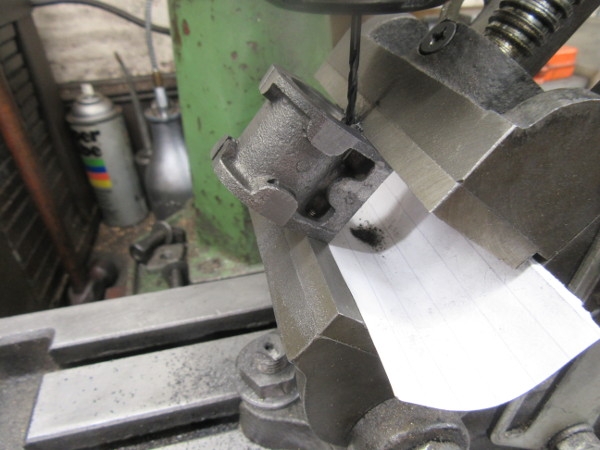

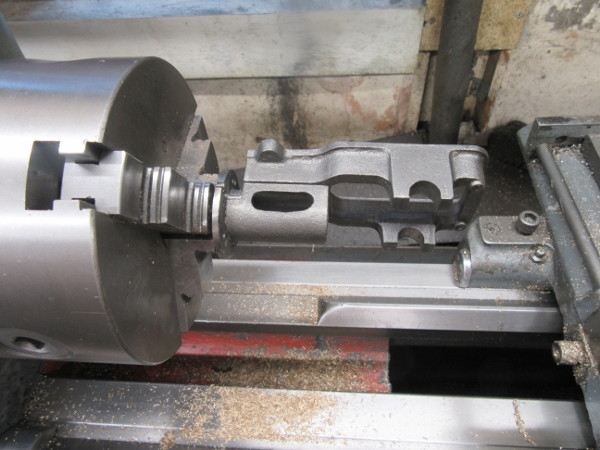

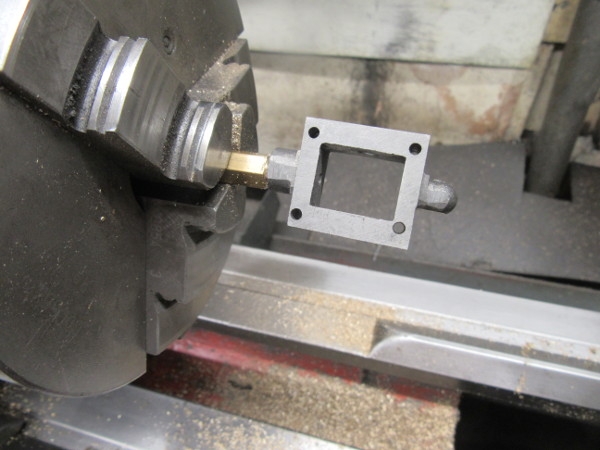

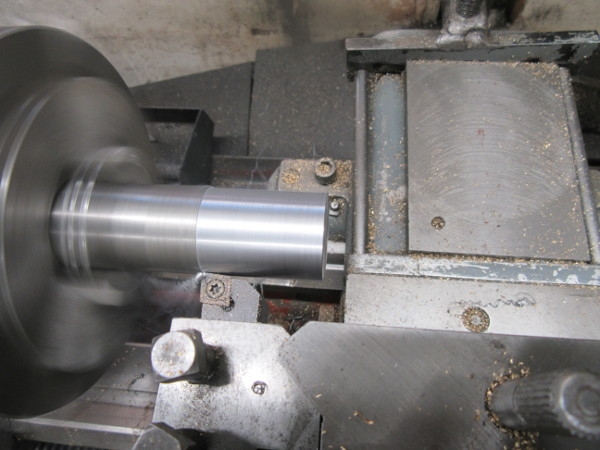

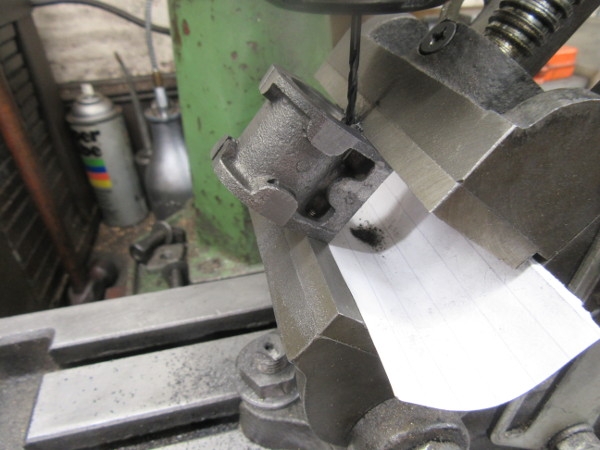

The first task this morning was to strip down the trial fit and isolate the cylinder. I have to drill the steam passage from the cylinder to the steam port. Needless to say this is not as easy as it looks. My method is to mark the exit point into the steam port on the outside of the cylinder and use that to set the vice at the right angle. It's always an educated guess and touch wood has always worked for me.

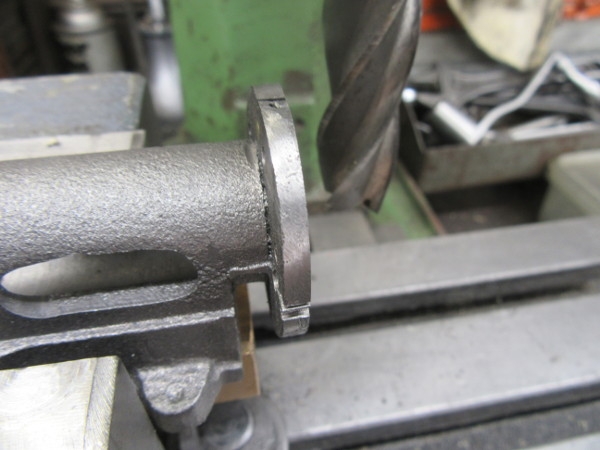

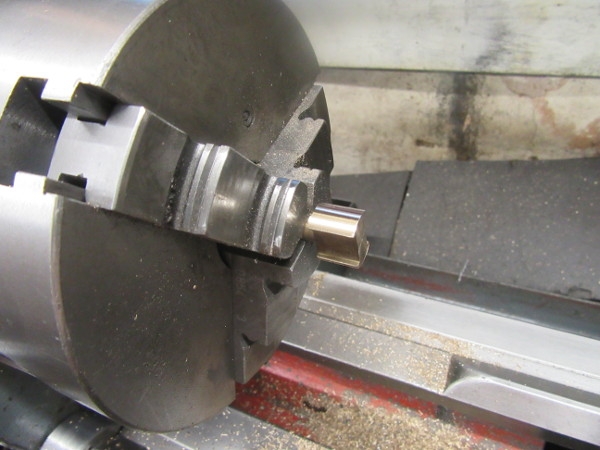

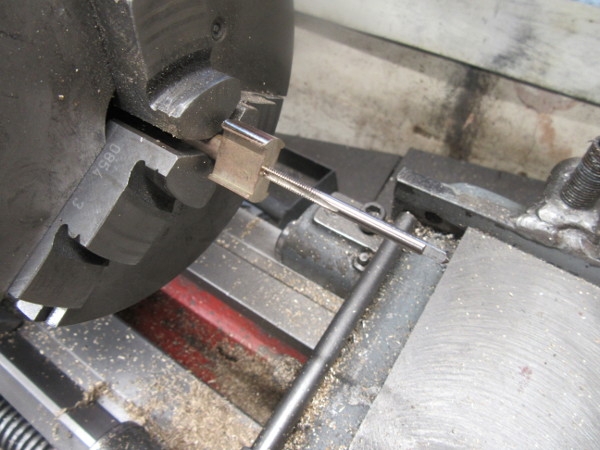

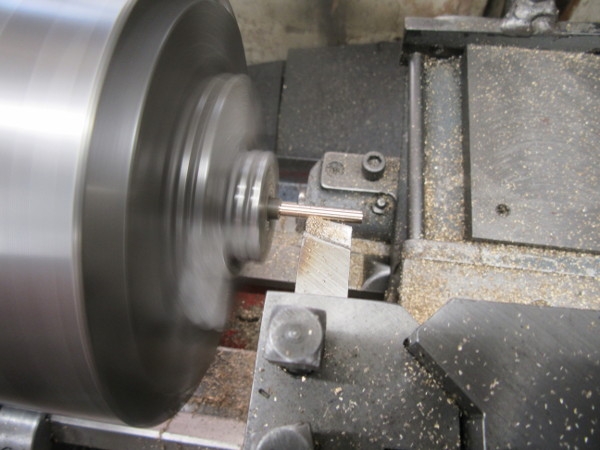

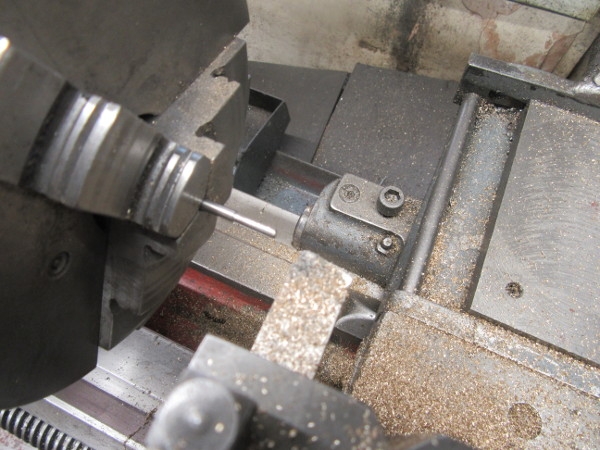

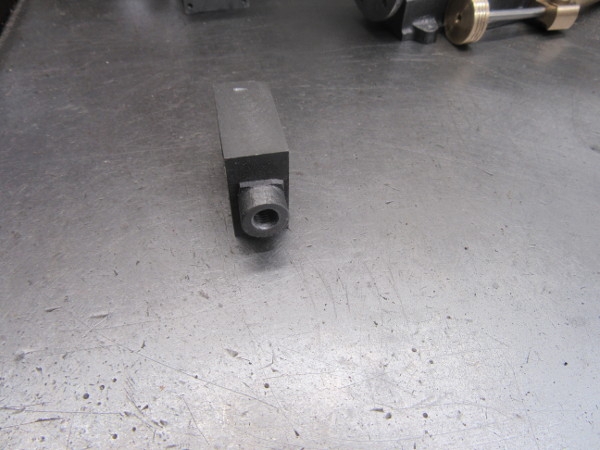

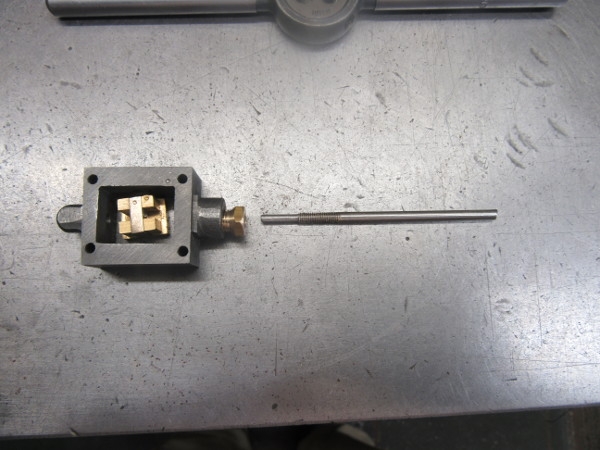

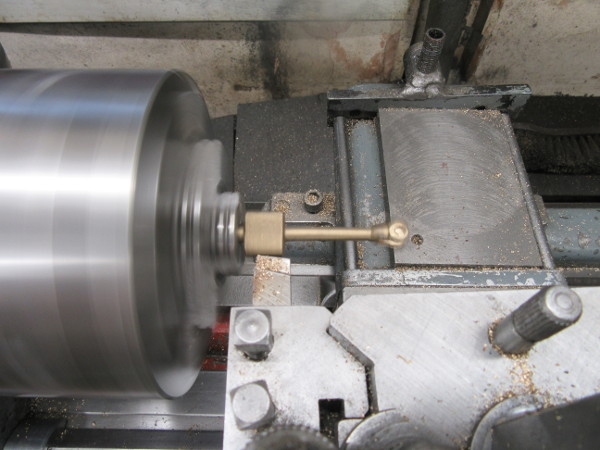

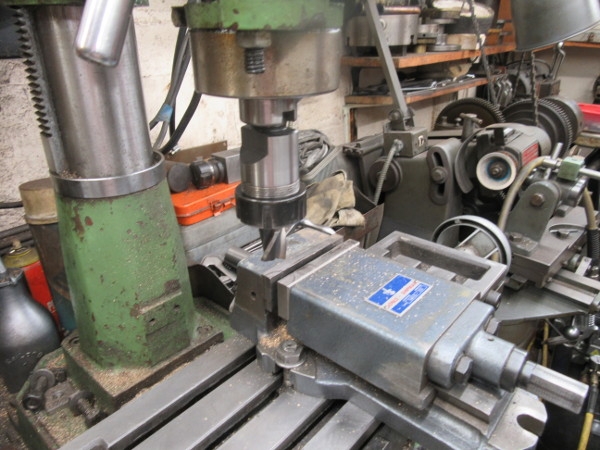

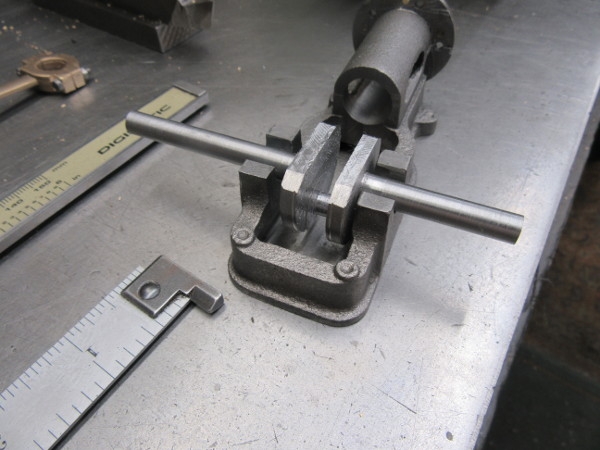

Here we are set up and ready to put a flat in the entry point so the N0 40 drill can enter straight.

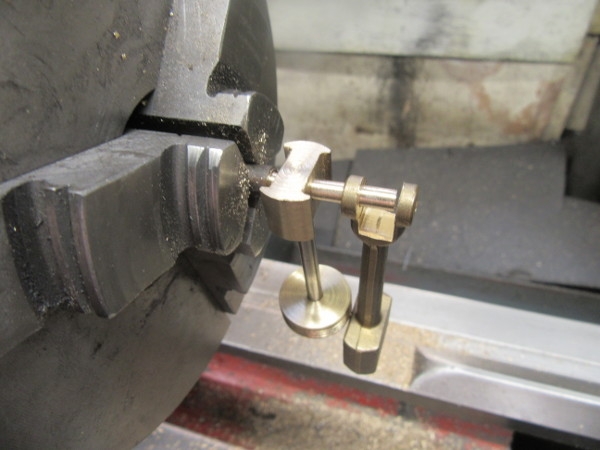

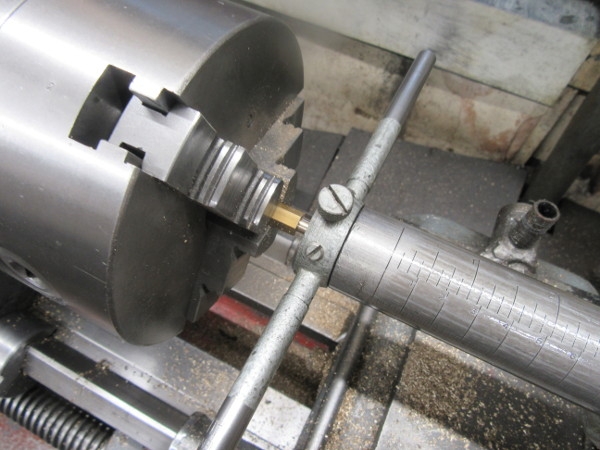

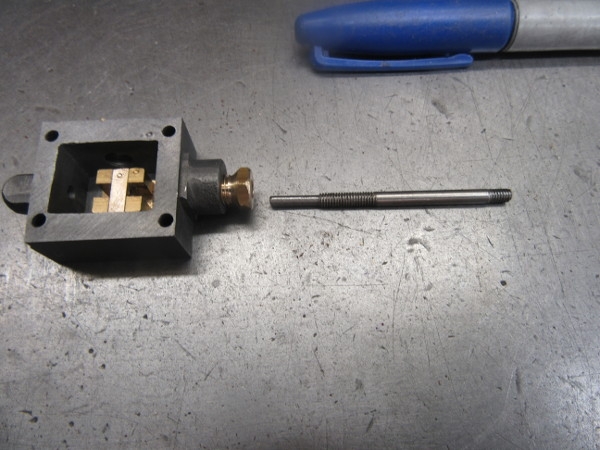

Here we are with the drill fitted and the hole is drilled. The piece of paper in the jaw of the vice is a tell tale. You can't see into the port but you want to stop drilling when your drill has entered the port. When you do cast iron dust drops on the paper and gives you an accurate warning of entry. (As long as you got the angle right in the first place and here we did.)

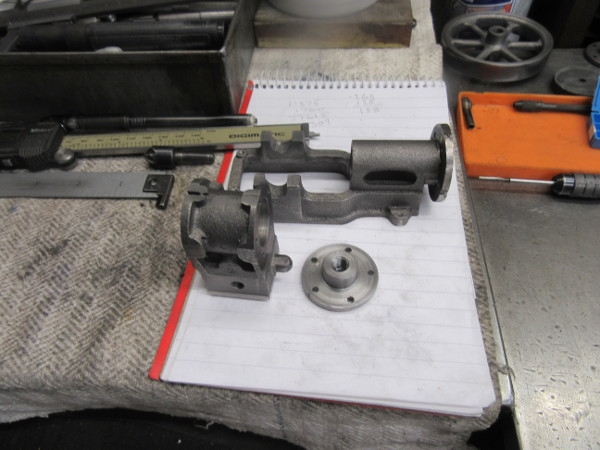

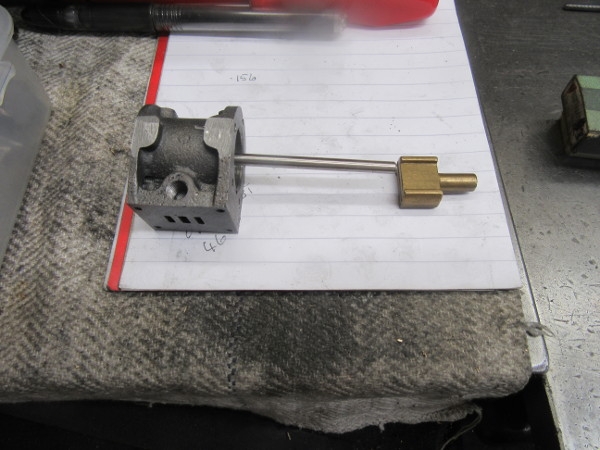

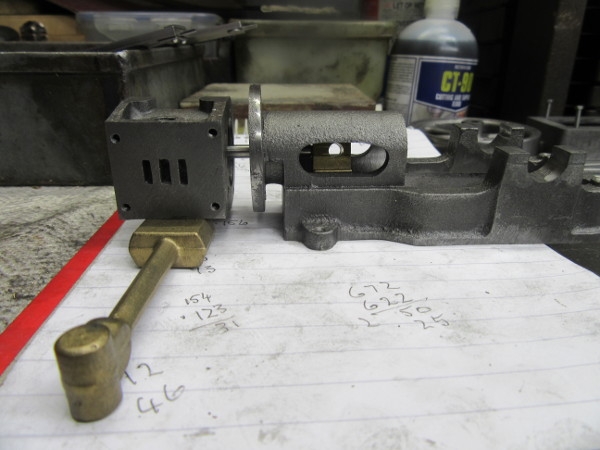

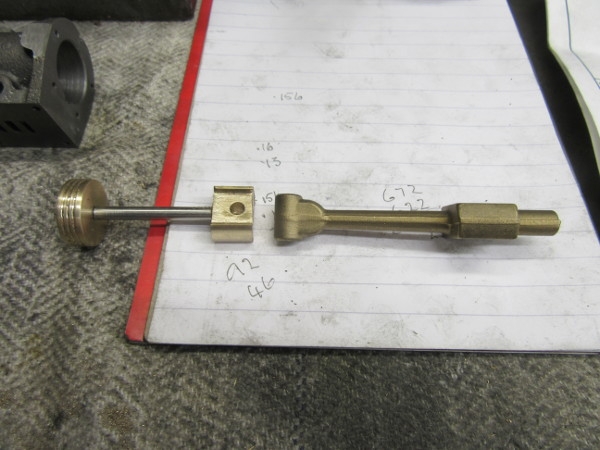

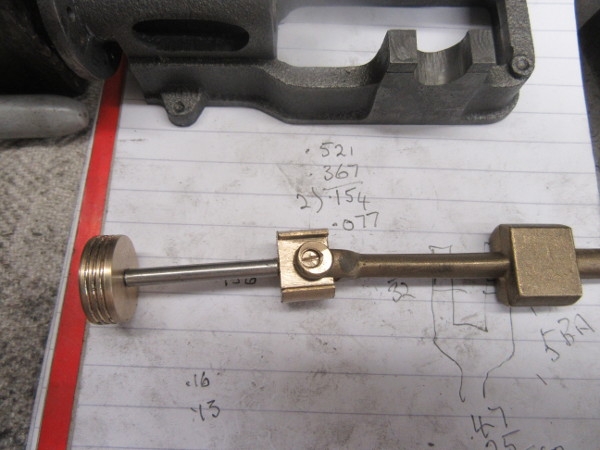

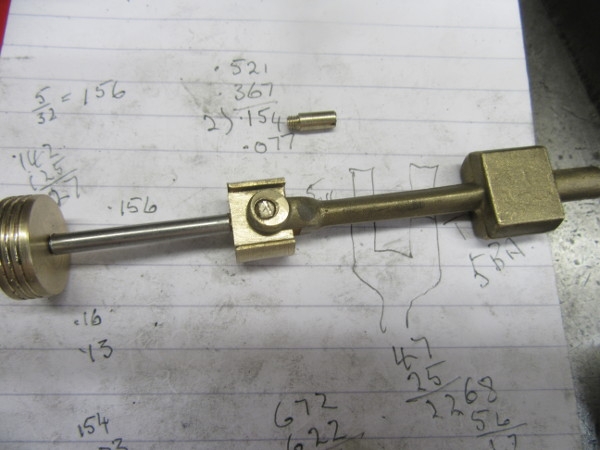

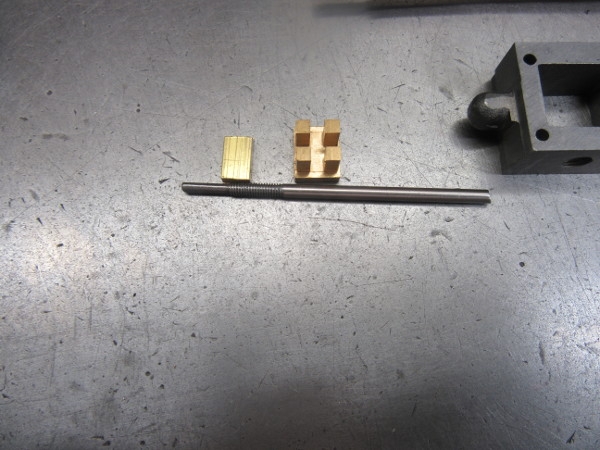

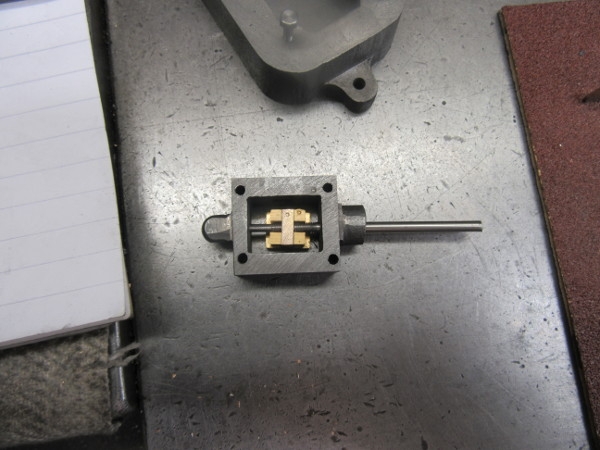

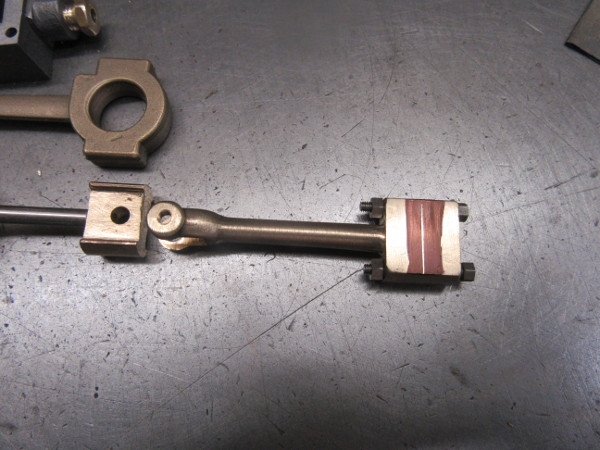

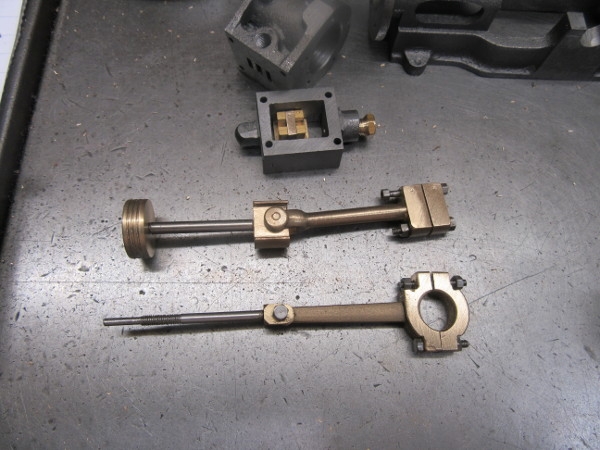

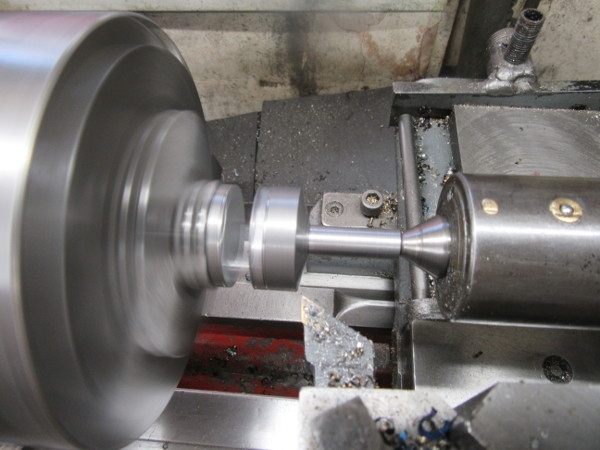

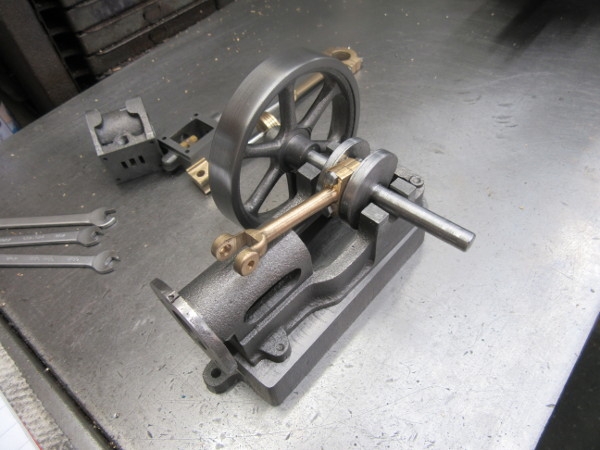

Here we are, both ports bored and as near dead accurate as makes no difference. Big sigh of relief.....

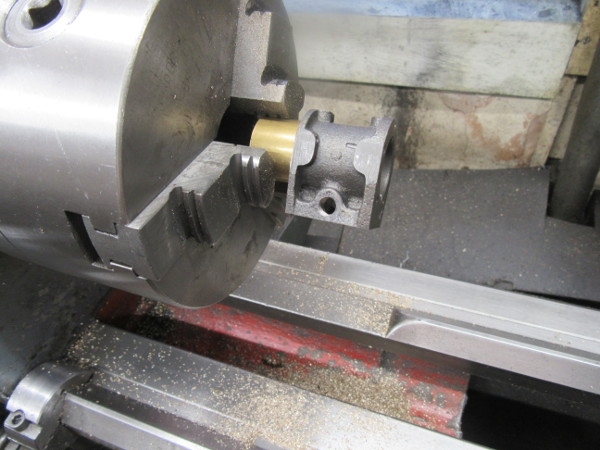

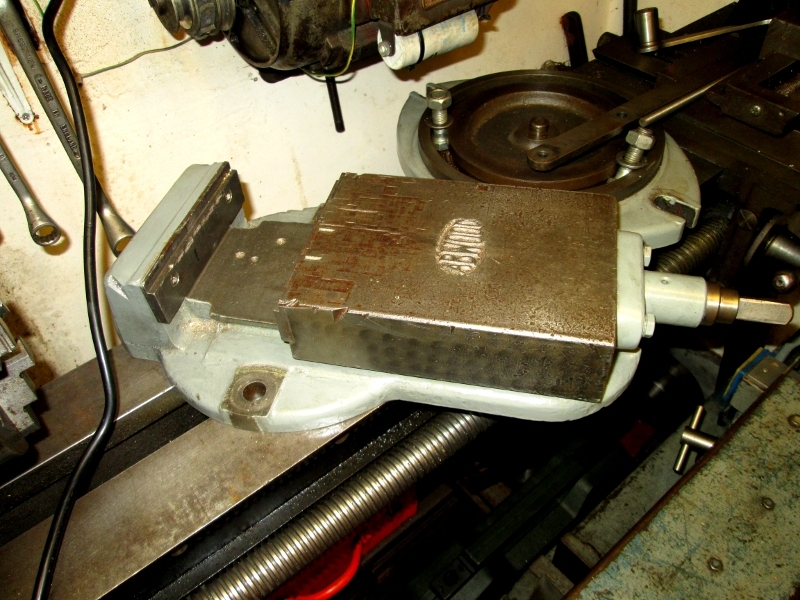

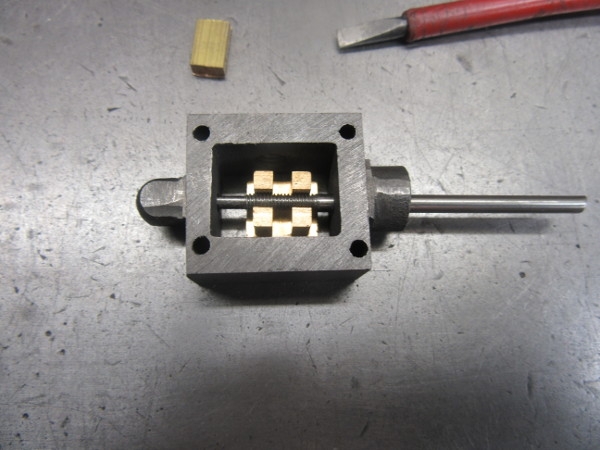

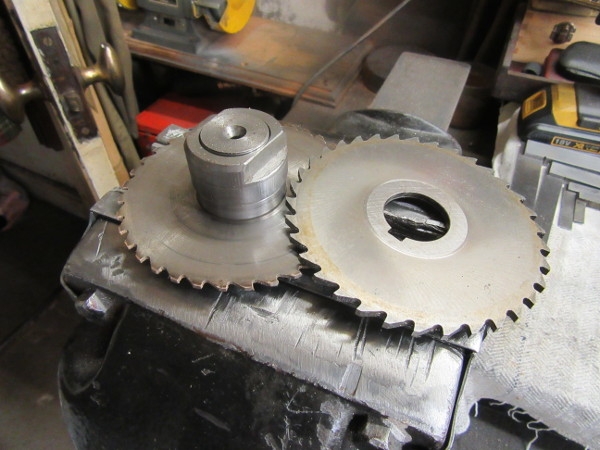

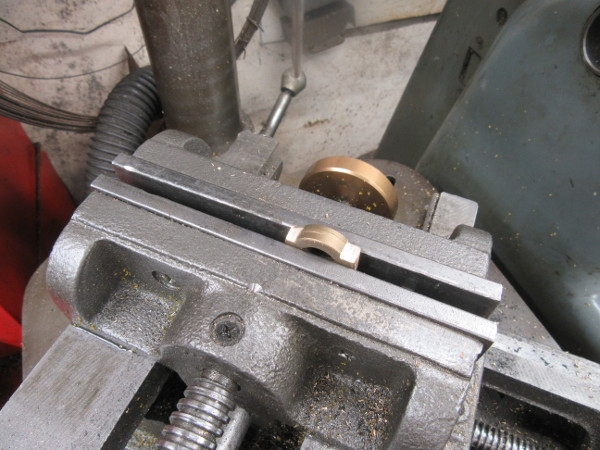

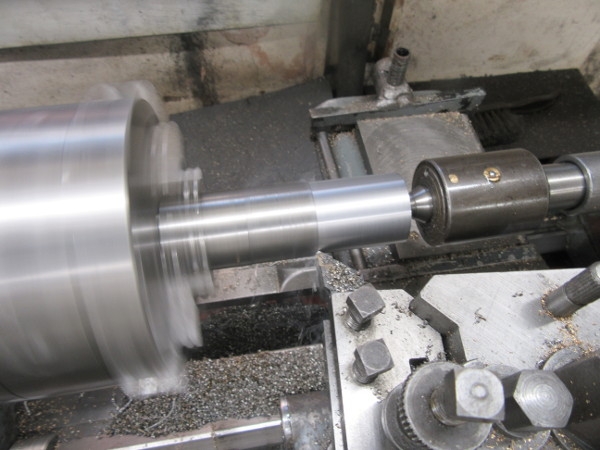

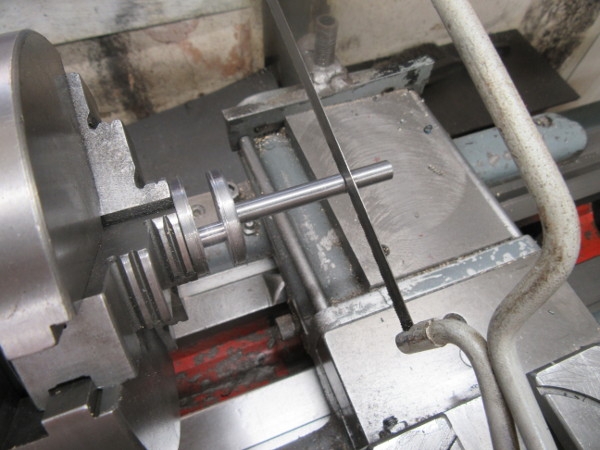

Then take the angle vise off, put the regular vise on the VM bed and tram it in.

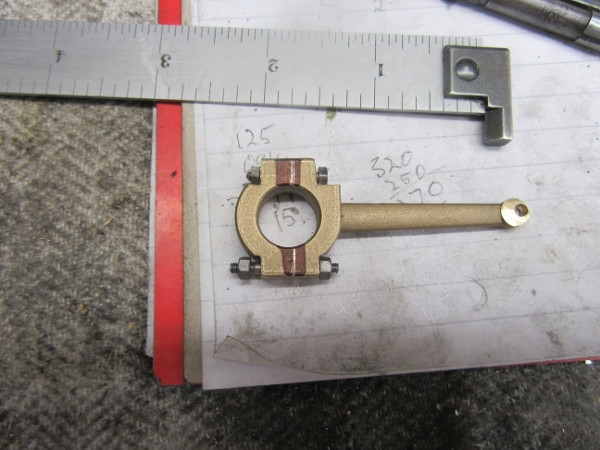

Knocking off time, everything back to normal and ready for further progress. Slow careful work and a good outcome. That's a bit better!