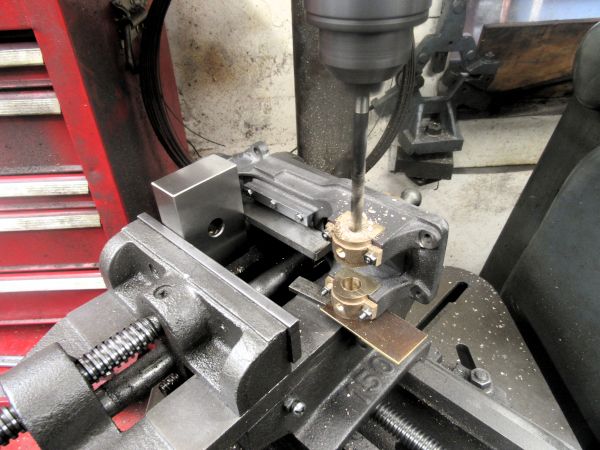

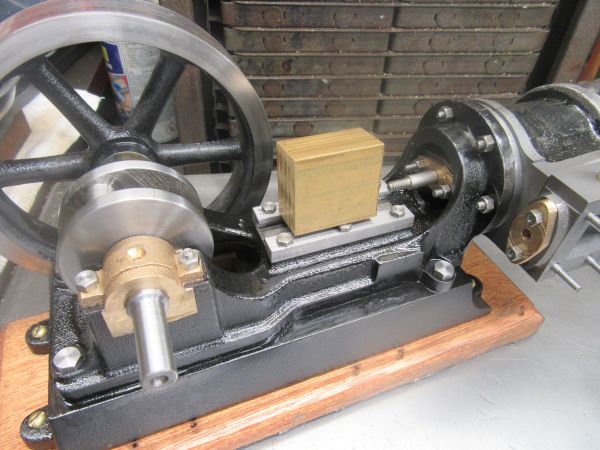

More work on the refinement and fitting of the bottom crankshaft bearings. I spent almost half an hour filing to a final fit and then realised I had one more cut to make. I had to put the 5/8" cutter back in but made the cut and fitted the brasses. Then I checked the width of the flywheel between the brasses. There's always something! Tomorrow I shall put the crankshaft back in the lathe and take a skim down each side of the wings..... We're getting there!