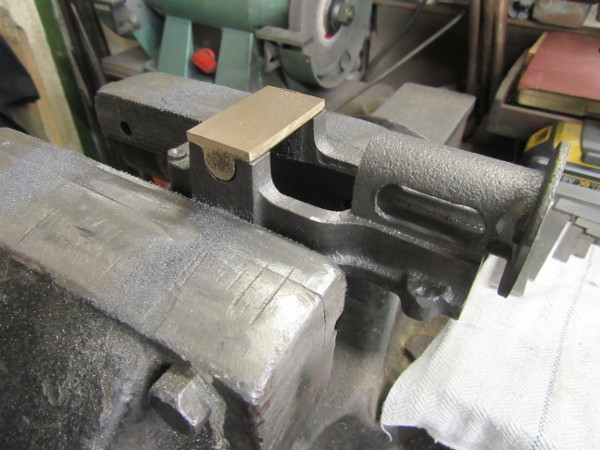

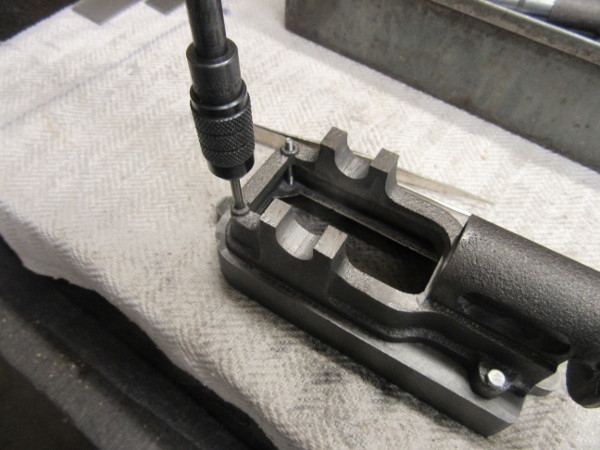

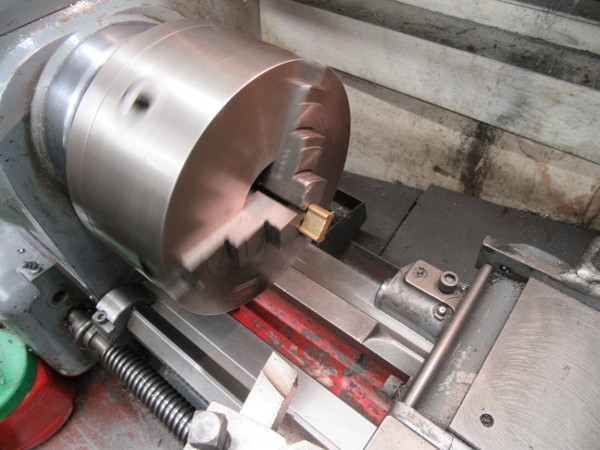

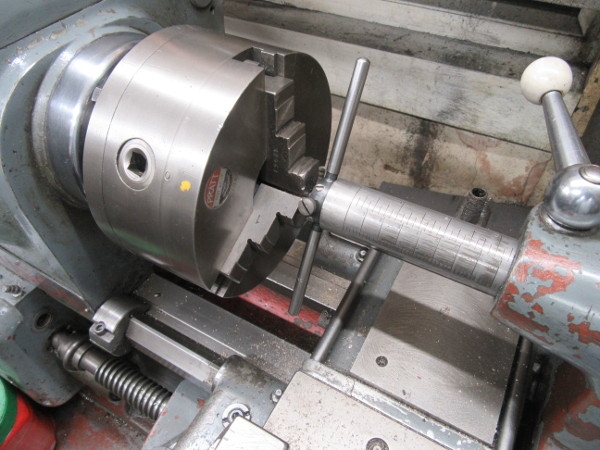

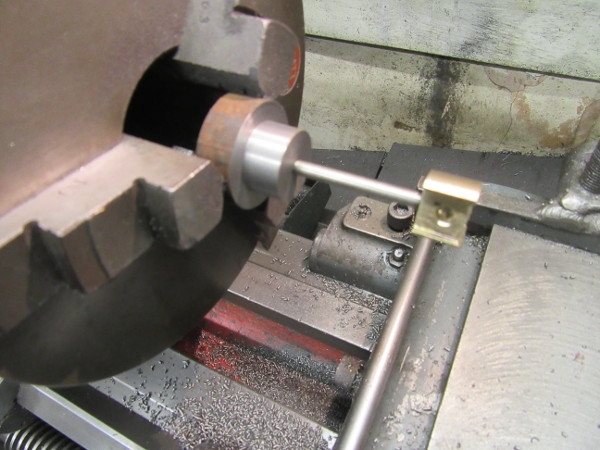

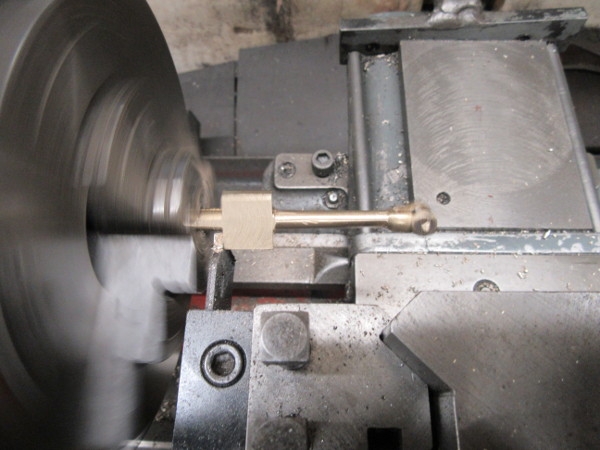

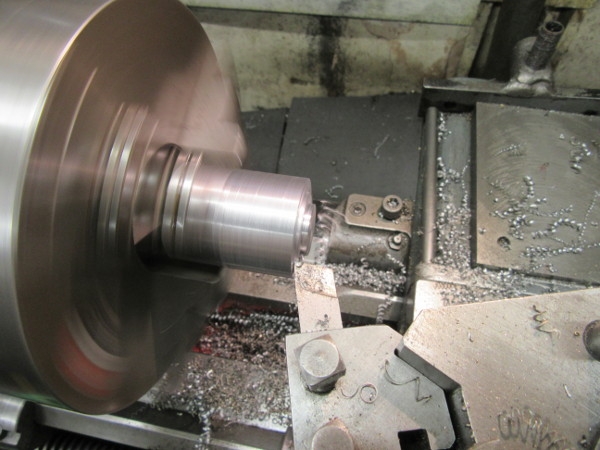

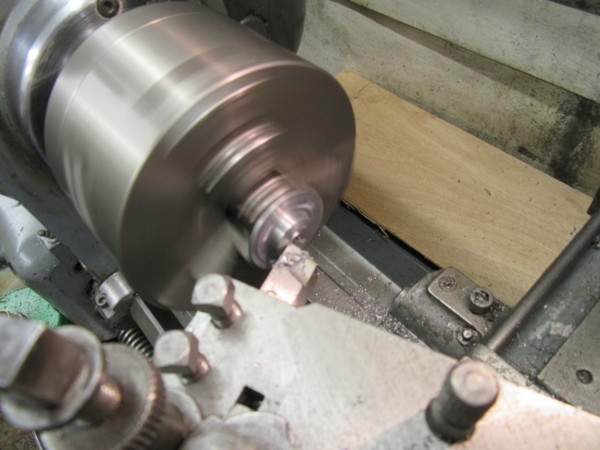

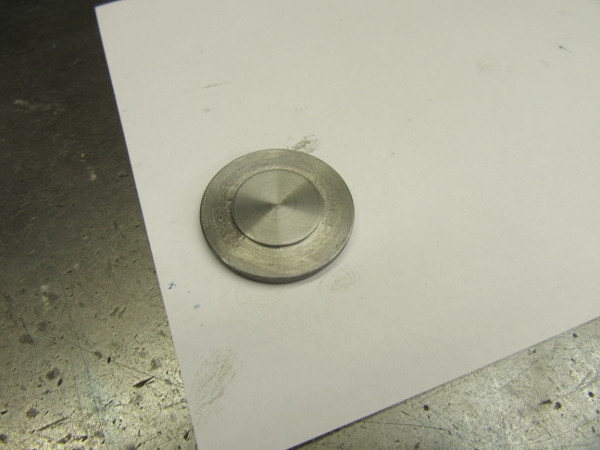

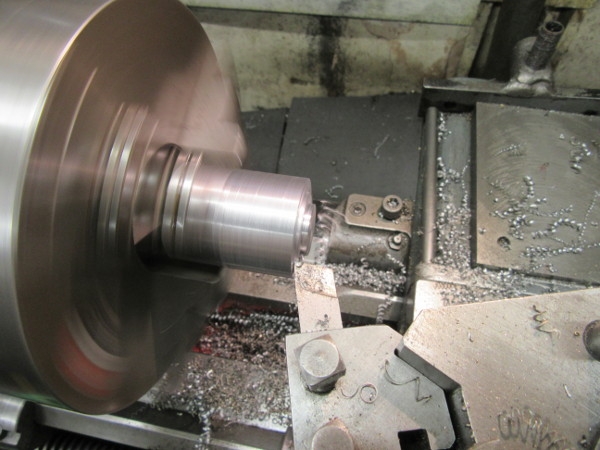

Fresh start this morning on the cylinder lids. The first thing I did was put the stock back in the lathe and turn it with an HSS cutter into a proper shape. I finished up with a piece of stock in the chuck properly faced and the right diameter for the front lid.

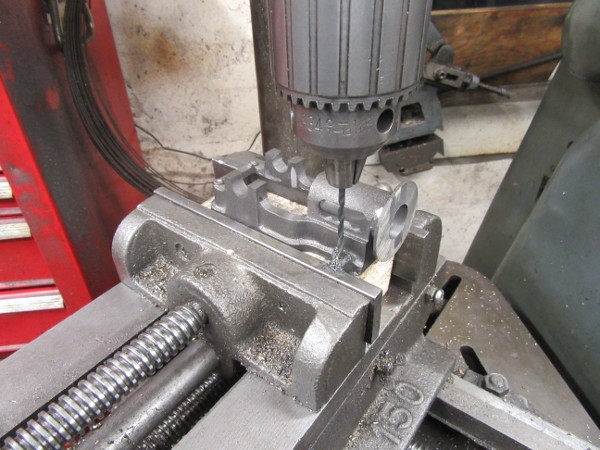

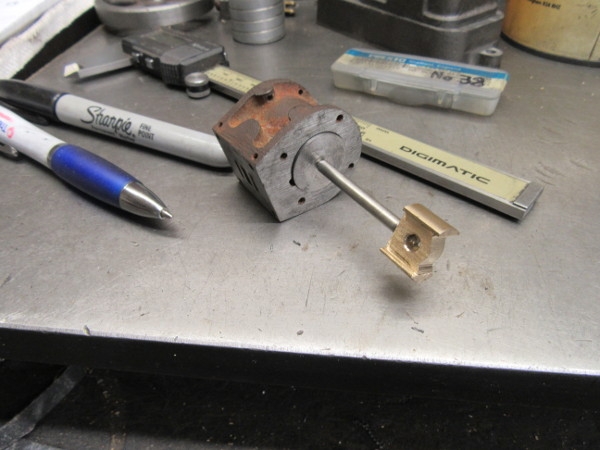

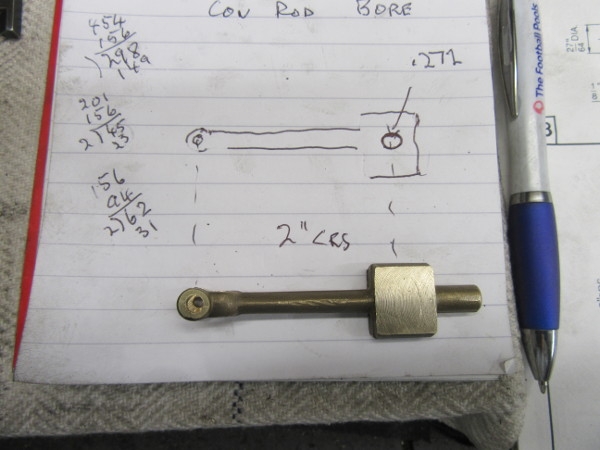

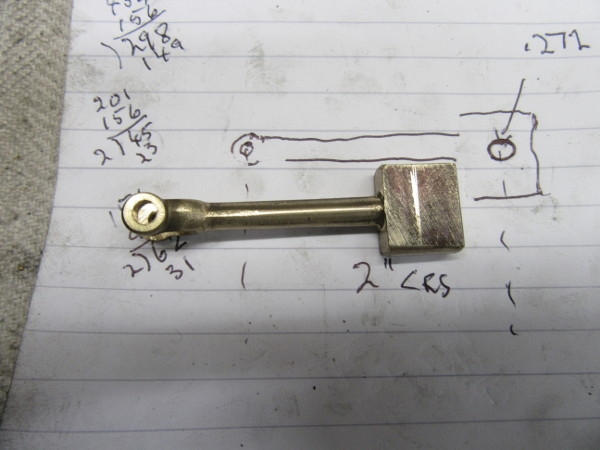

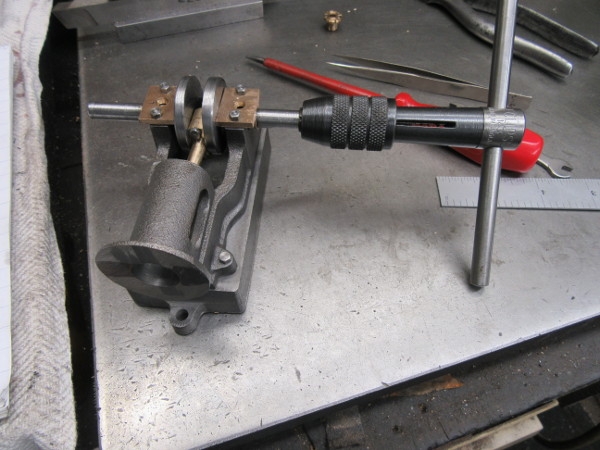

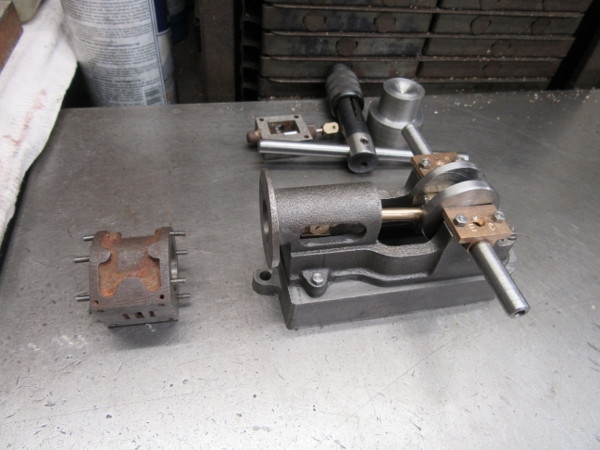

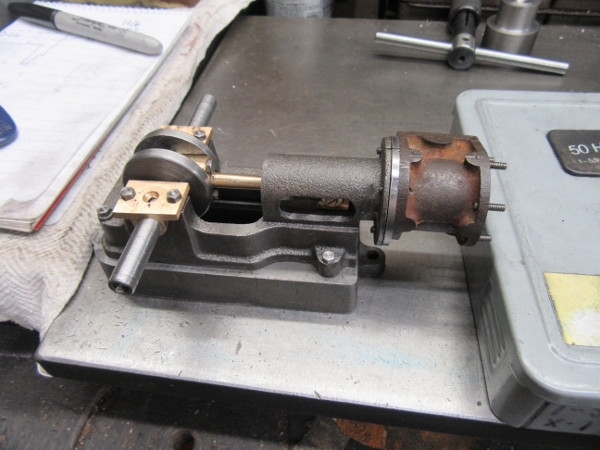

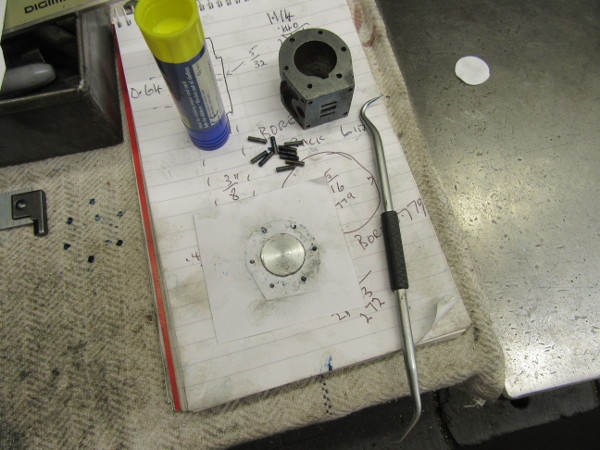

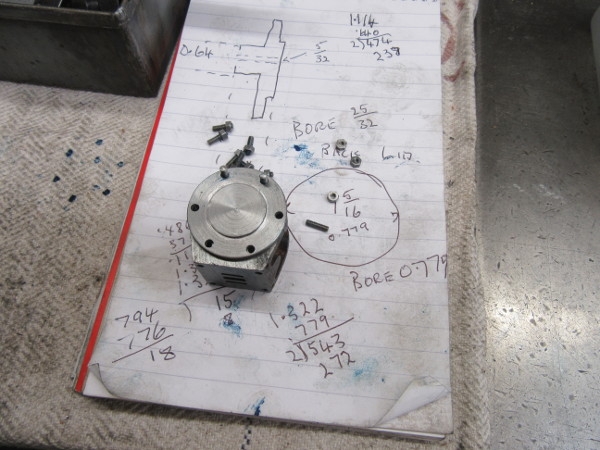

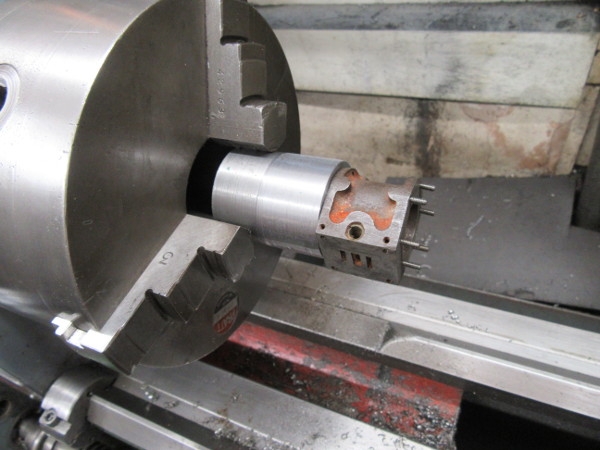

A word about what I'm doing, it's unusual because if this was a complete new build the stud holes in the cylinder wouldn't be already done but would be marked and drilled using the lids at templates. It's the opposite way round as all the stud holes are already done. So I am going to make spigots long enough on the lid to act as guides so that I can mark the lids by using the studs as transfer punches on a blued surface on the lid.

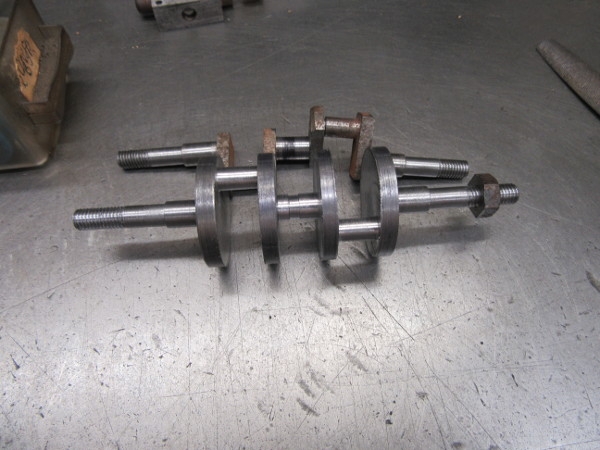

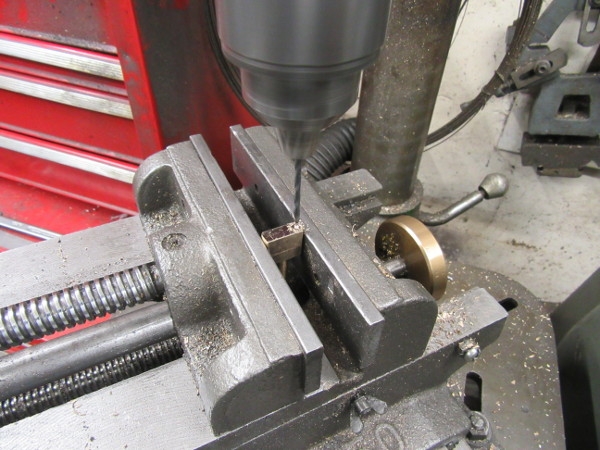

In order to do this my first job was to re-tap all the 7BA stud holes on the cylinder and find studs the right size.

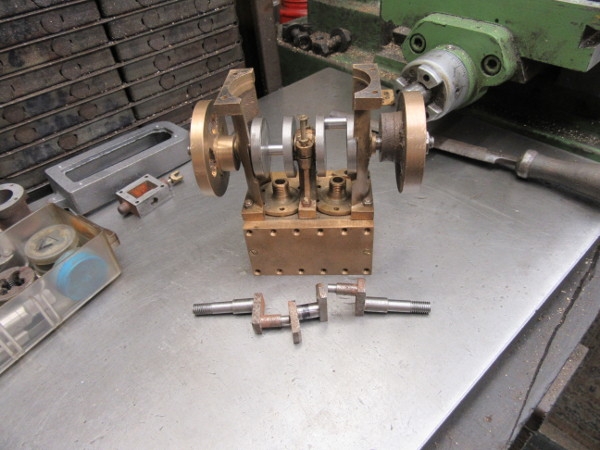

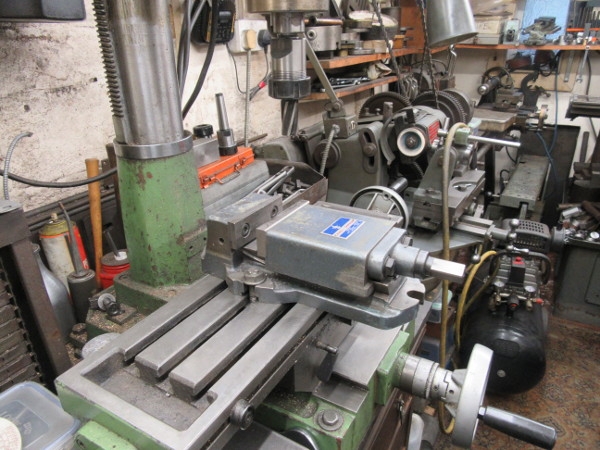

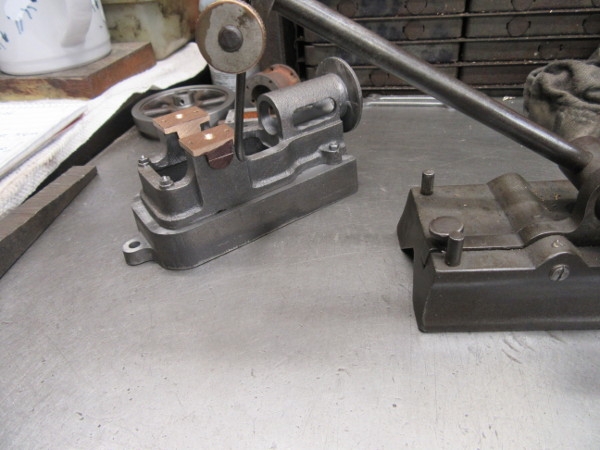

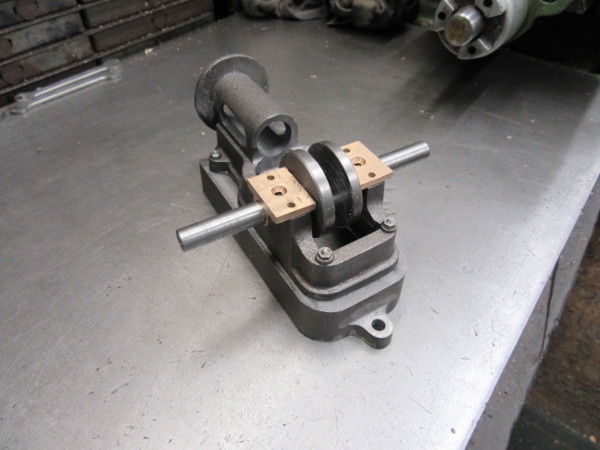

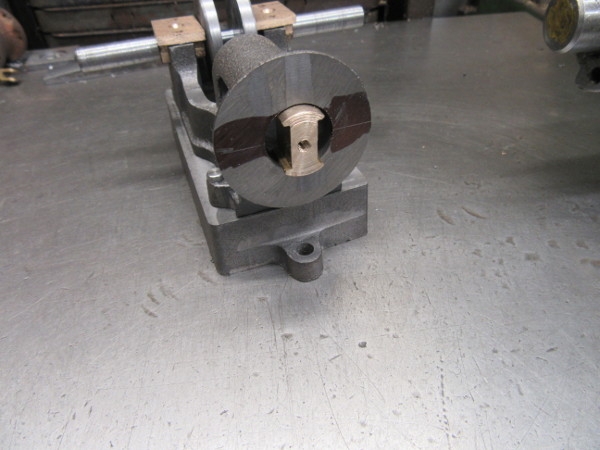

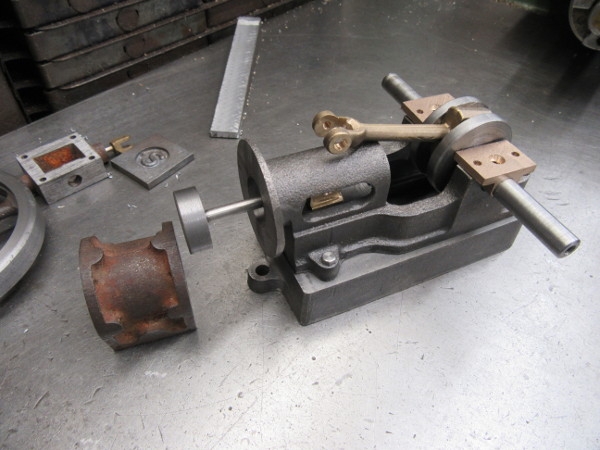

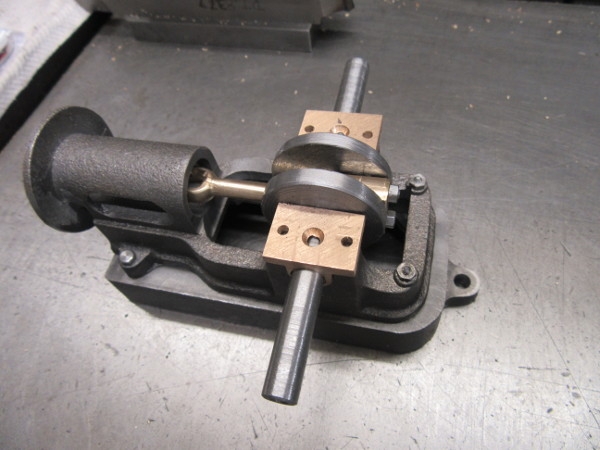

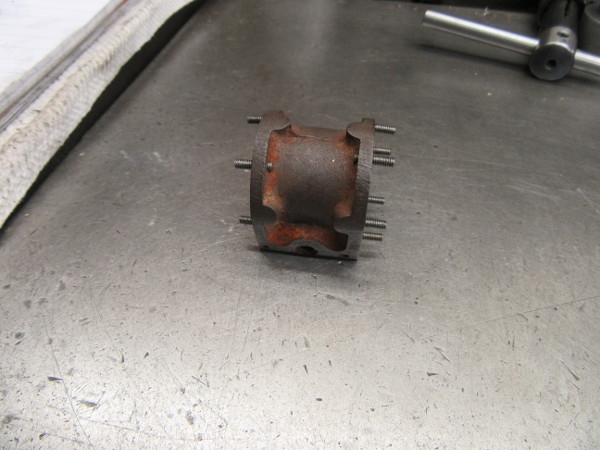

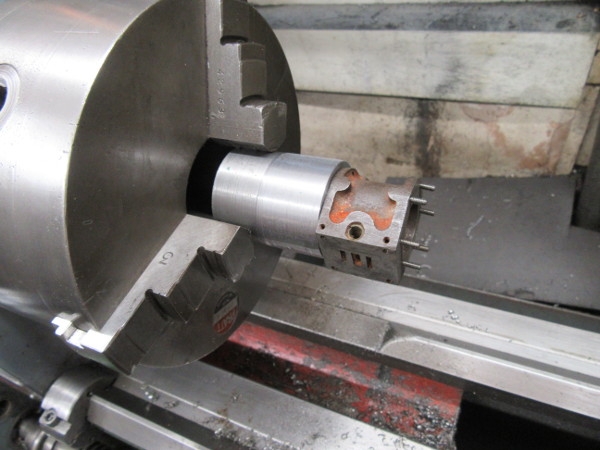

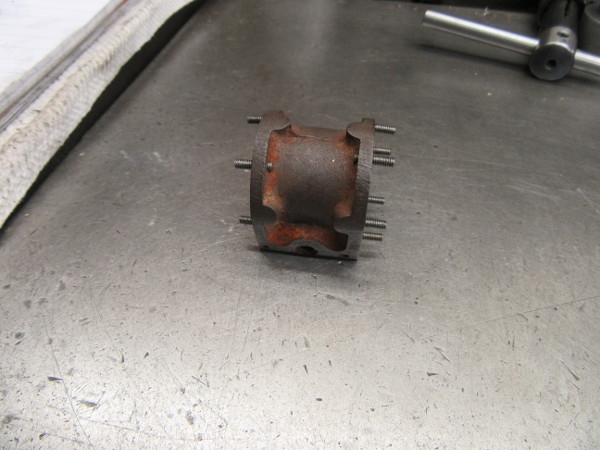

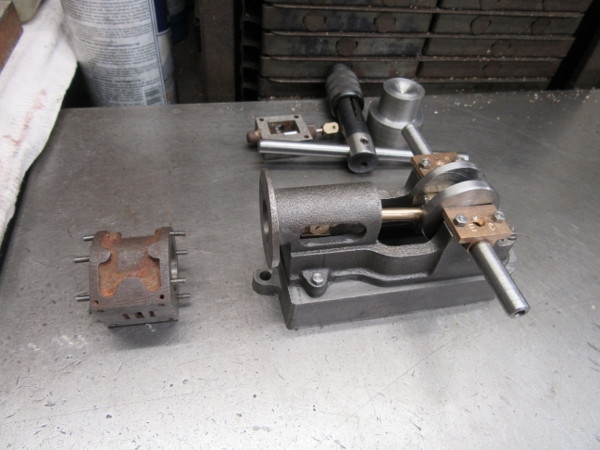

Here's the cylinder with all the stud holes cleaned and fitted with studs. I am going to put the face with 4 stud holes next to the target face on the bed so I only have two studs awkwardly placed at the bottom of the face.

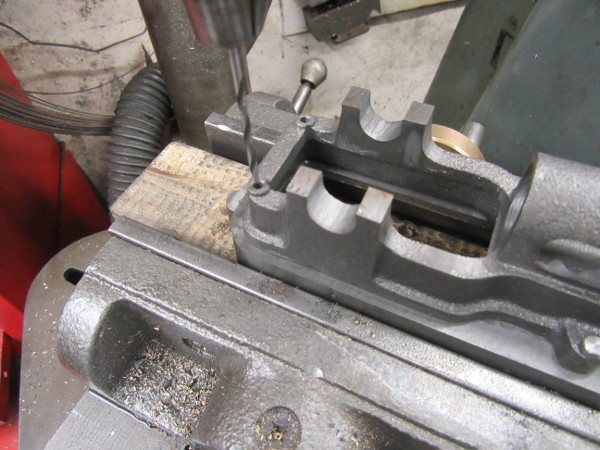

While I was working on the cylinder I re-tapped the stud holes for the steam chest and the steam inlet in the wall of the chest. I am leaving the exhaust port in the cylinder as it is and not tapping it. It can discharge under the cylinder. This isn't going to be running on steam!

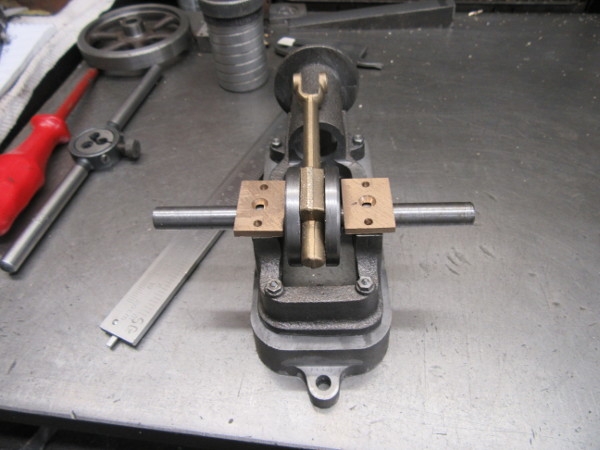

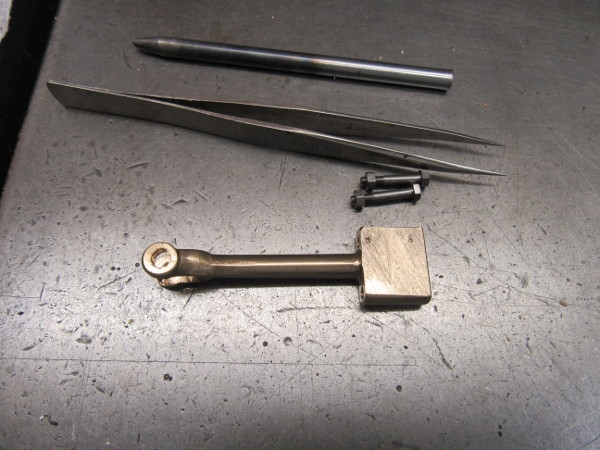

Next I decided on the orientation of the cylinder. I marked the bearing caps 'FW' for the flywheel and 'EC' for the eccentric. This way I might get everything right!

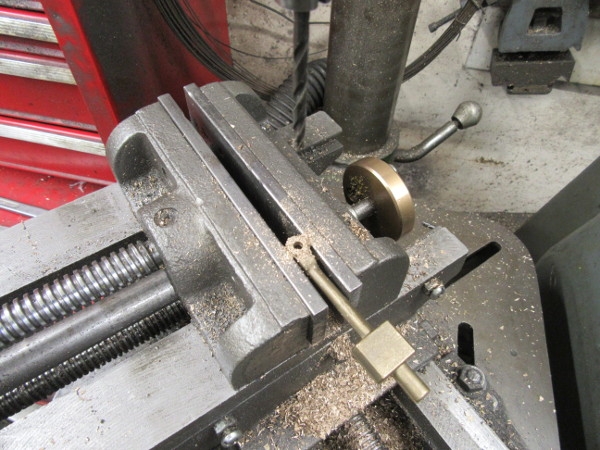

Then some boring careful turning and at knocking off time I had the cylinder a good fit on the spigot so I can mark for the stud holes. Once I have done that and used the spigot for work holding I can turn it down until it become a 1/16" register in the bore.

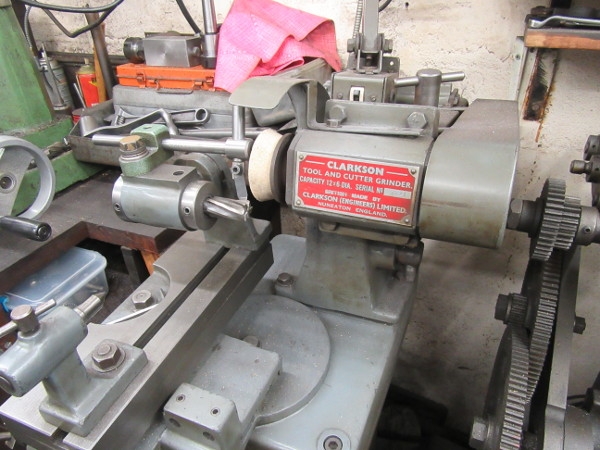

One other thing, I sorted out the parting tool that I broke yesterday. I went to order some spare inserts and got 5 from JB tools for same price as one on the more prominent web sites. You have to be very careful these days on Amazon!