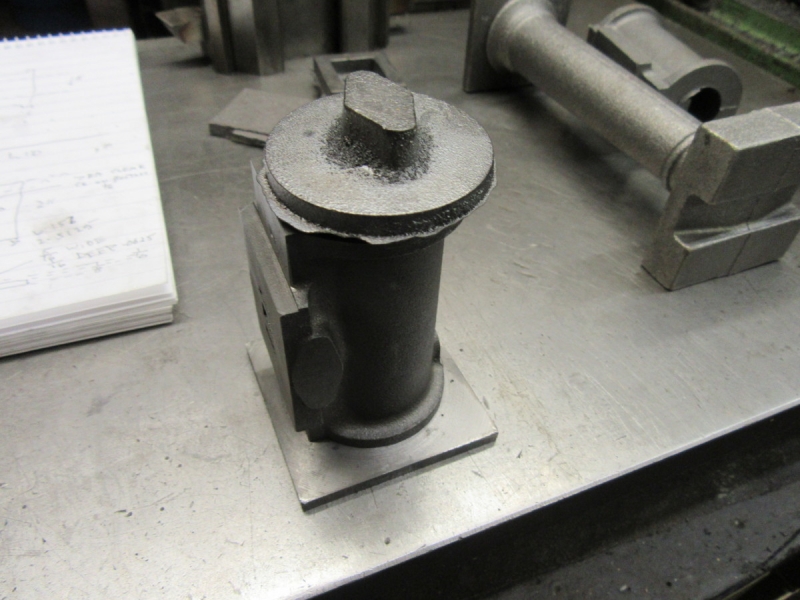

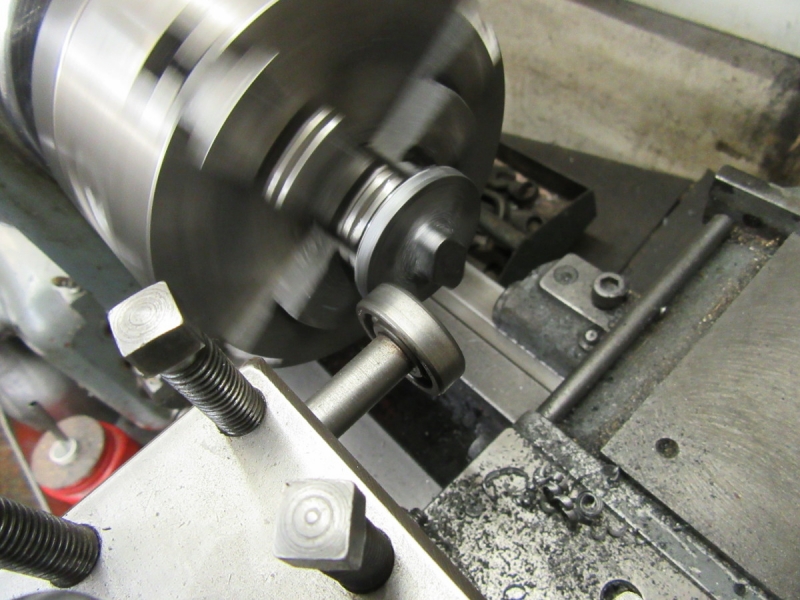

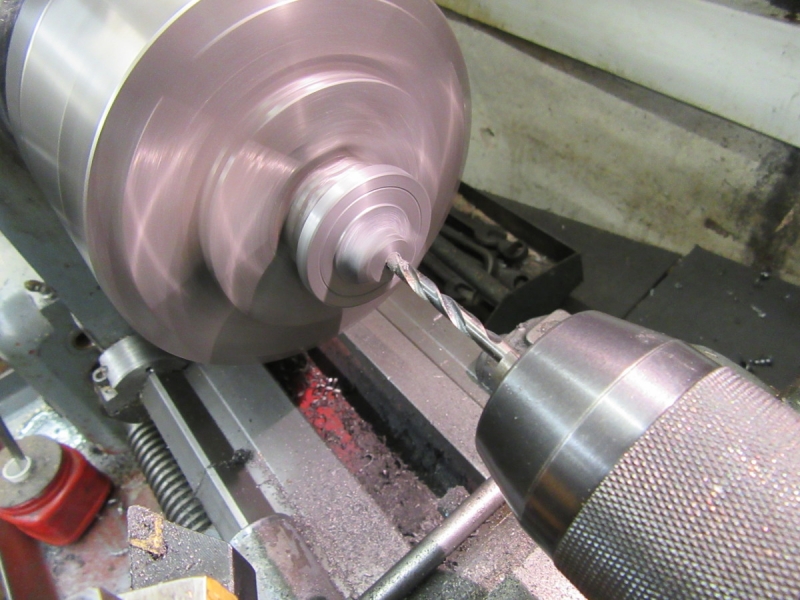

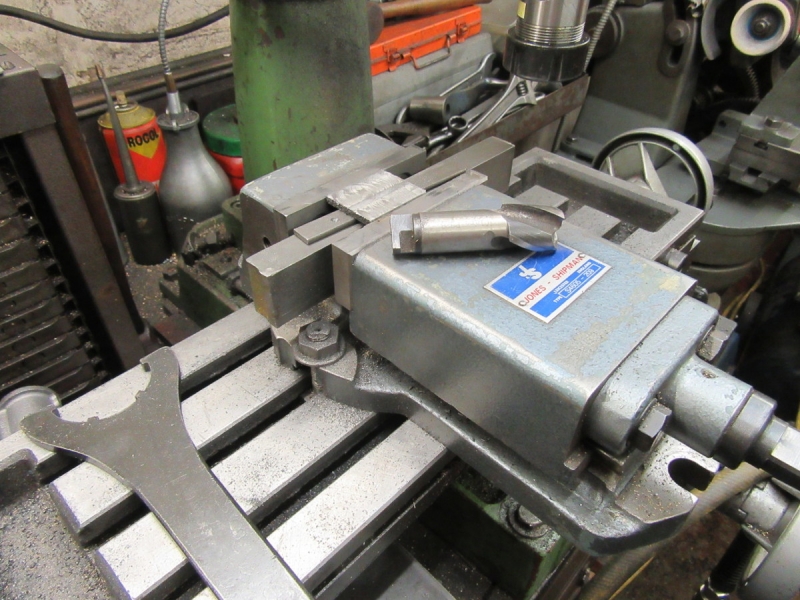

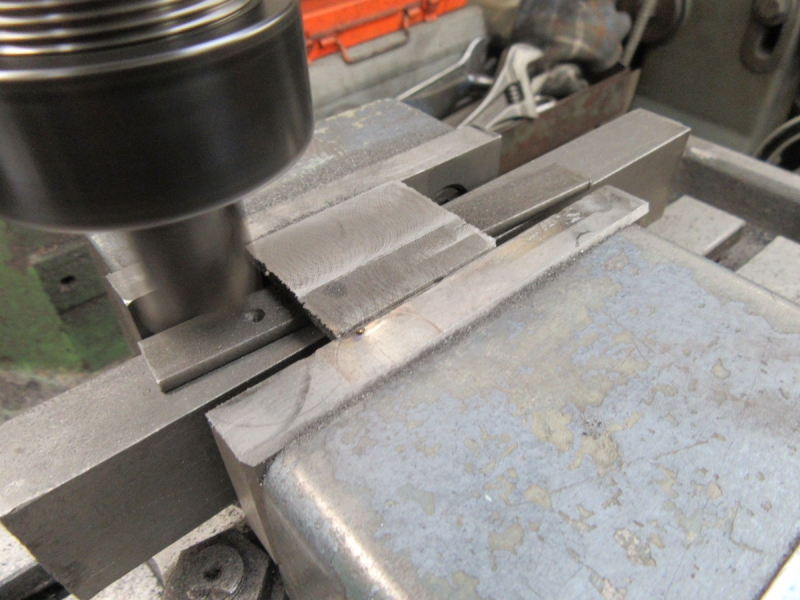

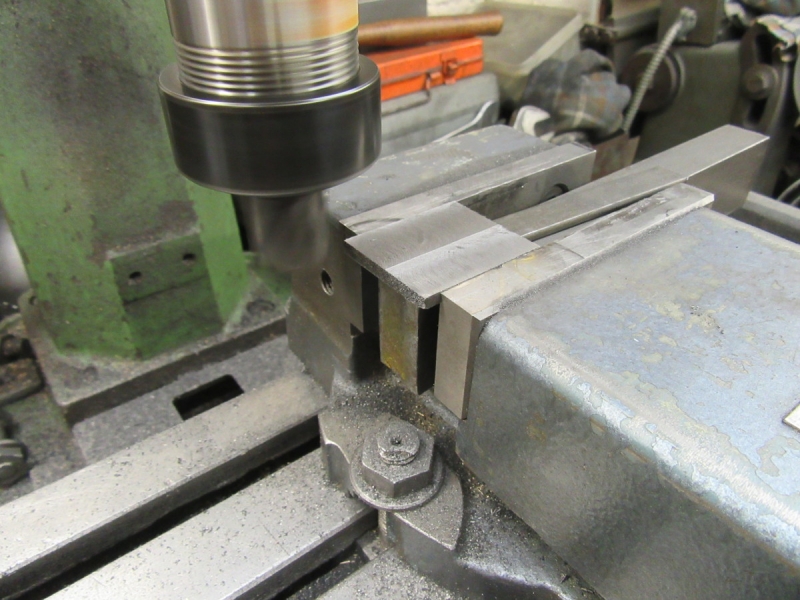

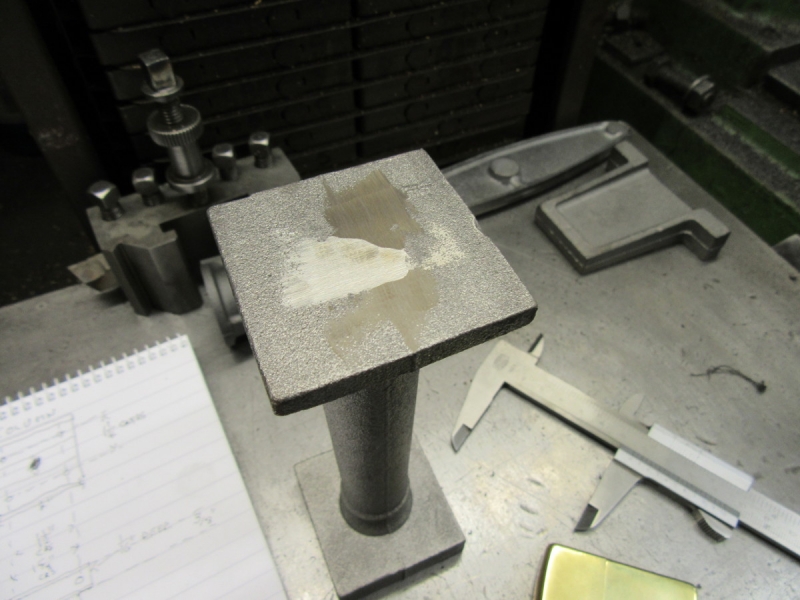

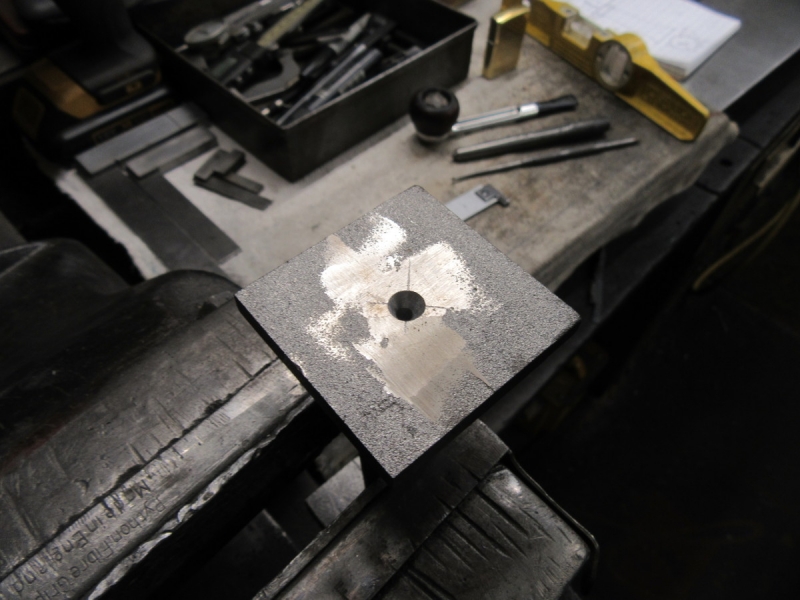

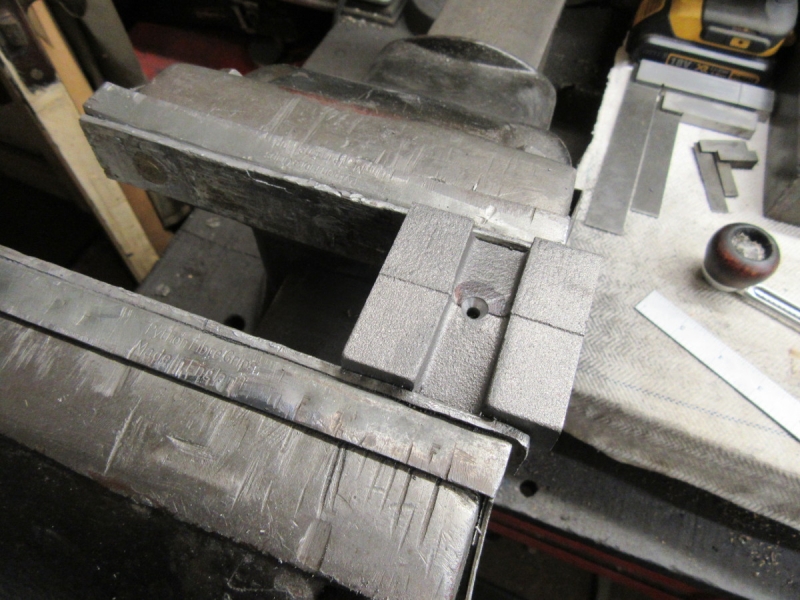

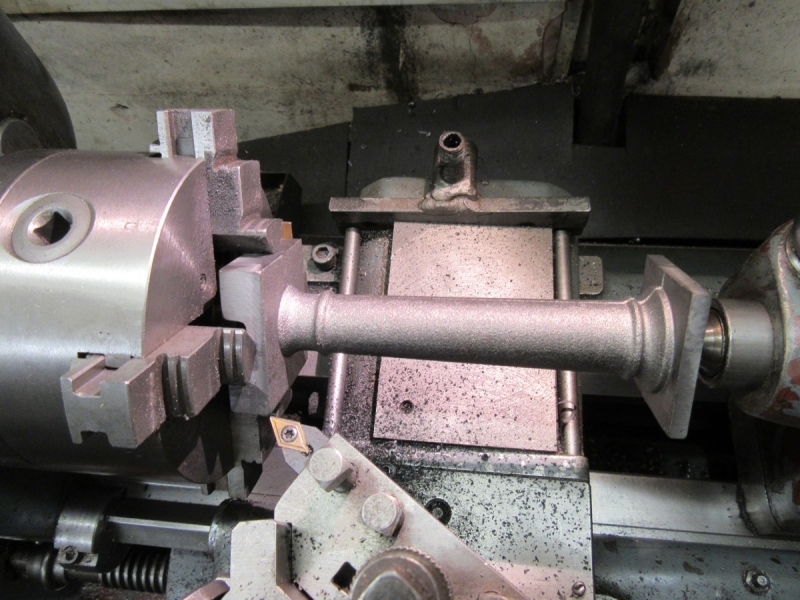

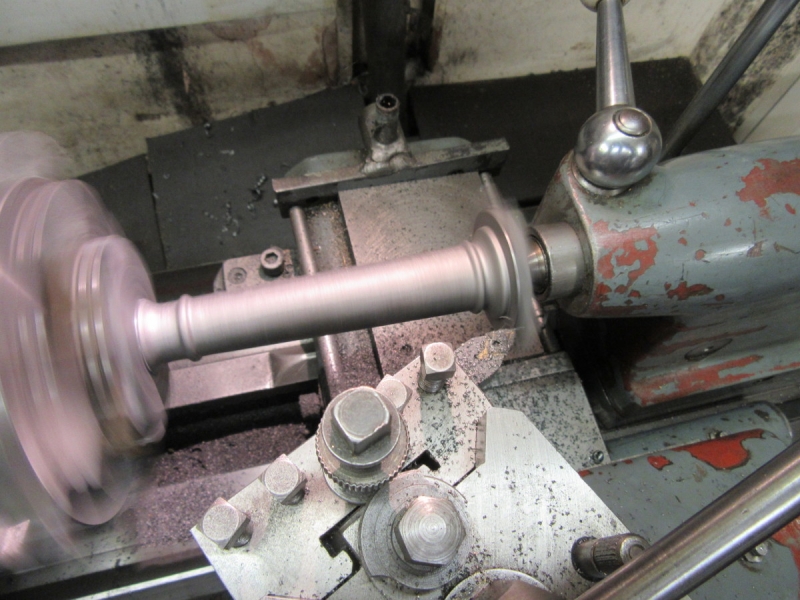

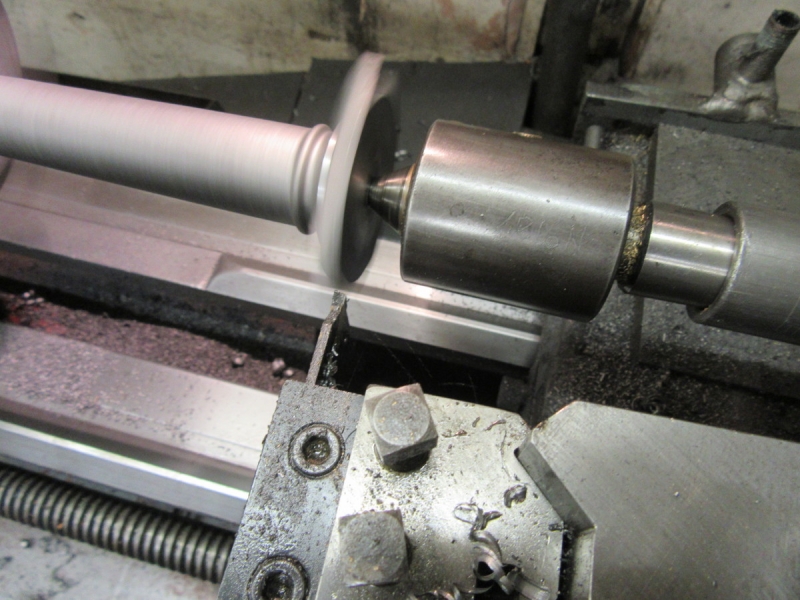

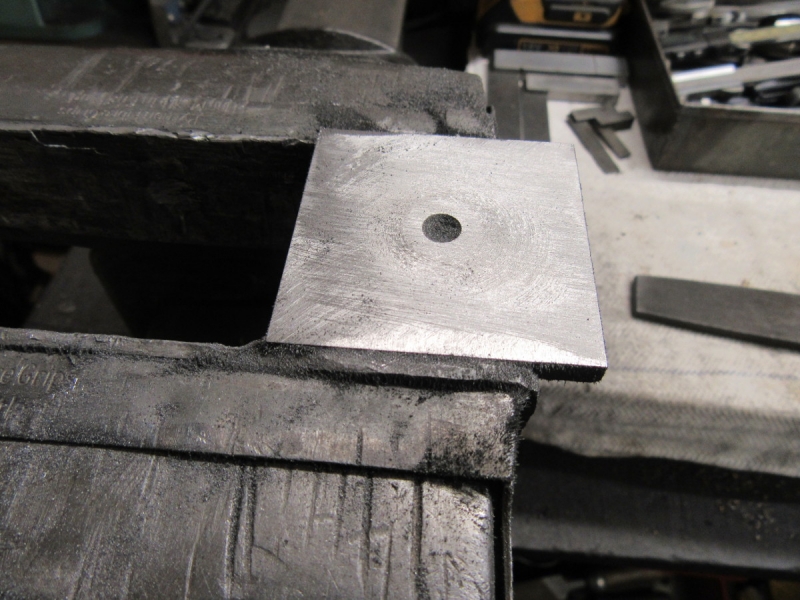

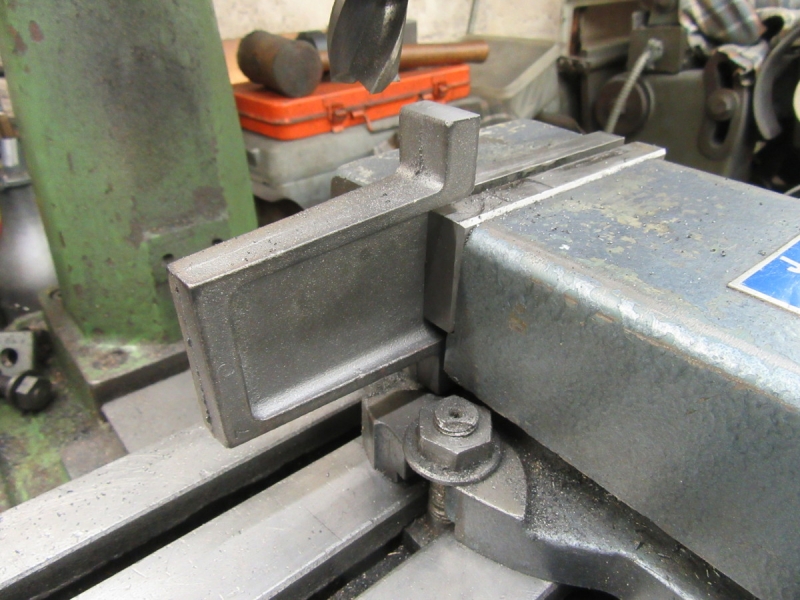

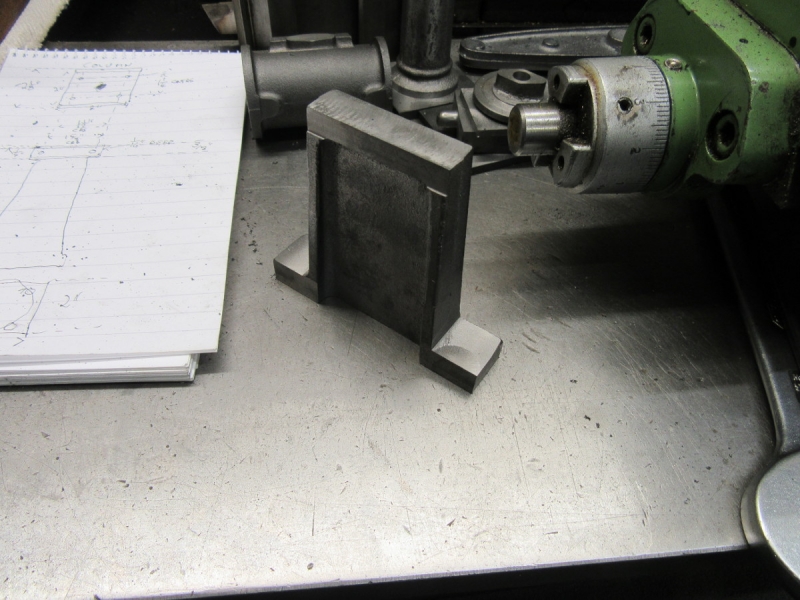

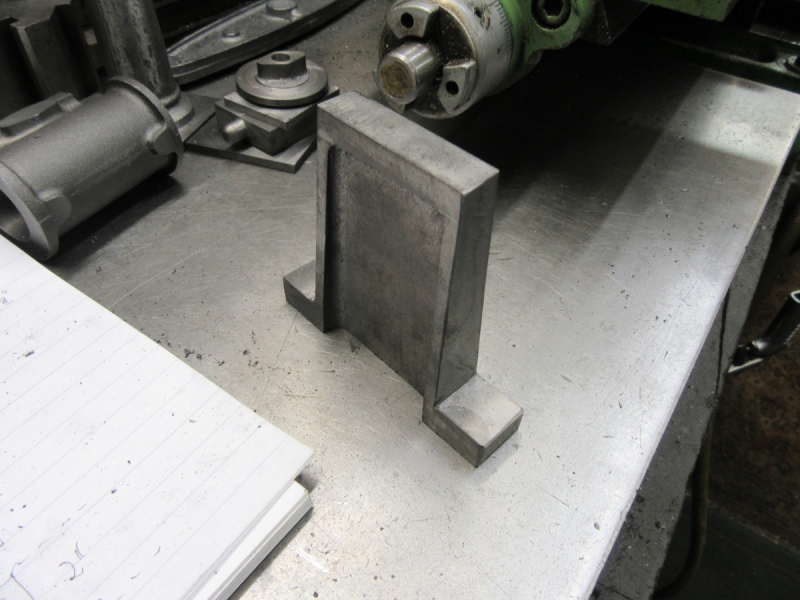

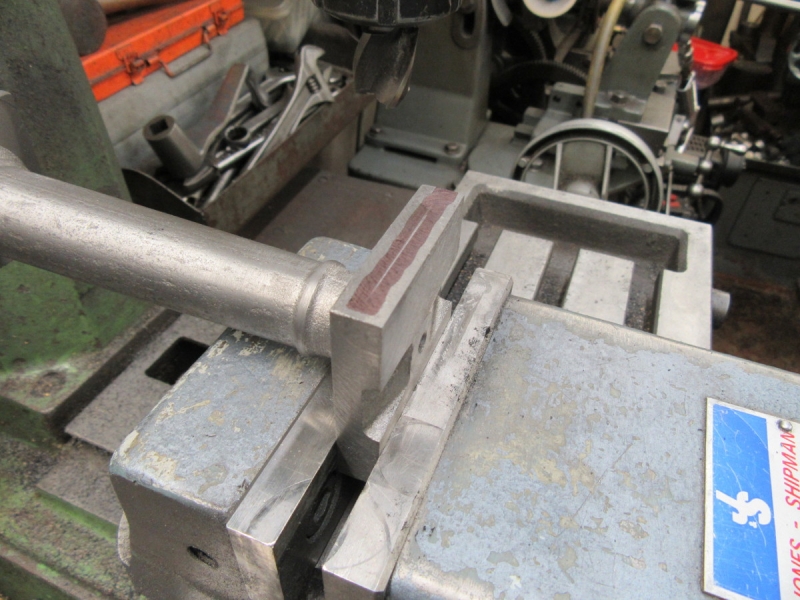

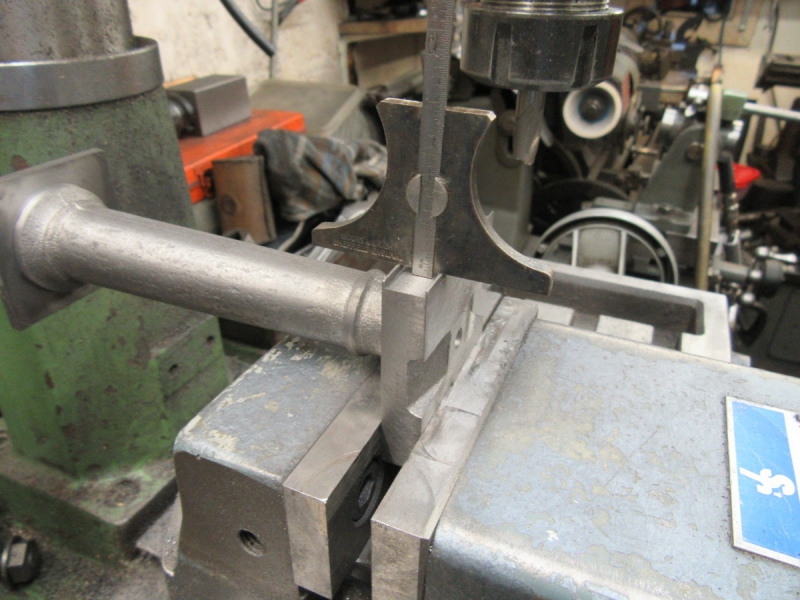

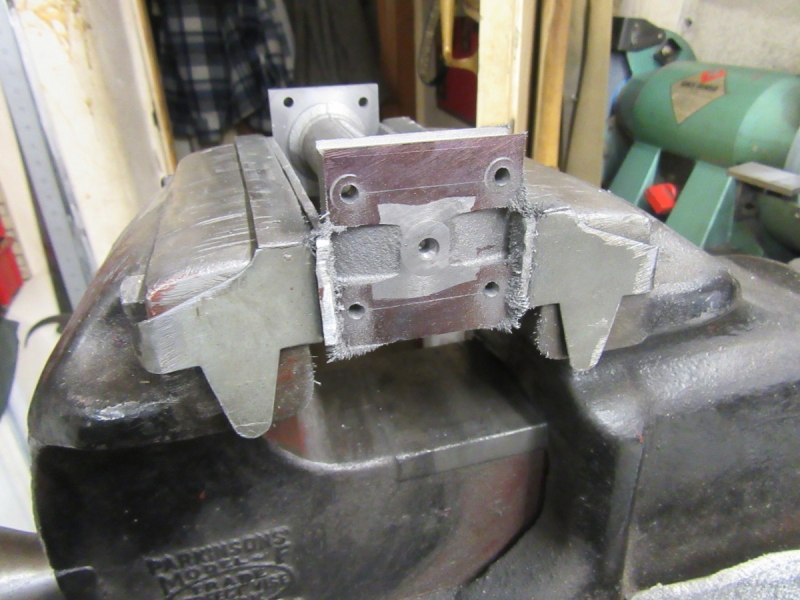

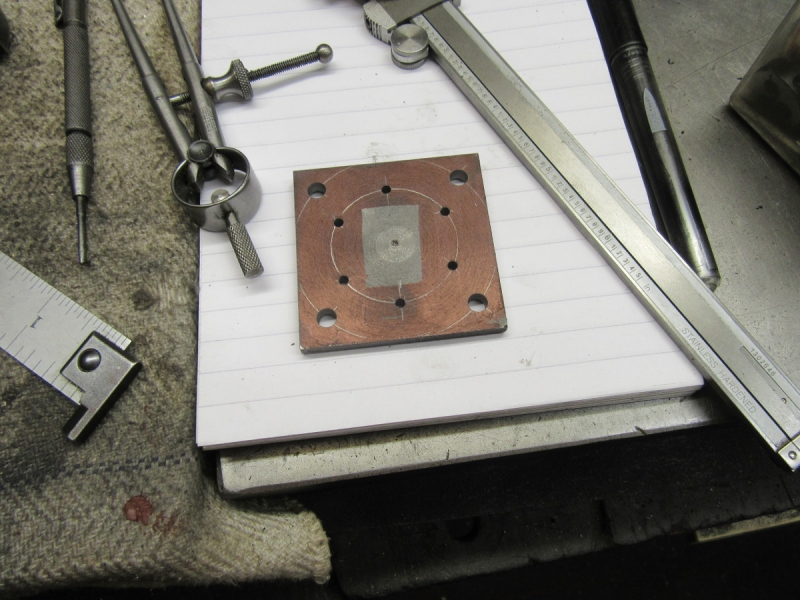

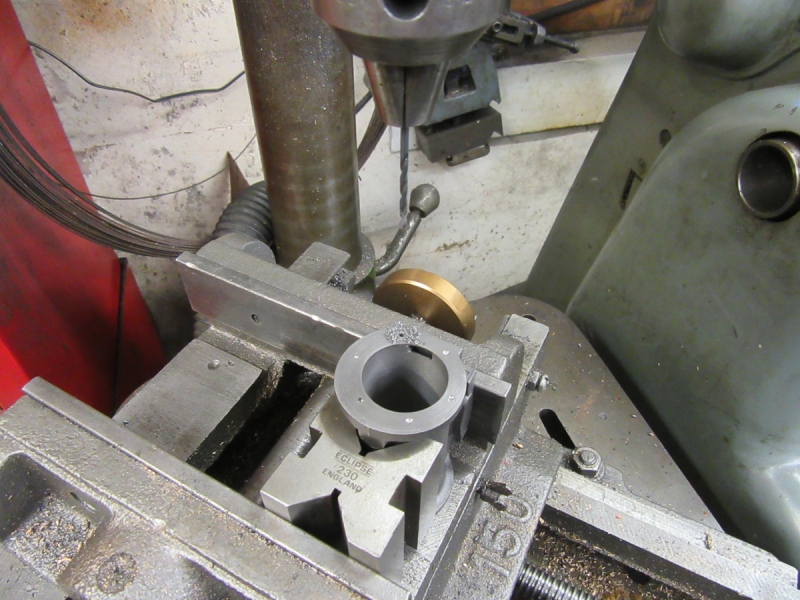

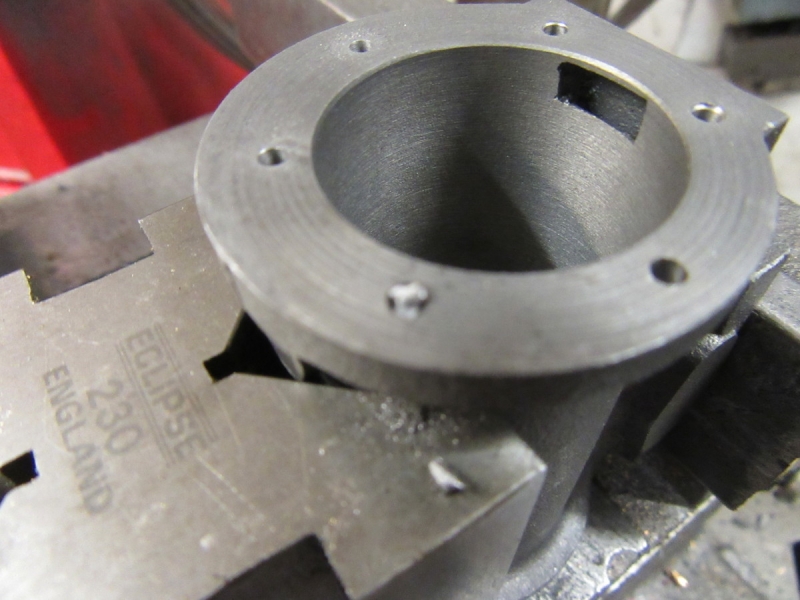

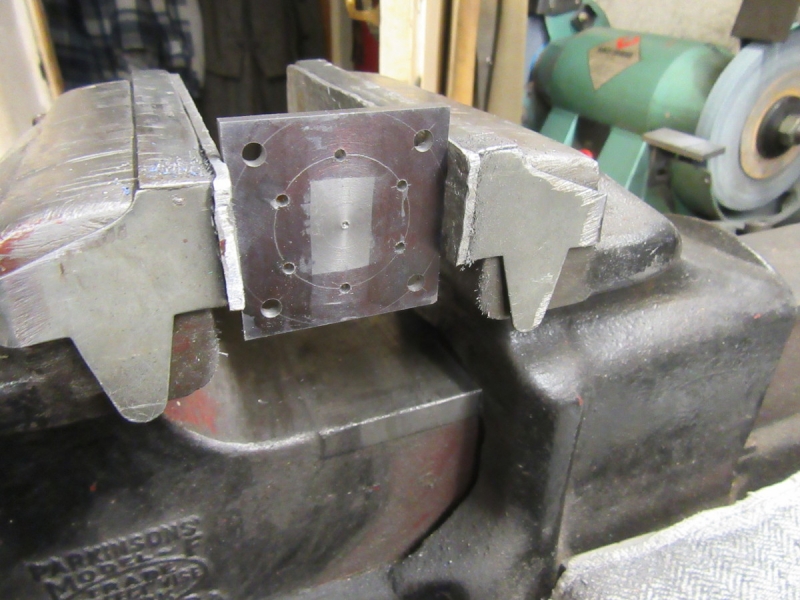

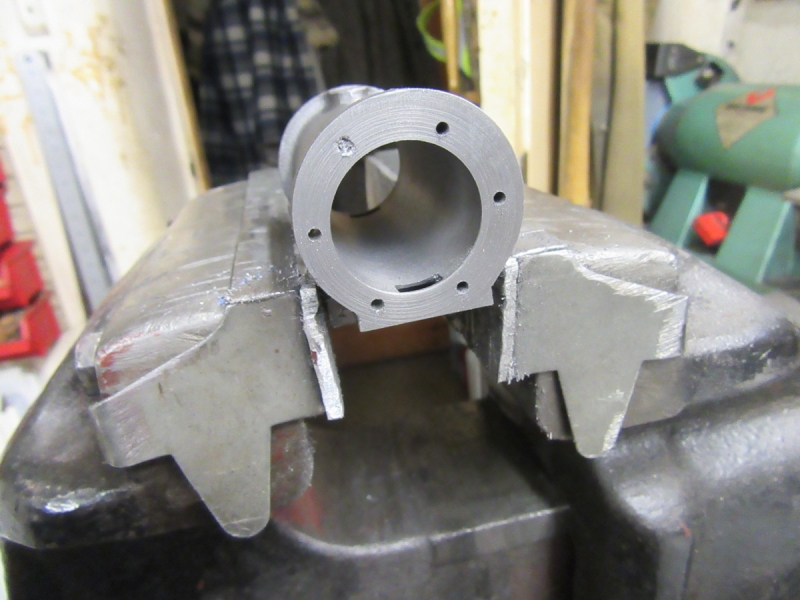

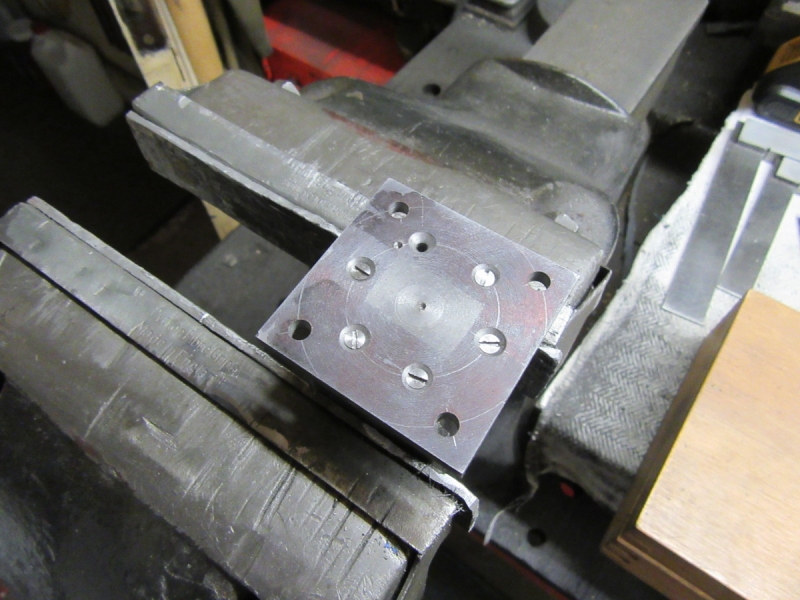

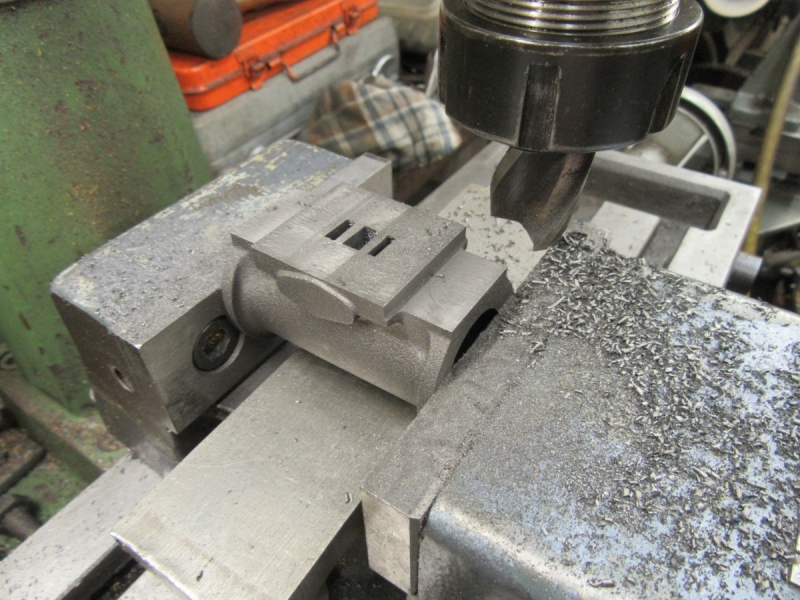

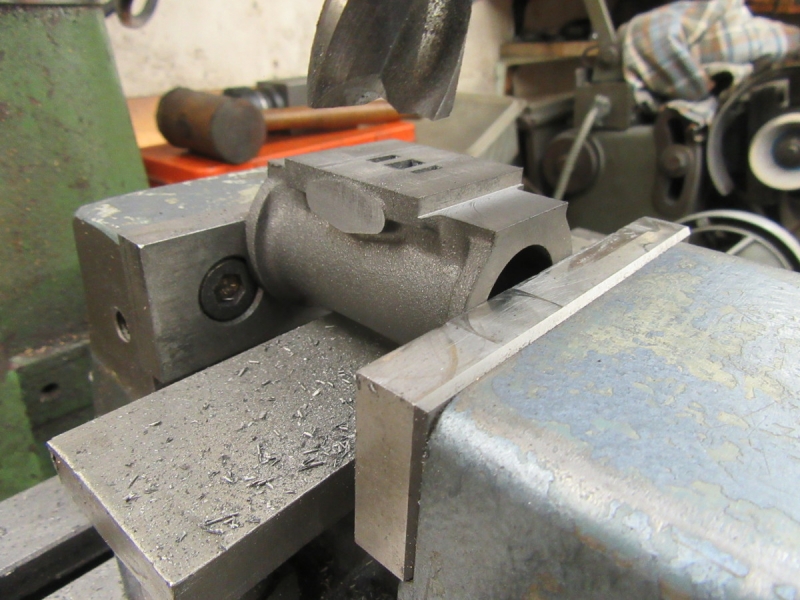

The first order of business was to finish machining all the faces on the cylinder. Nothing exotic about this, just careful machining finishing up with breaking all the sharp edges and cleaning the small amount of flash up that remained. Then check all the measurements and they are OK, not exactly to drawing but that can be allowed for in machining the associated parts.

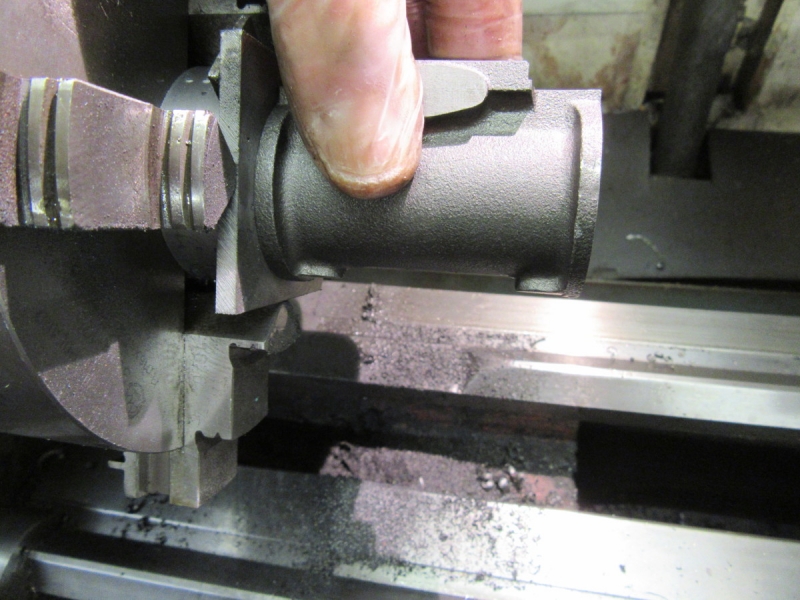

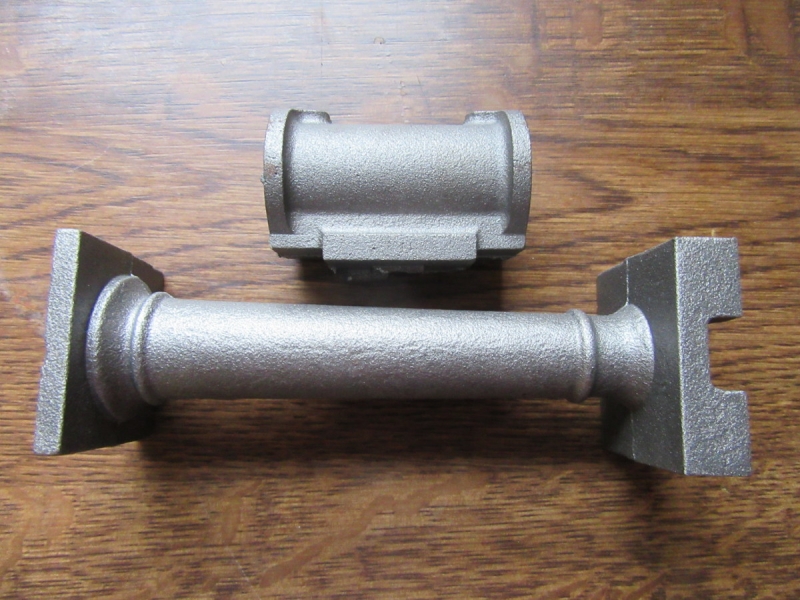

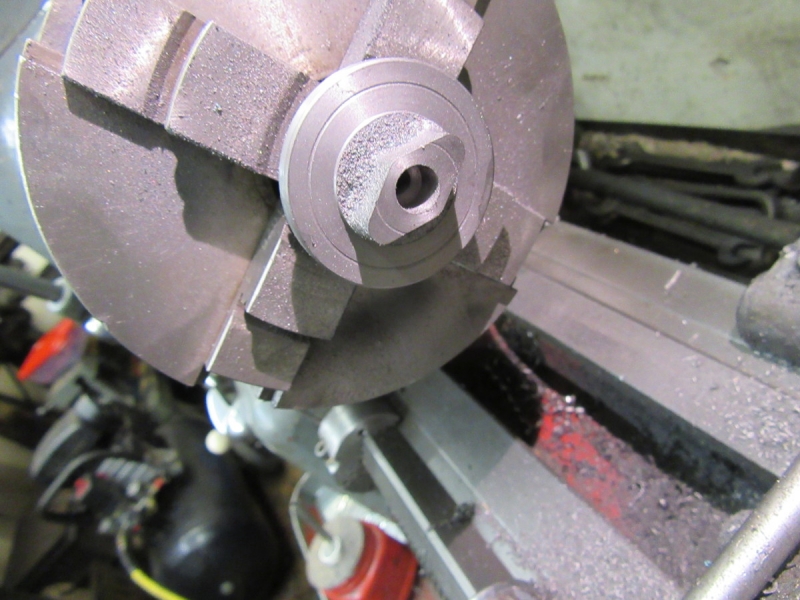

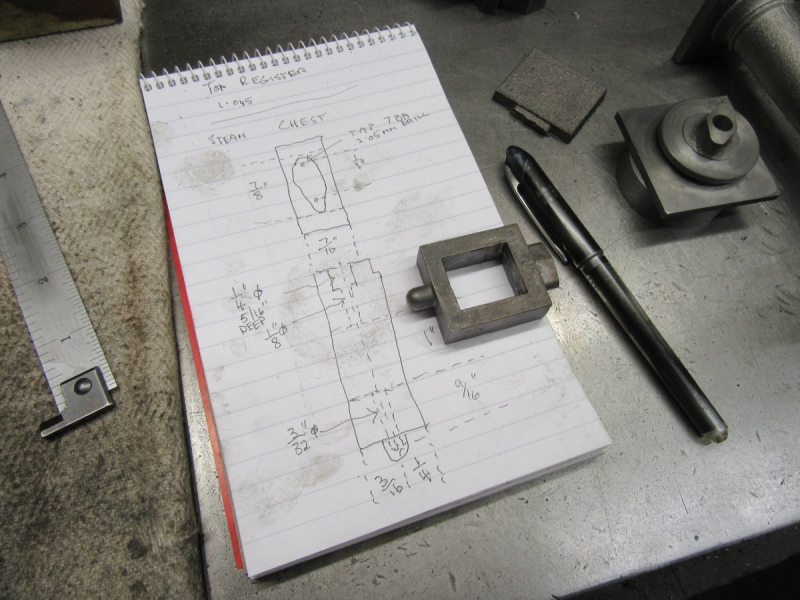

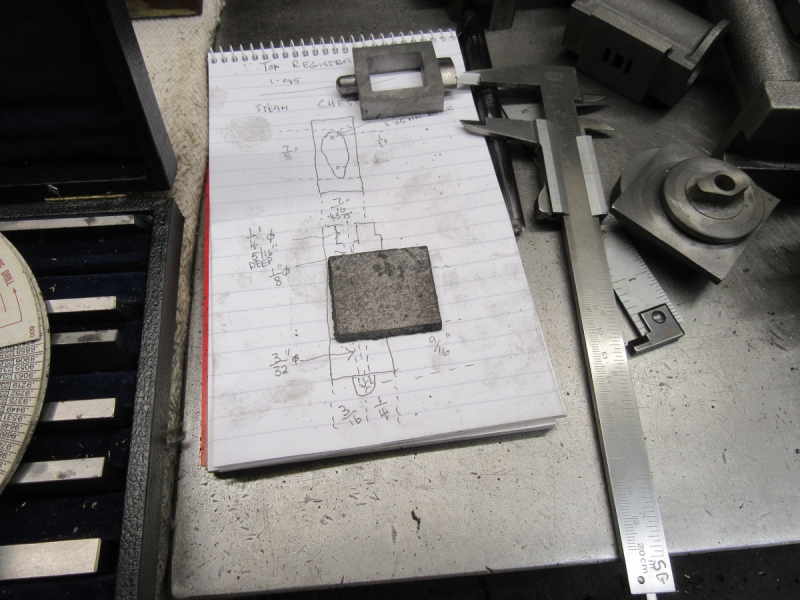

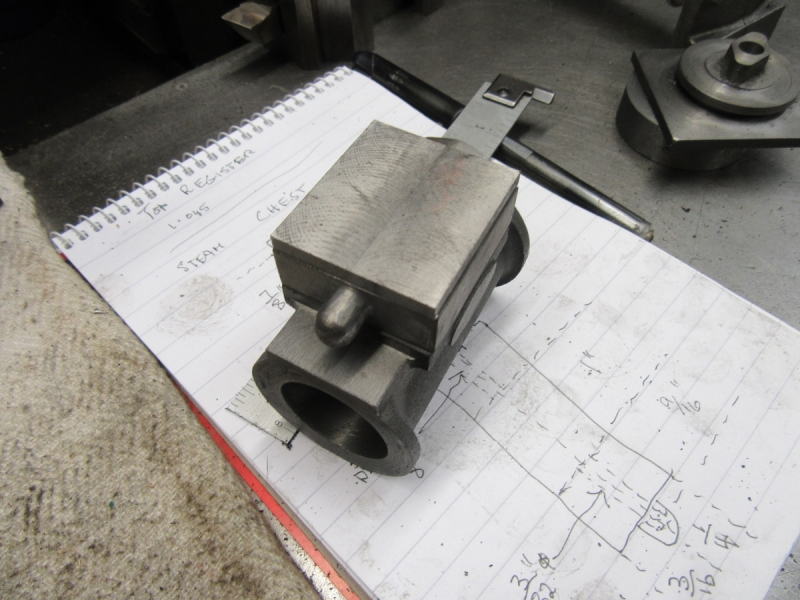

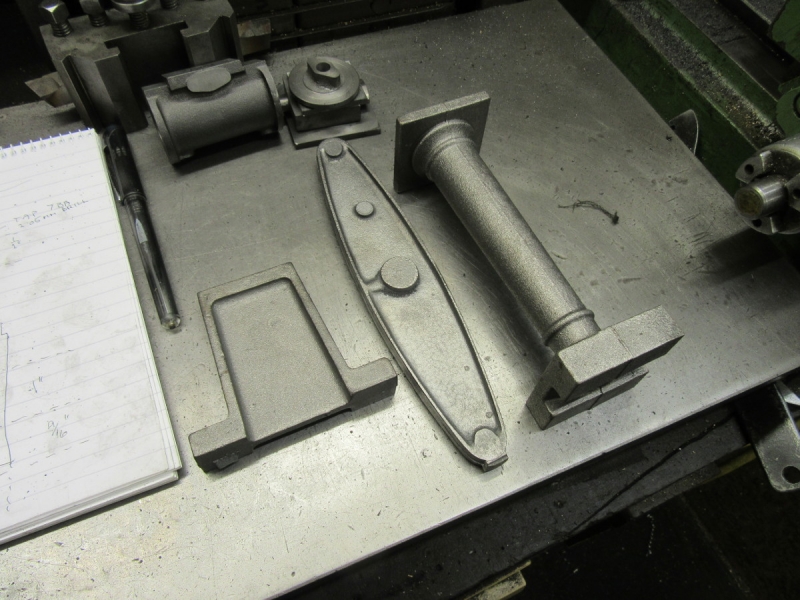

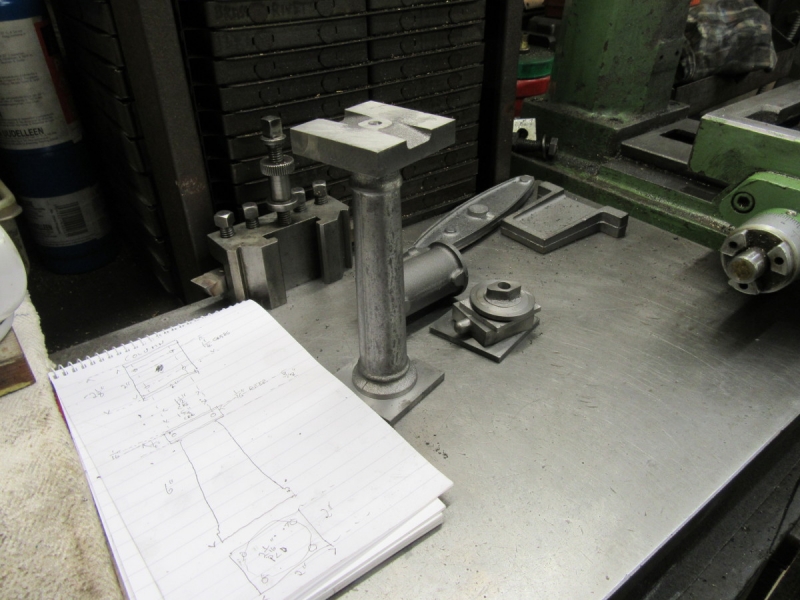

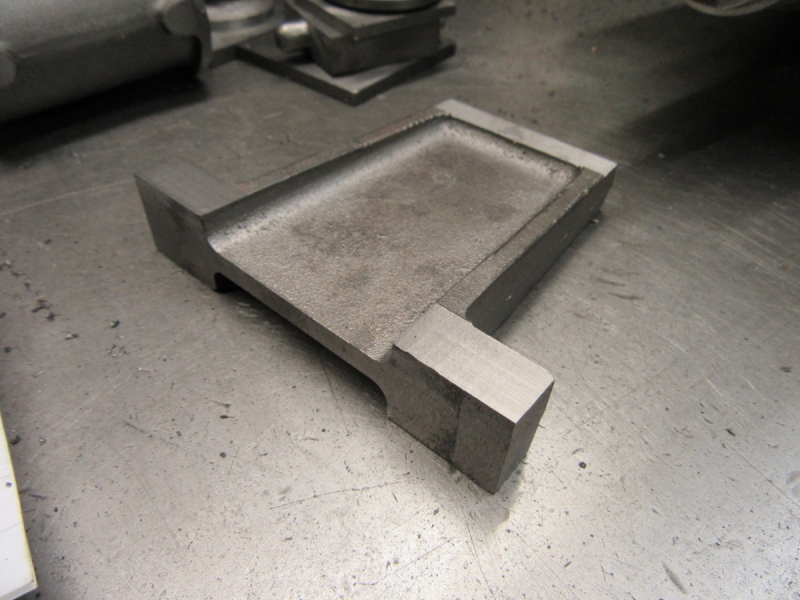

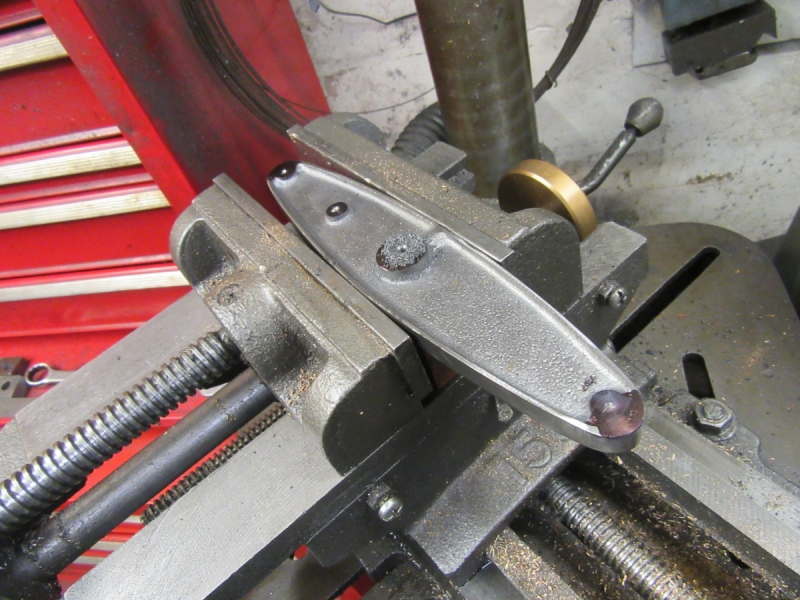

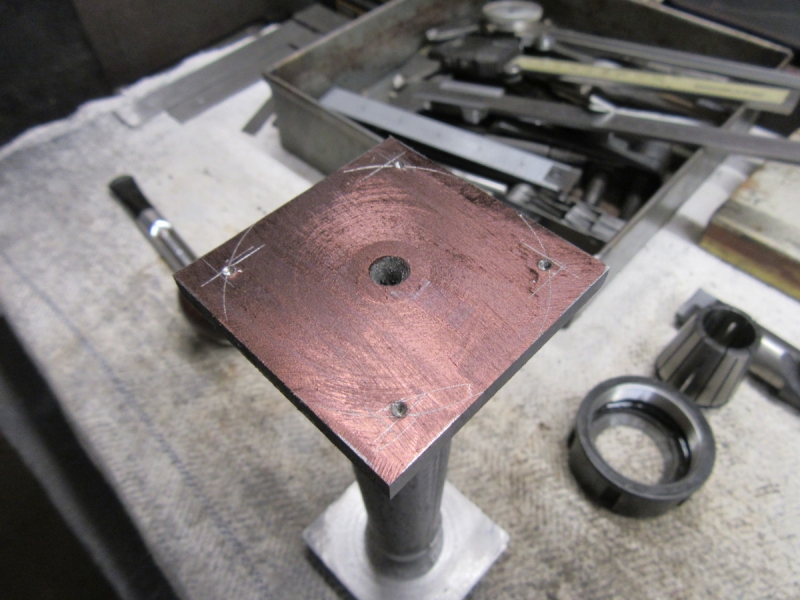

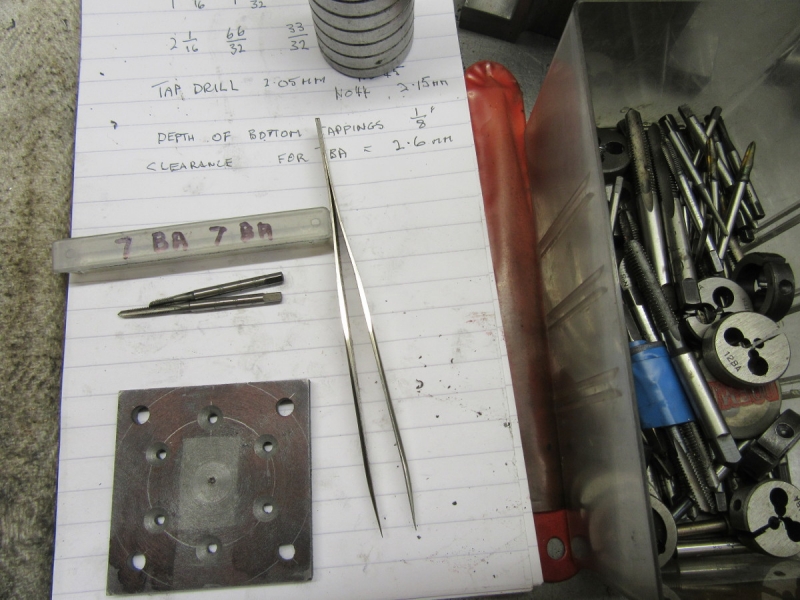

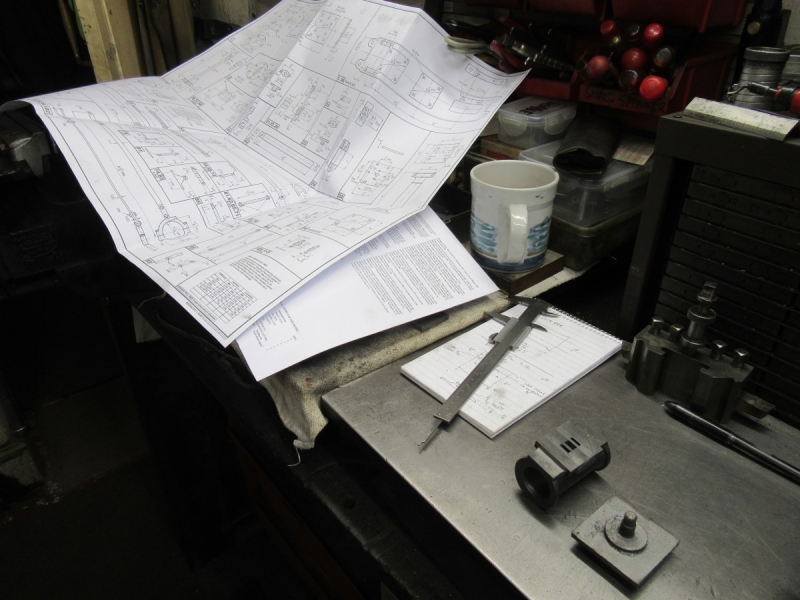

Next I went to my castings and picked out the ones that are associated with the cylinder. That was when I hit a problem.

The problem is that the design of the castings doesn't match what is needed. This mismatch is so glaring that I can't believe I haven't missed something but after a lot of thinking that got me to knocking off time, if there is something I can't find it. I shall come back to this fresh tomorrow morning and see if I can make sense out of what I'm looking at. At the moment it's a puzzle!

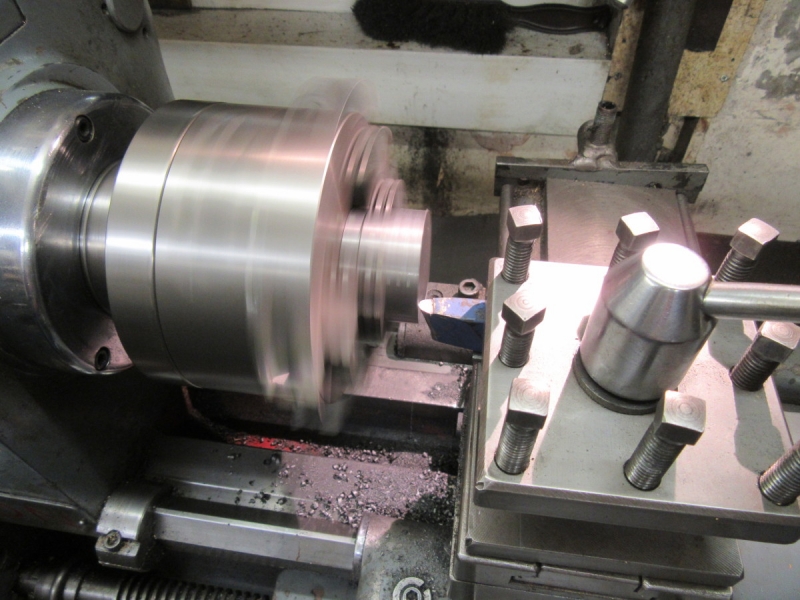

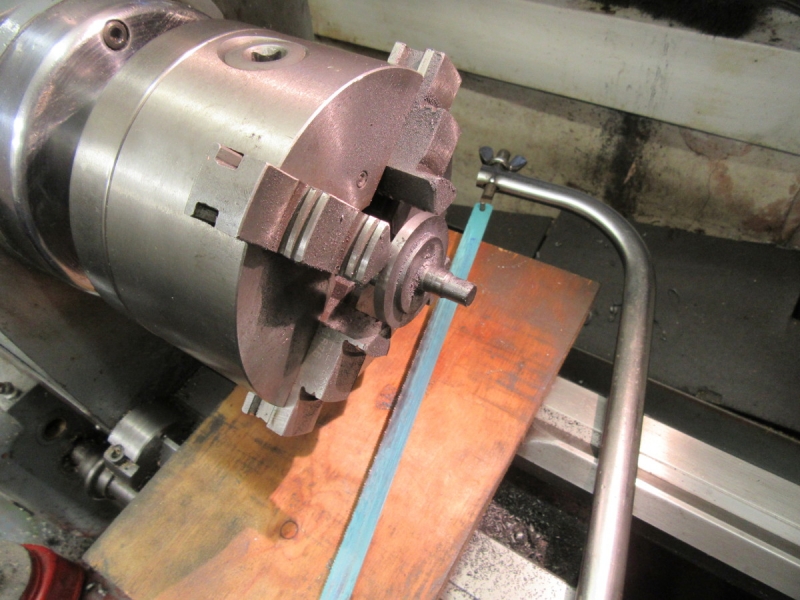

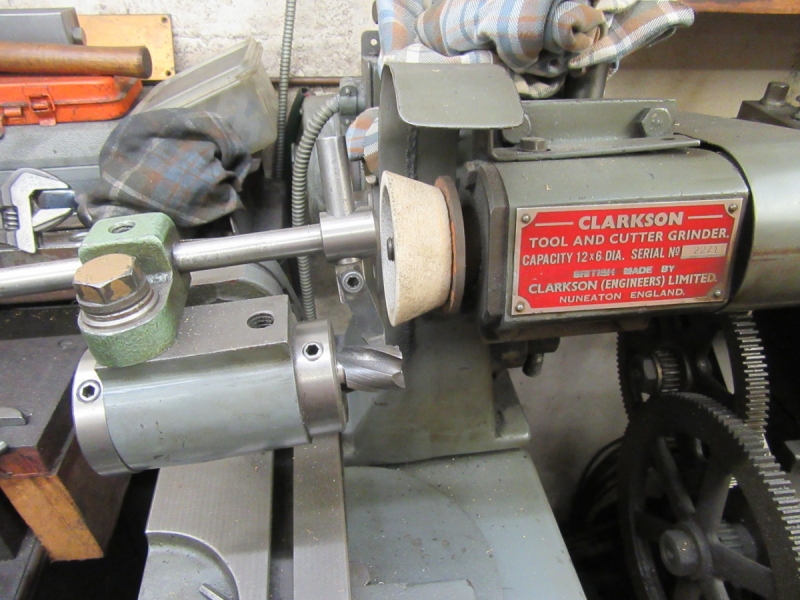

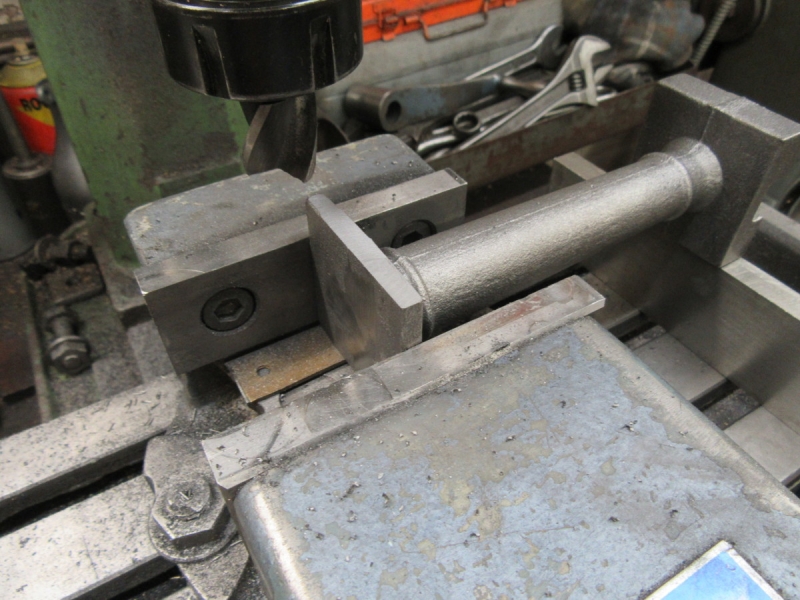

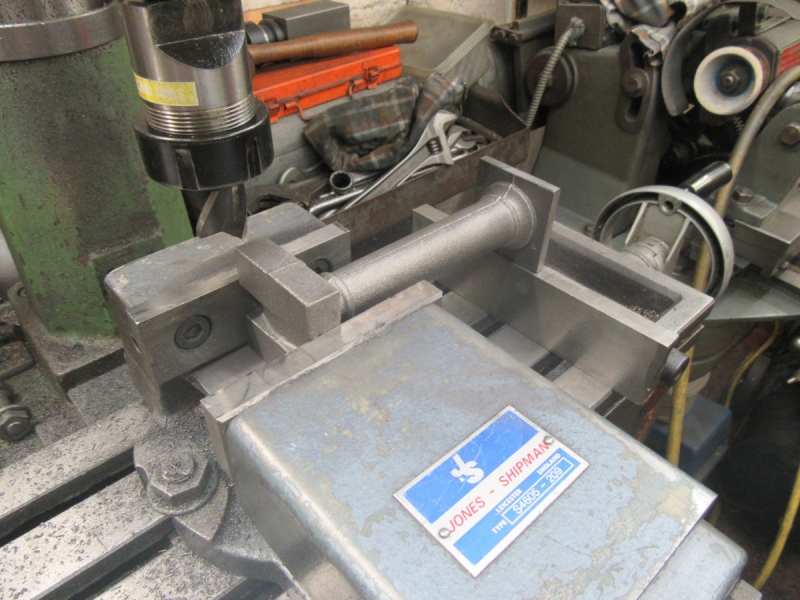

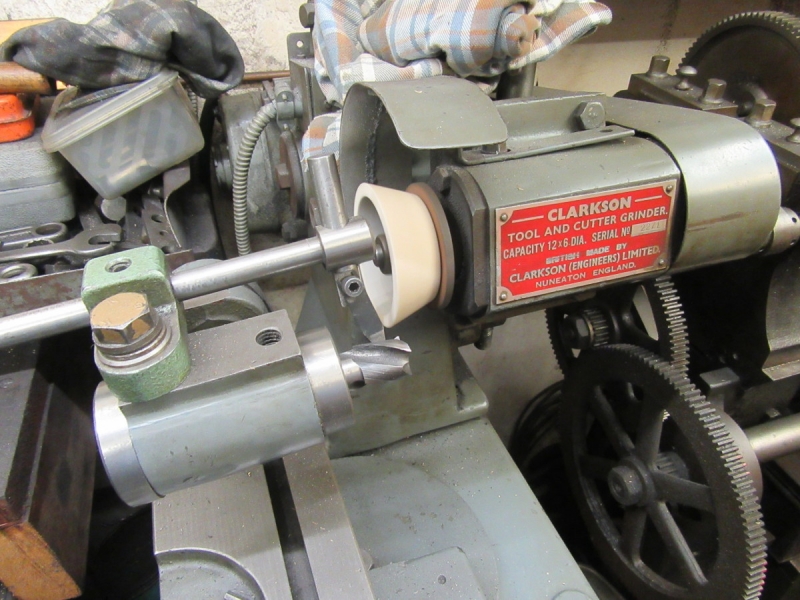

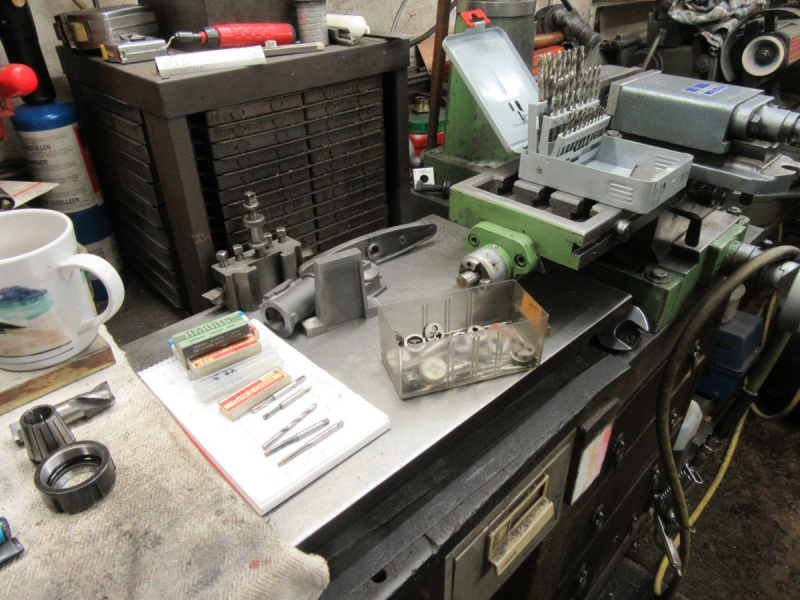

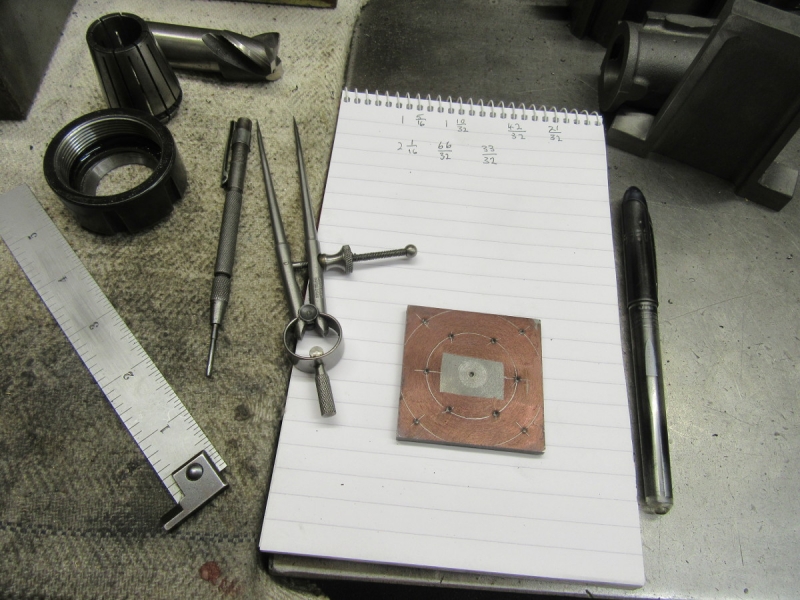

One other matter that I have been forgetting. Not many amateur sheds have a tool and cutter grinder. Even fewer have an inmate who has taken the trouble to get to an adequate level of proficiency. I'm sure many of you will remember my sharpening binges when I sharpened all my cutters for both the horizontal and vertical mills. I just want to say that at no point in that process was I wasting my time. Both the slab mill and this end mill perform perfectly. That's a matter of great satisfaction to me.