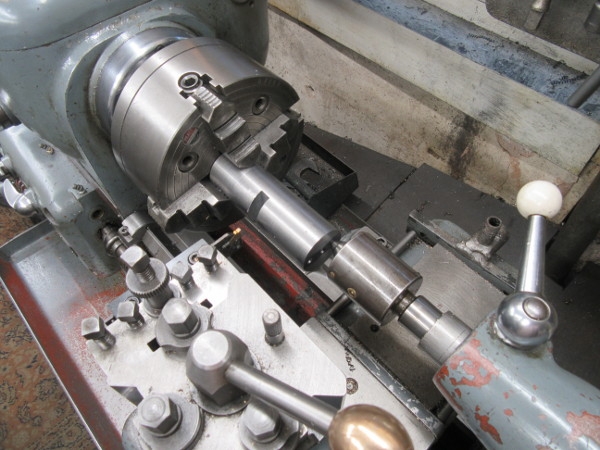

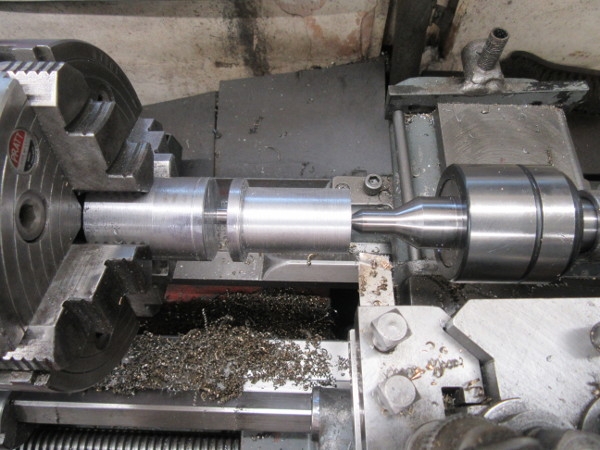

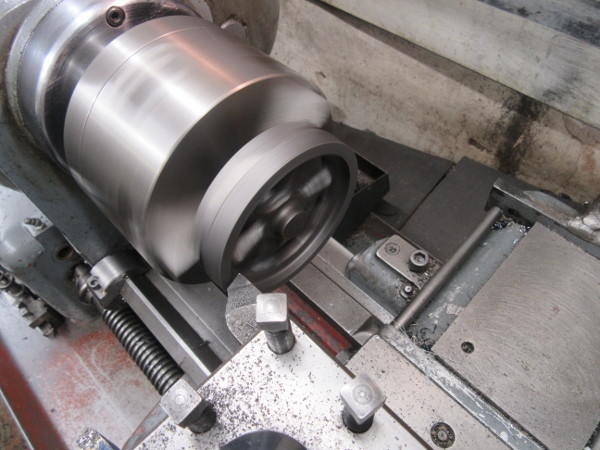

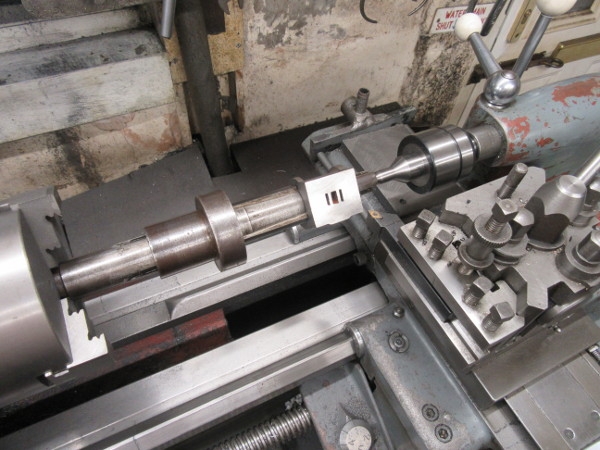

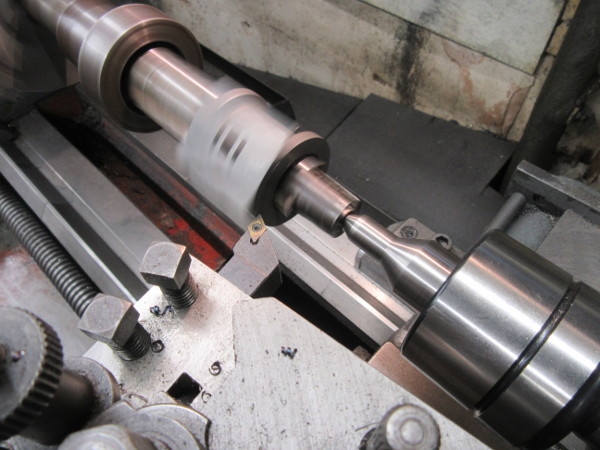

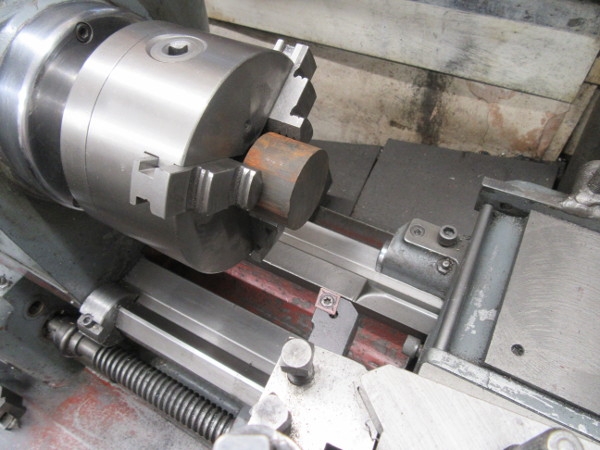

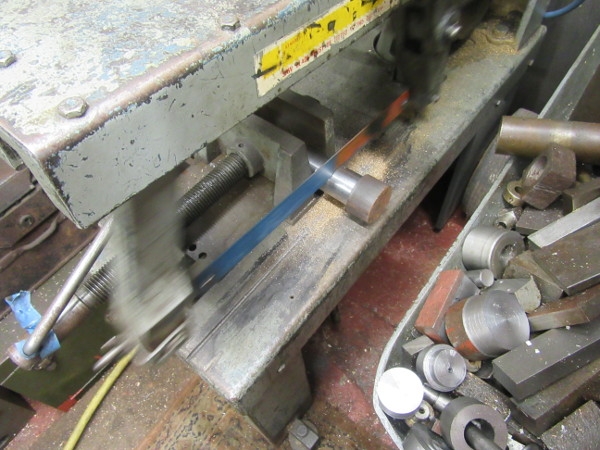

I started the day with a light cut to get me to finished size and then measure the length I want and cut it in Mrs McMaster.

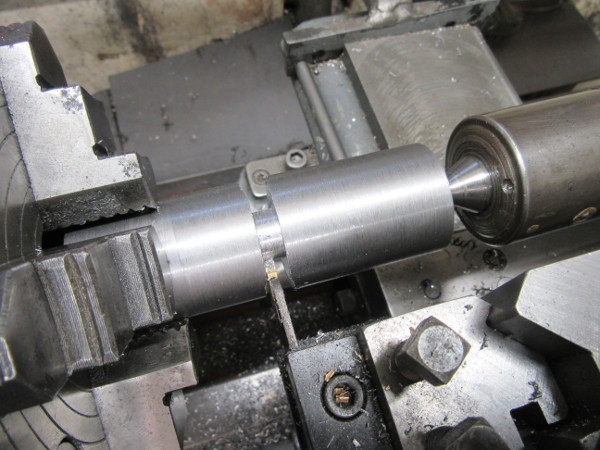

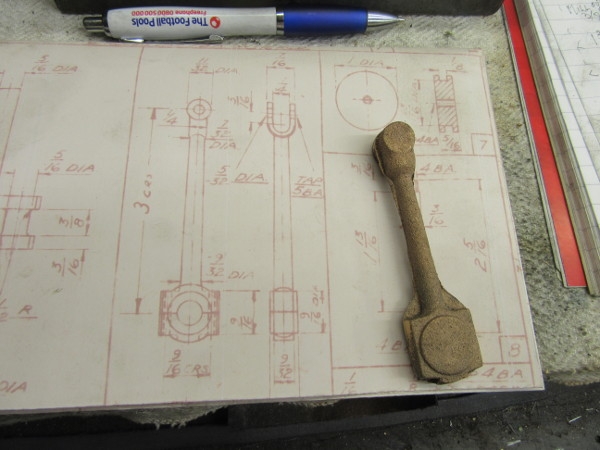

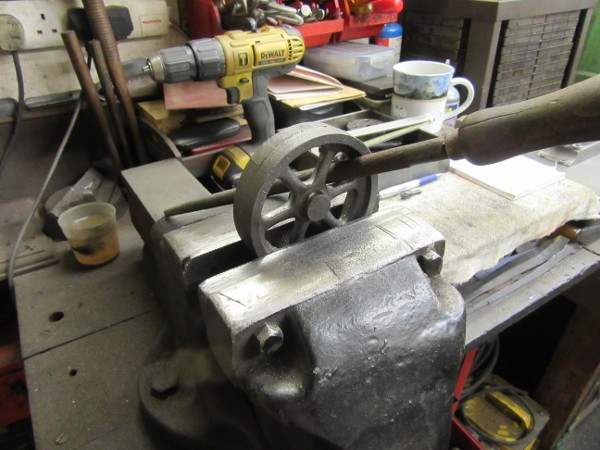

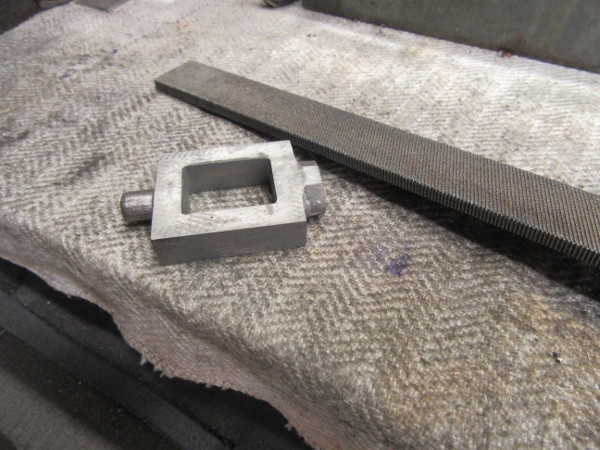

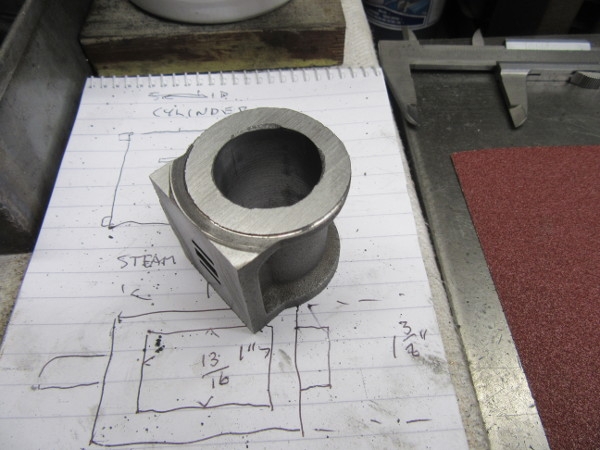

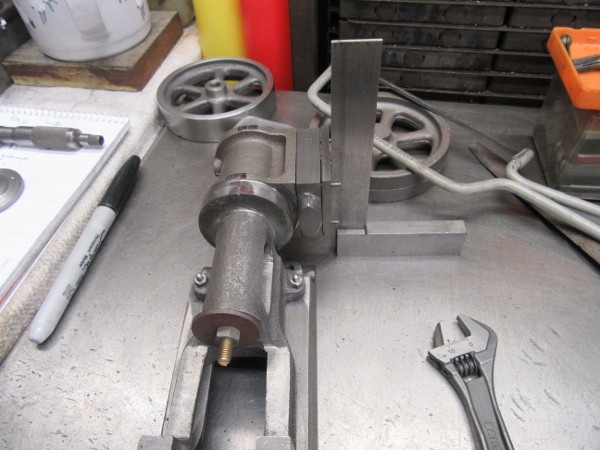

Then some measuring and marking to establish a centre on each end for the crank pin.

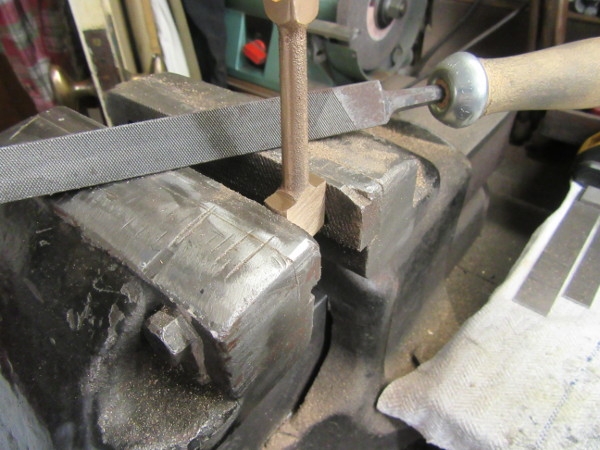

I put this pic in to demonstrate the use of the shaft ruler which, due to its shape, always makes a line parallel with the centre of the shaft.

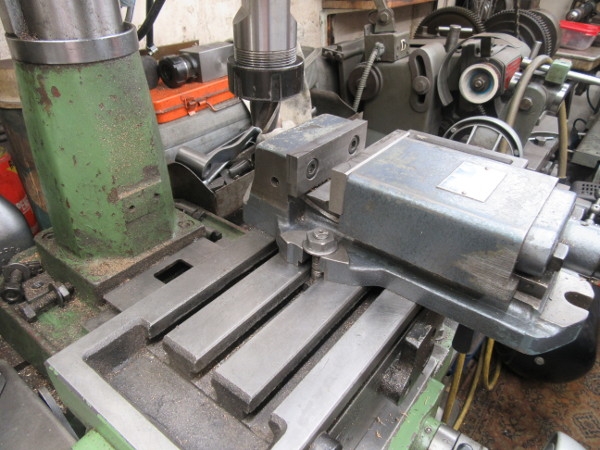

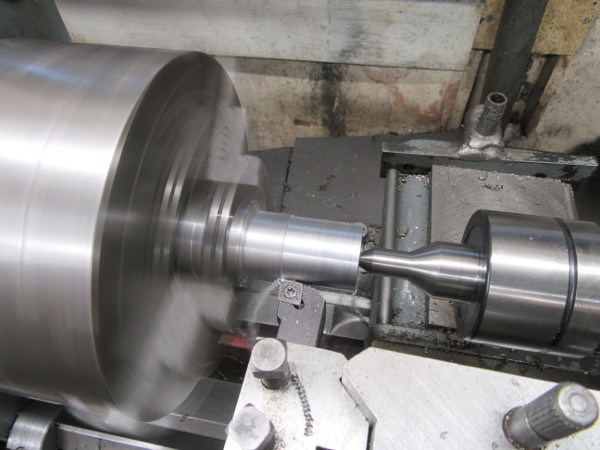

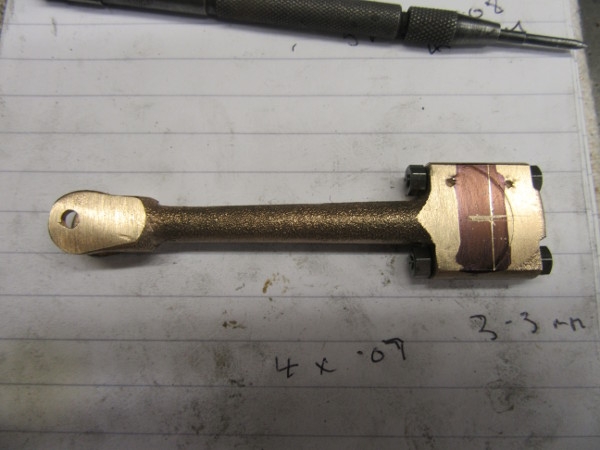

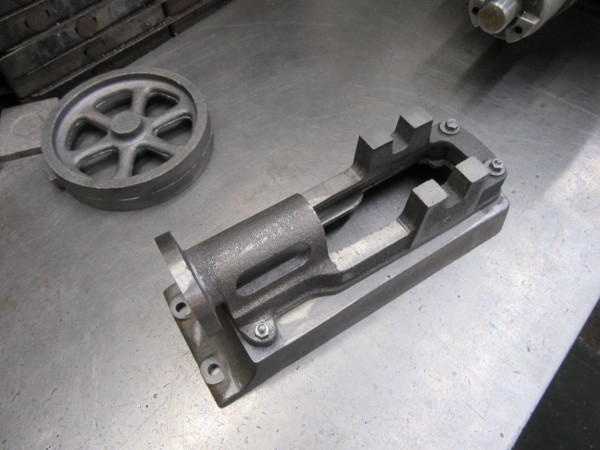

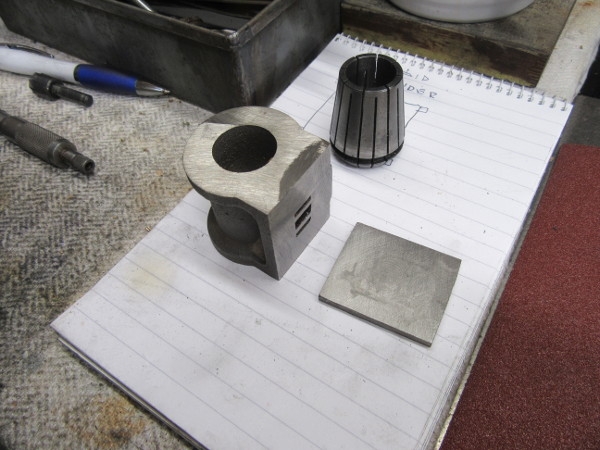

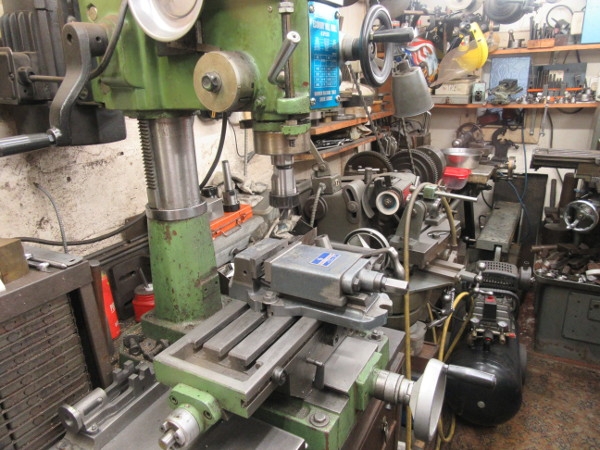

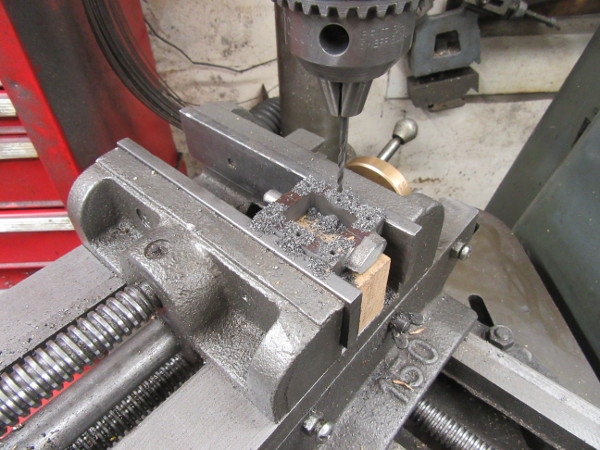

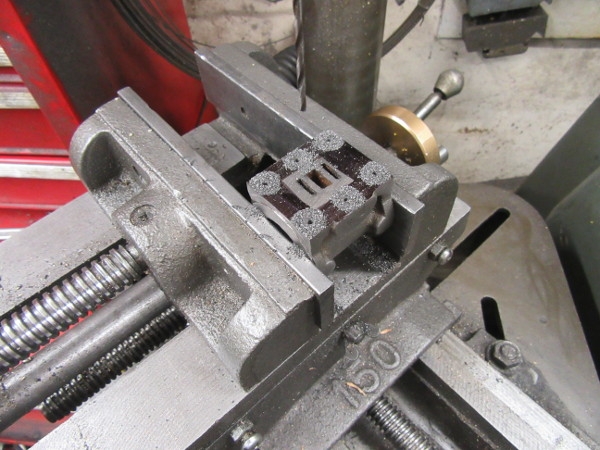

I'm going to cut my crank pin in a slightly different way (favoured by my mate Newton) which involves cutting out a lot of the waste material with the milling machine before you start turning. This is particularly helpful when you are chopping out more complicated shafts for compounds and triple expansion engines.

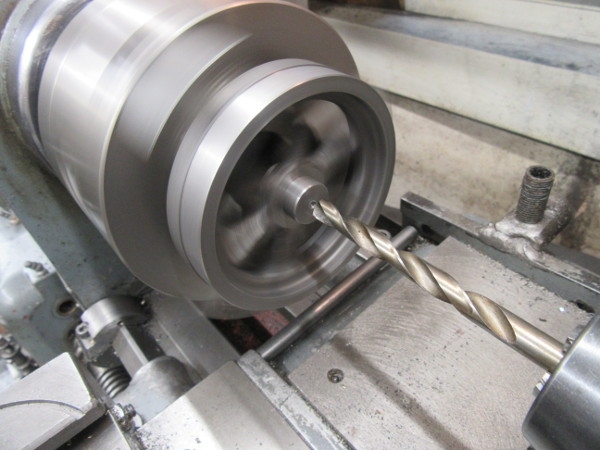

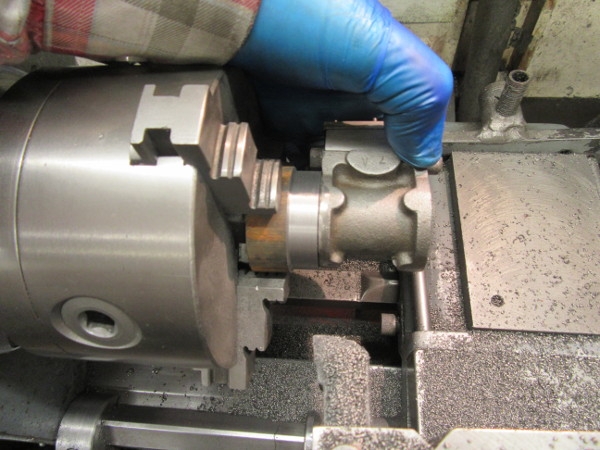

Into the VM and has anyone spotted the mistake? I'm cutting on the wrong side and will have to re-mark my centres 180 degrees from these. I'm getting old.... Luckily it won't make any difference.

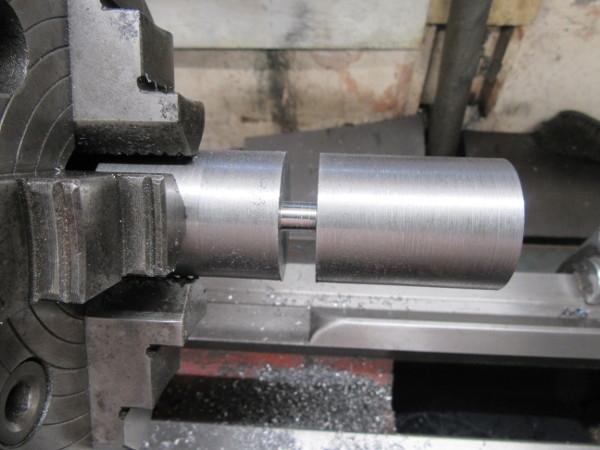

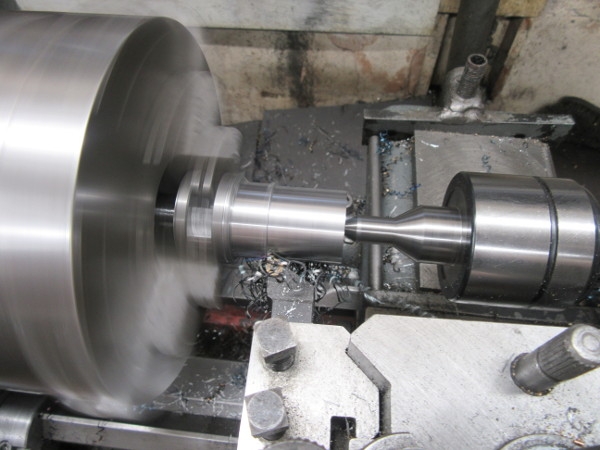

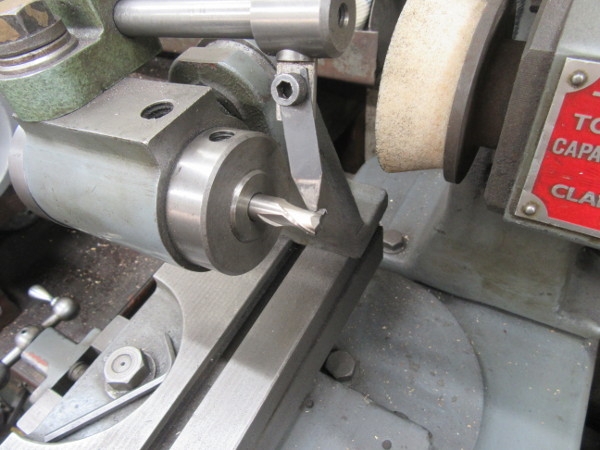

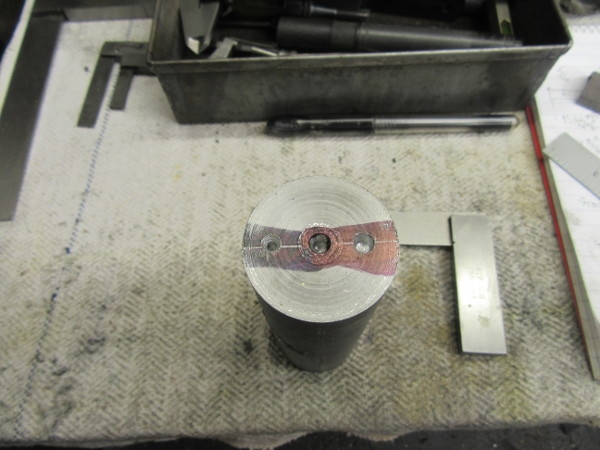

A new centre marked in each end....

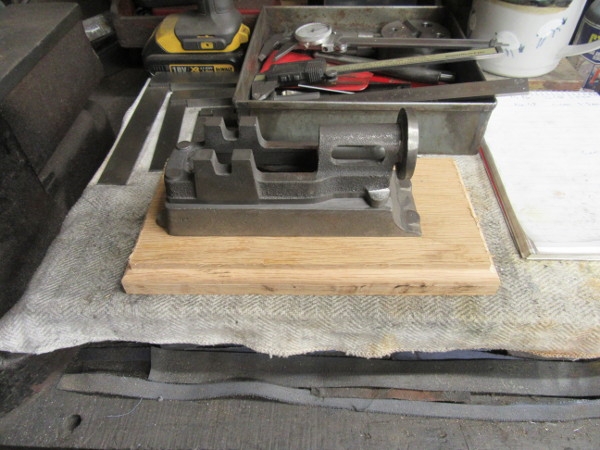

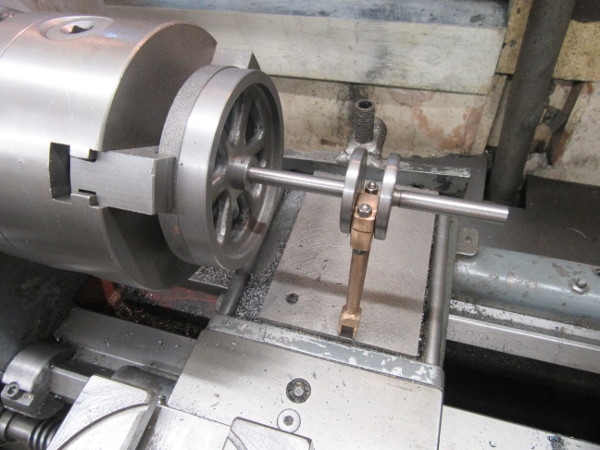

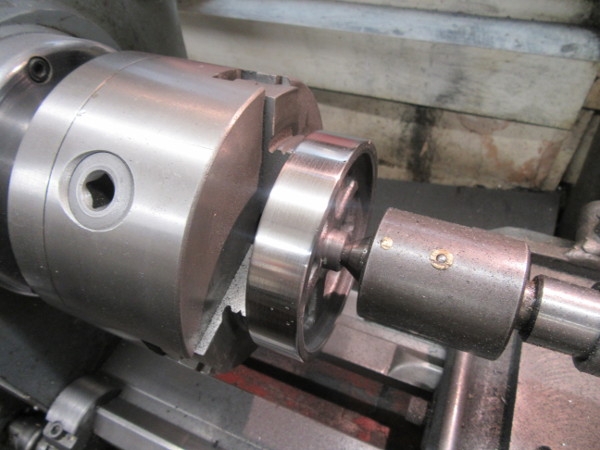

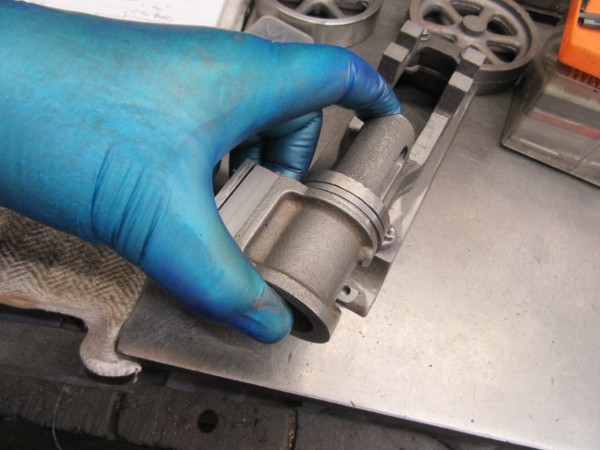

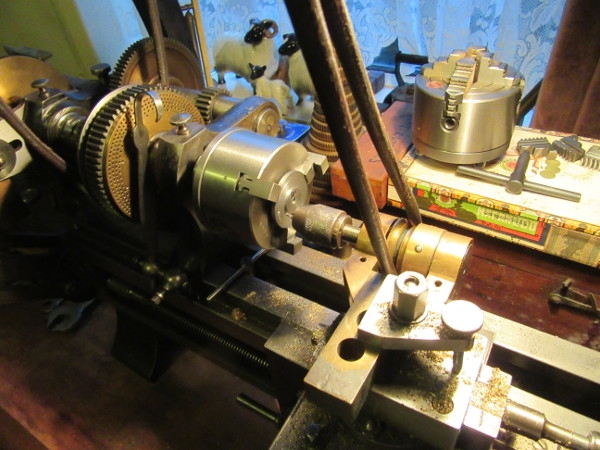

The three jaw SC off and the 4 jaw independent on. We're ready to set up for crankpin turning tomorrow....