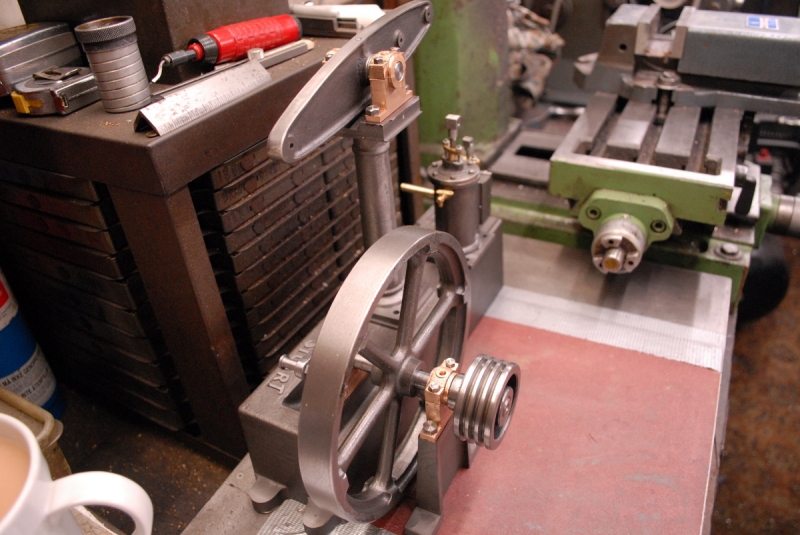

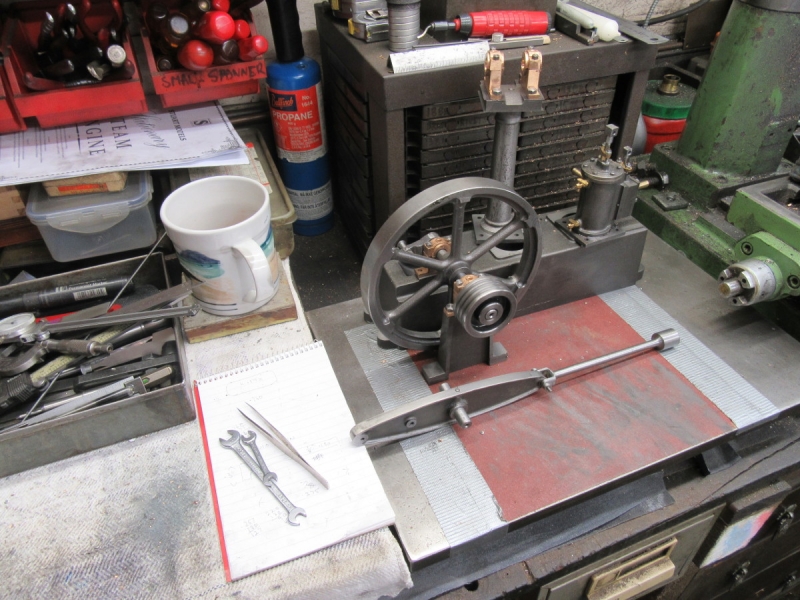

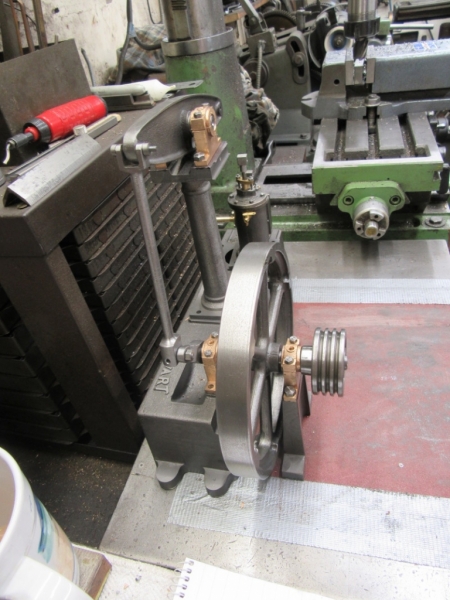

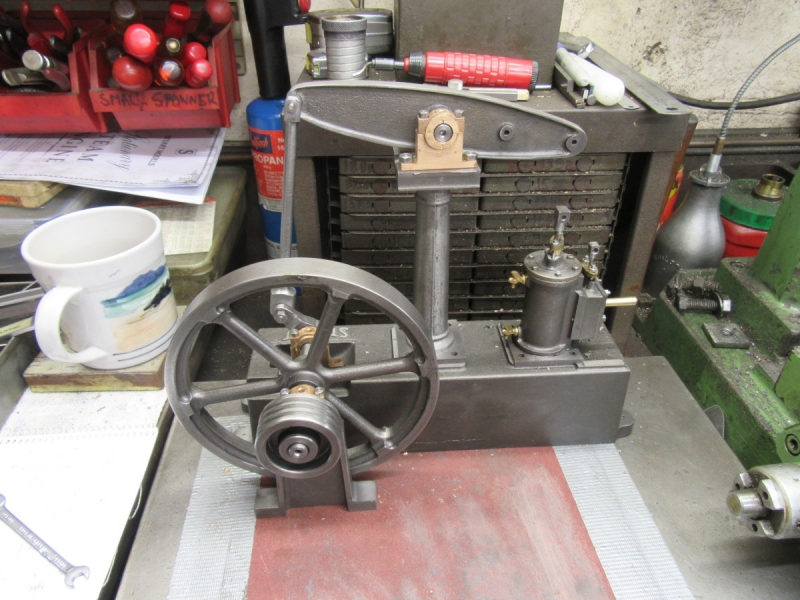

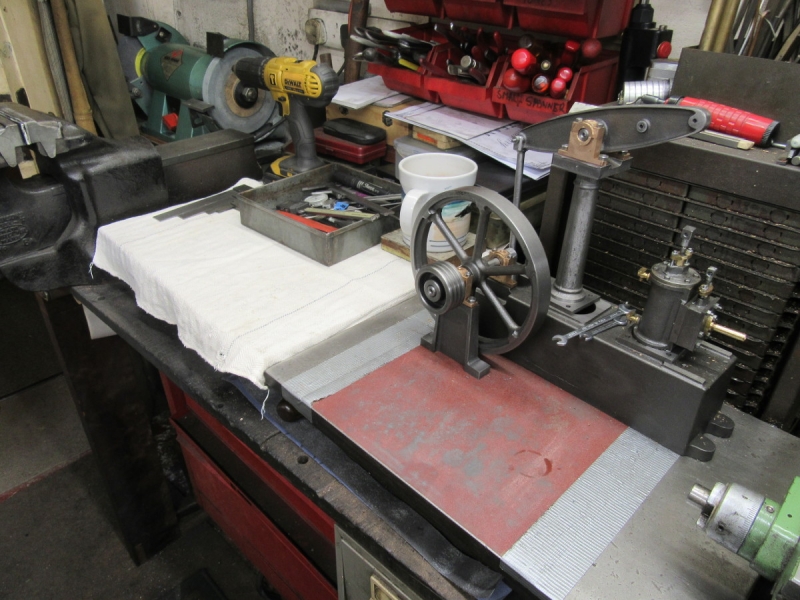

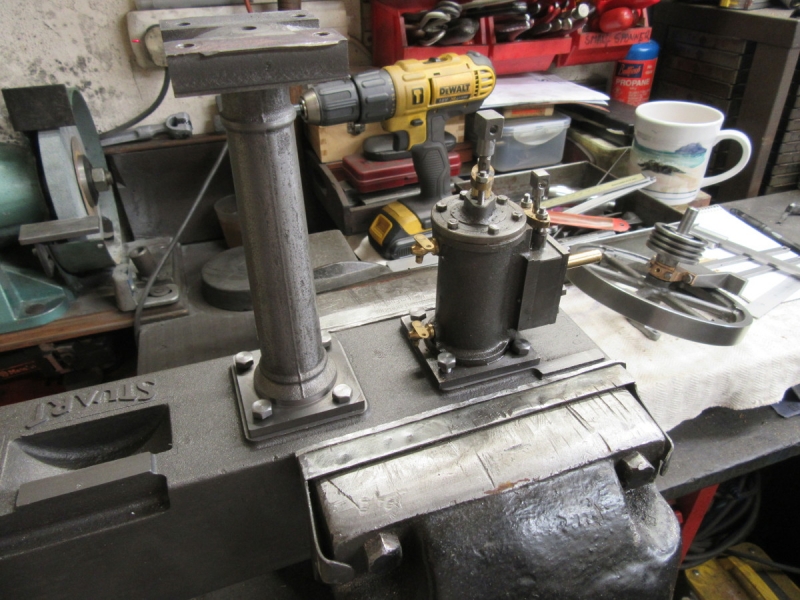

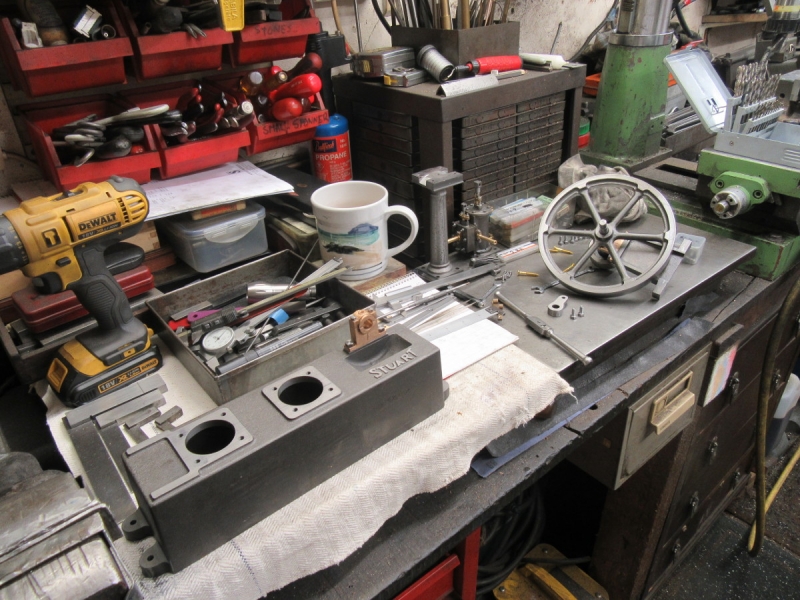

Not representing anything, just a simple rotative beam engine.

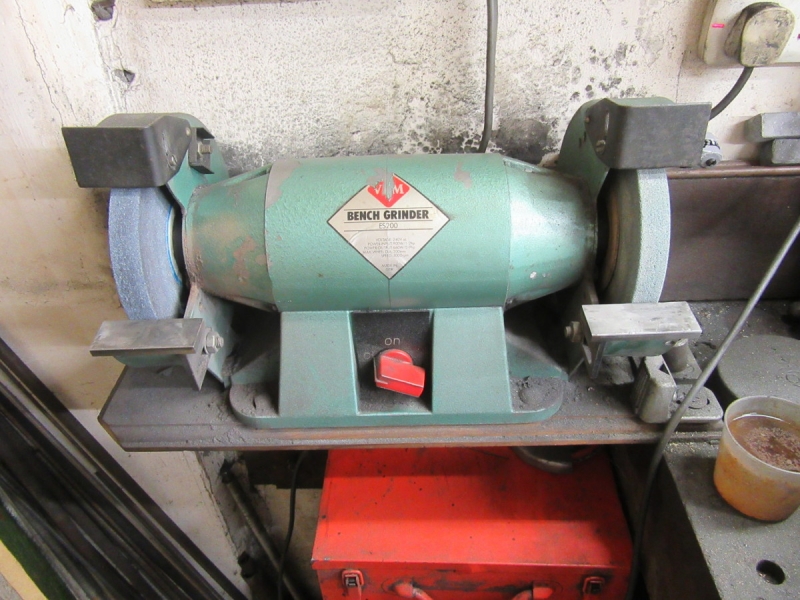

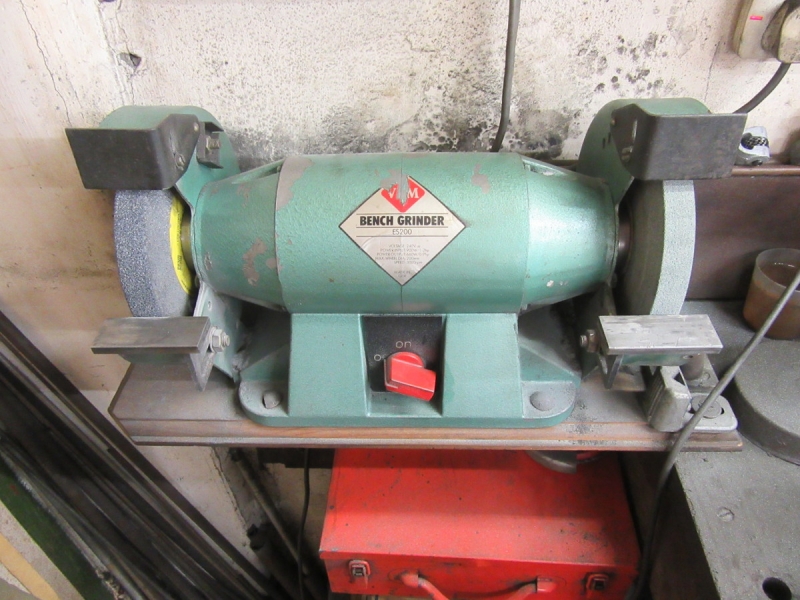

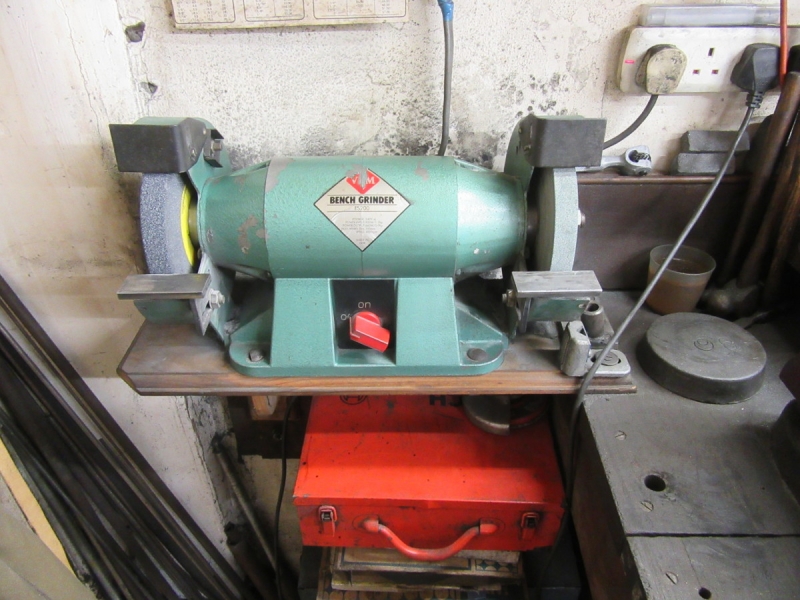

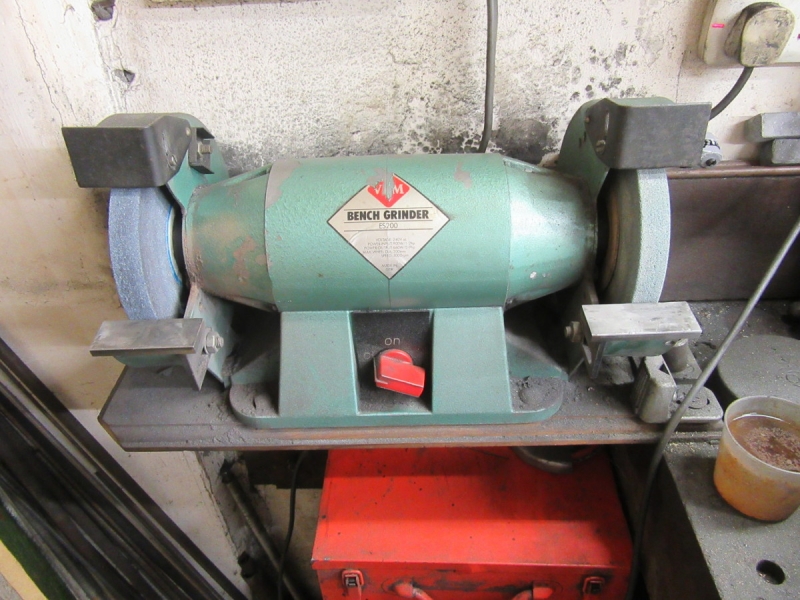

I told you I was going to have a rest from the beam engine to address a long term matter that's been nagging me. Here is the problem. I bought this East German grinder at least 40 years ago and have never regretted it. It's powerful, over 1hp, single phase and runs at 3,000rpm. It's been absolutely reliable. However, right from the start it had a nagging little vibration and this has varied with different grinding wheels, sometimes being really bad. I decided to go through it and see if I could find the source.

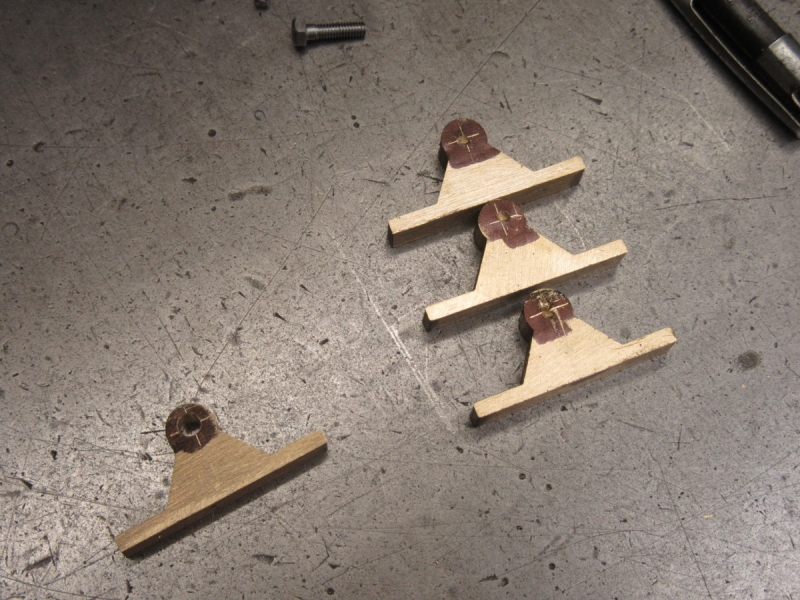

One little tip. The retaining nuts on the spindle don't need to be tight but over time can freeze up The best way to lock the wheel while you give the spanner a sharp bump is to wedge the wheel with a small wooden wedge.

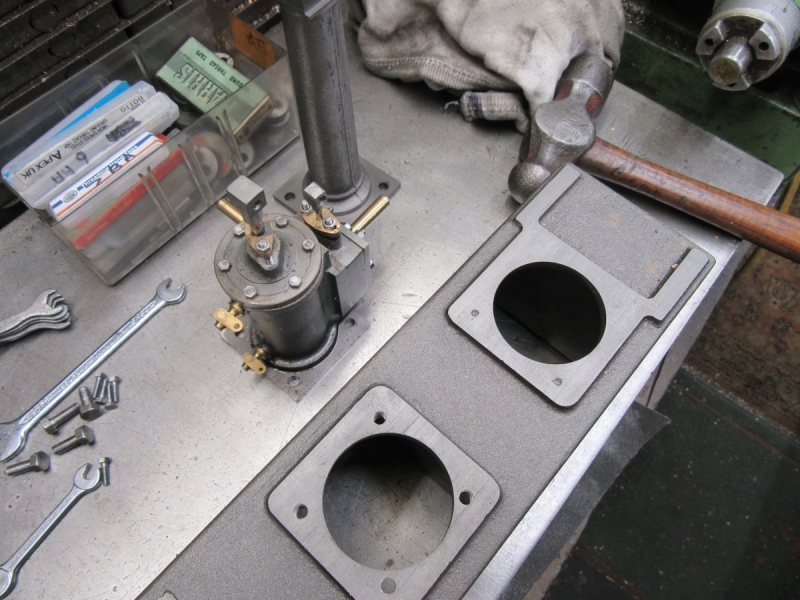

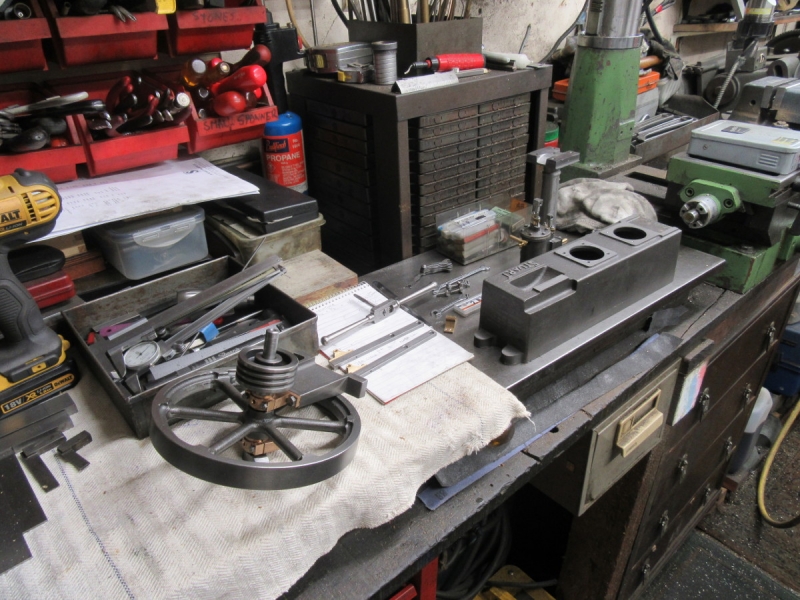

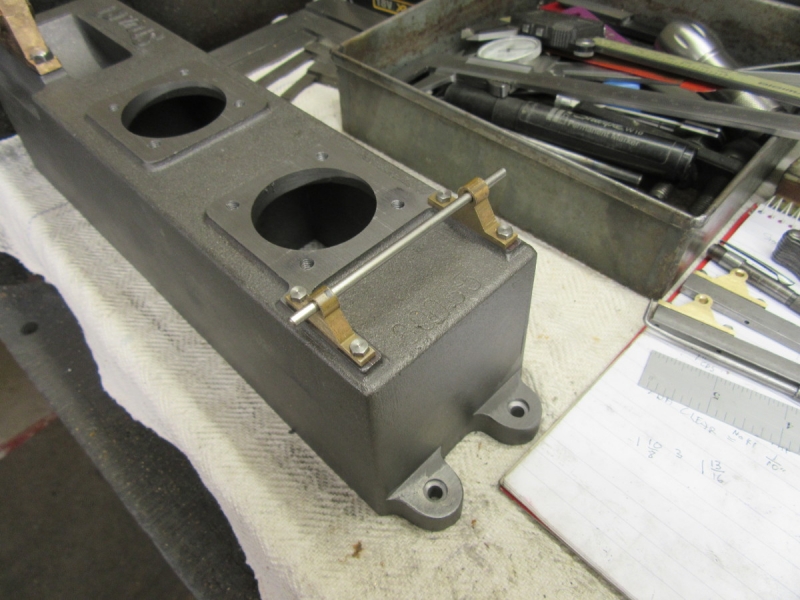

It didn't take long to get the grinder stripped down. Notice the rust on some retaining plates. Notice also the 12" Bahco adjustable for the nuts, such a treat to be to be using a decent sized spanner for a change!

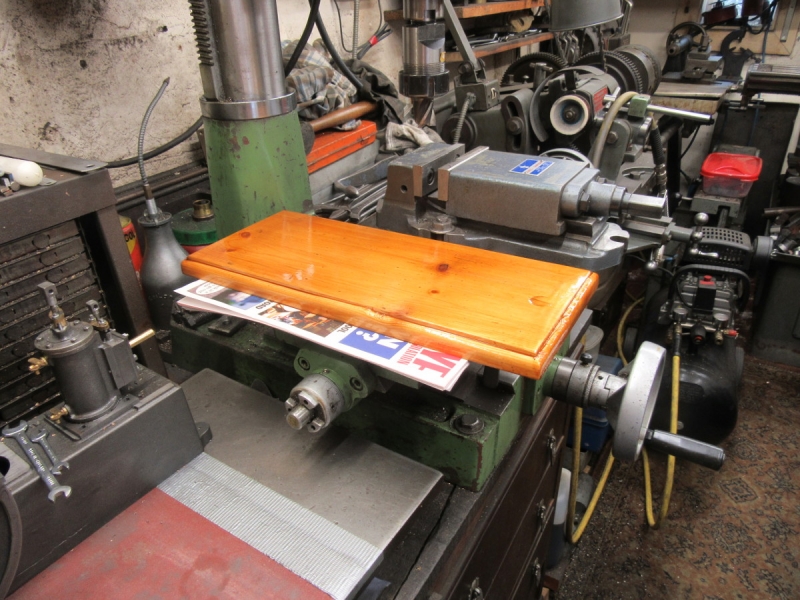

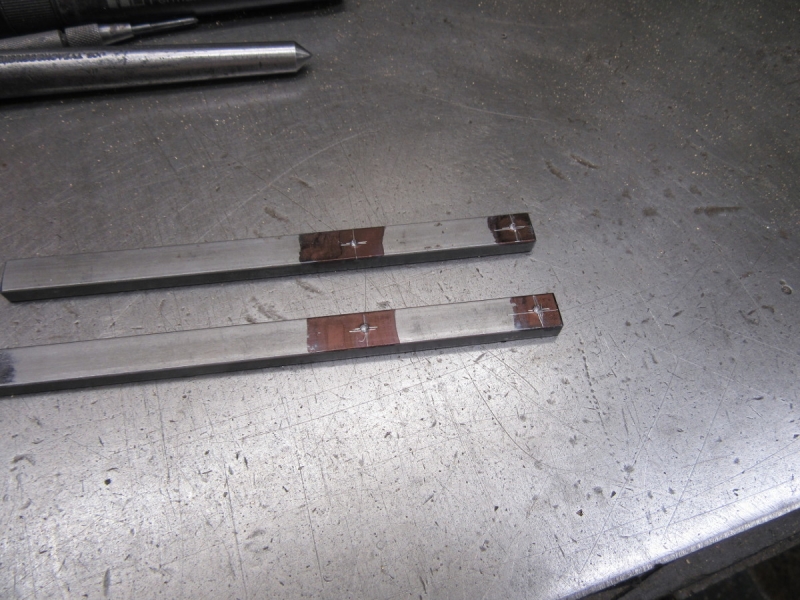

I gave the grinder a good clean and polished the spindles with emery strip. At the same time I measured them and not surprisingly seeing as it is a continental machine they are 20mm. The retaining plates are a good fit on these spindles so I can trust the central hole in them.

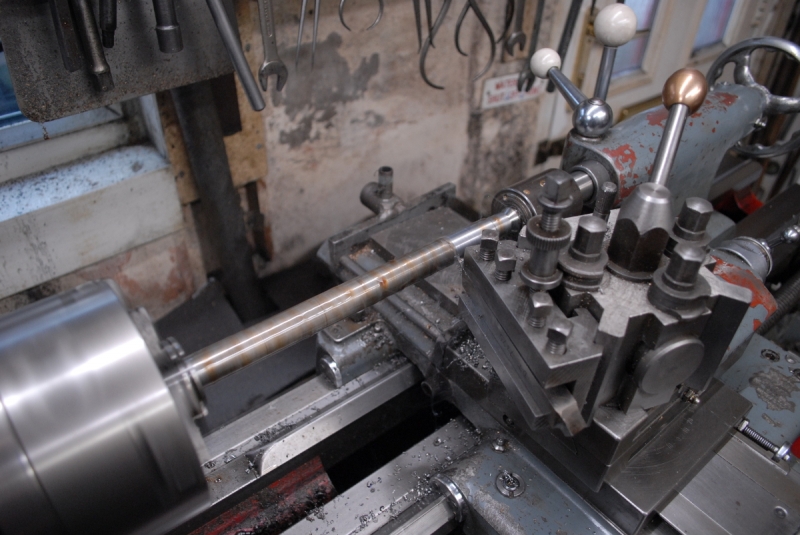

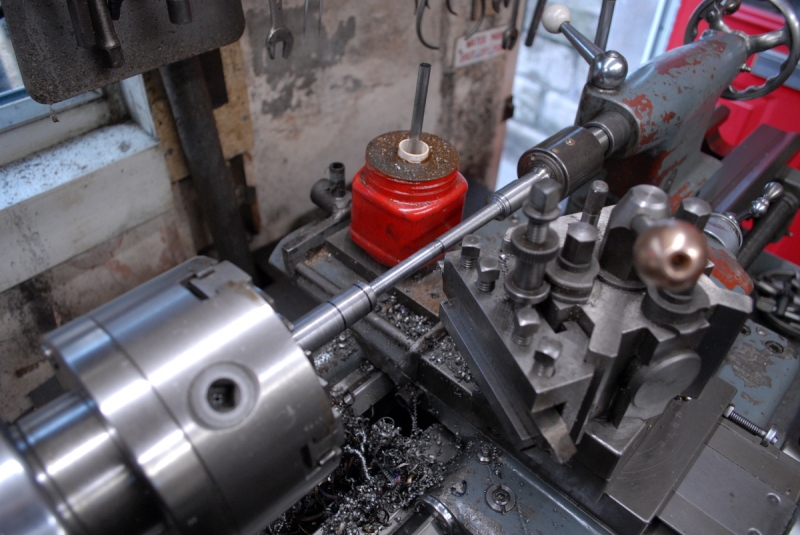

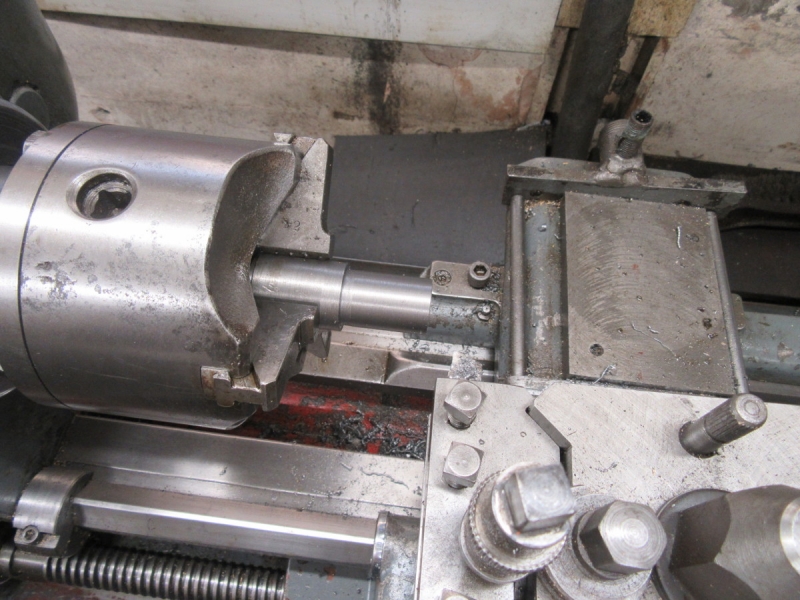

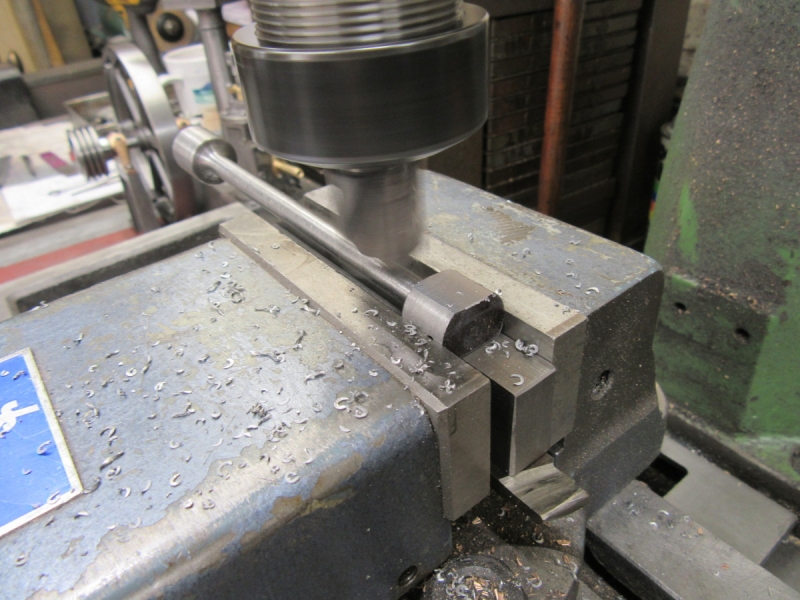

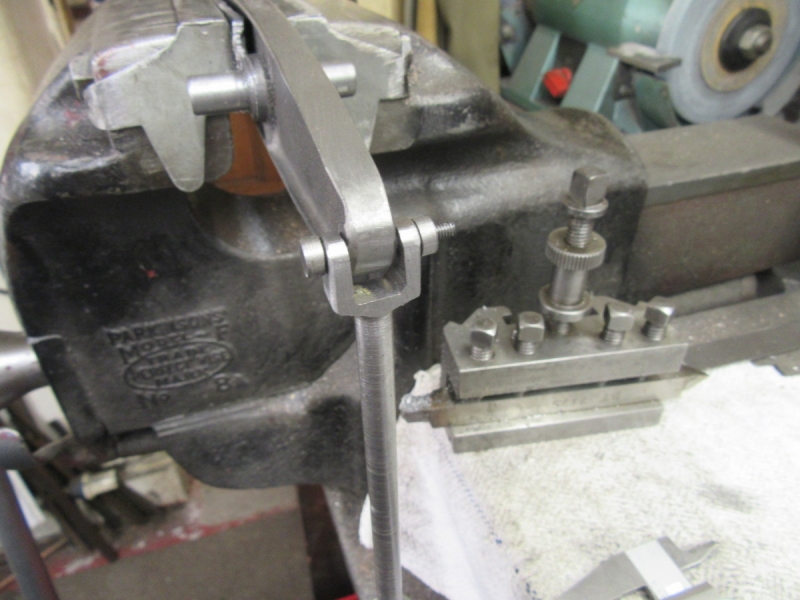

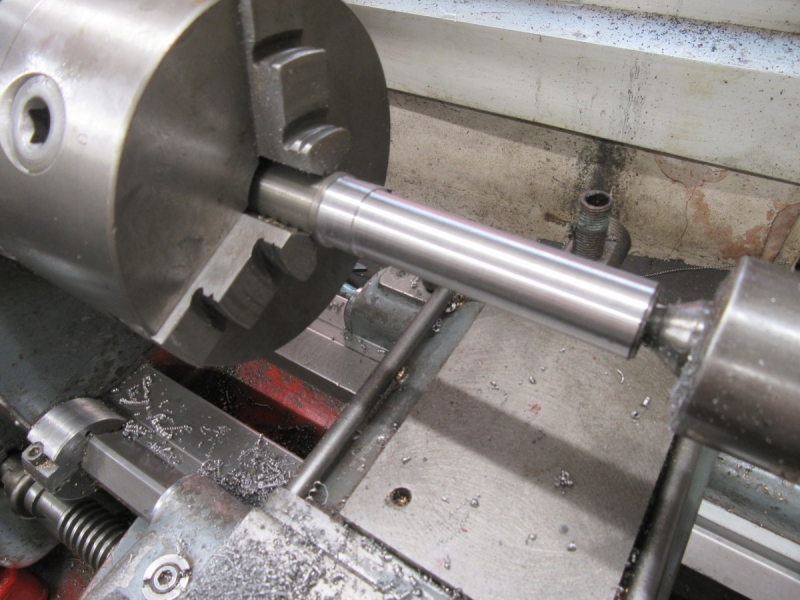

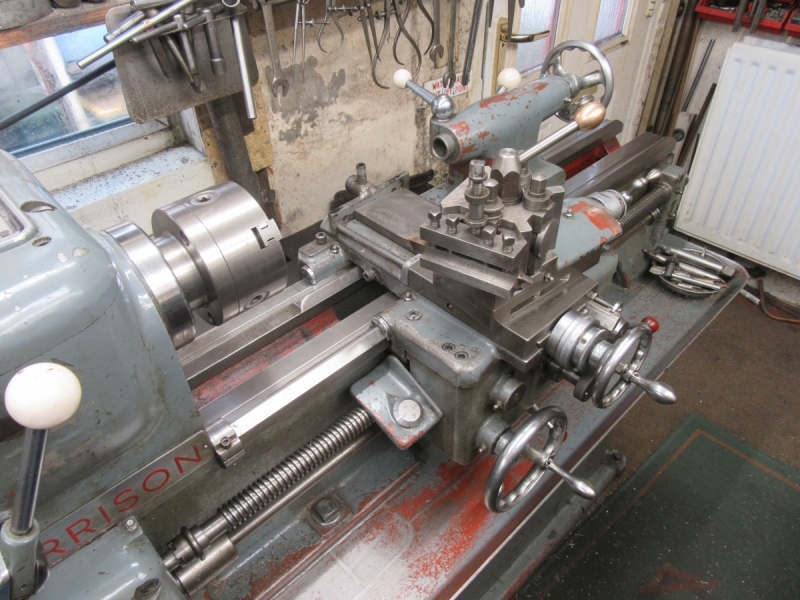

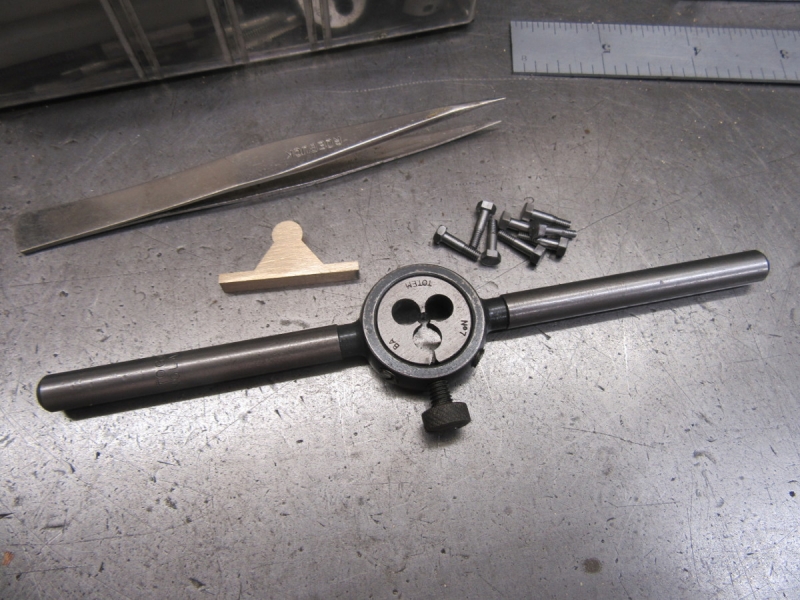

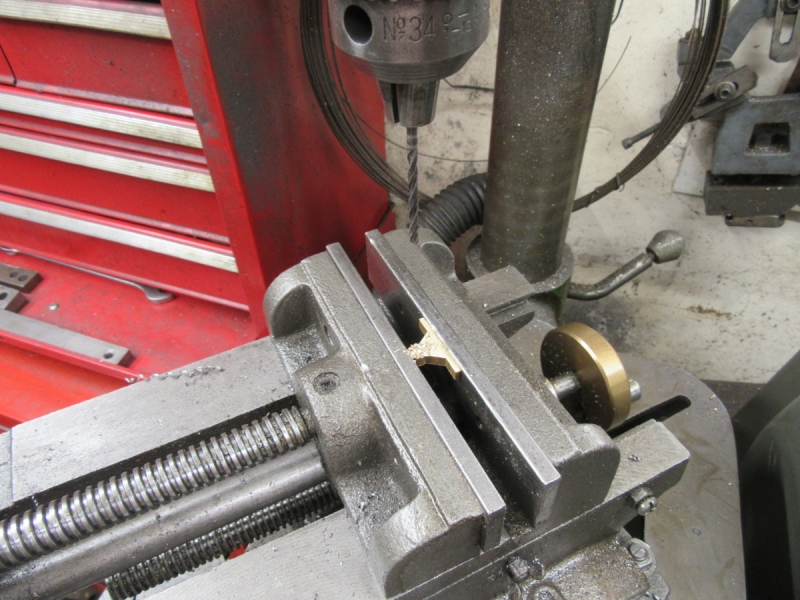

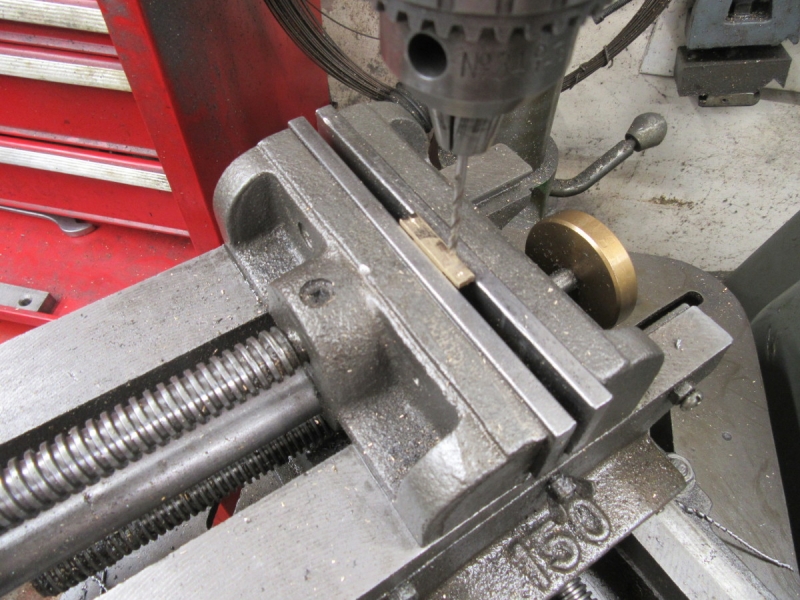

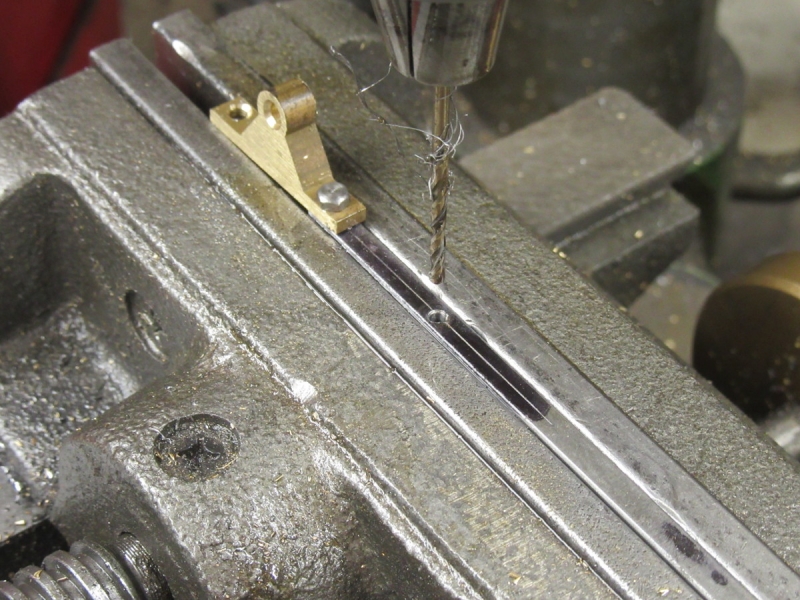

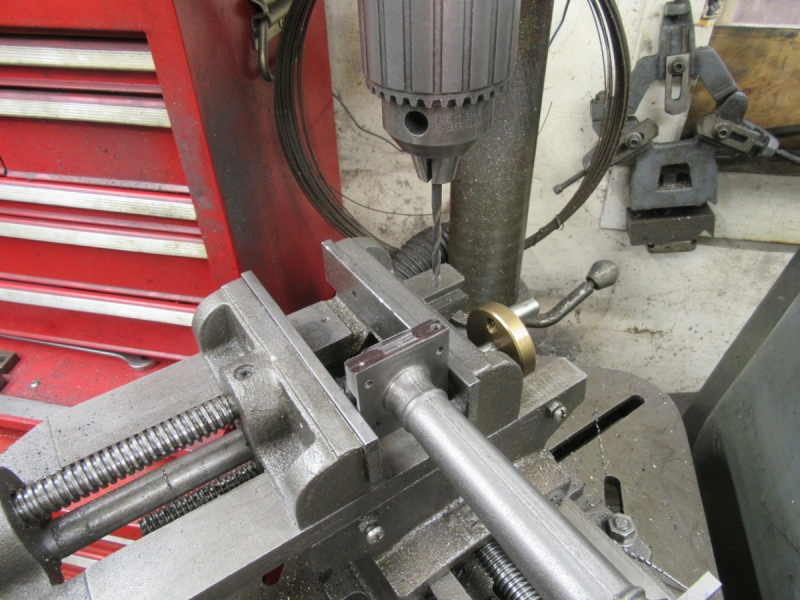

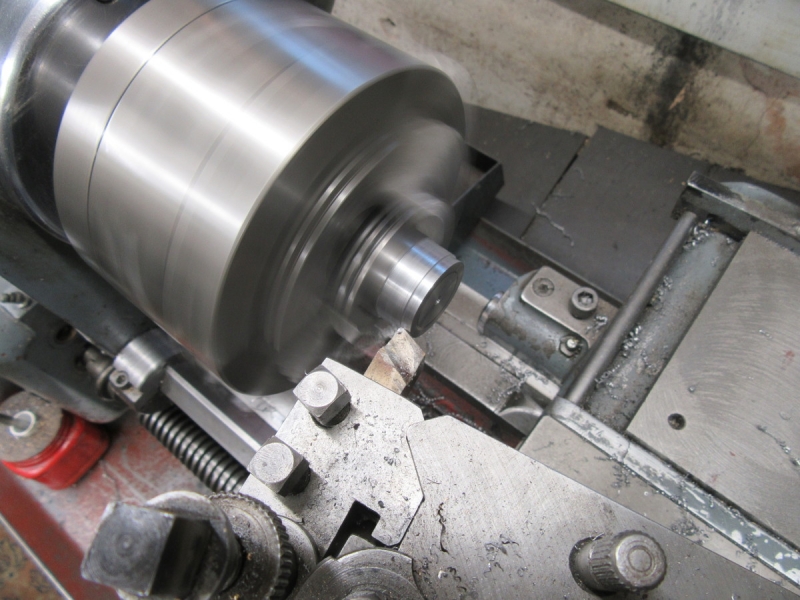

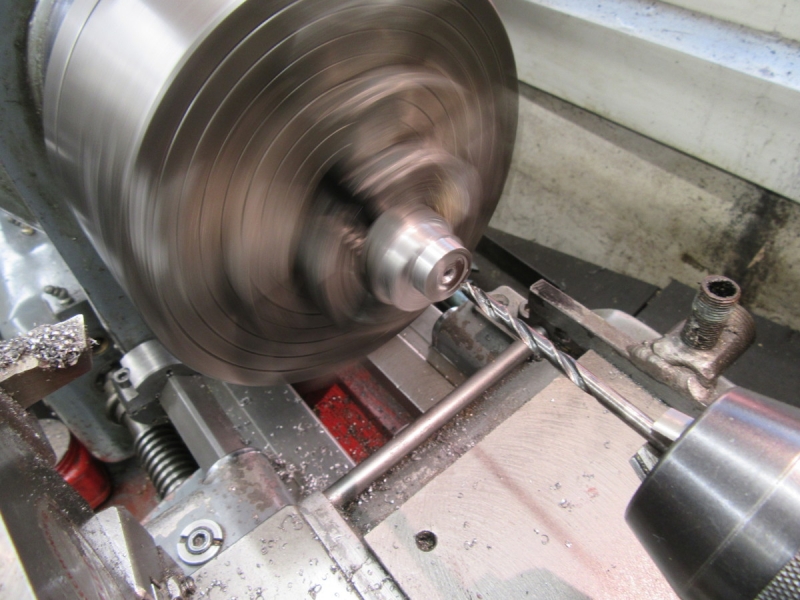

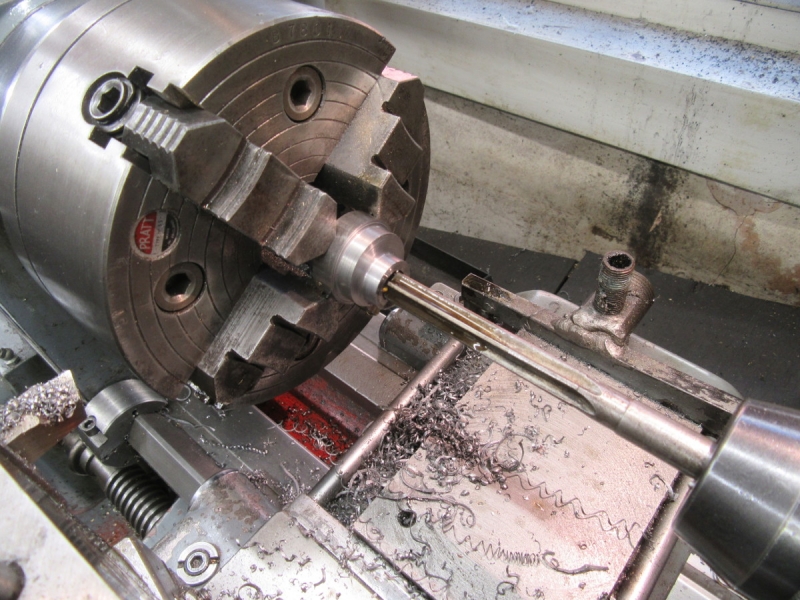

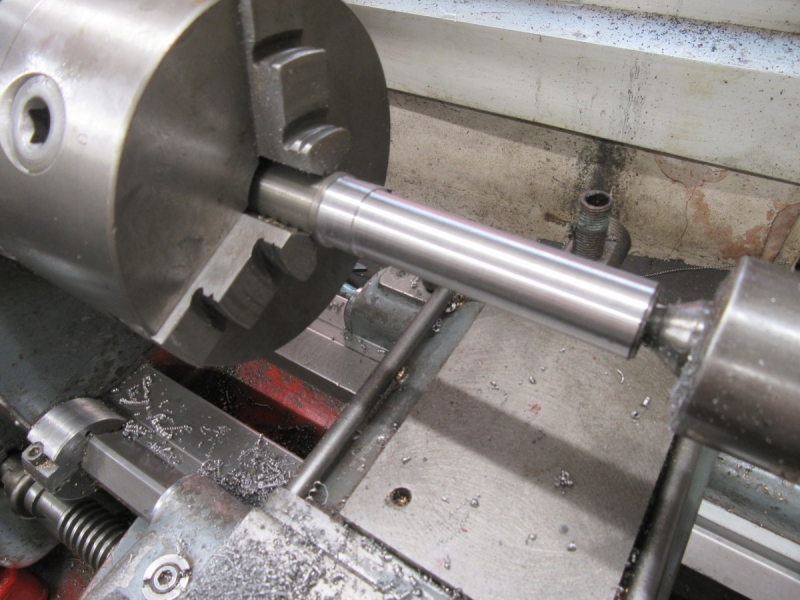

I changed the chuck for my most accurate 3 jaw in the expectation that the jaws would fit in the central hole but no way, far too big. So I went in the front room and tried the three jaw on the smaller 1927 lathe but that was no good either. Only one thing for it, I needed to make a 20mm tapered mandrel. So into the scrap box and I found this piece that was very close. I shall turn it to size and use it without disturbing it, that way it will be dead accurate. All I have to do is turn it close and put a very slight taper in it. Less than 2 thou over the approximately 5" length. Not an easy matter.

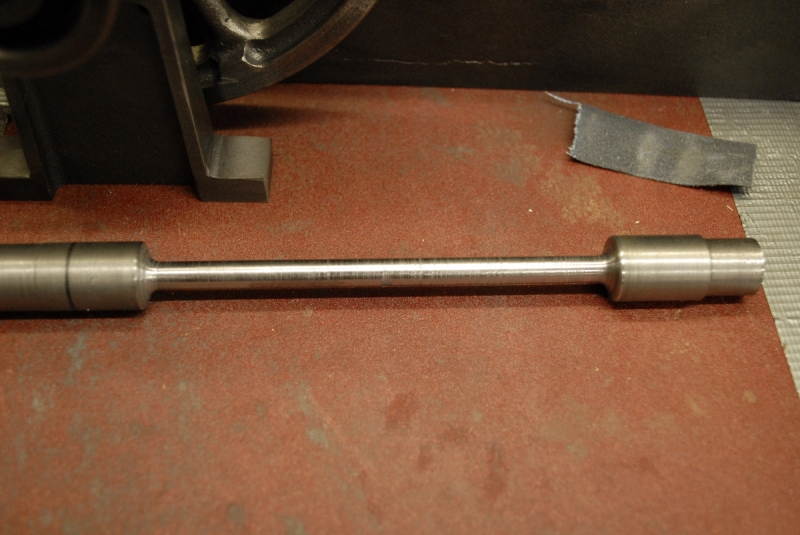

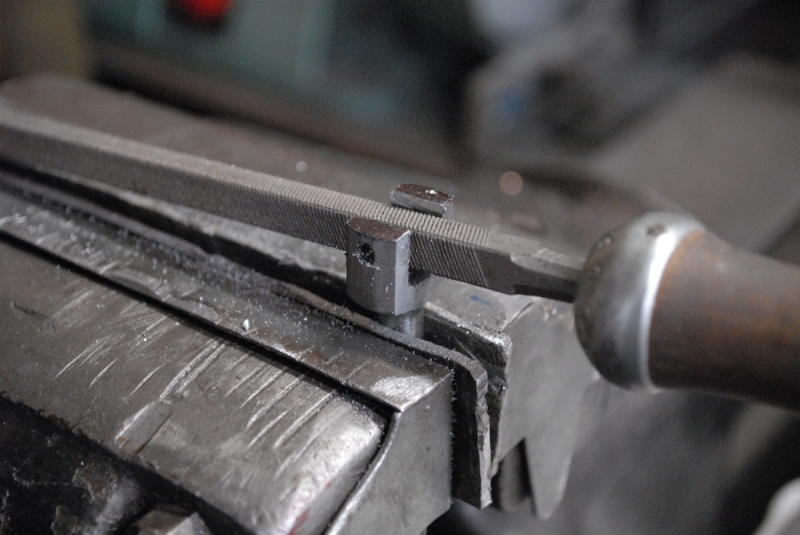

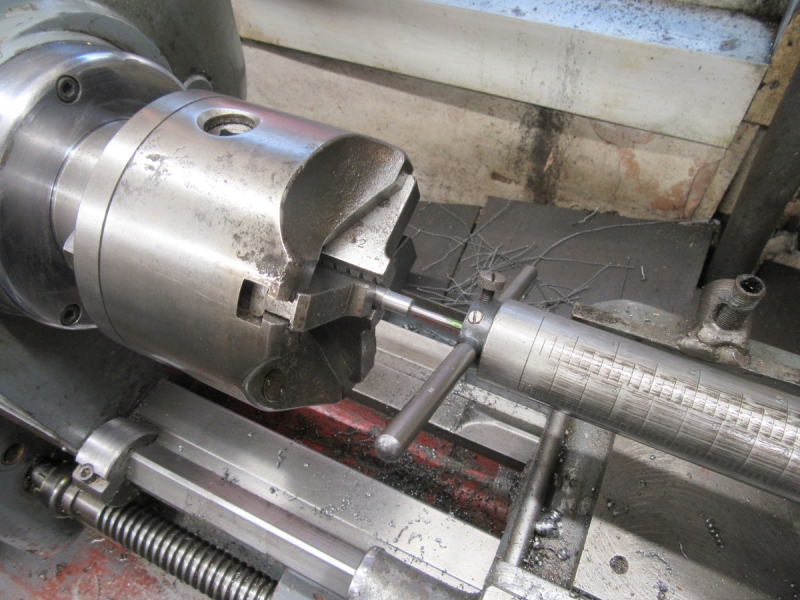

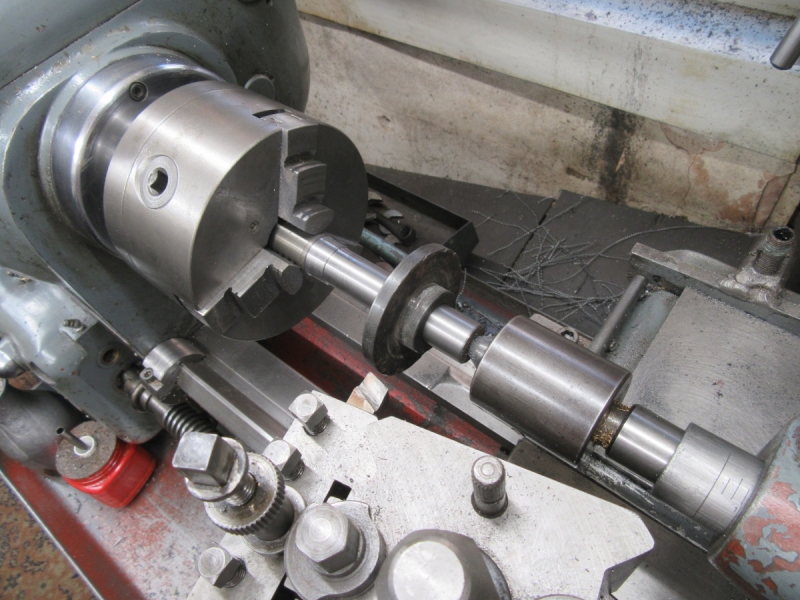

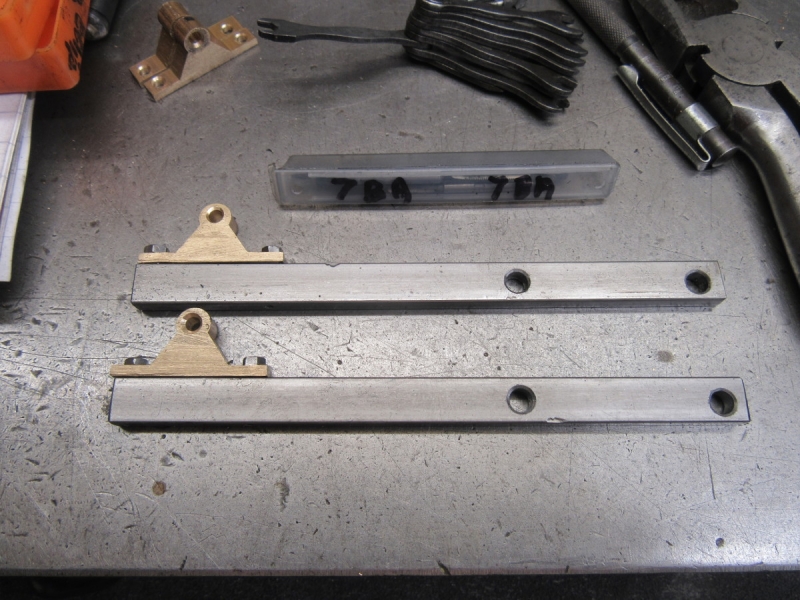

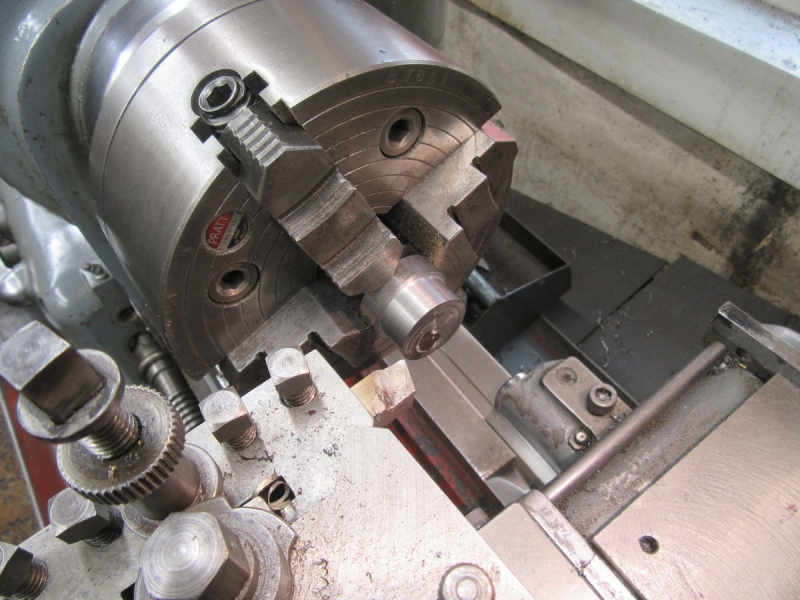

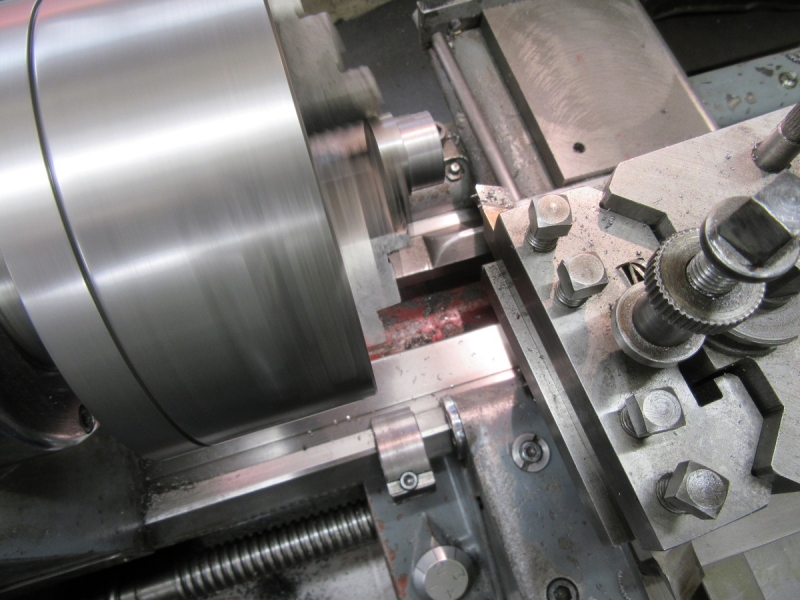

Here we are after some careful turning and the making of the taper by filing the mandrel and making the final adjustment with fine emery strip. Slow and needing a lot of patience but there was no way I could set the lathe accurately enough to make a taper as fine as this. I got there in the end and I could mount the plates simply by hand and tight enough to turn with very light cuts. It worked well.

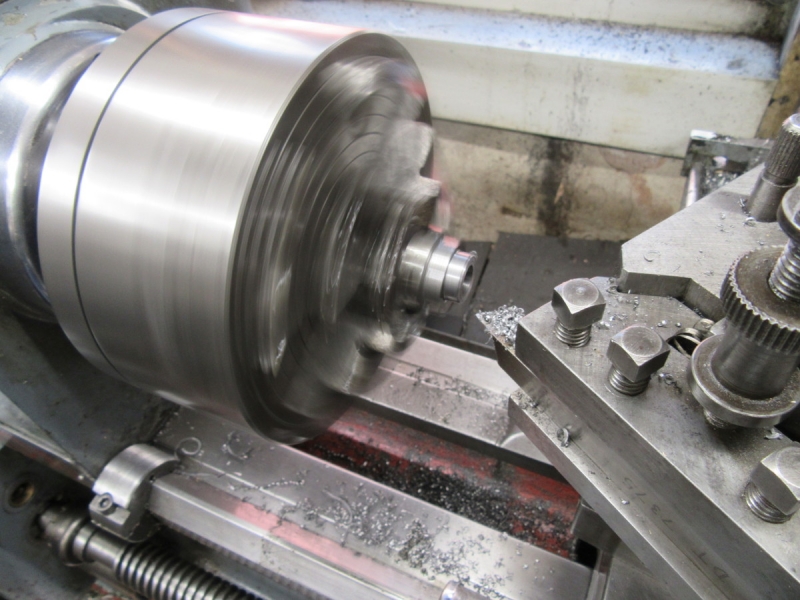

Here we are at knocking off time after more than 2 hours concentrated work. I am certain the mandrel is dead accurate and when I mounted this first plate it was slightly out on both the periphery and the mating face with the wheel. I don't think it was enough to cause serious vibration but there are three more and they could be worse. I shall find out tomorrow as it will be dead easy to do them.

A good morning and I am satisfied with the work. Nice....